Hardware surface treatment device

A surface treatment device and hardware technology, which is applied to the device for coating liquid on the surface, the spray device, the surface pretreatment, etc., which can solve the problems of time-consuming, unsatisfactory treatment effect, and poor treatment efficiency. , to achieve the effect of improving the effect and efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

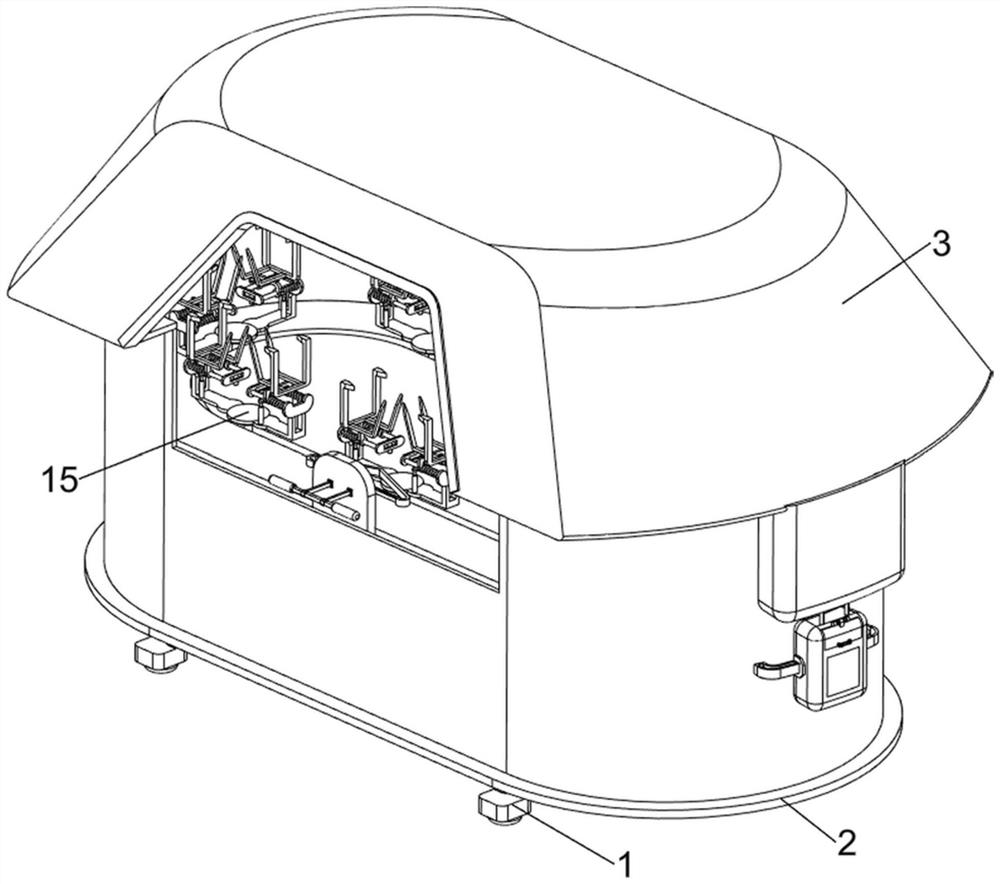

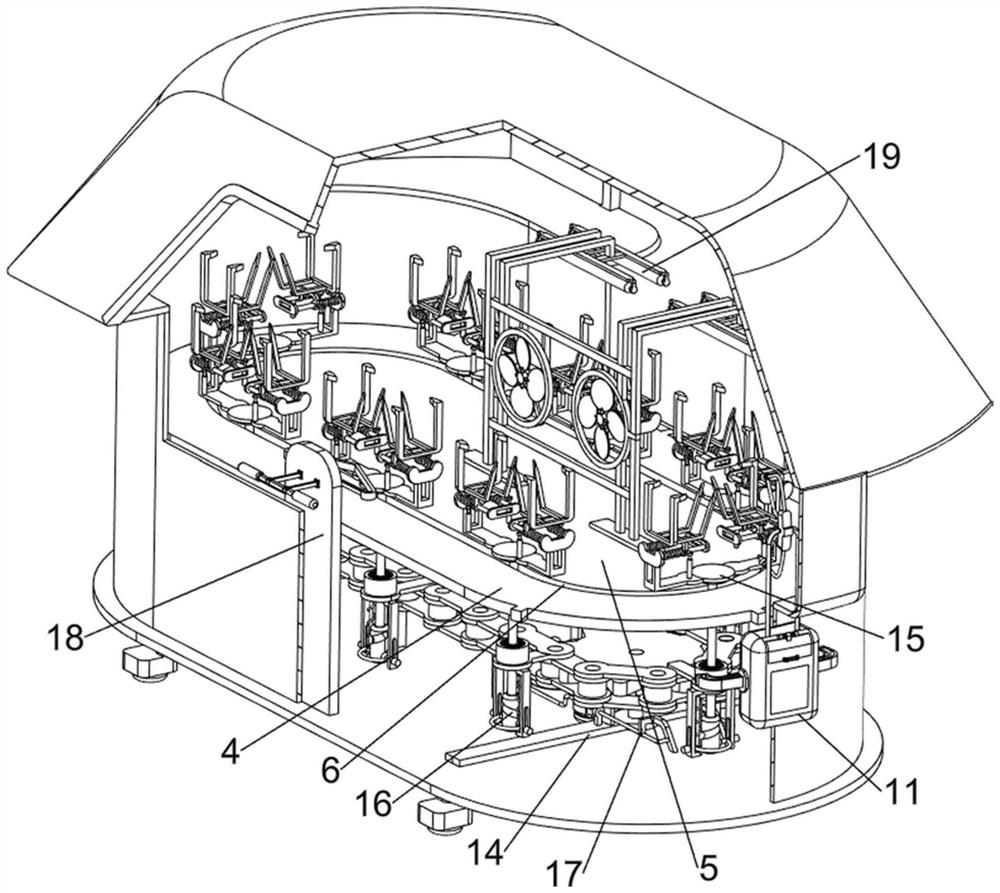

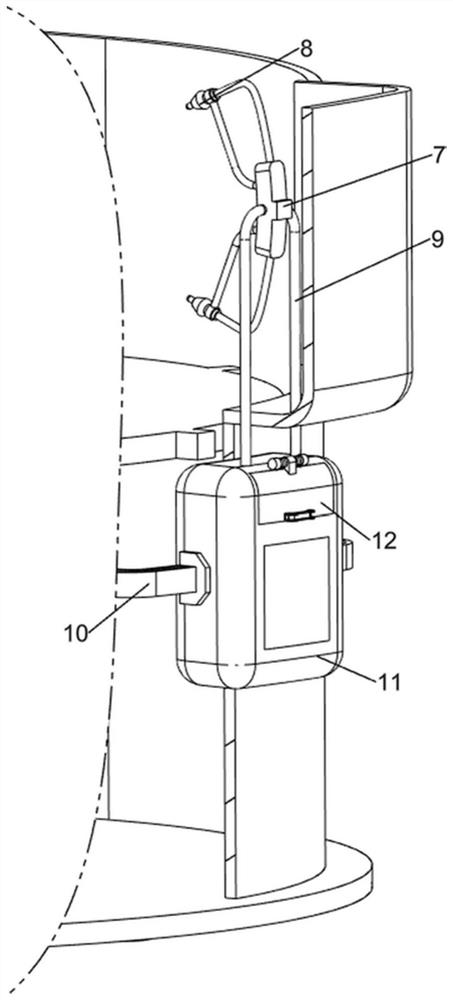

[0035] A five -gold surface processing device, such as Figure 1-4It shows that there are support blocks, fixed boards 2. outer frame 3, first fixation frame 4, first fixing frame 5, pump body 7, spray head 8, conveying tube 9, support board 10, leaflet box 11, blocking, blocking, blocking Board 12, clamping mechanism 15 and teleportation agency 14, the bottom bolt of the outer frame 3 with a fixed board 2, the left bottom and the bottom side of the right side of the fixed board 2 are also supporting block 1, support block 1, support The material of the block 1 is made of rubber, which can play a non -slip. The top side of the fixed board 2 has the first fixing frame 5, and the inner welded in the middle of the outer frame 3 has the first binding frame around the first fixing frame 5 4, the gap between the first fixed bit 4 and the first fixed frame 5 is named the first oriental slot 6, and there are two support plate 10 welded on the lower right side of the outer frame 3, and the ...

Embodiment 2

[0041] On the basis of Example 1, such as figure 2 and Figure 10 It also shows that the rotating mechanism 17 used to drive the clipped grip 155 rotation agency 17, the rotating mechanism 17 includes a fixed rod 171, arc -shaped rod 173, promoting ball 174, space cam 1741, first elastic component 175, and second torque spring 176, a second torque spring between the rotating rod 152 and the second positioning box 151, the bottom bolt of the rotor 152 is connected with space camsome 1741, the lower outside welding of the second positioning box 151 has a fixed rod 171, a fixed rod is fixed rod The third -oriented slot 172 is opened on both sides of the lower part of 171. The sliding type between the third -directional slot 172 is set with a arc rod 173, the arc -shaped rod 173 and the fixed rod 171 are connected to the first elastic piece 175 175 , The arc rod 173 is connected to the spatial cam 1741 sliding push ball 174.

[0042] like figure 2 As well as Figure 8 and Figure 9 It al...

Embodiment 3

[0045] On the basis of Example 2, such as figure 2 As well as Figure 11 and Figure 12 It also includes the opening mechanism 18 that is used for the auxiliary clamping mechanism 15. The opening mechanism 18 includes a positioning board 181, handle 182, supporting rod 183, connected column 184 and second elastic parts 185, slide block 154 The lower part of the connection column 184, the front upper welding of the fixed board 2 has a positioning board 181, the upper sliding type of the positioning board 181 has a handle 182. The movement rod 183, the supporting rod 183 and the positioning board 181 are connected to the second elastic parts 185.

[0046] The operator promotes the supporting rod 183 backward by the handle 182, and the second elastic parts 185 stretch. The support rod 183 will squeeze the symmetrical pillar 184 during the movement of the backward movement. Move in the direction that is far away from each other. Connection column 184 movement will drive the slider 154 t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com