Mobile phone assembling line and assembling method

An assembly line and assembly method technology, applied in the direction of conveyors, assembly machines, transportation and packaging, etc., can solve the problems of unfavorable automatic assembly of mobile phones and affect the efficiency of the assembly process, and achieve low efficiency, improve efficiency, improve efficiency and effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

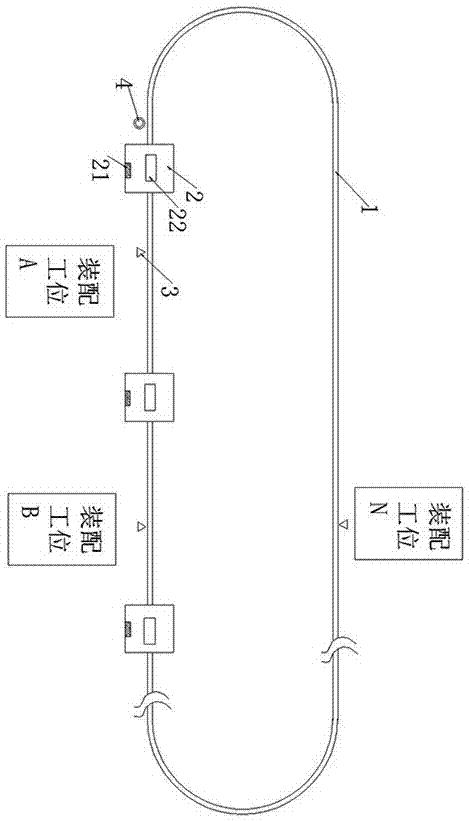

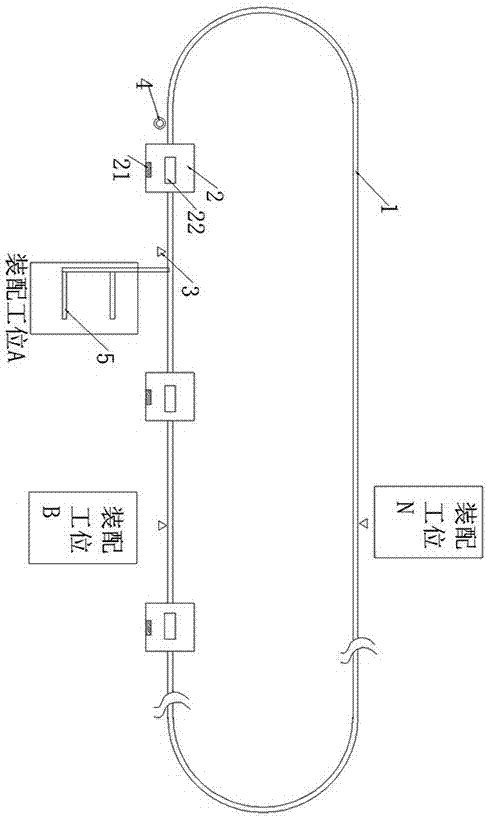

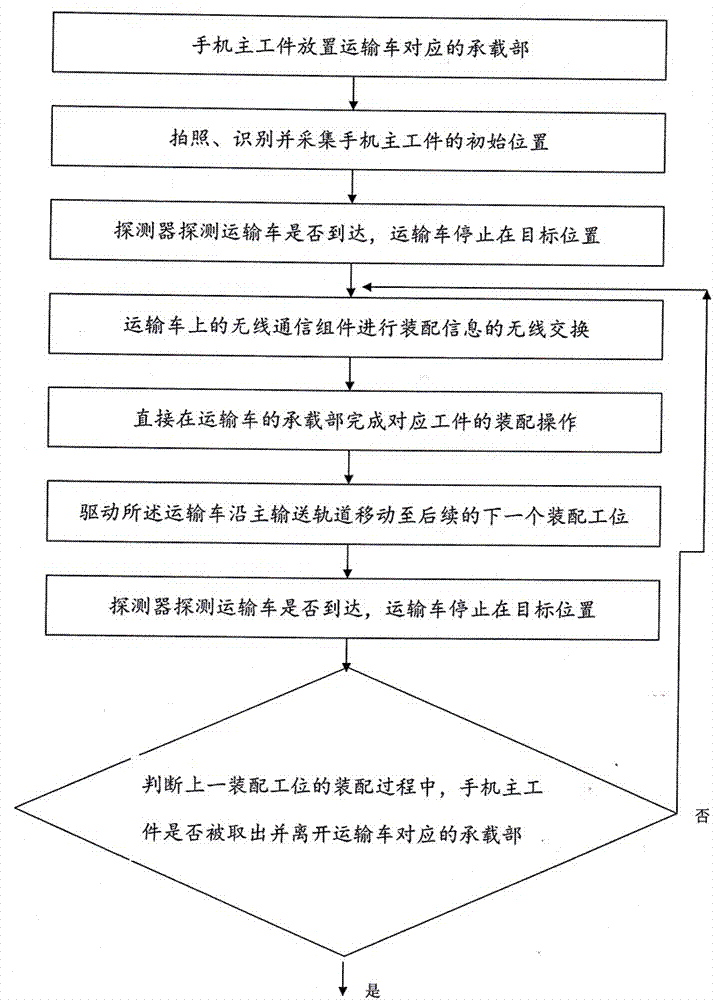

[0028] refer to figure 1 , In a preferred embodiment, the mobile phone assembly production line includes a main conveyor track 1, a CCD camera 4, a number of transport vehicles 2 and a number of detectors 3, and the main conveyor track 1 connects some or all of the assembly stations in the mobile phone assembly process. Preferably, the main conveying track 1 adopts a monorail structure, the bottom of the transport vehicle 2 cooperates with the main transport track 1, and the transport vehicle 2 can perform precise displacement control under the guidance of the main conveying track 1 and the driving of the electric drive device, and move to Subsequent assembly stations move. The transport vehicle 2 includes a carrying part 22 and a wireless communication component 21. The carrying part 22 is used to place and fix the main workpiece of the mobile phone, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com