Patents

Literature

80results about How to "Achieving Stirring and Mixing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

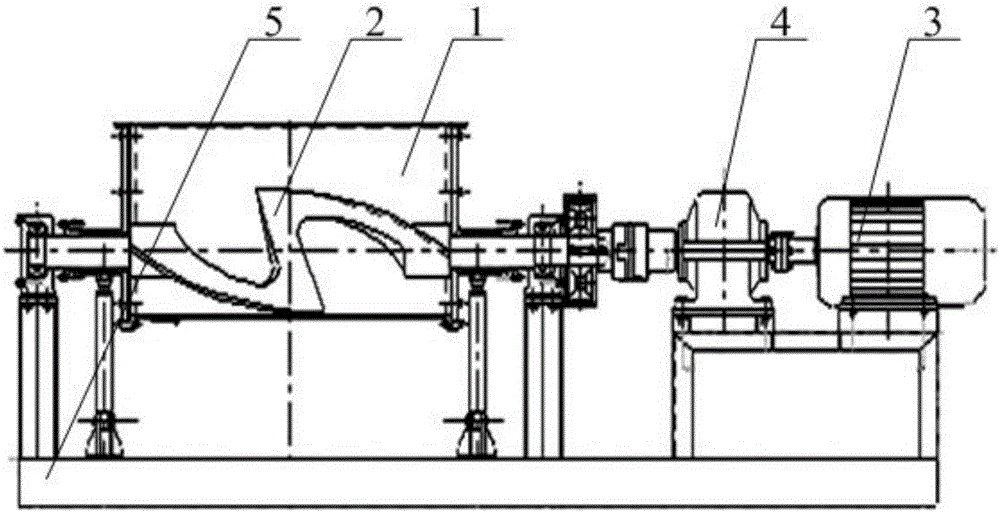

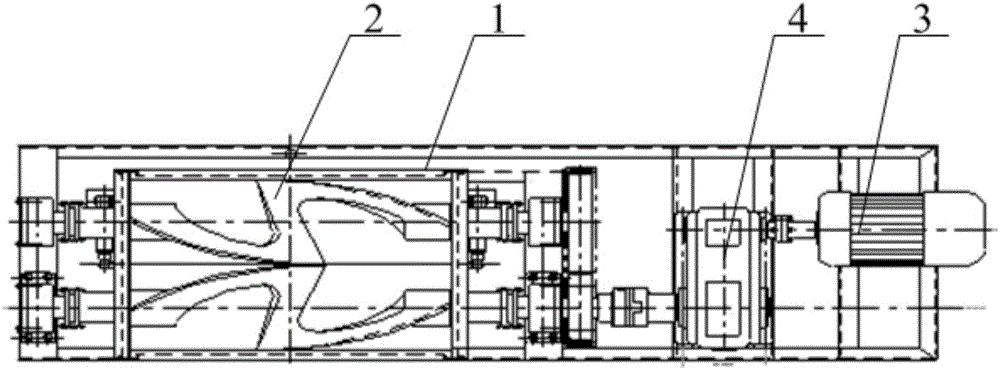

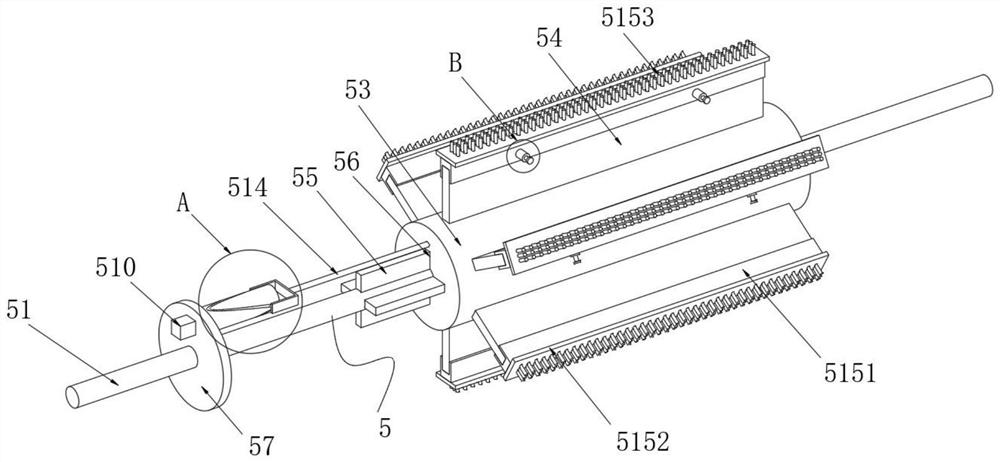

Molten iron full-domain stirring and desulfurization stirrer and using method thereof

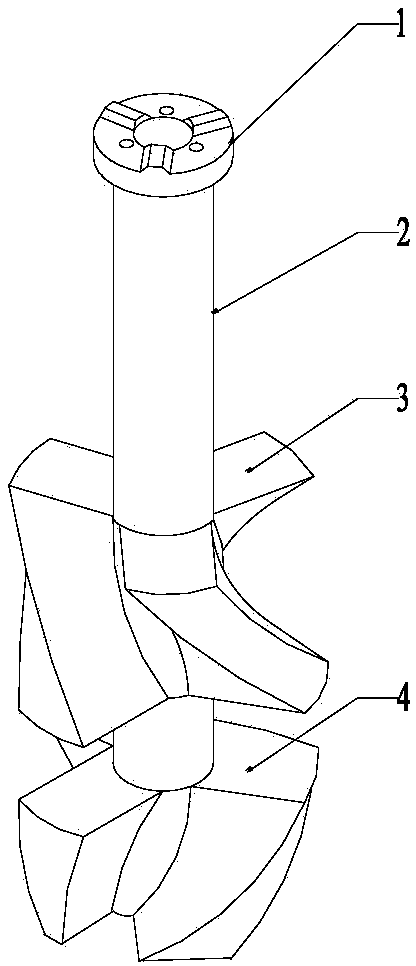

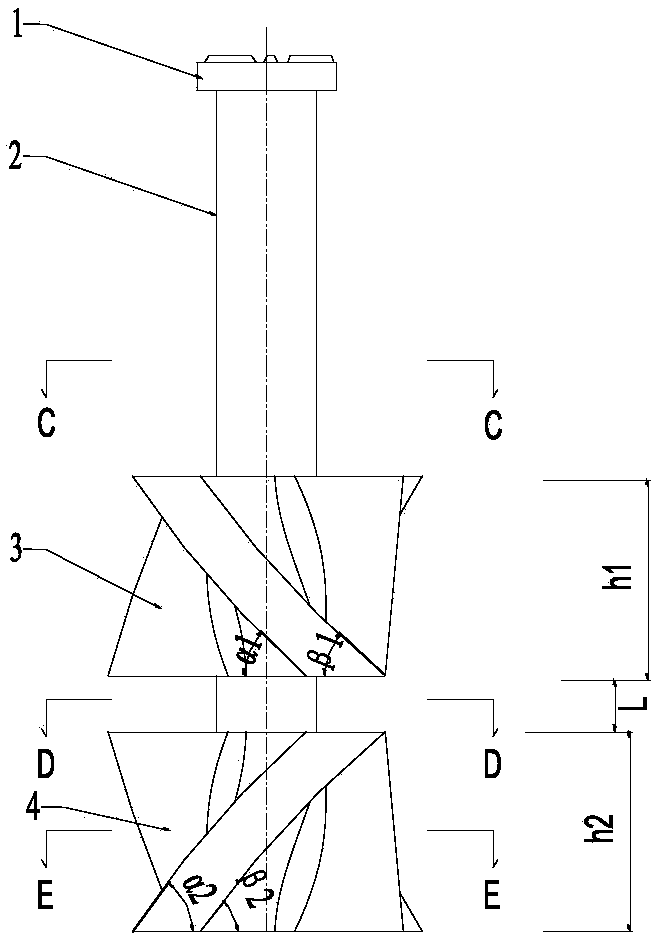

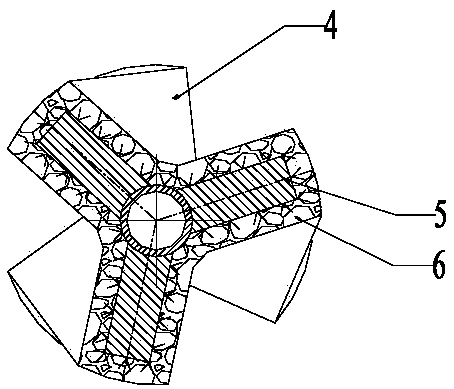

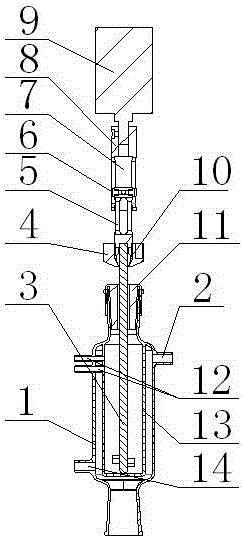

The invention discloses a molten iron full-domain stirring and desulfurization stirrer. The stirrer comprises a stirring shaft, a stirrer connecting flange, upper-layer stirring blades and lower-layerstirring blades, each upper-layer stirring blade and each lower-layer stirring blade each comprises a stirring blade core and a stirring blade core fire-resistant pouring material lining, each upper-layer stirring blade is a left-rotated spiral blade rotating in the same direction as the stirring direction, each lower-layer stirring blade is a right-rotated spiral blade rotating in the directionopposite to the stirring direction, and the lower-layer stirring blades and the upper-layer stirring blades are arranged at the same circumferential angle in the circumferential direction of the stirring shaft or are arranged in a front-back equal-angle staggered angle mode. Through the double-layer stirring blade structure arranged up and down, the arrangement distance of the stirring blades in the length direction of the stirring shaft is greatly increased, the stirring depth and the effective stirring area of the stirrer on the molten iron in a molten iron ladle are expanded, stirring of the molten iron at the bottom of the molten iron ladle and stirring, mixing and mass transfer of the full-domain molten iron are remarkably enhanced, and the dynamic conditions of the full-domain molteniron stirring and desulfurization reaction are greatly improved.

Owner:武汉钢铁有限公司

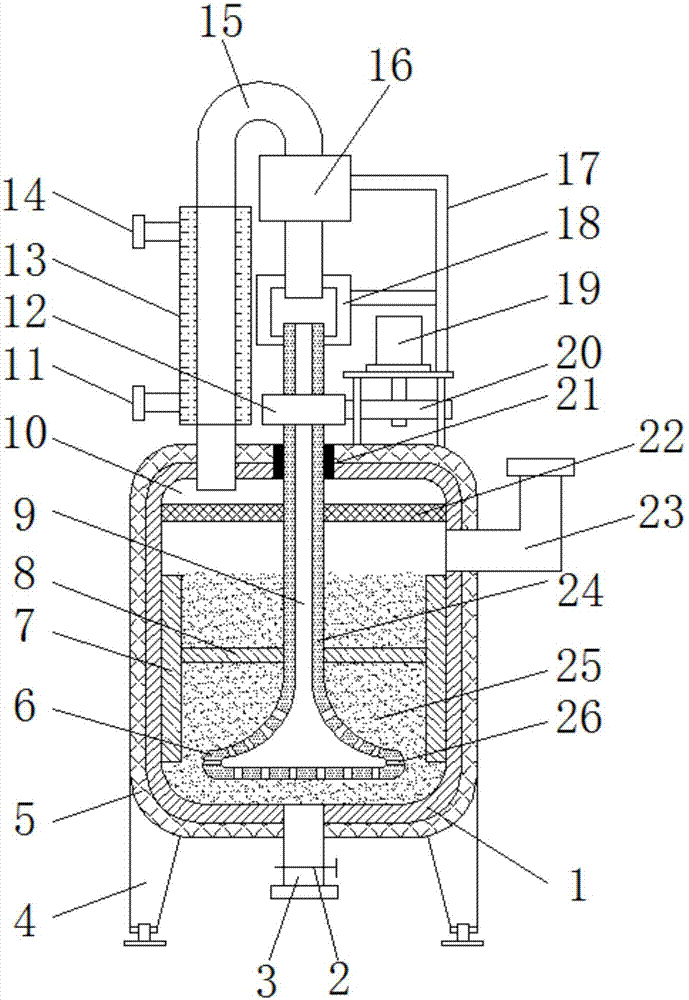

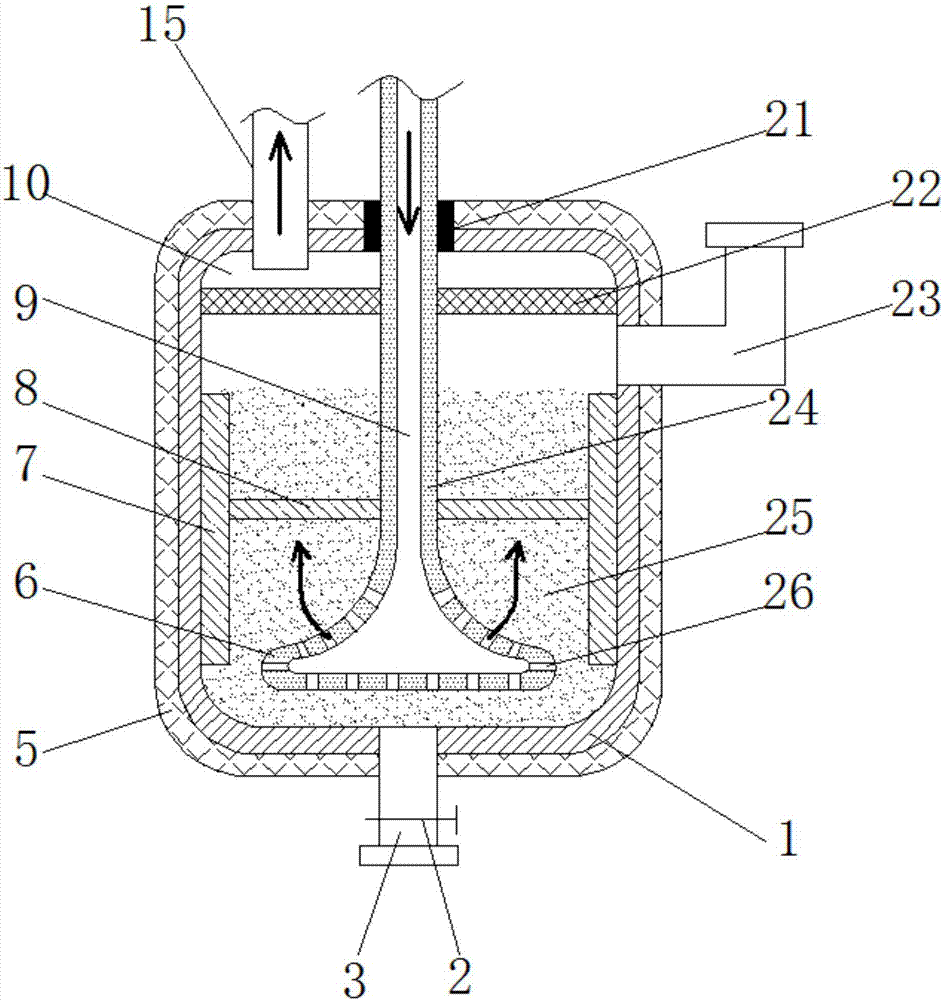

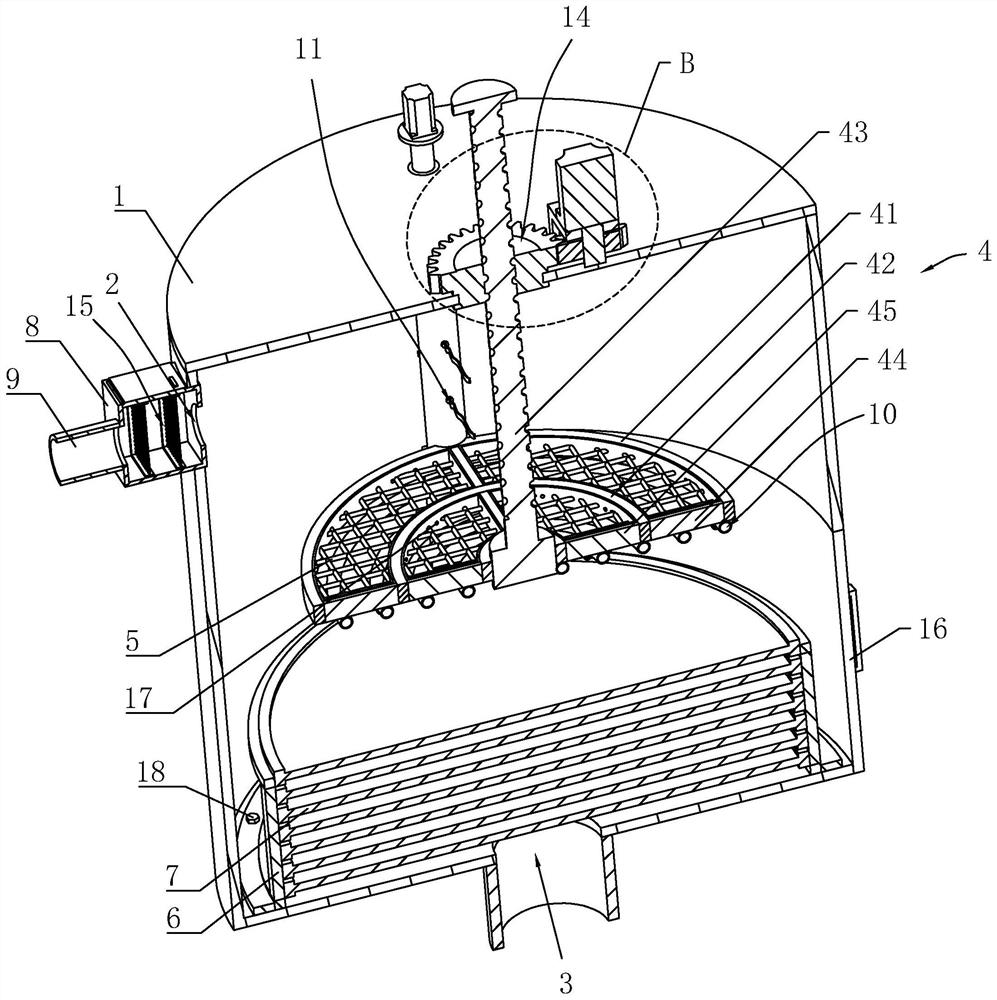

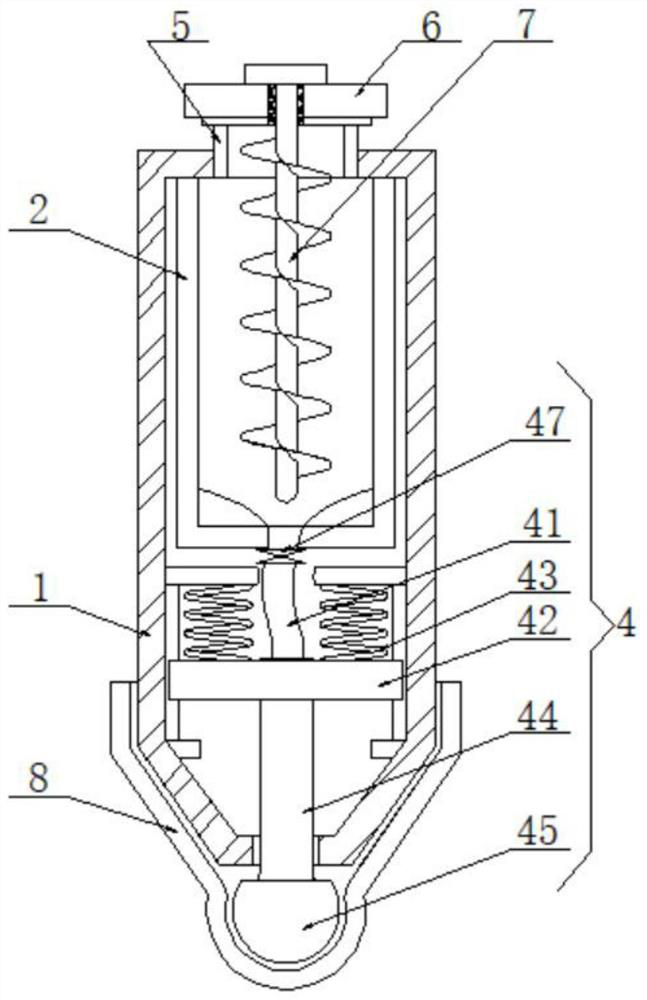

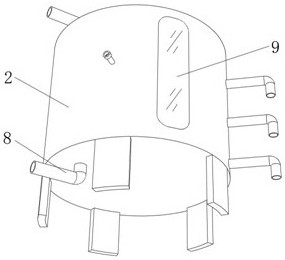

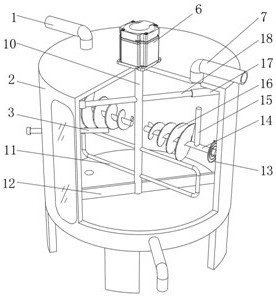

Vertical type animal gastrointestinal bionic digester

ActiveCN105842407AImprove accuracyImprove stabilityEducational modelsMaterial analysisAnimal scienceMedicine

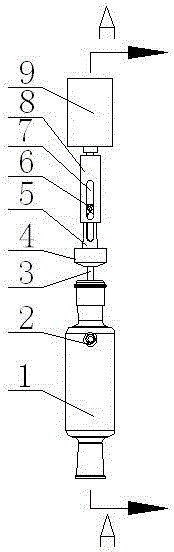

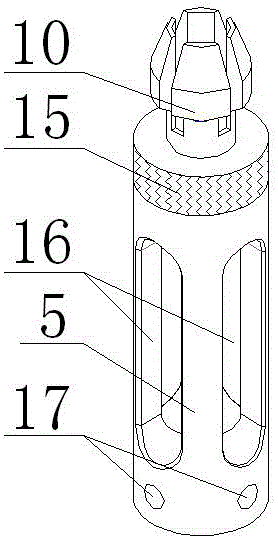

The invention relates to a vertical type animal gastrointestinal bionic digester, which comprises a motor, a connecting shaft sleeve, a heightening transmission rod, a stirring rod and a simulated digestive tract, wherein the connecting shaft sleeve is sleeved on an output shaft of the motor and synchronously rotates along with the motor, and the top end of the heightening transmission rod is fixedly sleeved in a sliding chute below the connecting shaft sleeve by a screw rod, so that the heightening transmission rod can move up and down in the connecting shaft sleeve; a locking nut is arranged on the heightening transmission rod and is used for adjusting the locking degree of the heightening transmission rod and the stirring rod, and the simulated digestive tract is a double-layer hollow vertical glass tube; the stirring rod is arranged in an accommodating cavity of the simulated digestive tract, and the top end of the stirring rod penetrates through a sealing plug at the top of the simulated digestive tract and is connected with the bottom end of the heightening transmission rod. The vertical type animal gastrointestinal bionic digester provided by the invention has the advantages of simple structure, convenience in use, avoidance of leakage of a bionic digestion reaction liquid, high accuracy and good repeatability of digestion simulation, and small errors; the degradation difficulty of cellulose on a dialysis bag in the existing simulated digestive tract in a bionic digestion reaction is effectively solved.

Owner:HUNAN ZHONGBEN INTELLIGENT TECH DEVCO

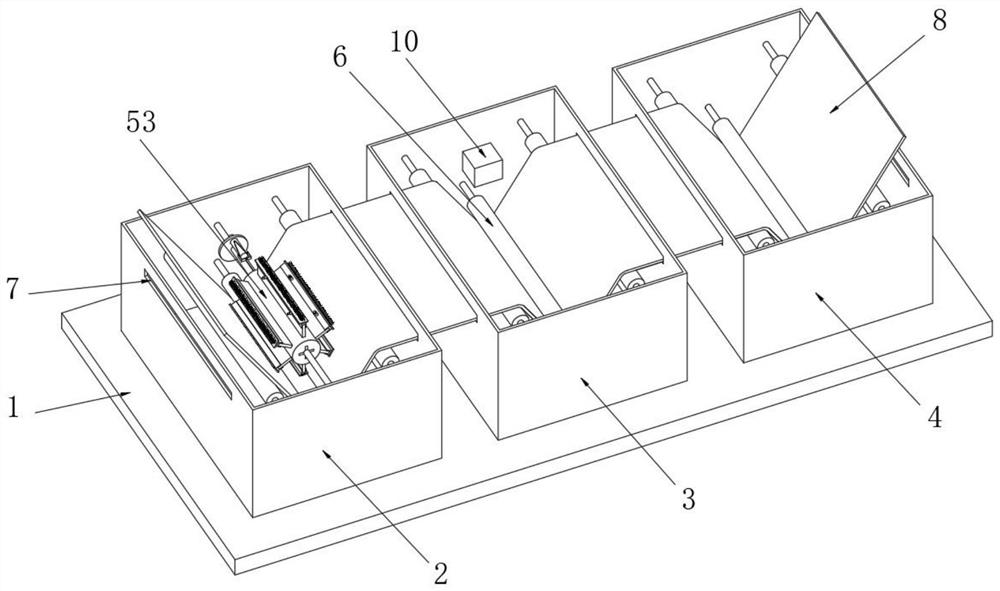

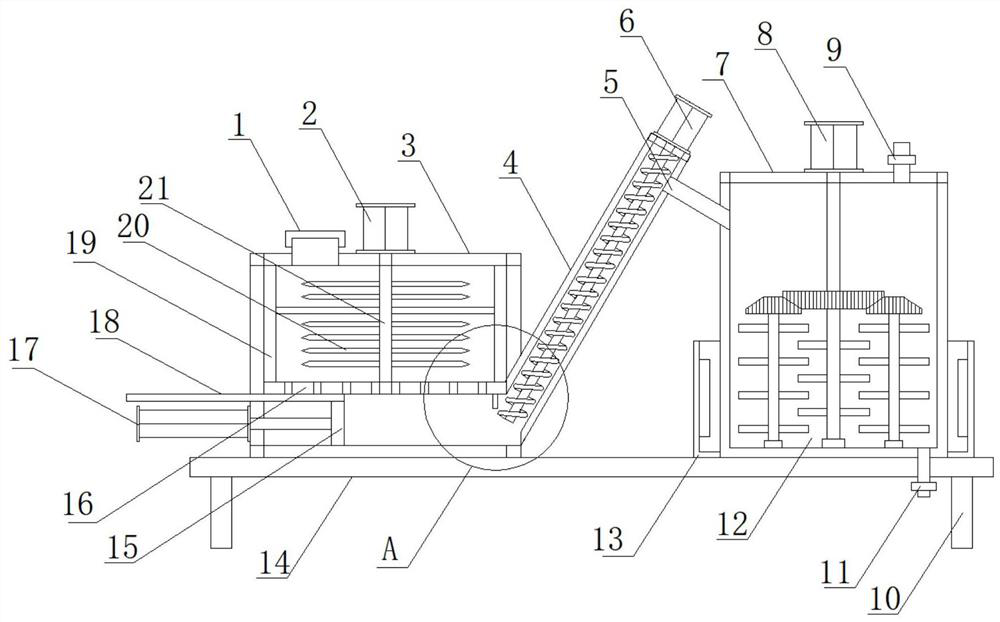

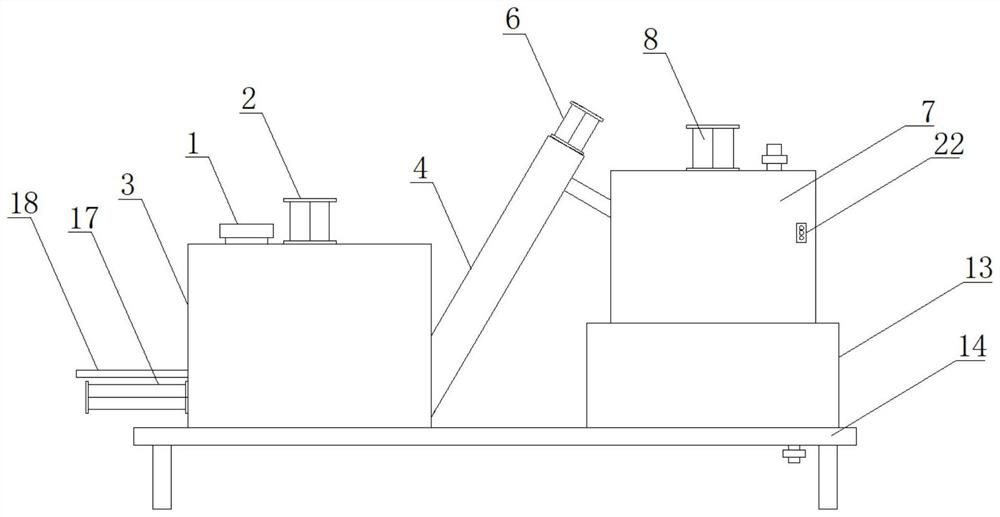

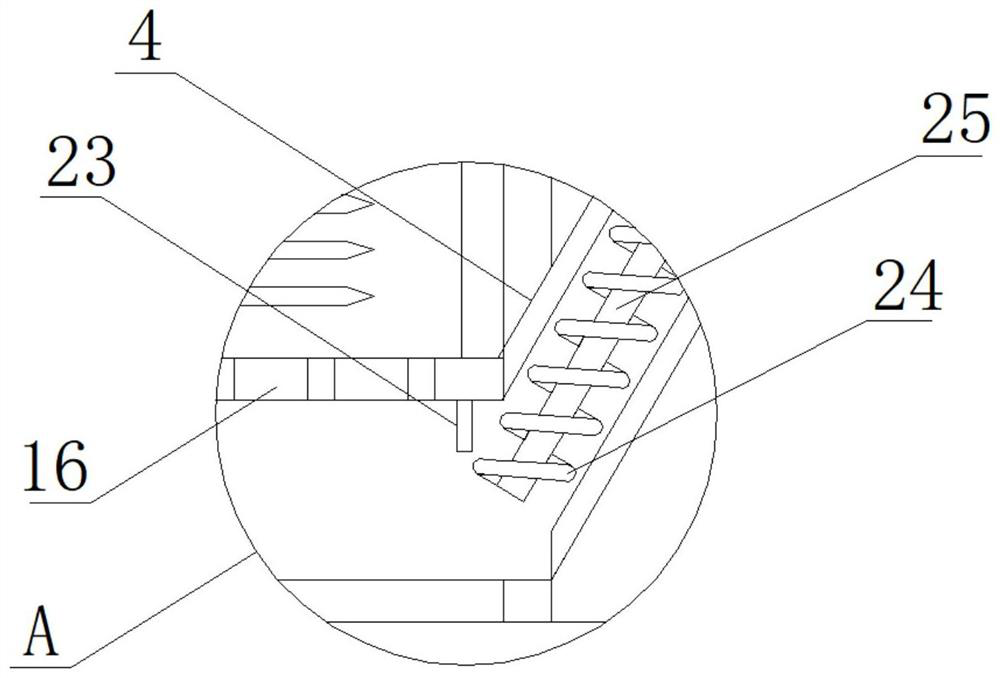

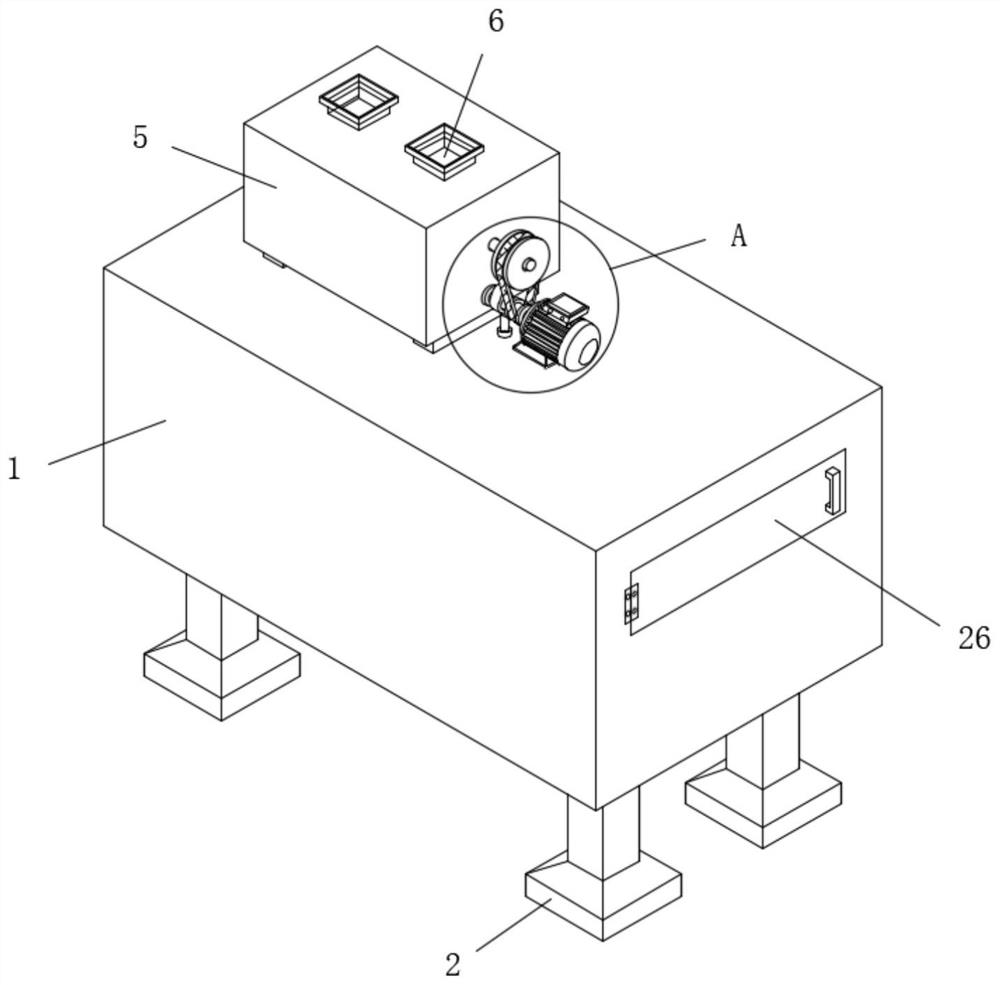

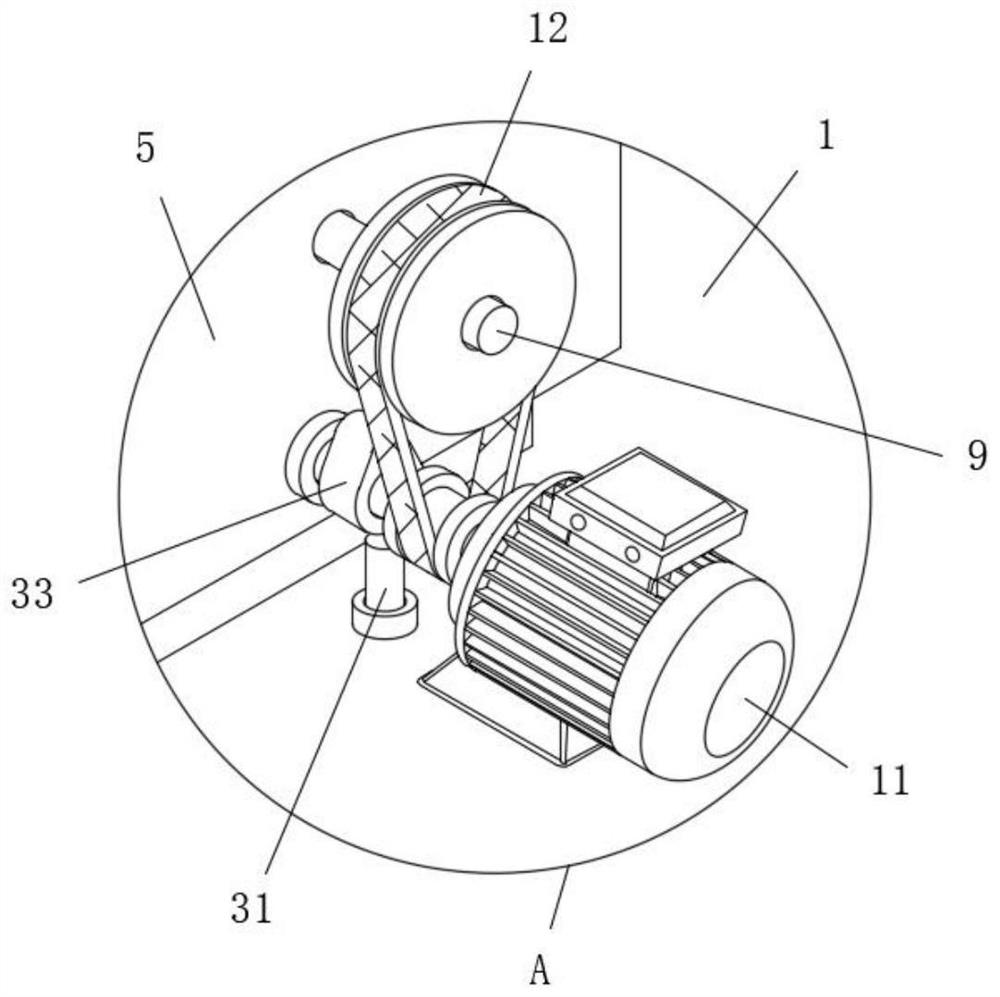

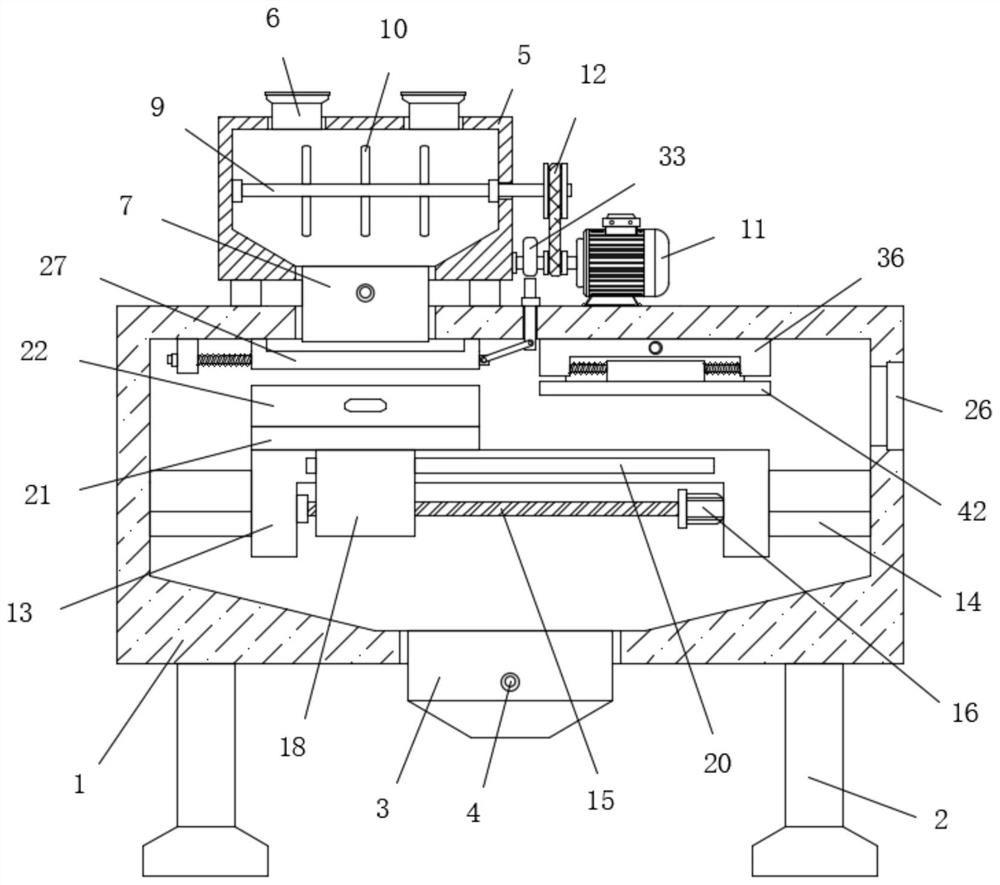

Intelligent equipment for composite material production

The invention discloses intelligent equipment for composite material production. A box and supporting legs are included. The supporting legs are fixedly connected to the four corners of the lower endof the box. A feeding assembly is arranged above the box and comprises spiral blades, a first gear, a motor set, a first bevel gear, a second gear, feeding pipes, a first rotation shaft, a second rotation shaft, a buckle plate and a second bevel gear. The feeding pipes are all fixedly connected with the box. The intelligent equipment for composite material production is scientific and reasonable in structure and safe and convenient to use. Through cooperation of the box, the first gear, the second gear, the feeding pipes, the first rotation shaft, the motor set, the second rotation shaft, thespiral blades and a feeding port, the speed ratio of the left-right spiral blades can be 6:4 through transmission of the first gear and the second gear, and after full material filling is achieved atthe spiral blade positions, a motor above the motor set is started so that left-right materials can be input according to the proportion, and the situation that in the prior art, intelligent and accurate control of the raw material input proportion cannot be achieved is avoided.

Owner:羽源洋(宁波)科技有限公司

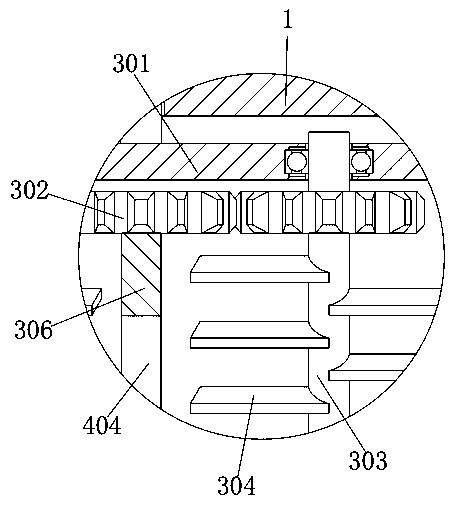

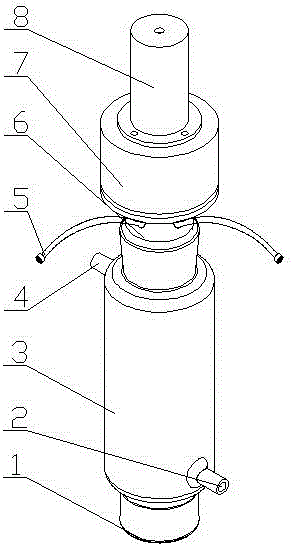

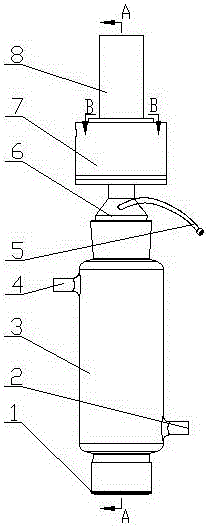

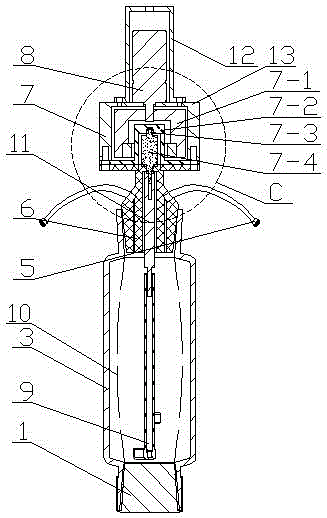

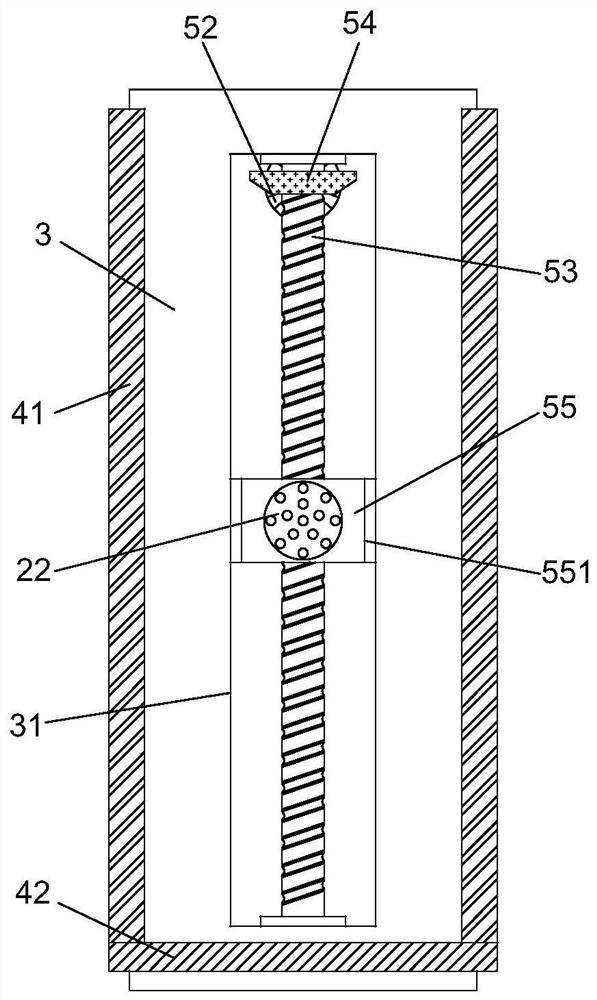

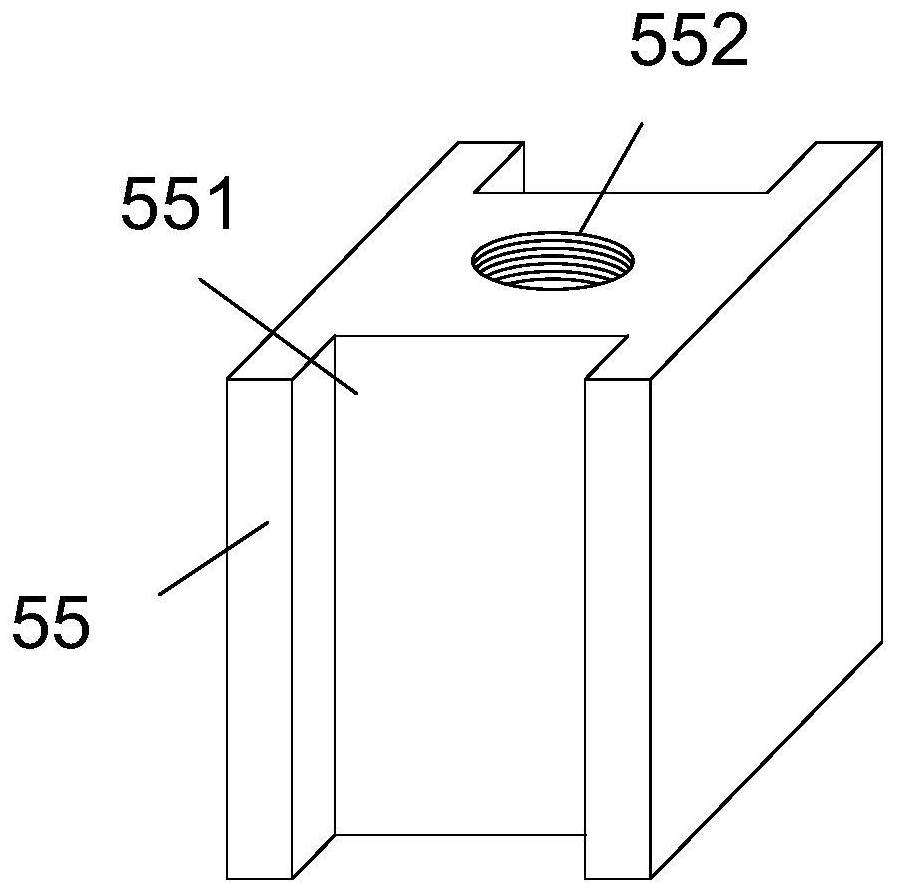

Vertical type animal gastrointestinal tract bionic digestion device

A vertical type animal gastrointestinal tract bionic digestion device comprises a simulation digestive tract, a stirring rod, a motor and a magnetic transmission device. The simulation digestive tract comprises a vertical glass tube body and a dialysis tube body which is placed inside the vertical glass tube body. The stirring rod is installed in the dialysis tube body, and the top end of the stirring rod is detachably connected with the magnetic transmission device. The magnetic transmission device is installed above a silica gel plug at the top end of the simulation digestive tract and electrically connected with the motor. The motor is installed above the magnetic transmission device through a motor fixing base. The vertical type animal gastrointestinal tract bionic digestion device is simple in structure, convenient to use, good in accuracy and repeatability of digestion simulation and small in error, and bionic digestion reaction liquid leakage can be avoided.

Owner:HUNAN ZHONGBEN INTELLIGENT TECH DEVCO

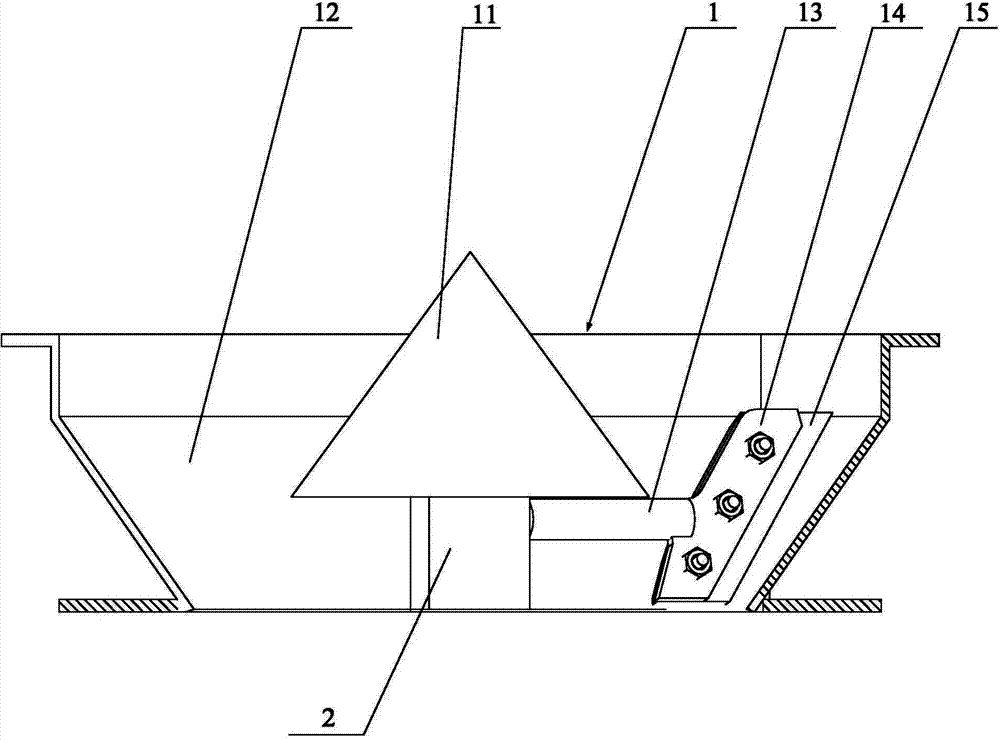

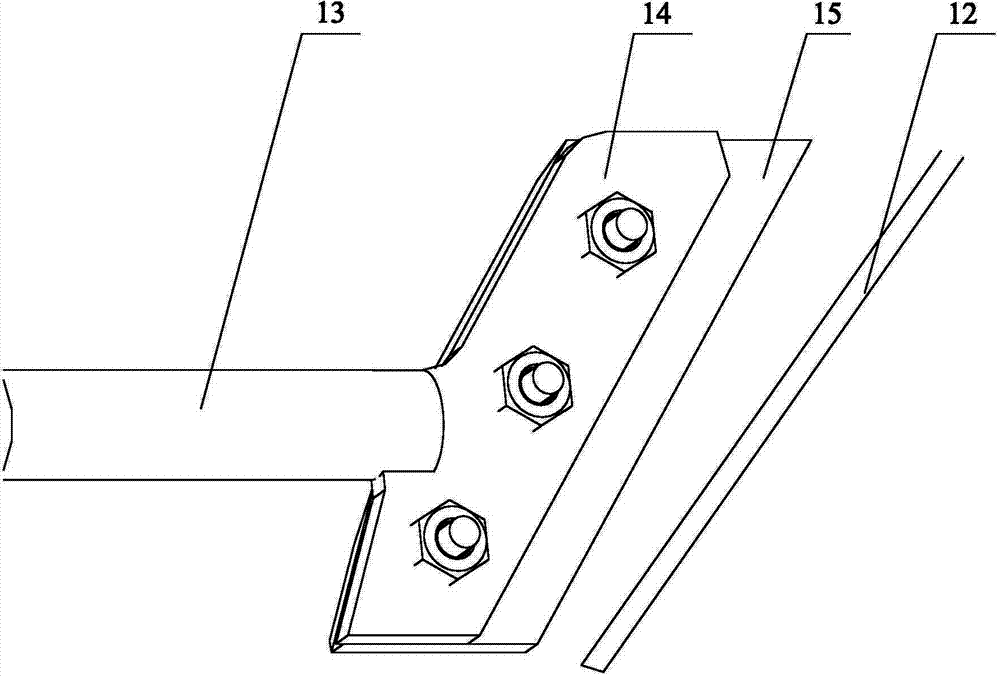

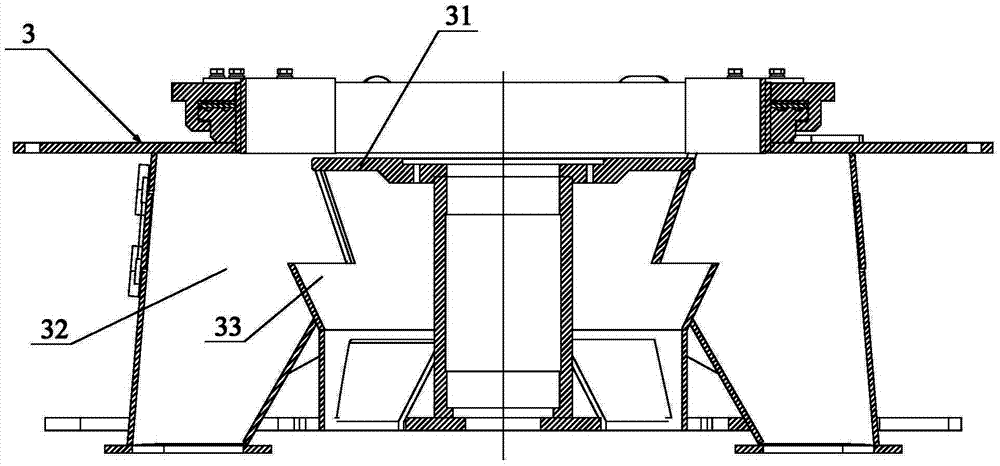

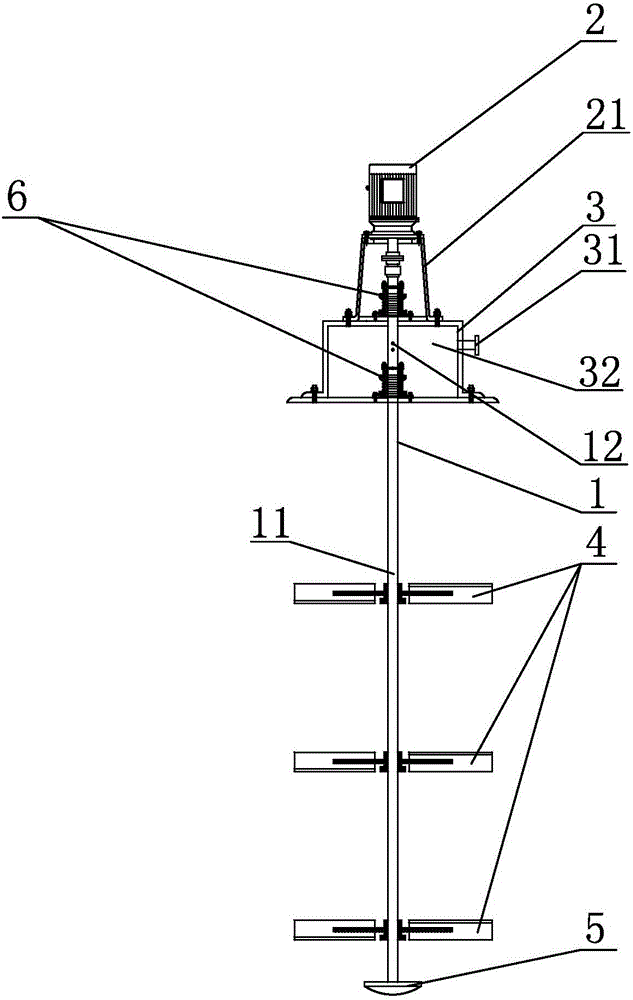

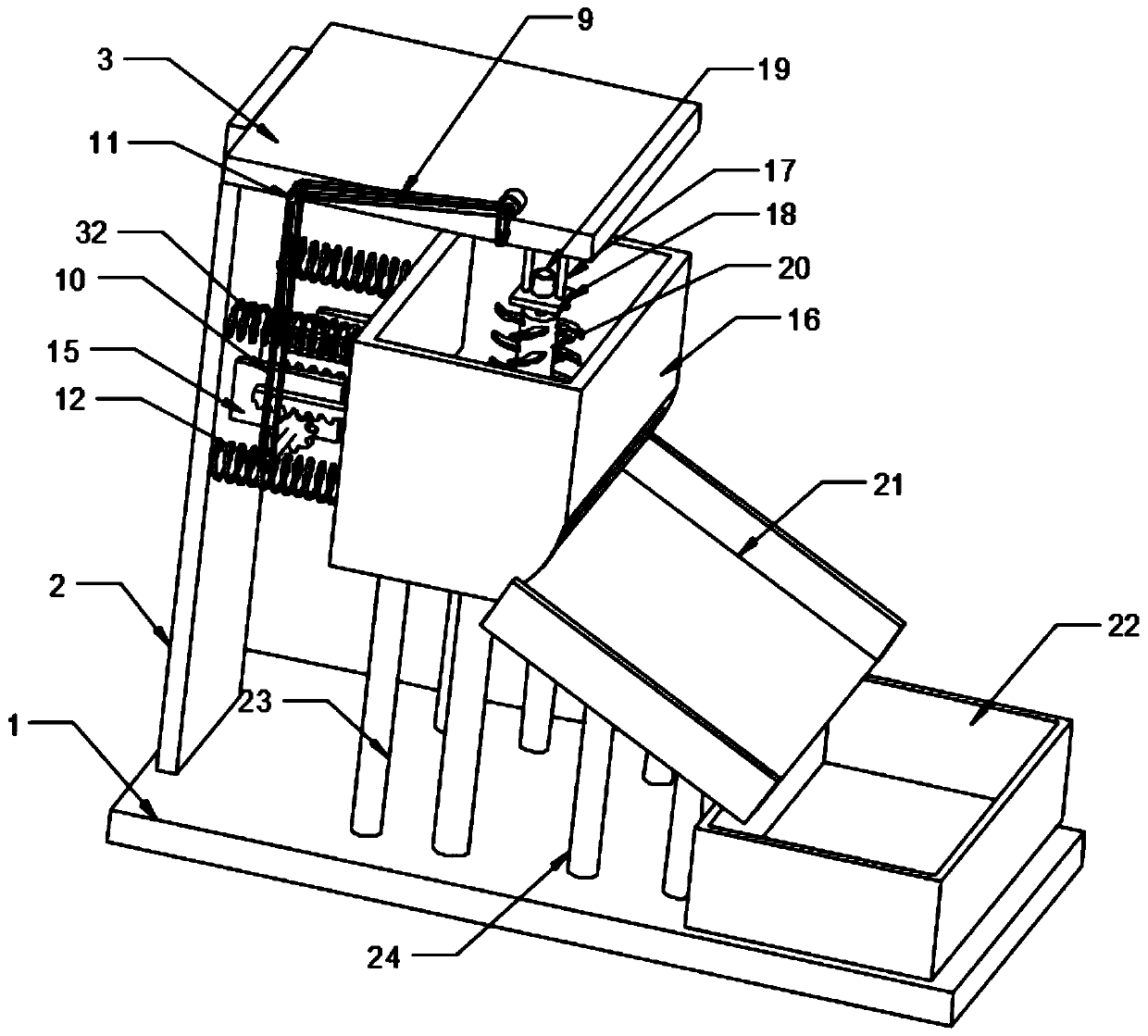

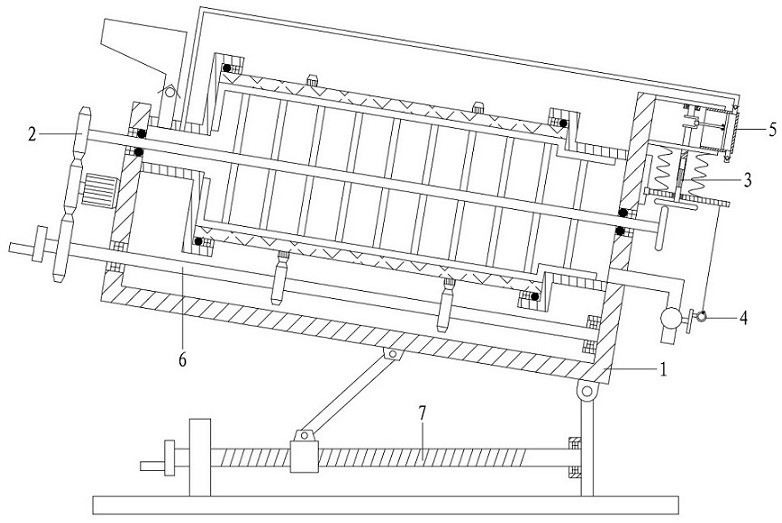

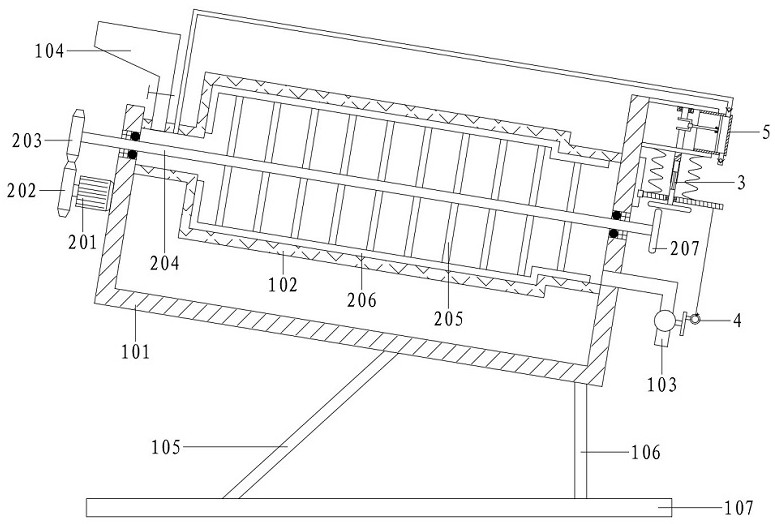

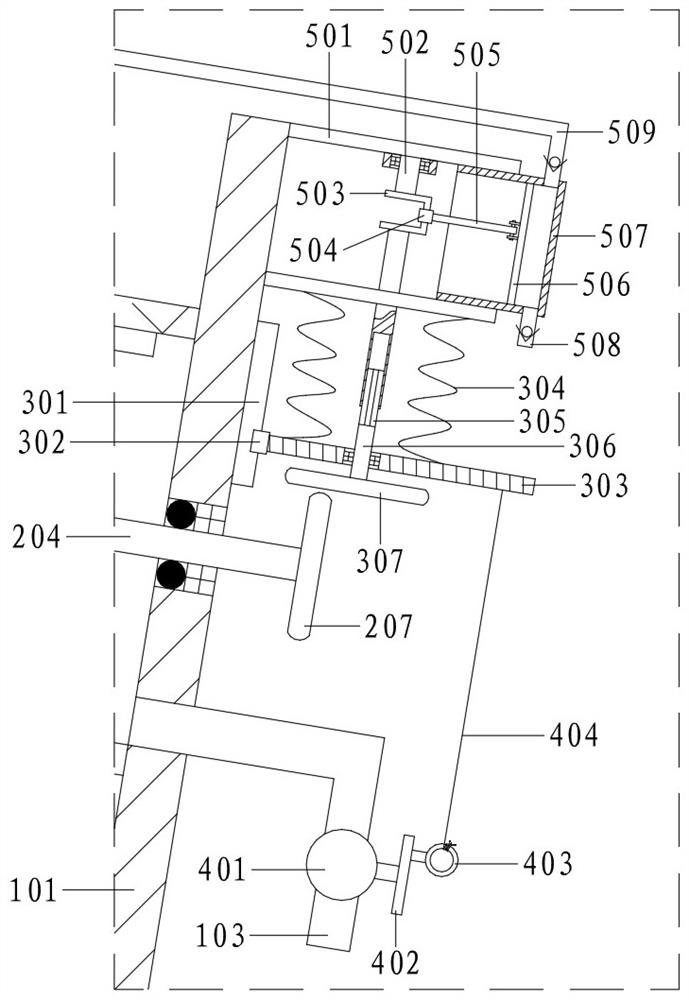

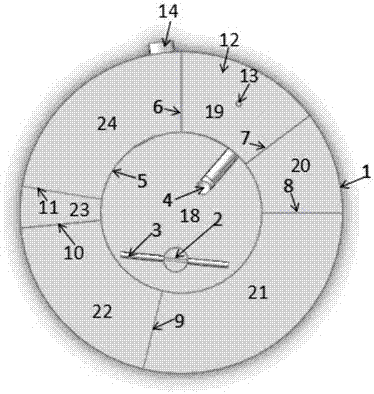

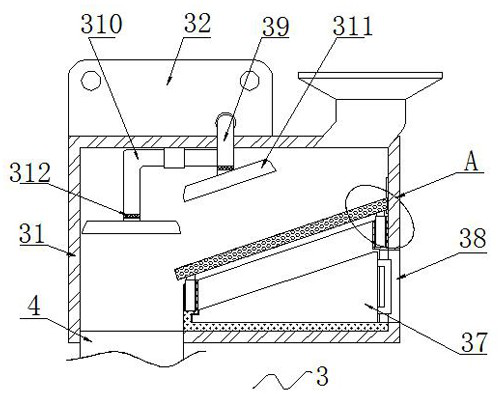

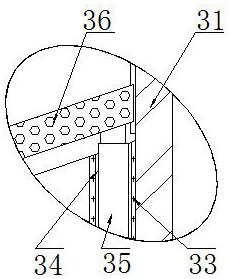

Dividing machine

InactiveCN103616253AAchieving Stirring and MixingImprove work efficiencyWithdrawing sample devicesPreparing sample for investigationEngineeringMixed materials

The invention discloses a dividing machine. The dividing machine comprises a uniform-mixing device and a dividing device, wherein the uniform-mixing device comprises a driving device, a stander, a cone hopper, a conical surface disc, a main shaft and a uniform-mixing scraping plate; the driving device drives the main shaft to rotate, the cone hopper is fixed on the stander, the conical surface disc is arranged in the cone hopper and forms a circumferential interval with the hopper wall of the cone hopper, the conical surface disc is fixedly connected with the main shaft, the uniform-mixing scraping plate is fixed on one side of the main shaft and is arranged in the circumferential interval, and the dividing device is arranged below the cone hopper. When the dividing machine is used, the driving device is started to drive the main shaft, the conical surface and the uniform-mixing scraping plate to rotate, and meanwhile, to-be-uniformly-mixed materials are poured to the conical surface disc, are uniformly thrown to the wall surface of the hopper wall of the cone hopper under the action of the centrifugal force of the conical surface disc, are uniformly mixed and concentrated again by the uniform-mixing scraping plate and are divided after falling into the dividing device under the action of the gravity, so that the materials are automatically divided after being uniformly mixed, and the working efficiency is increased.

Owner:长沙开元机电设备有限公司

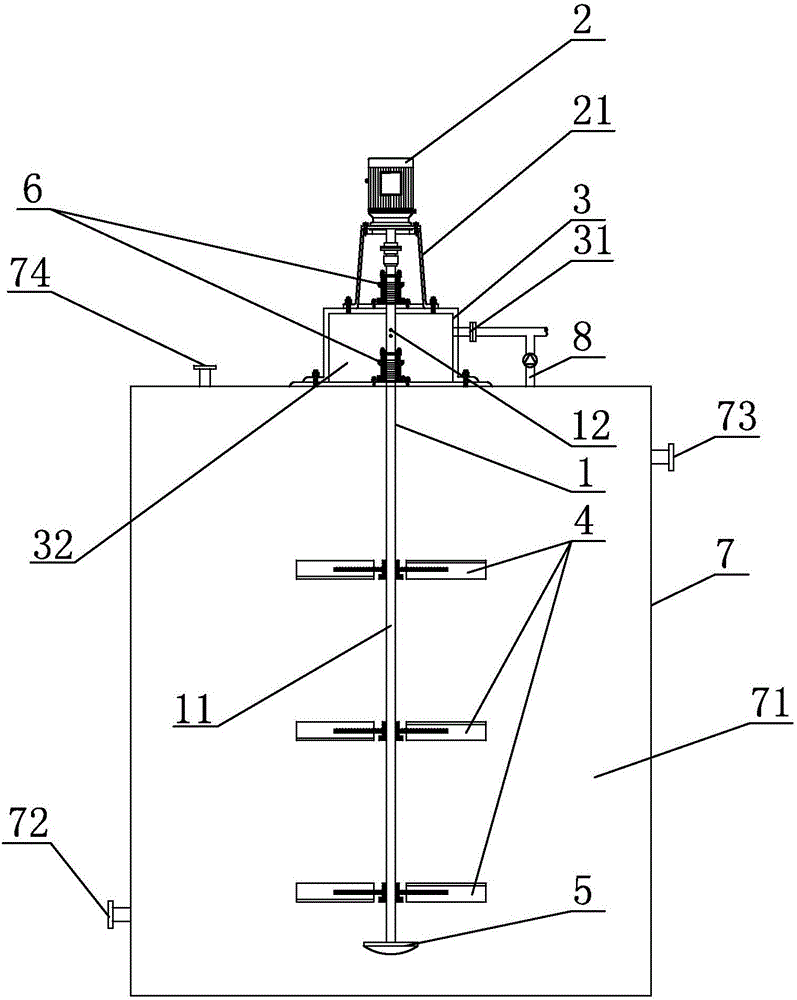

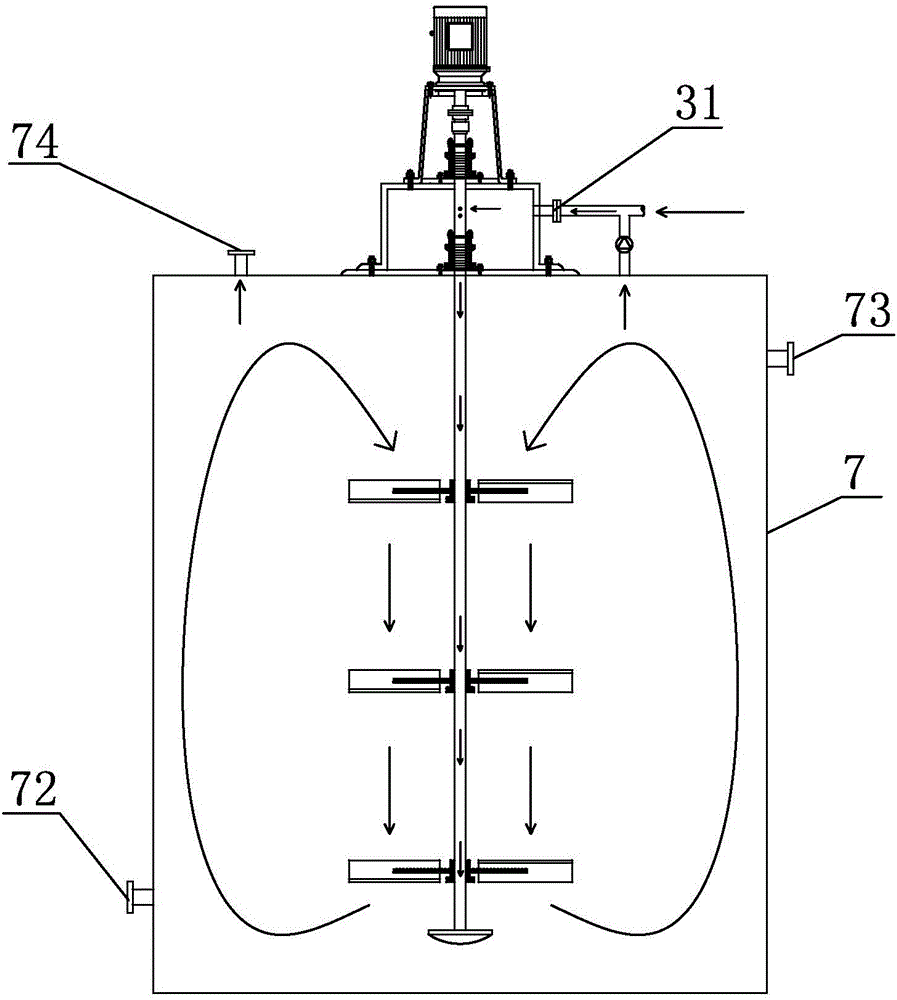

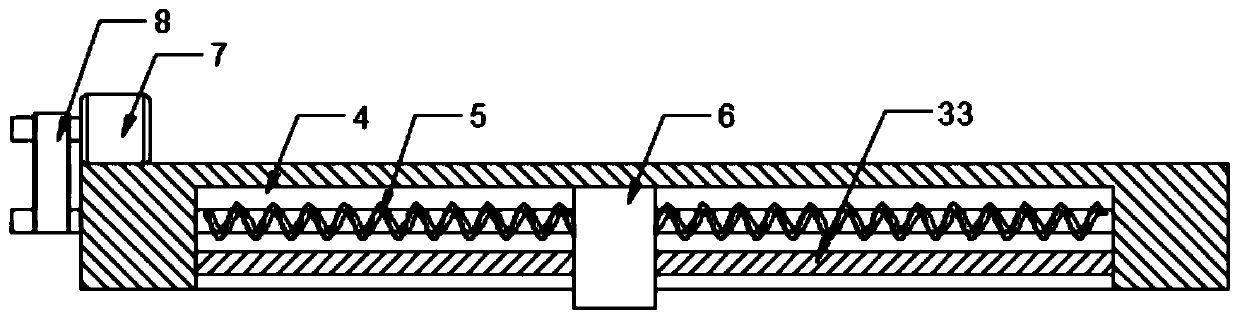

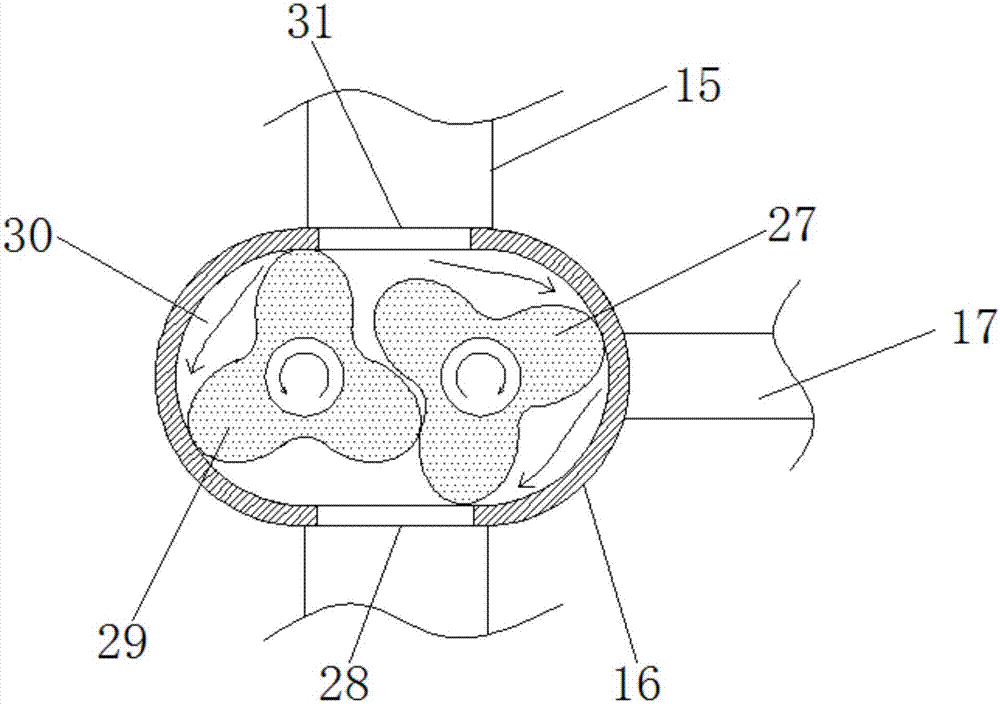

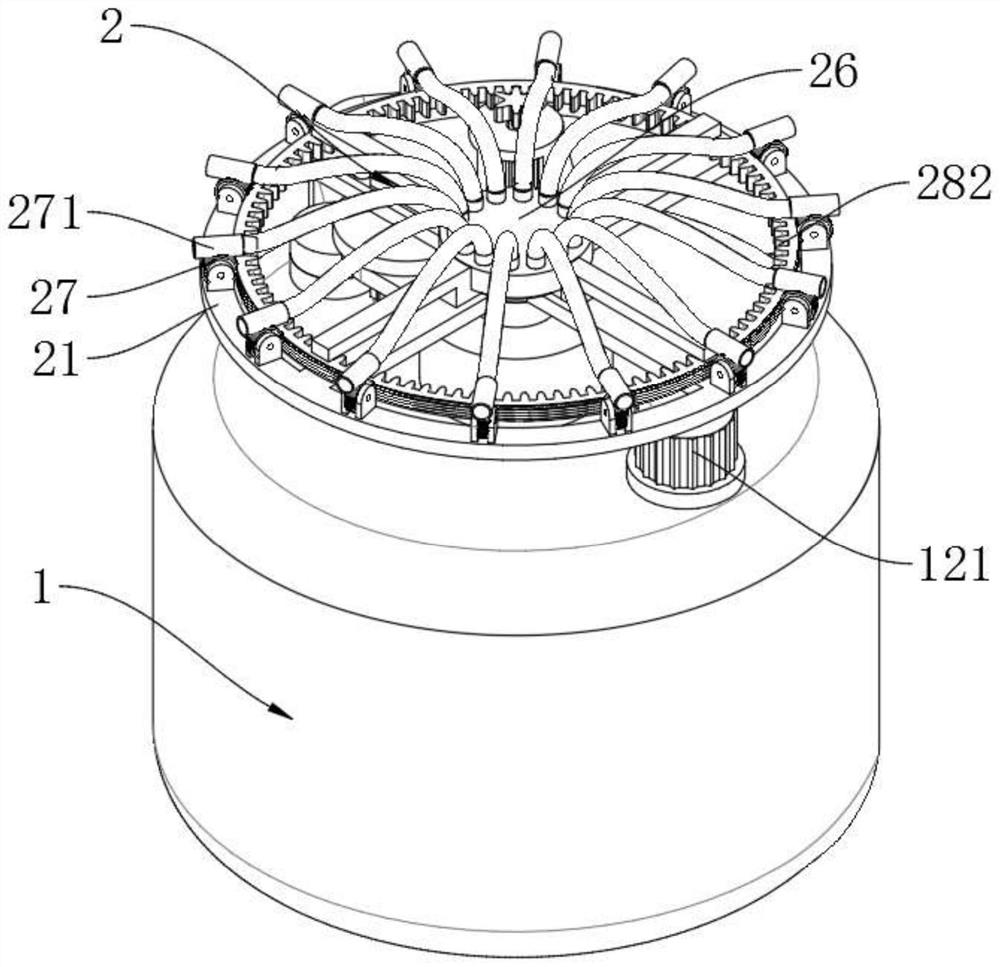

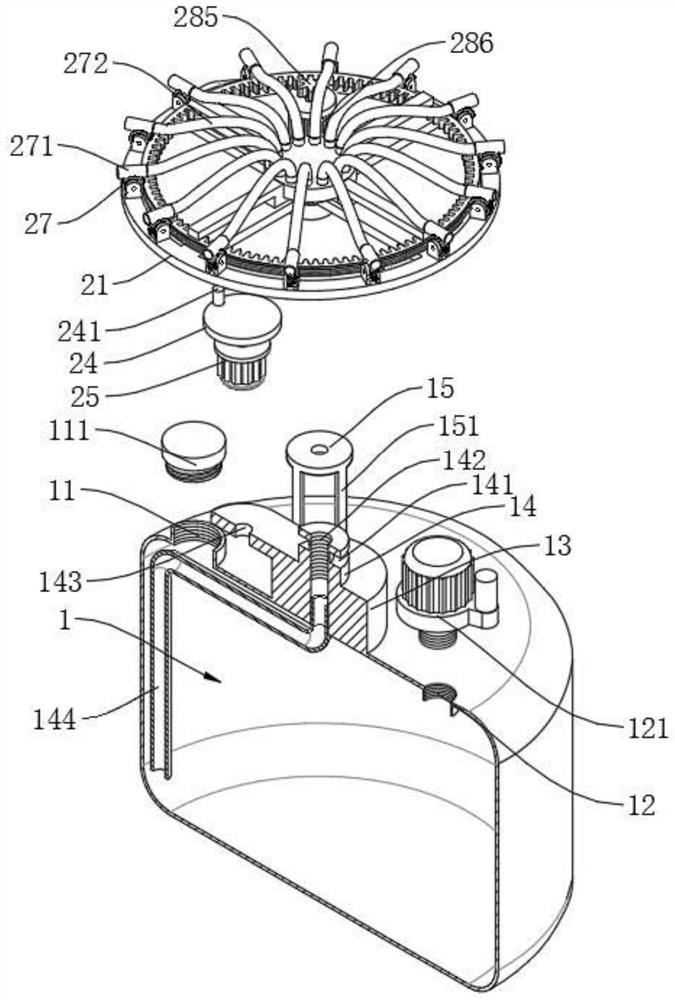

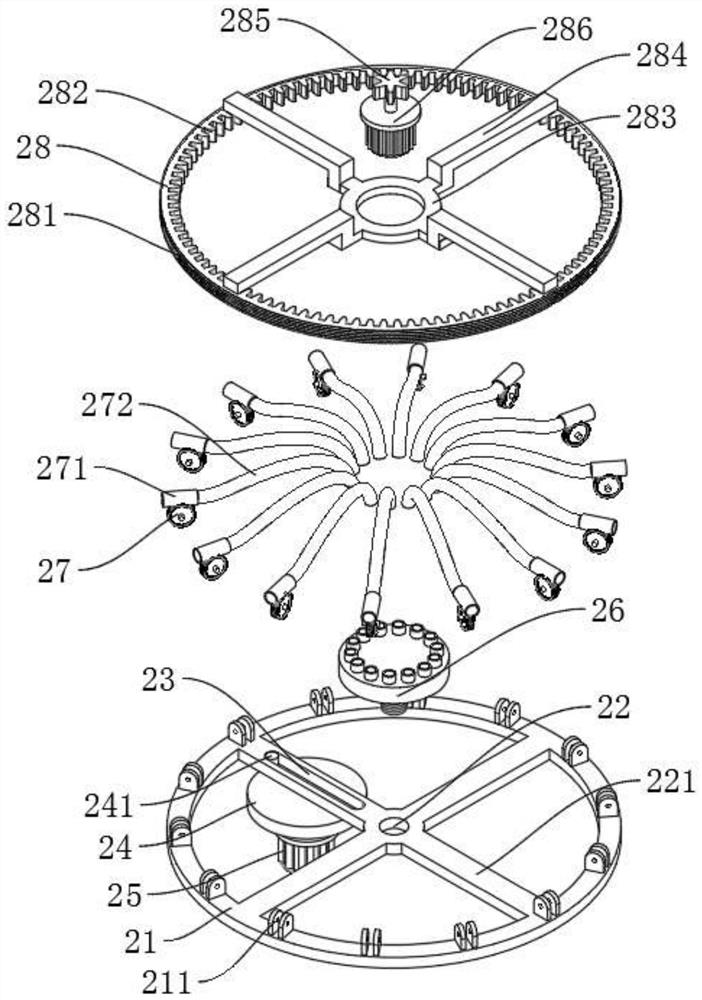

Integrated device for conveying gas and stirring materials, and bioreactor comprising same

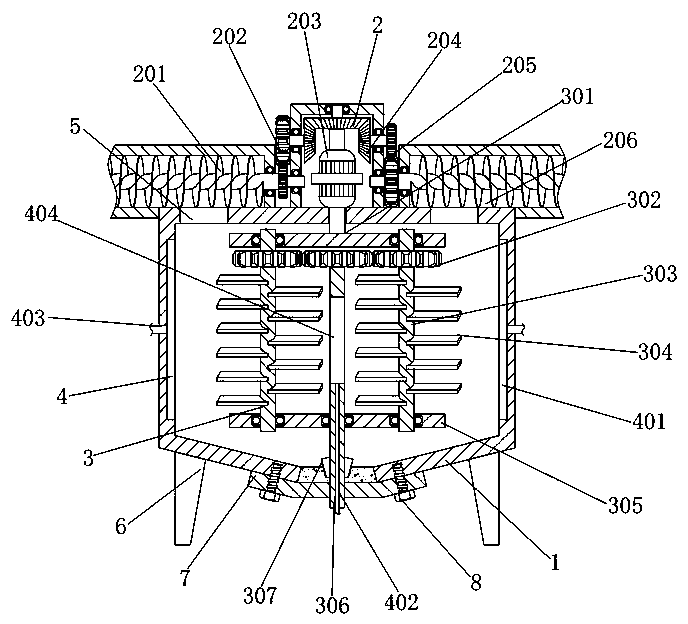

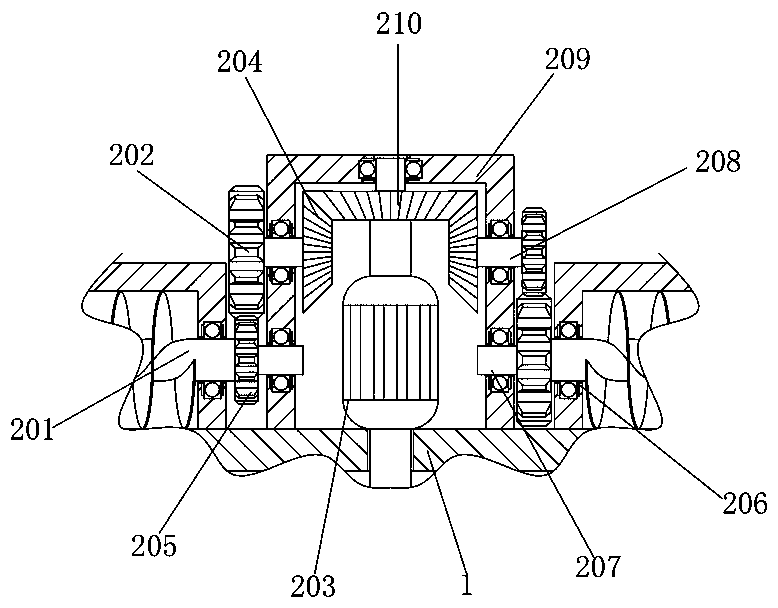

InactiveCN105695309AReduce shockEfficient and thorough conversionBioreactor/fermenter combinationsBiological substance pretreatmentsCircular discEngineering

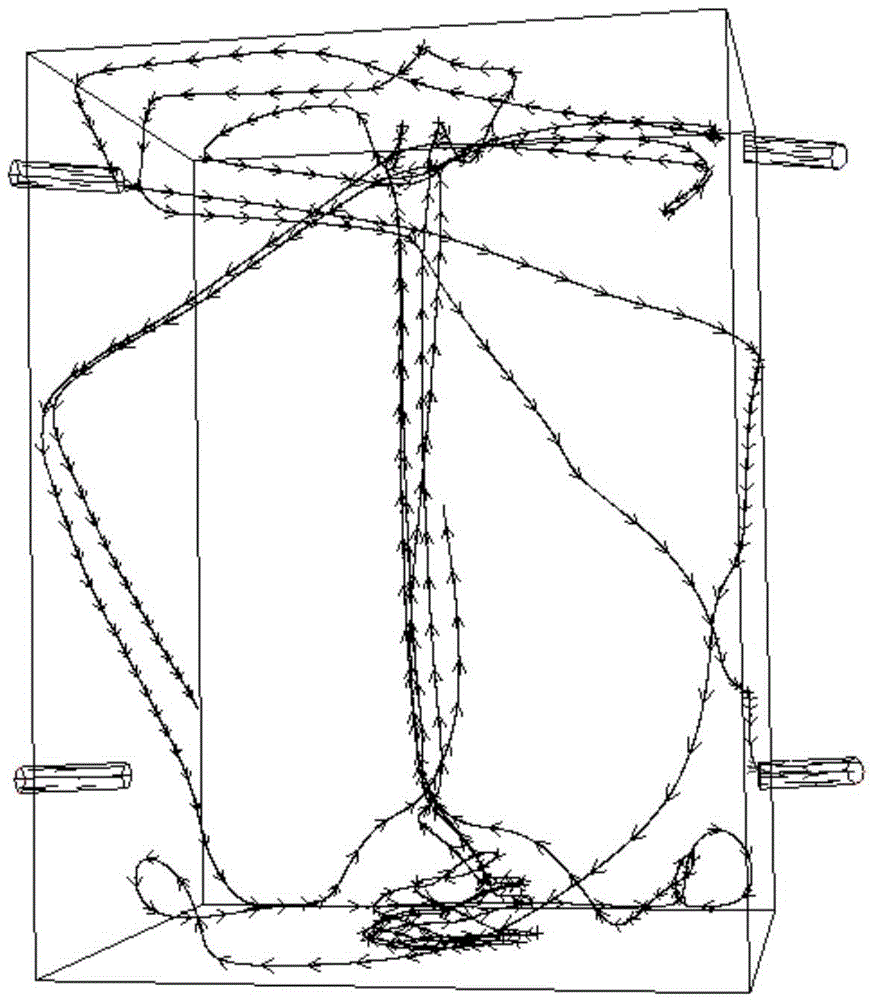

The invention discloses an integrated device for gas conveying and material stirring, which comprises a rotating stirring shaft and a motor; The connection between them is sealed; the stirring part of the rotating stirring shaft is equipped with a slanted blade disc turbine agitator, and the bottom end is equipped with a microporous aeration device; the shaft wall of the rotating stirring shaft in the buffer air inlet chamber is provided with ventilation The ventilation channel is arranged in communication with the microporous aeration device through the air inlet chamber provided in the rotating stirring shaft. The invention increases the buffer air intake chamber to reduce the impact on the microorganisms when the air intake velocity fluctuates, and uses a microporous aeration device to increase the contact area between fine air bubbles and microorganisms, and at the same time cooperates with a multi-layer oblique blade disc turbine agitator The material in the bioreactor can be circulated downward from the center and then upward along the inner wall around the main body of the bioreactor to strengthen the biotransformation process of the gas.

Owner:BEIJING UNIV OF CHEM TECH +1

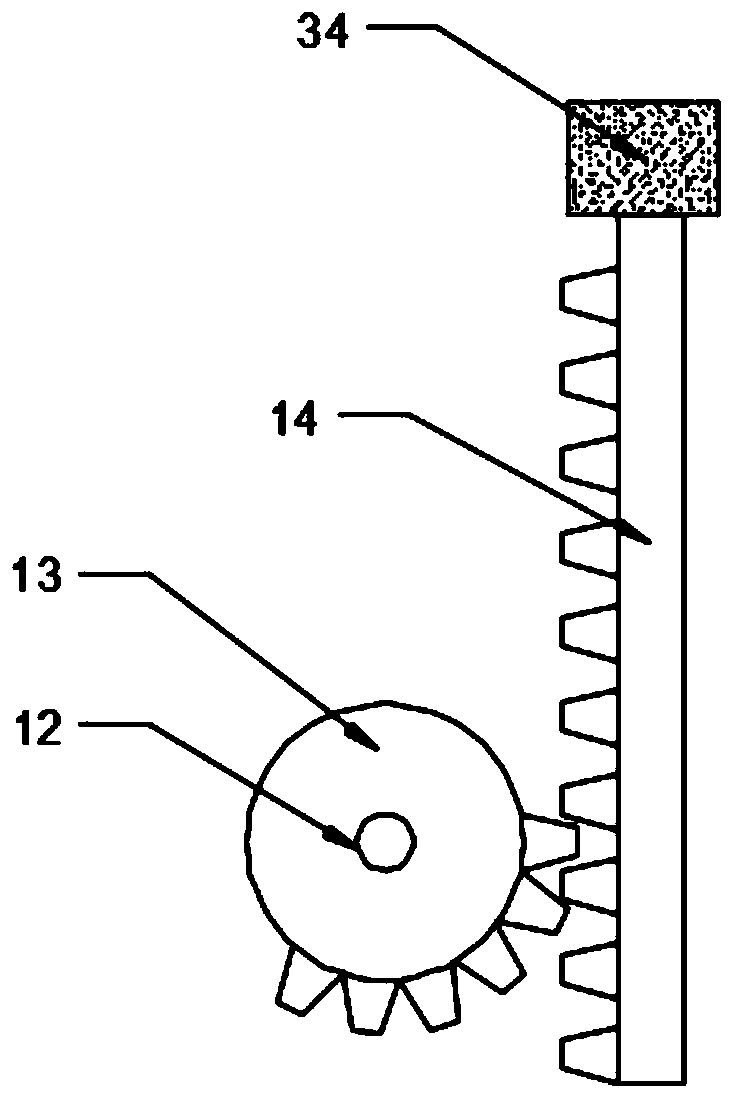

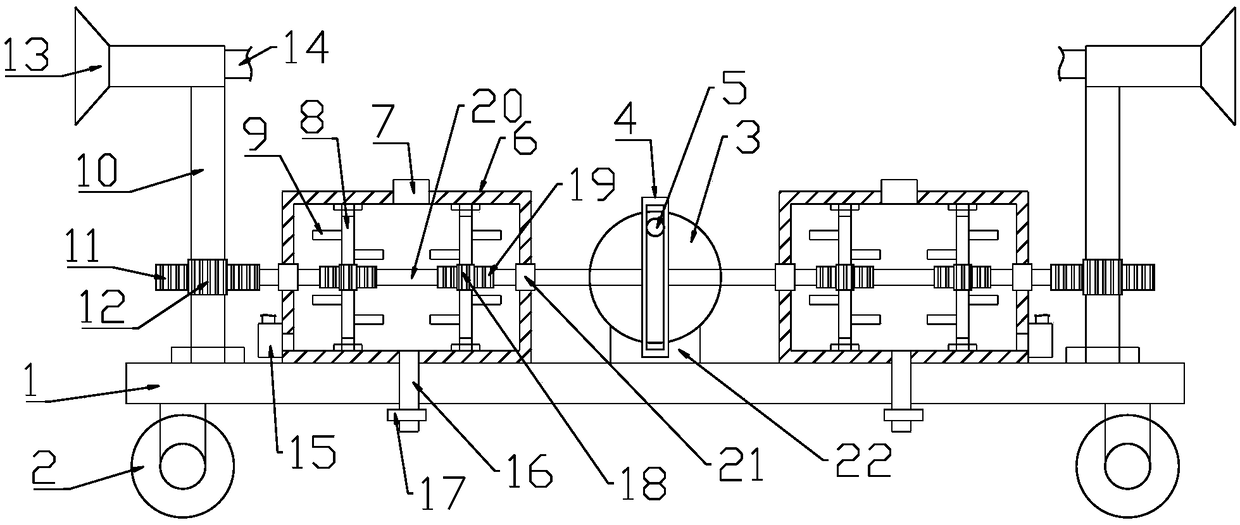

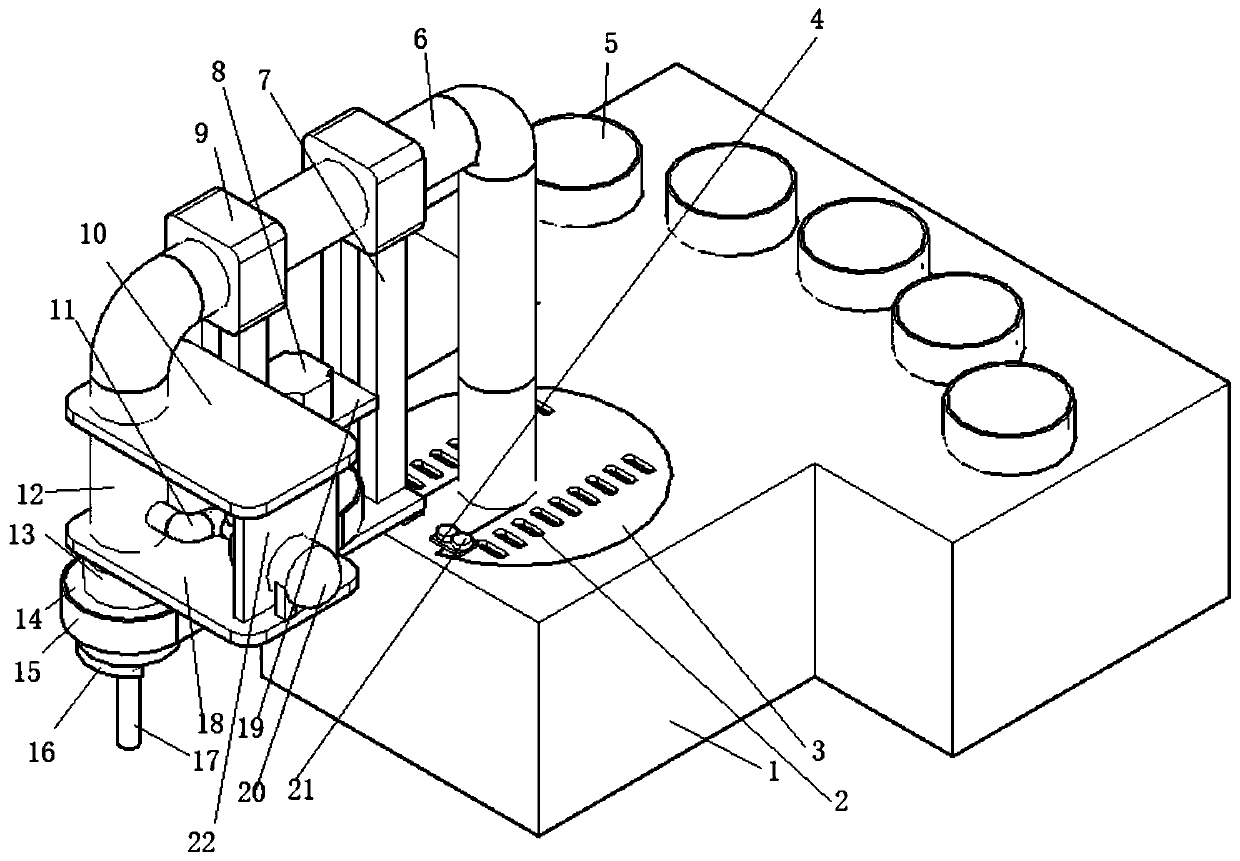

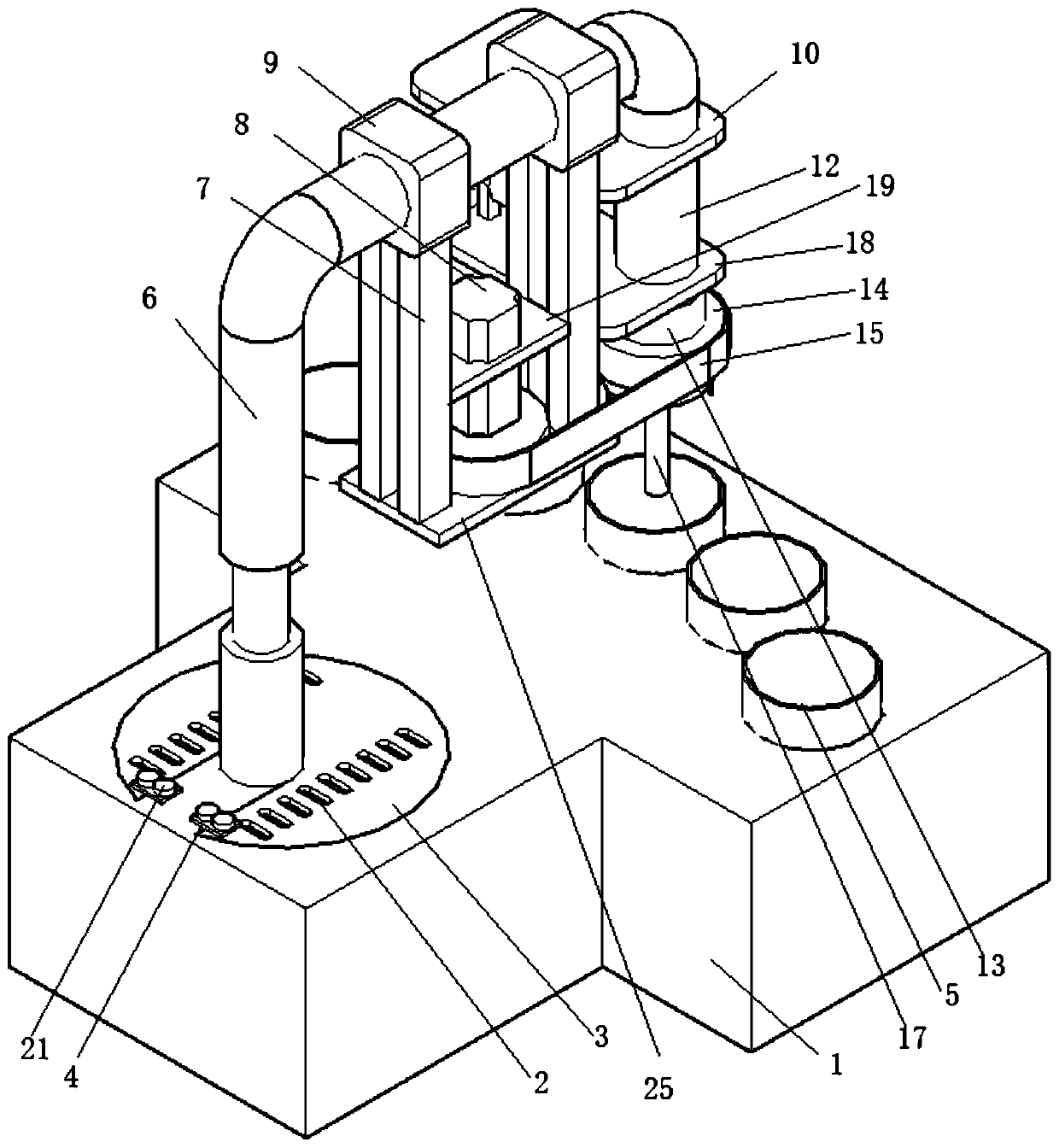

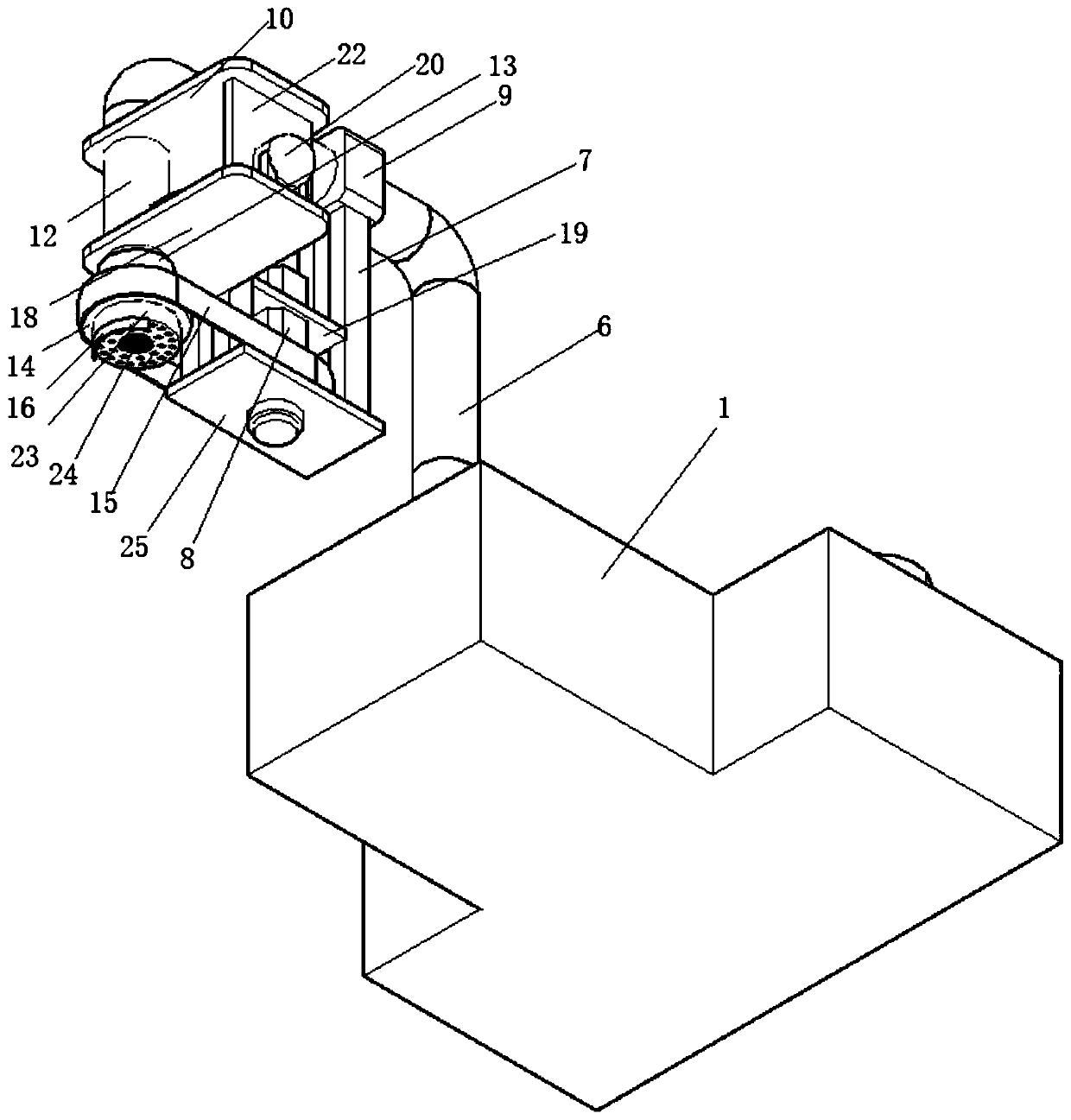

Feeding device for livestock breeding

ActiveCN111406661AImprove crushing effectAchieving Stirring and MixingFood processingAnimal feeding devicesCrop livestockGear wheel

The invention discloses a feeding device for livestock breeding. The feeding device comprises a base, a vertical plate, a mounting plate, a crushing frame, first support posts, a crushing assembly forcrushing raw materials and a vibration assembly, wherein the crushing frame is arranged on the base through the first support posts; the crushing assembly comprises a first fixing plate, a crushing motor and a crushing roller; the fixing plate is connected with a drive assembly for driving the crushing roller to move in the crushing frame; the drive assembly comprises a first sliding chute, a reciprocating screw, a first sliding block, a drive motor, a first belt and a connecting rod; and the vibration assembly is used for driving the crushing frame to shake and comprises a transmission belt,a second belt, a transmission shaft, a driven shaft, incomplete gears, a rack guide post, auxiliary plates, a third sliding chute, third sliding blocks and reset springs. Through the arrangement of the crushing assembly, the drive assembly and the vibration assembly, the crushing effect on the raw materials is greatly improved.

Owner:贵州黄牛产业集团科技服务有限公司

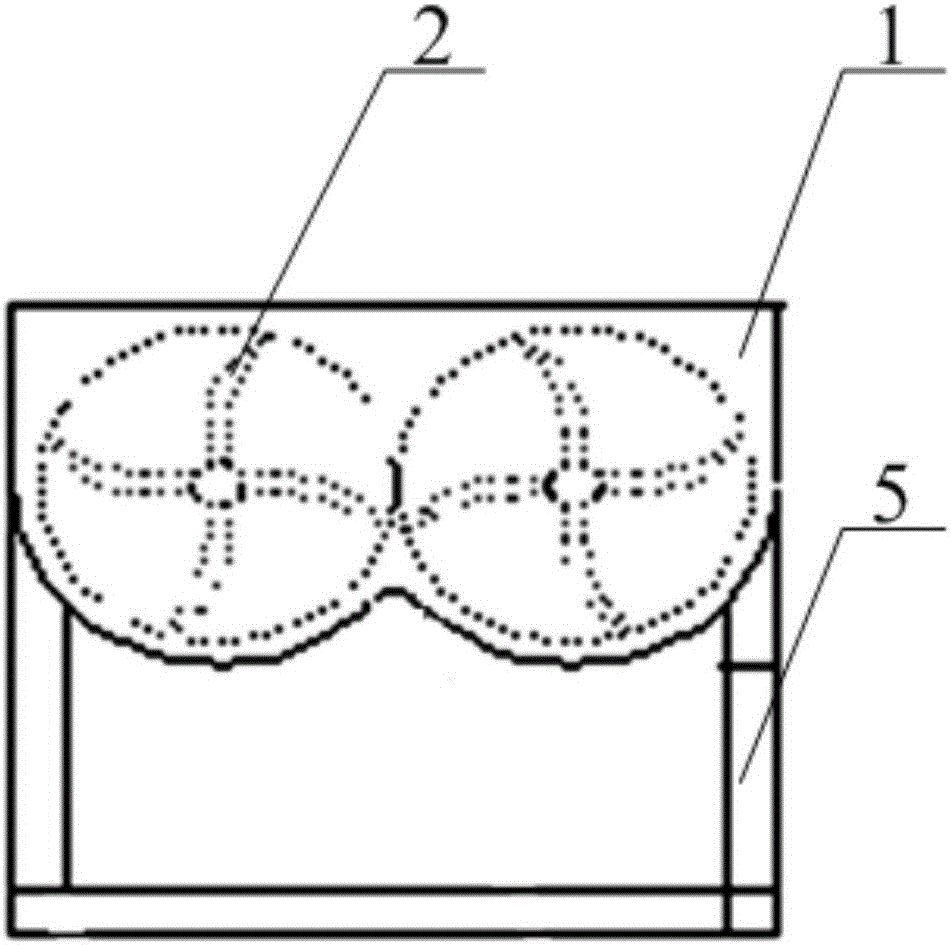

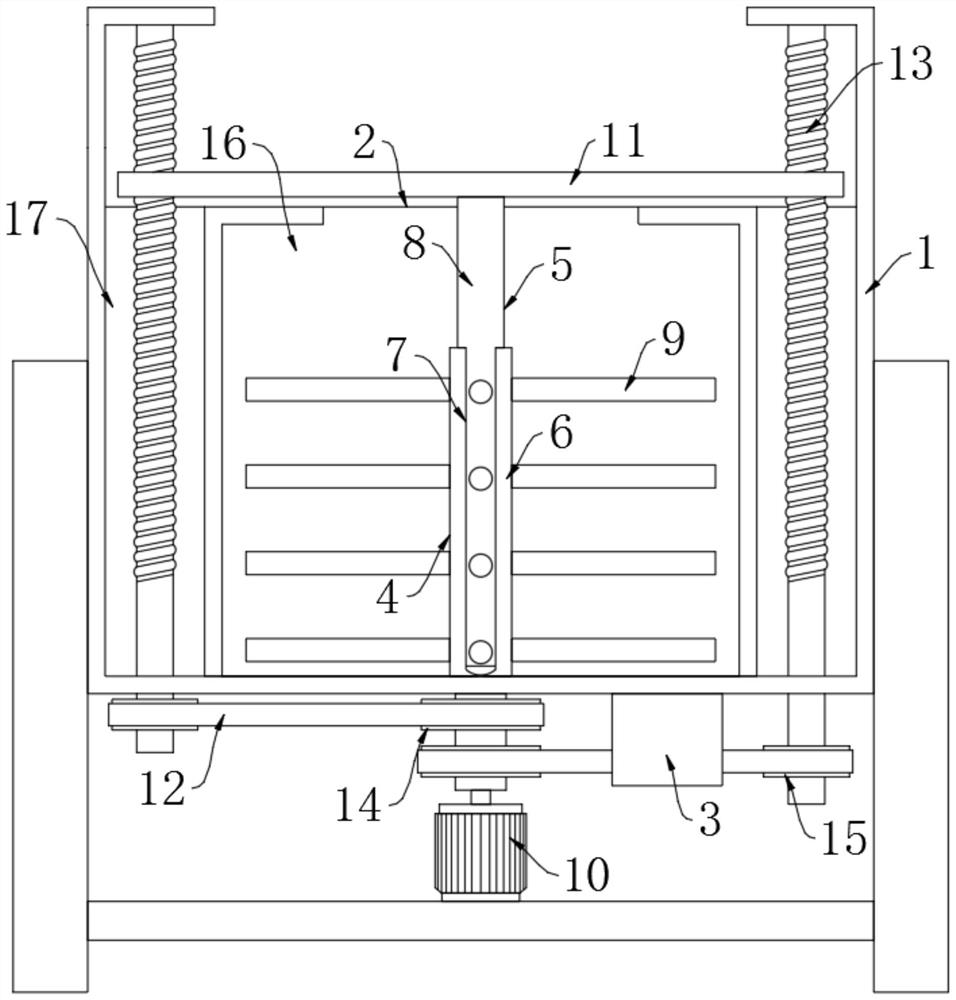

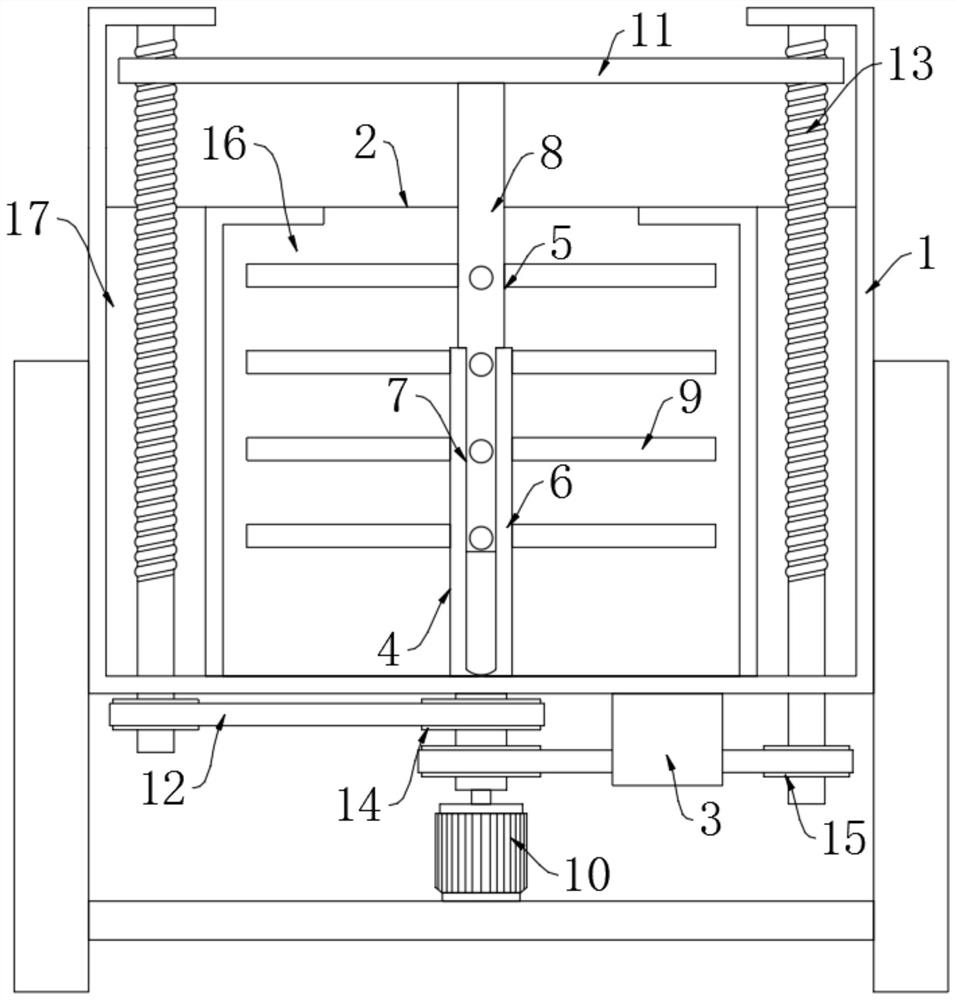

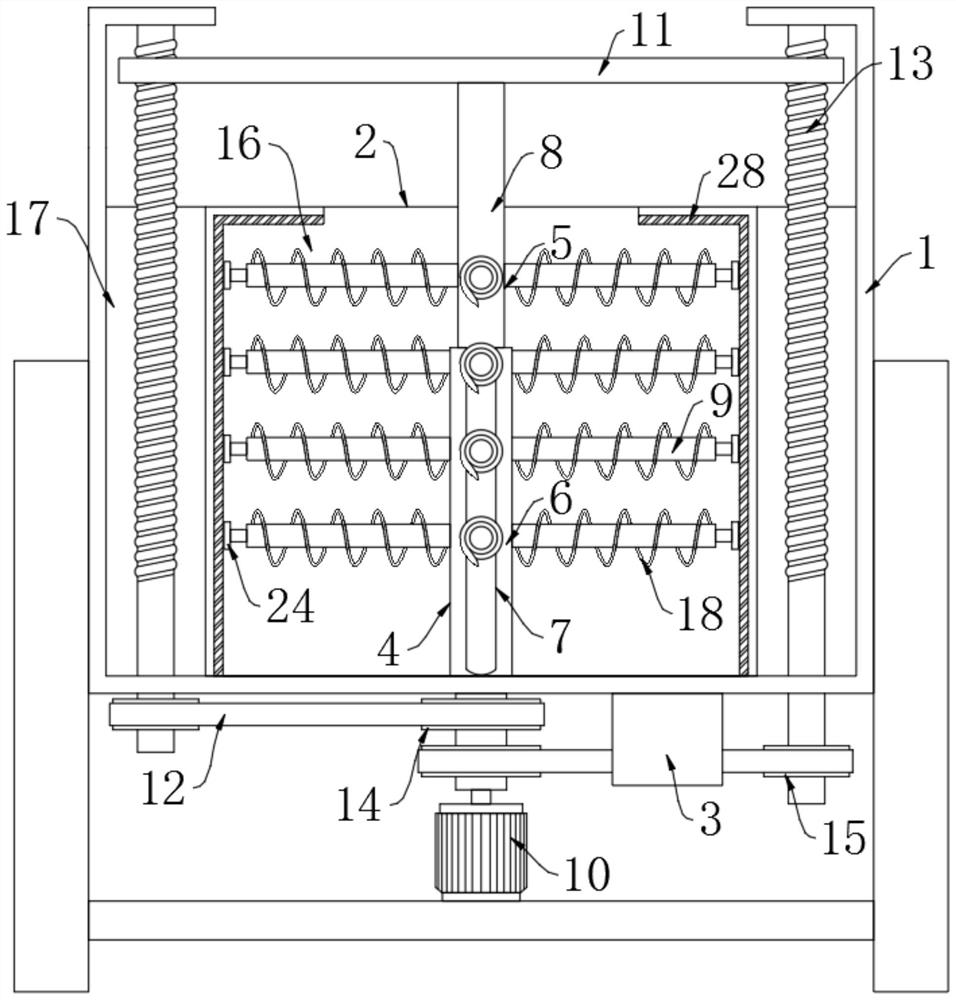

Inorganic filler and natural latex mixing equipment

The invention discloses inorganic filler and natural latex mixing equipment. The inorganic filler and natural latex mixing equipment comprises a container body used for containing inorganic filler and natural latex, and at least two built-in stirrers arranged in the container body. According to the inorganic filler and natural latex mixing equipment, the built-in stirrers are arranged in the container body, stirring and mixing of the latex can be achieved, and the latex can be stretched and tore through the built-in stirrers, so that the latex is prevented from adhering to the built-in stirrers; meanwhile, in the process of stretching and tearing the latex, the latex can be prevented from being solidified rapidly, and accordingly the effect that the inorganic filler and the natural latex are sufficiently mixed can be guaranteed through the mixing equipment; and furthermore, the reaction solidification effect of products is good, the latex is not prone to adhering to the container body or the built-in stirrers, the production efficiency is improved, latex waste is avoided, and the cost is reduced.

Owner:SHANGHAI ZHONGHUA TECH CO LTD

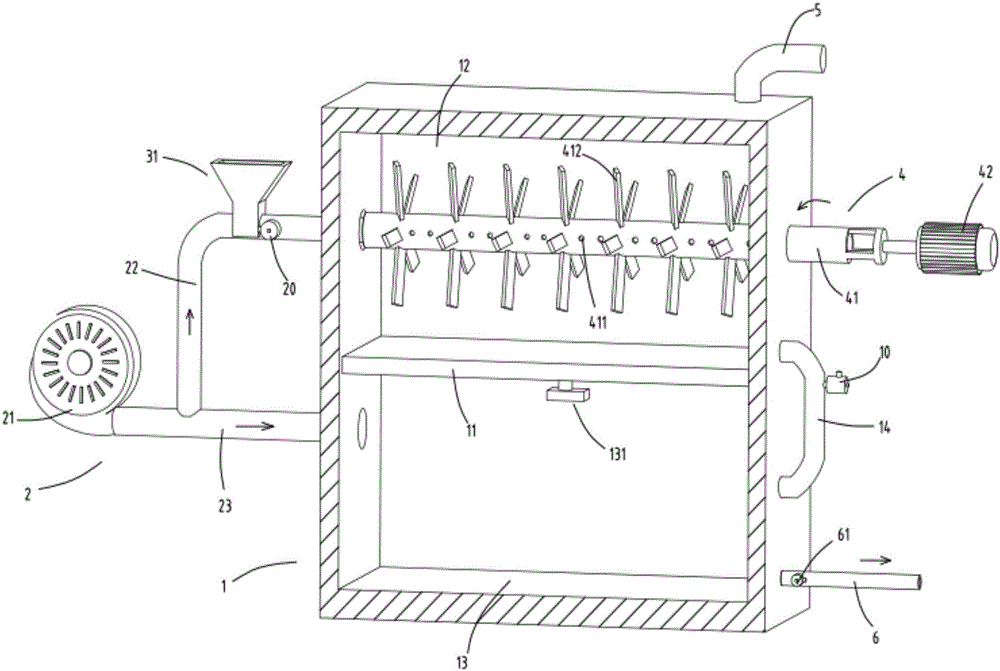

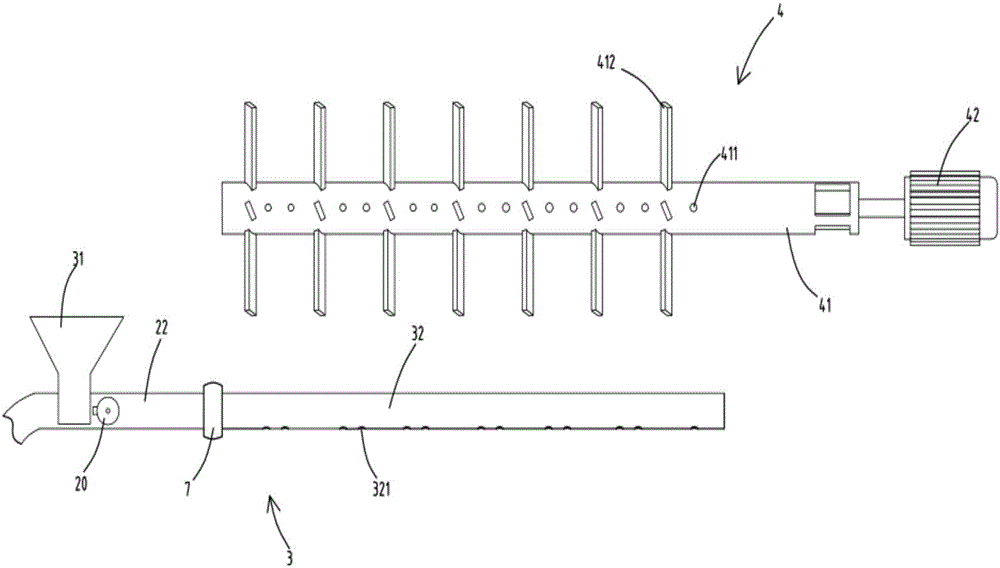

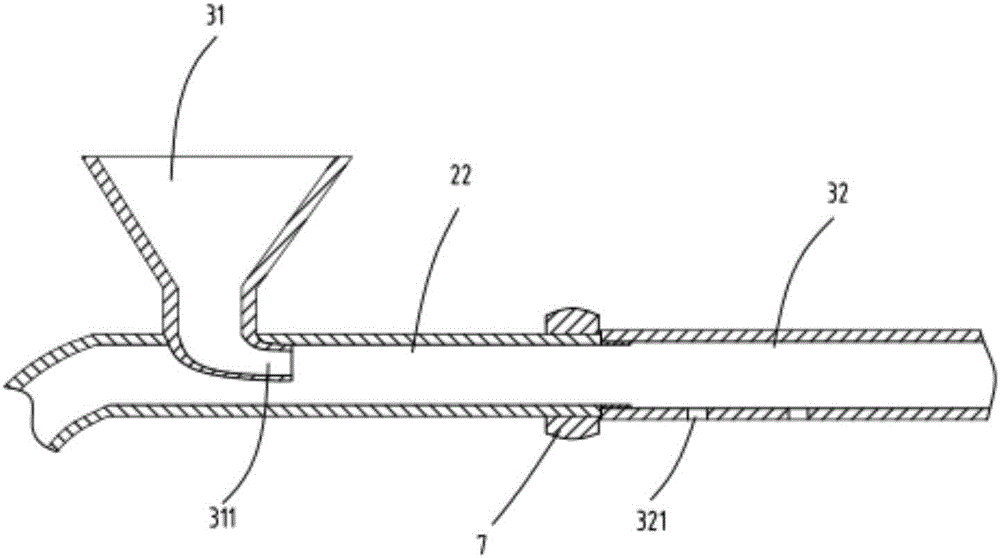

Continuous feeding and spraying device

InactiveCN106577610AImprove efficiencySimple device structureInsect catchers and killersEngineeringControl valves

The invention relates to a continuous feeding and spraying device, which comprises a box body, a blower device, a medicine powder supplying part, a stirring part, a water inlet pipe and a spraying pipe. The box body is divided into a mixing cavity and a spraying cavity through a division plate; a pipeline is connected between the mixing cavity and the spraying cavity; an electronic control valve a is arranged in the pipeline; the blower device comprises a blower, an air inlet pipe a communicating with the mixing cavity, and an air inlet pipe b communicating with the spraying cavity; an electronic control valve b is arranged on the air inlet pipe a; the medicine powder supplying part comprises a medicine powder cabin and a powder outlet pipe; a plurality of powder outlets a are formed in the lower position of the powder outlet pipe along a length direction of the powder outlet pipe; the stirring part comprises a rotary sleeve sleeving on the powder outlet pipe; a plurality of powder outlets b are formed in the rotary sleeve along a length direction of the rotary sleeve; and a plurality of stirring paddles are further arranged on the rotary sleeve. The continuous feeding and spraying device solves the problems that a pesticide mixing device is complex in structure, inconvenient, poor in dissolving and mixing effect when powder pesticide and water are mixed, uneven in concentration, low in efficiency, and incapable of realizing mixing while spraying at the same time.

Owner:长兴创智科技有限公司

Powder coating uniform premixing equipment

PendingCN112387147AAchieving Stirring and MixingAchieve cleanupRotary stirring mixersTransportation and packagingPowder mixtureStructural engineering

The invention discloses powder coating uniform premixing equipment which comprises a base and a servo motor, an electric sliding rod is fixedly connected to the top of the base, a fixing plate is fixedly connected to the end of the electric sliding rod, and an upper stirring box is fixedly connected to the outer side wall of the fixing plate.The outer side wall of the upper stirring box is fixedlyconnected with a hinge, the outer side wall of the hinge is fixedly connected with a lower stirring box. The magnetism of the lower stirring box is opposite to that of a cleaning block, so that duston the outer side wall of a stirring rod is cleaned by the cleaning block, and an air bag is extruded by a push plate through downward sliding of an electric sliding block, so that the air bag can generate pushing force on a pushing block, the pushing block can instantaneously push an impact ball to impact the top of the lower stirring box when breaking away from the constraint of a clamping block, personnel can conveniently collect a powder mixture in the lower stirring box and clean the inner side wall of the lower stirring box, the time is saved, and the working efficiency is improved.

Owner:赵大勇

Anti-sticking wall type mixer for processing grain and fruit comprehensive oatmeal and using method thereof

InactiveCN111437752AFirmly connectedEasy accessRotary stirring mixersTransportation and packagingProcess engineeringMechanical engineering

The invention relates to the technical field of oatmeal processing, and discloses an anti-sticking wall type mixer for processing grain and fruit comprehensive oatmeal and a using method thereof. Theanti-sticking wall type mixer comprises a machine shell. A transmission mechanism is arranged in the machine shell, the transmission mechanism is connected with a stirring mechanism, the lower portionof the transmission mechanism is connected with a discharging mechanism, the discharging mechanism is located below the transmission mechanism, the stirring mechanism is located in the machine shell,and the discharging mechanism is located below the machine shell; the end part of the stirring mechanism is connected with a scraping mechanism; the scraping mechanism is attached to the inner wall of the machine shell. Grain and fruit comprehensive oatmeal raw materials can conveniently enter the machine shell through the arranged feeding hopper, driving is achieved through the arranged transmission mechanism, the transmission mechanism drives the stirring mechanism to rotate circumferentially in the machine shell and the stirring mechanism can rotate, and thus the grain and fruit comprehensive oatmeal raw materials can be fully stirred.

Owner:ANHUI YANZHIFANG FOOD

Split aeration upflow sludge bed integrated sewage treatment equipment

PendingCN112408597AAchieve reflowReduce energy consumptionWater contaminantsWater aerationAeration rateSludge

The invention discloses split aeration upflow sludge bed integrated sewage treatment equipment, which comprises an aeration tank, a biochemical reaction tank and a water collecting tank. Aeration in the aeration tank is power for sewage circulation of the equipment, and the aeration quantity determines the reflux quantity, the types of microorganisms in the biochemical reaction tank and the sewagetreatment effect. The biochemical reaction tank is a main place for microbial growth and pollutant treatment, sludge in the tank is layered by controlling the ascending flow rate and the dissolved oxygen in water, the lower layer is mainly aerobic granular sludge with good precipitation performance, and the upper layer is sludge with poor precipitation performance and attached with a large amountof denitrifying bacteria; nitrogen and organic matters are removed through aerobic microbial oxidation and anaerobic bacteria denitrification, and water flow is circulated for multiple times, so thatthe treatment effect of equipment is improved. Aerobic granular sludge culture and sewage treatment by utilizing aerobic granular sludge are realized by adopting a split aeration mode, and various types of sludge and reactions in a biochemical region coexist by controlling the aeration rate, so that efficient removal of pollutants is realized.

Owner:BEIJING UNIV OF TECH +1

Medicine mixing device for preventing liquid medicine from remaining on bottle wall

InactiveCN112973492AAchieving Stirring and MixingAvoid stickingRotary stirring mixersTransportation and packagingGear wheelEngineering

The invention relates to the technical field of medicine mixing, in particular to a medicine mixing device for preventing liquid medicine from remaining on a bottle wall. A servo motor is adopted to drive a first-class gear to rotate, the first-class gear enables a second-class gear to drive a stirring shaft to rotate, so a stirring rod and a scraping plate do circumferential rotation in a medicine mixing cavity, the stirring rod is used for stirring and mixing medicine liquid, and the scraping plate is used for preventing the medicine liquid from adhering to the wall during subsequent medicine discharging; when a hand wheel drives a valve rod to rotate to open a liquid discharging valve during medicine discharging, a rope tying ring also synchronously drives a pull rope to pull down a moving plate, so a second friction wheel is in contact with and tightly presses a first friction wheel, the first friction wheel is in transmission fit with a transmission assembly, an inflation assembly is driven to work, and a medicine mixing cavity is continuously pressurized; therefore, liquid medicine can be discharged from the medicine discharging pipe quickly.

Owner:华智机械(烟台)有限公司 +1

Jetting type heating and mixing equipment of building dry powder paint

InactiveCN107051306ASimple structureEasy to addTransportation and packagingMixer accessoriesDry powderArchitectural engineering

The invention discloses a jetting type heating and mixing equipment of building dry powder paint. The equipment comprises a paint mixing can body, an external insulation can, an air distribution disc, a circulation air pipe and a rotation shaft, the outside of the paint mixing can body is provided with an external insulation can in a sleeving mode, the bottom side of the external insulation can is welded to support legs, the top of the external insulation can is welded to a support frame, the bottom side of the support frame is provided with a motor, the rotation shaft of the motor is welded to a driving gear, the side face of the driving gear is connected with a driven gear in a meshed mode, the driven gear is welded to the upper part of the rotation shaft, and the bottom of the rotation shaft penetrates into the paint mixing can body through the top walls of the external insulation can and the paint mixing can body; hot air enters a hot air input channel and is ejected out from several jetting holes in the air distribution disc, through the coordination of the rotation shaft, a paint scraping plate and the air distribution disc, the hot air flows from the bottom to the top, the building dry powder paint in a heating and stirring chamber is heated and dehumidified, drying treatment is achieved, the cyclic utilization of the hot air is achieved, the heating cost is lowered, and the sufficiency of heating and mixing of the building dry powder paint is also improved.

Owner:刘月明

SCR (Selective Catalytic Reduction) flue gas denitration and dust removal device

ActiveCN113117521AAdequate responseIncrease contact areaGas treatmentDispersed particle filtrationPtru catalystFlue gas

The invention discloses an SCR (Selective Catalytic Reduction) flue gas denitration and dust removal device. The SCR flue gas denitration and dust removal device comprises a tower body, a flue gas inlet is formed in the side wall of the tower body, and a flue gas outlet is formed in the bottom wall of the tower body. The device further comprises an annular frame, a plurality of first plate type catalysts detachably mounted on the annular frame, a rack detachably mounted on the inner bottom wall of the tower body, a plurality of second plate type catalysts filling the rack, a dust removal cover mounted on the side wall of the tower body, and a flue gas inlet pipe connected with the dust removal cover; and the annular frame is provided with an ammonia gas spraying piece and a turbulent flow piece used for mixing ammonia gas and flue gas, the top wall of the tower body is provided with an adjusting assembly used for driving the annular frame to ascend and descend, the dust removal cover is installed on the side wall, located at the flue gas inlet, of the tower body, and a dust removal assembly used for filtering the flue gas is arranged in the dust removal cover. According to the denitration and dust removal device, dust in flue gas is removed in advance, so that the probability that dust in the flue gas blocks pores of a catalyst is effectively reduced, the flue gas can be fully reacted, and the denitration efficiency is improved.

Owner:浙江千尧环境工程有限公司

Treatment technology for printing and dyeing wastewater

InactiveCN109824177AIngenious and reasonable structureEasy to useMultistage water/sewage treatmentWaste water treatment from textile industryTherapeutic effectDyeing wastewater

The invention provides a treatment technology for printing and dyeing wastewater. A device body, an air floating cavity which is located in the device body and provided with an upward opening and a stirring cavity located at the left side of the air floating cavity are involved, an aeration cavity communicated with the air floating cavity is fixedly formed in the bottom wall of the air floating cavity, an aeration device is arranged in the aeration cavity, and a first sliding cavity with a rightward opening is formed in the end wall of the left side of the air floating cavity. According to thetreatment technology, a wastewater treatment device is more reasonable and ingenious in overall structure and convenient to use, the wastewater and a coagulant thereof can be stirred and mixed and the wastewater can be fed at the same time, the operation is conveniently conducted, and the device is stable; automatic operation is achieved, the efficiency is higher, the effect is better, a filtering plate is adopted for the device and inclines so as to more cleanly and completely dump floating residues, the wastewater is subjected to secondary treatment, the treatment effect is better, and thetreatment technology has high application and popularization value.

Owner:杭州欣亿广告有限公司

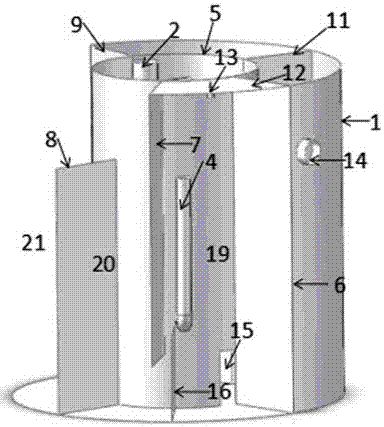

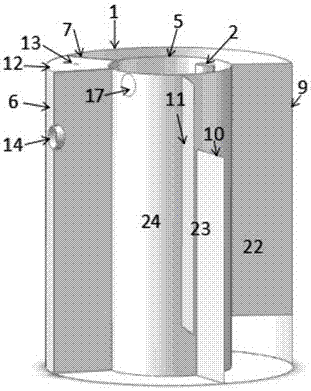

Pneumatic stirring mixing sludge automatic reflux domestic sewage purification treatment device

ActiveCN107973490AEliminate dead zoneAchieving Stirring and MixingWater treatment parameter controlBiological treatment apparatusRefluxSludge

The invention relates to a pneumatic stirring mixing sludge automatic reflux domestic sewage purification treatment device. The pneumatic stirring mixing sludge automatic reflux domestic sewage purification treatment device comprises an inner cylinder and an outer cylinder; the inner cylinder is a water inlet tank; the space between the inner cylinder and the outer cylinder is divided into an anaerobic tank, an anoxic tank, an aerobic tank, a precipitation tank, a dosing tank and a clean water tank sequentially by partition plates; to-be-treated sewage enters the water inlet tank from the topend; a water inlet in the lower end of the water inlet tank is communicated with the anaerobic tank and the water inlet is formed in one end far away from the anoxic tank; the anaerobic tank, the anoxic tank, the aerobic tank, the precipitation tank, the dosing tank and the clean water tank are communicated with each other sequentially in a fold line manner according to the sequence of bottom, topand bottom; the top of the clean water tank is connected with a water outlet pipeline; the top of the anaerobic tank is sealed and connected with an air-blowing port; and a U-shaped pipe is arrangedon the inner cylinder between the water inlet tank and the anaerobic tank. A gas pump blows air into the anaerobic tank to descend the water level of the anaerobic tank, and the U-shaped pipe releasesenergy to realize stirring and mixing of the anaerobic tank and the anoxic area as well as refluxing of anoxic sludge towards the anaerobic tank, so the denitrification effect of a small sewage purification tank is improved, and the purification and treatment speed of the sewage is increased; and the device is not provided with a power stirring facility, so the device is simple to operate and maintain and convenient to apply and popularize.

Owner:北京中立鸿环境技术有限公司

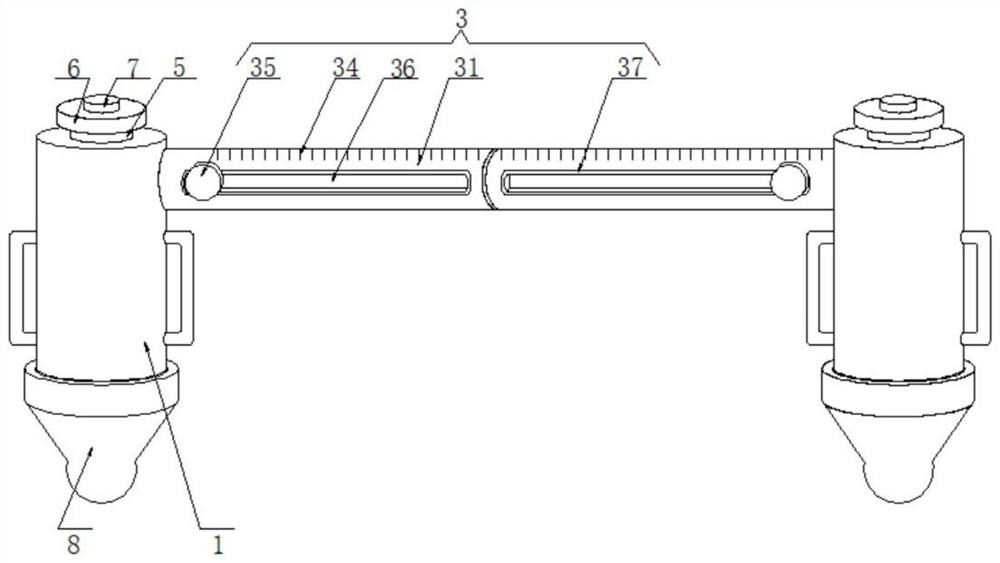

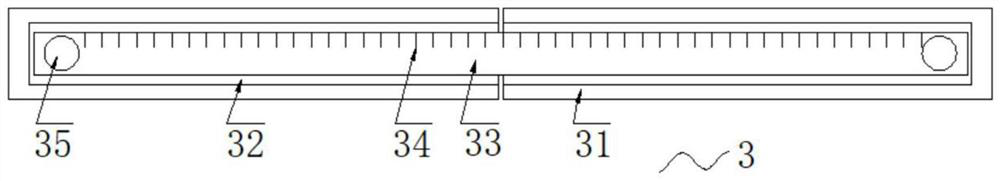

Road and bridge dotting method for municipal construction

InactiveCN111827127AProblems prone to breakageWell mixedBridge erection/assemblyRoads maintainenceArchitectural engineeringMarking out

The invention discloses a road and bridge dotting method for municipal construction. The method specifically comprises the steps of S1 rotationally taking down a sealing cover and a stirring rod froma feeding pipe, conveying ink paint for dotting and marking into a storage barrel, tightly covering the sealing cover, and uniformly mixing the ink paint by rotating the stirring rod; and S2 carryingout dotting by determining the distance between two marking points, and after the distance value is determined, adjusting the distance between two fixing cylinders through scales on a distance measuring cylinder and a distance measuring rod, and at the moment, enabling a sliding block to slide along a sliding groove. The invention relates to the technical field of municipal construction. According to the road and bridge dotting method for municipal construction, dotting and marking can be conducted through ink paint, the problems that marking is not clear and chalks are broken easily due to chalk marking are solved, meanwhile, distance measurement between two points is conducted before dotting and marking, the distance measurement accuracy is guaranteed, and a foundation is laid for normal proceeding of subsequent road and bridge construction work.

Owner:武汉木合石建筑科技有限公司

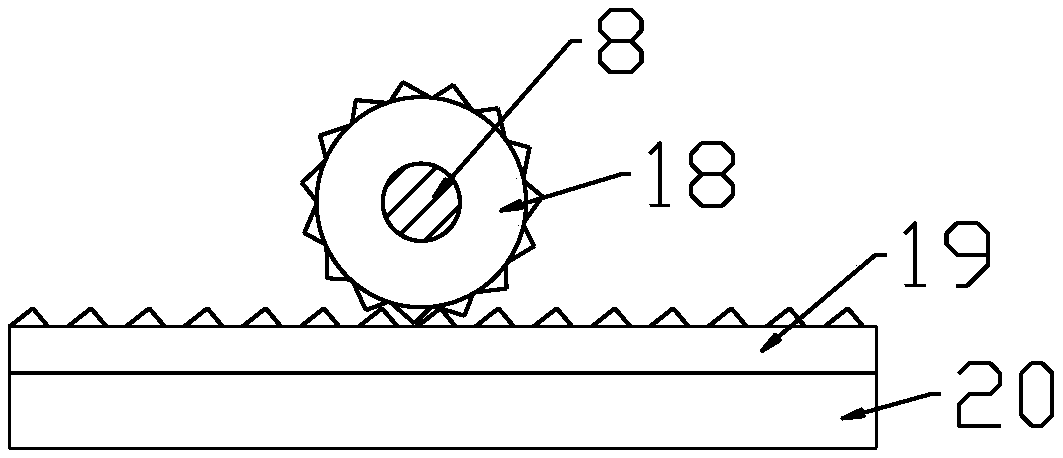

Sprinkling and fertilization device for municipal greening

InactiveCN109258051AAchieve sprayingAchieving Stirring and MixingPressurised distribution of liquid fertiliserCircular discPush pull

The invention discloses a sprinkling and fertilization device for municipal greening. The device comprises a rack, walking wheels, a rotating disc, a medicine liquid tank, spray heads and a push-pullrod, wherein the upper surfaces of the two ends of the rack are rotationally provided with rotating vertical columns respectively, and the top ends of the two rotating vertical columns are fixedly provided with the spray heads respectively; the outer rings of the lower portions of the rotating vertical columns are fixedly provided with first annular gear racks; the outer end surface of the rotating disc is fixedly provided with a rotating column, a swinging sleeve plate slidably sleeves the rotating column through a strip-shaped through hole formed in the swinging sleeve plate, one end of thepush-pull rod is fixedly connected with the swinging sleeve plate, the other end of the push-pull rod is fixedly connected with a first toothed plate, and the first toothed plate is meshed with the first annular gear racks. The sprinkling and fertilization device for municipal greening has the advantages that it is achieved that the spray heads spray a medicine liquid uniformly, the precipitationof the medicine liquid in the medicine liquid tank can be avoided, and not only are sprinkling and fertilization uniform, but also the pesticide effect of the fertilization is ensured.

Owner:吴丹花

Sampling device for food safety detection

PendingCN111473995AAchieving Stirring and MixingWithdrawing sample devicesPreparing sample for investigationStructural engineeringElectrical and Electronics engineering

The invention discloses a sampling device for food safety detection. The sampling device comprises a T-shaped base, a power cavity is formed in the T-shaped base; a power assembly for driving the liftable 7-shaped rotating shaft is arranged in the power cavity; a liquid storage pipe integrally formed with the 7-shaped rotating shaft is arranged at the tail end of the 7-shaped rotating shaft; a mounting head which is communicated with the liquid storage pipe and is driven by a driver is movably clamped at the bottom of the liquid storage pipe; a porous sucker is fixedly mounted at the bottom ofthe mounting head; a liquid suction pipe is in threaded connection with the center of the bottom of the porous suction cup, an arc-shaped cutter is installed on one side of the bottom of the porous suction cup, an air suction assembly communicated with the liquid storage pipe is arranged on one side of the liquid storage pipe, and a sample containing assembly is arranged on the side, located on the power cavity, of the top of the T-shaped base. Sampling operation can be carried out according to different food states.

Owner:上海莎么信息技术有限公司

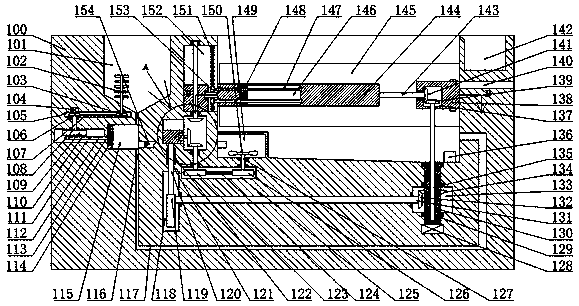

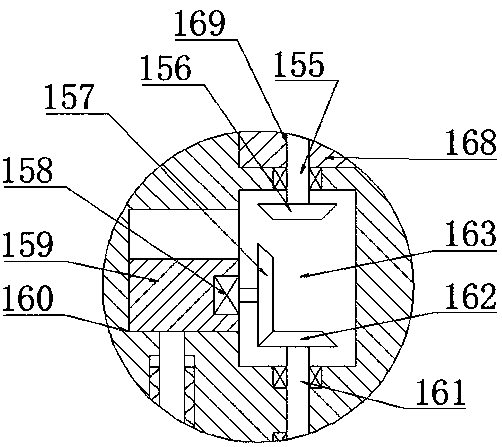

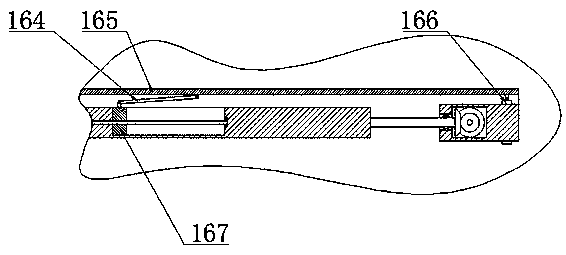

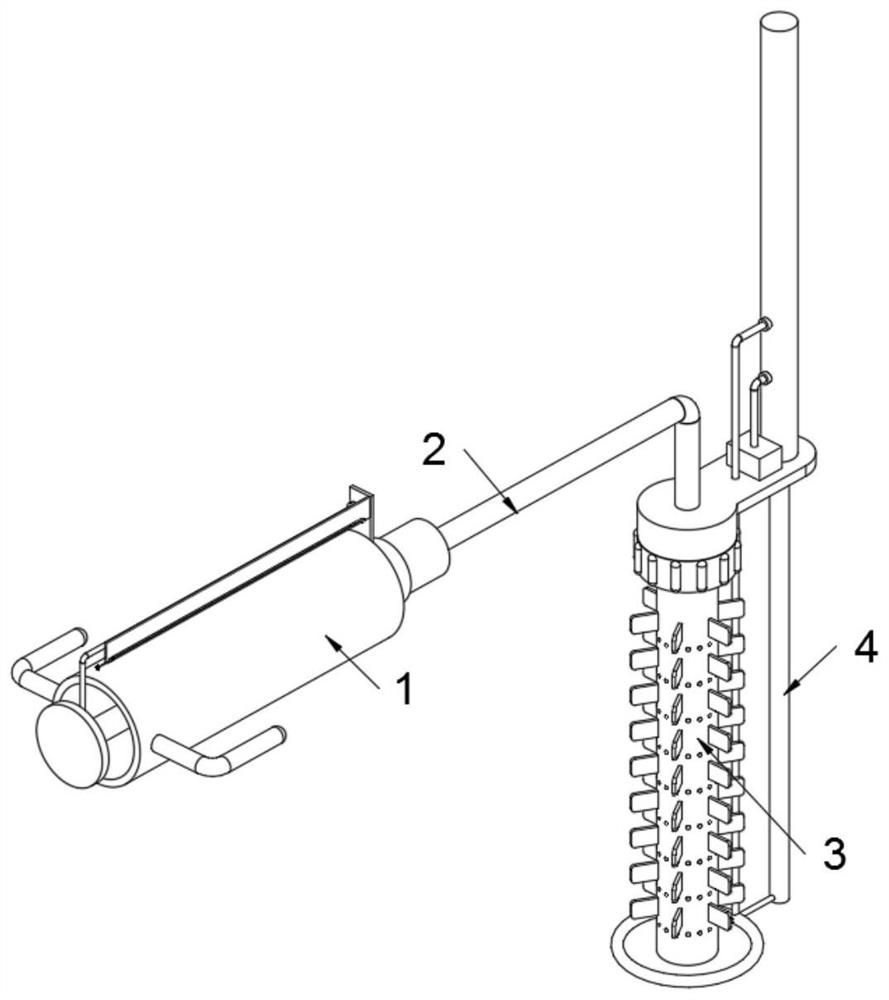

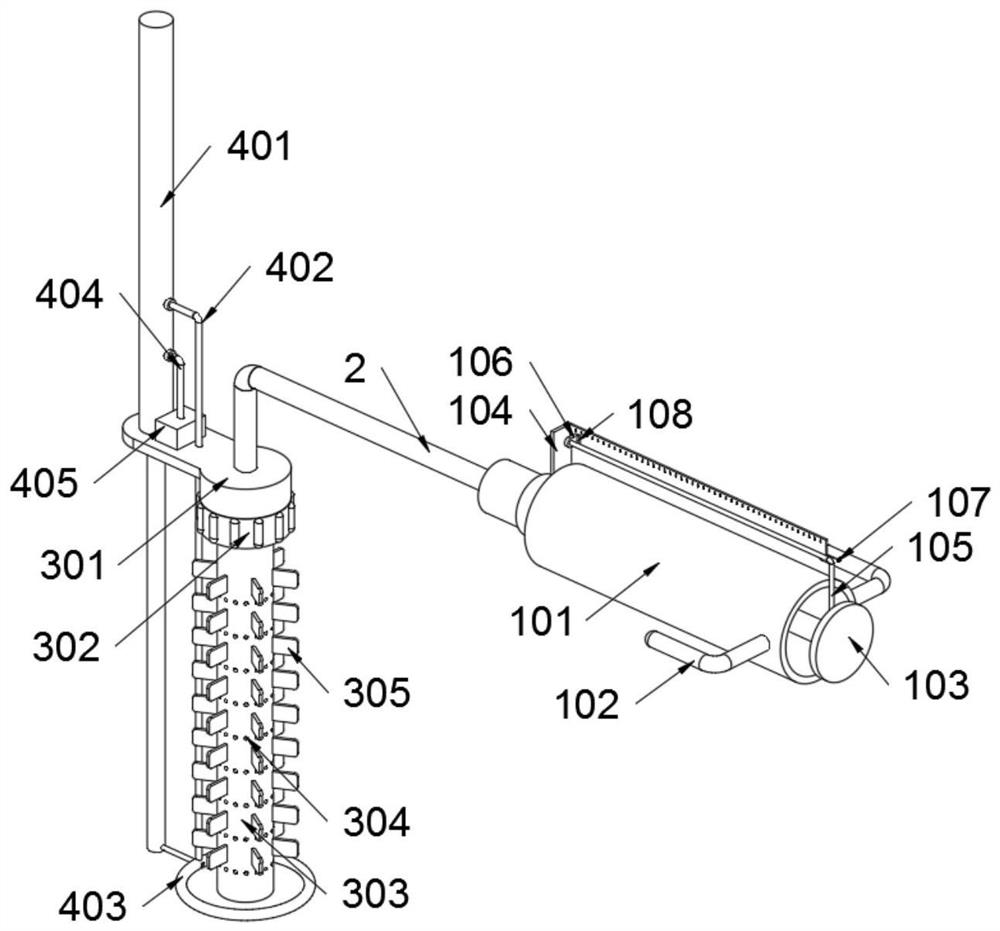

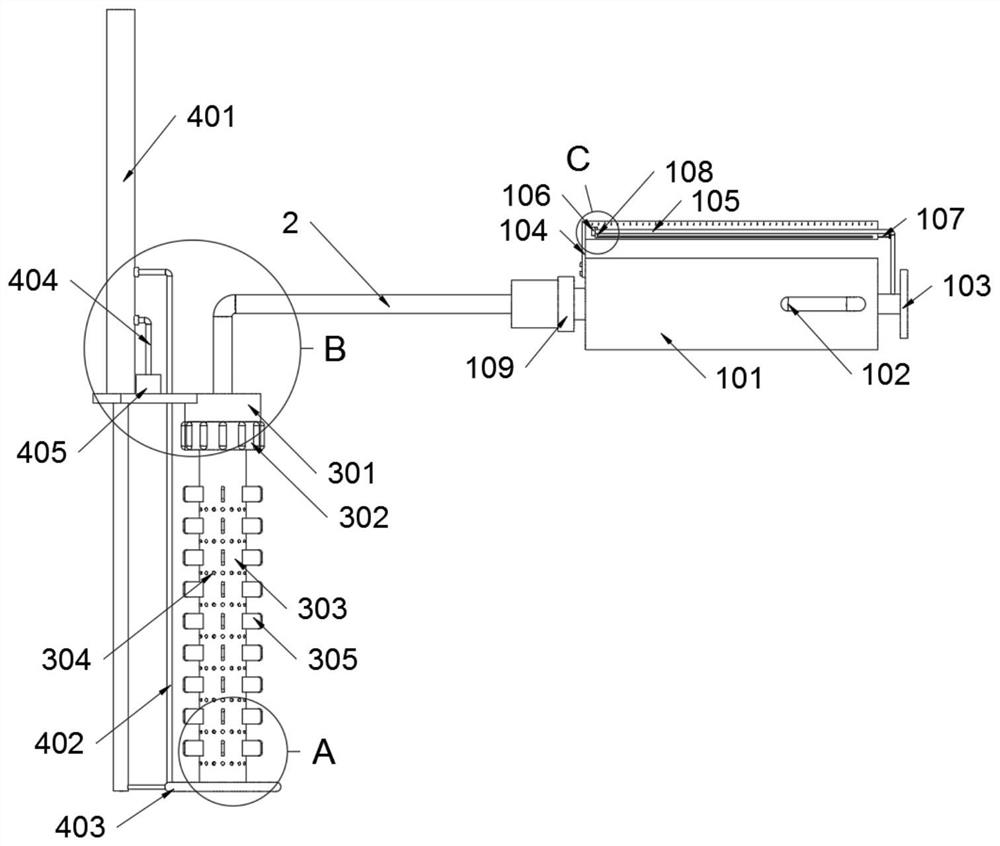

Liquid tungsten hexafluoride sampling device

ActiveCN113125235APrevent leakageImprove sampling accuracyWithdrawing sample devicesPreparing sample for investigationPhysical chemistryEngineering

The invention discloses a liquid tungsten hexafluoride sampling device and relates to the technical field of chemical engineering sampling. The sampling device comprises a sampling pipe assembly, a connecting pipe, a sampling head assembly and a purification assembly, wherein the sampling pipe assembly and the sampling head assembly are connected through a connecting pipe, and a purification assembly is mounted on the sampling head assembly; the sampling pipe assembly is used for driving the sampling head assembly to perform premixing and diffusion type liquid absorption on liquid tungsten hexafluoride, and the purification assembly is used for purifying gaseous tungsten hexafluoride diffused by the liquid tungsten hexafluoride; according to the sampling device, pre-mixing and diffusion type liquid absorption of samples can be realized, so sampling precision is improved; meanwhile, harmful gas in the to-be-sampled liquid can be synchronously absorbed, so the harmful gas is prevented from leaking, and safe sampling is facilitated.

Owner:PERIC SPECIAL GASES CO LTD

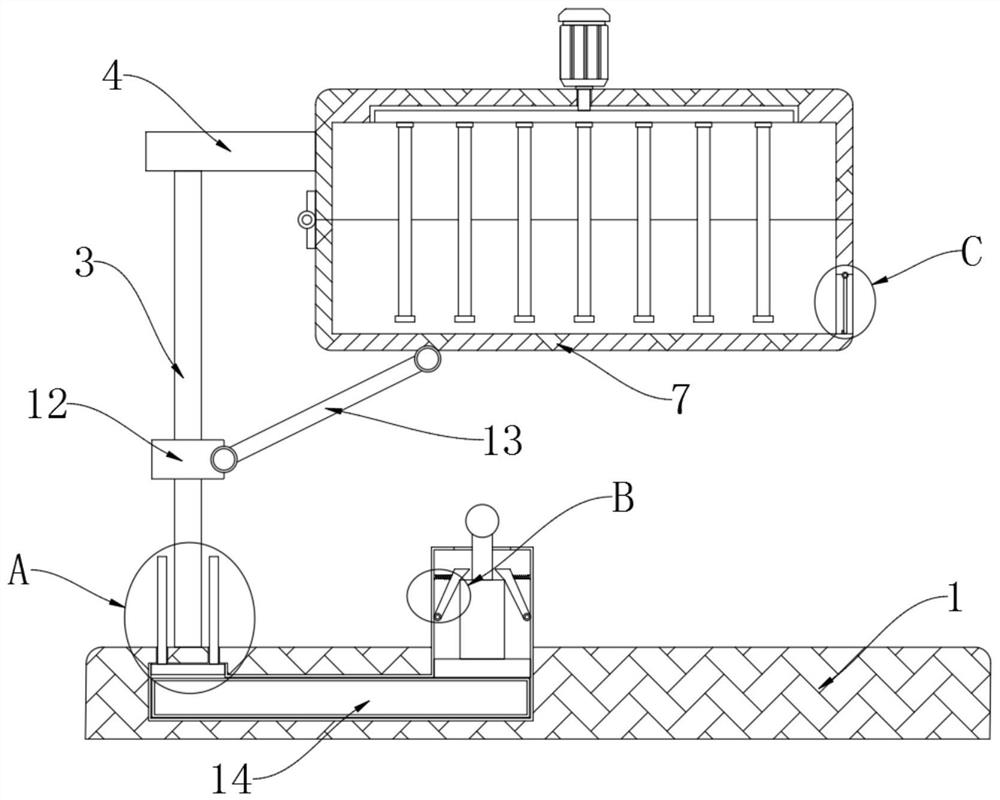

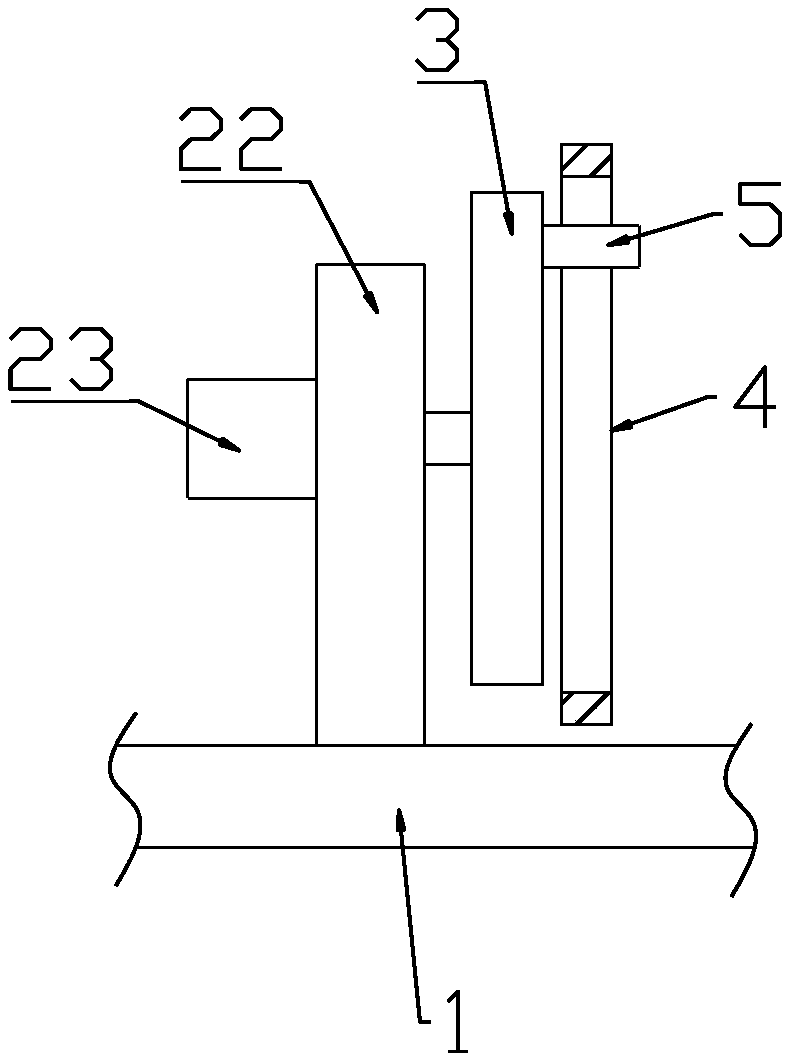

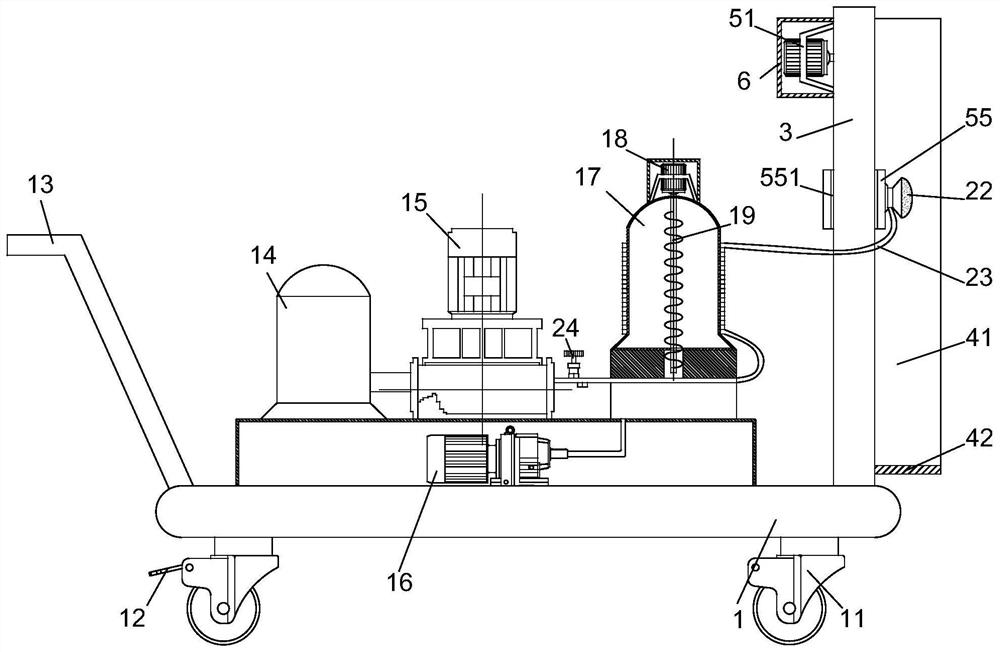

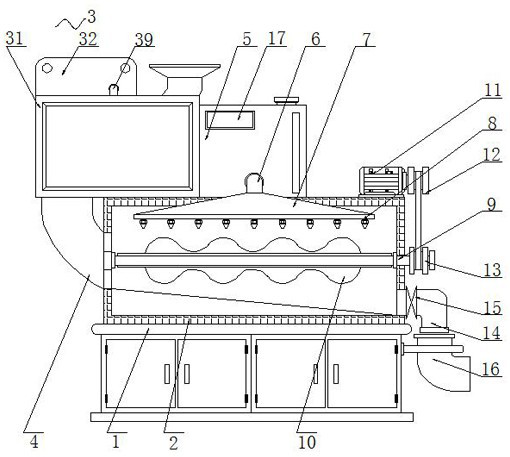

Automatic spraying machine

ActiveCN113385339ARealize up and down moving sprayingTime-consuming and laborious to solveLiquid spraying apparatusAir pumpElectric machinery

The invention relates to the technical field of spraying machines, in particular to an automatic spraying machine. The automatic spraying machine comprises a bottom plate and a stirring assembly arranged above the bottom plate, the upper end of the bottom plate is provided with a vertical plate, the vertical plate is provided with an automatic assembly, the automatic assembly is connected with a spray head, a motor operates to drive a sliding block in threaded connection with a screw rod, and the motor moves up and down in a rectangular through hole, so that the spray head can move up and down for spraying, and the problem that a handheld spray gun wastes time and labor is solved; a stirring motor, a water pump and an air pump operate, coating powder, water and air are supplied into a water hose, water and the coating powder can be effectively stirred and mixed through drawing pins, and the problem of coating manufacturing by a user is solved; and the arranged side baffles and the bottom collecting box can effectively block the coating sprayed out of the spray heads towards the two sides, the coating is collected through the bottom collecting box, recycling is convenient, stirring, mixing and uniform spraying of the coating are achieved, the automation degree is high, and the use requirement is met.

Owner:东莞市凌进精密制造有限公司

Desizing, scouring and bleaching one-bath process system and method for pure cotton woven fabric short-process pretreatment

PendingCN113914045AMeet clean upImprove efficiencyLiquid/gas/vapor treatment machines driving mechanismsSucessive textile treatmentsProcess engineeringWoven fabric

The invention discloses a desizing, scouring and bleaching one-bath process system and method for pure cotton woven fabric short-process pretreatment, and relates to the technical field of cloth production. The desizing, scouring and bleaching one-bath process system comprises a bottom plate, a desizing bin, a scouring bin and a bleaching bin are fixedly connected with the top of the bottom plate in sequence from left to right, and a reciprocating stirring mechanism is arranged in the desizing bin; and the reciprocating stirring mechanism comprises a rotating rod rotationally connected between the front side and the rear side of the inner wall of the desizing bin, and the rear end of the rotating rod penetrates through the desizing bin and extends to the rear side of the desizing bin. According to the desizing, scouring and bleaching one-bath process system and method for pure cotton woven fabric short-process pretreatment, by arranging the reciprocating stirring mechanism, desizing liquid is stirred and mixed by a stirring paddle, full desizing of the desizing liquid on the surface of the fabric is facilitated, through the front-back-side reciprocating motion of a stirring wheel, the stirring wheel drives the stirring paddle and bristles to movably clean the surface of the cloth, cleaning of the surfaces of the cloth with different widths is met, and the desizing efficiency of the cloth is greatly improved.

Owner:佛山市顺德金纺集团有限公司

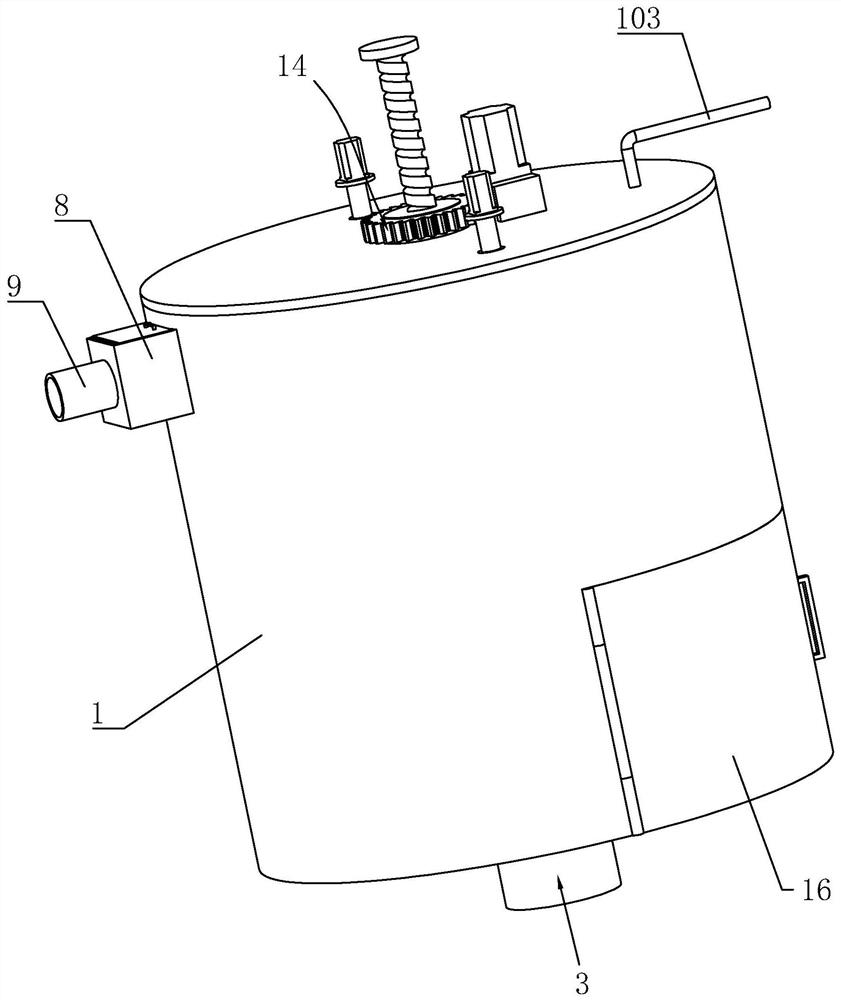

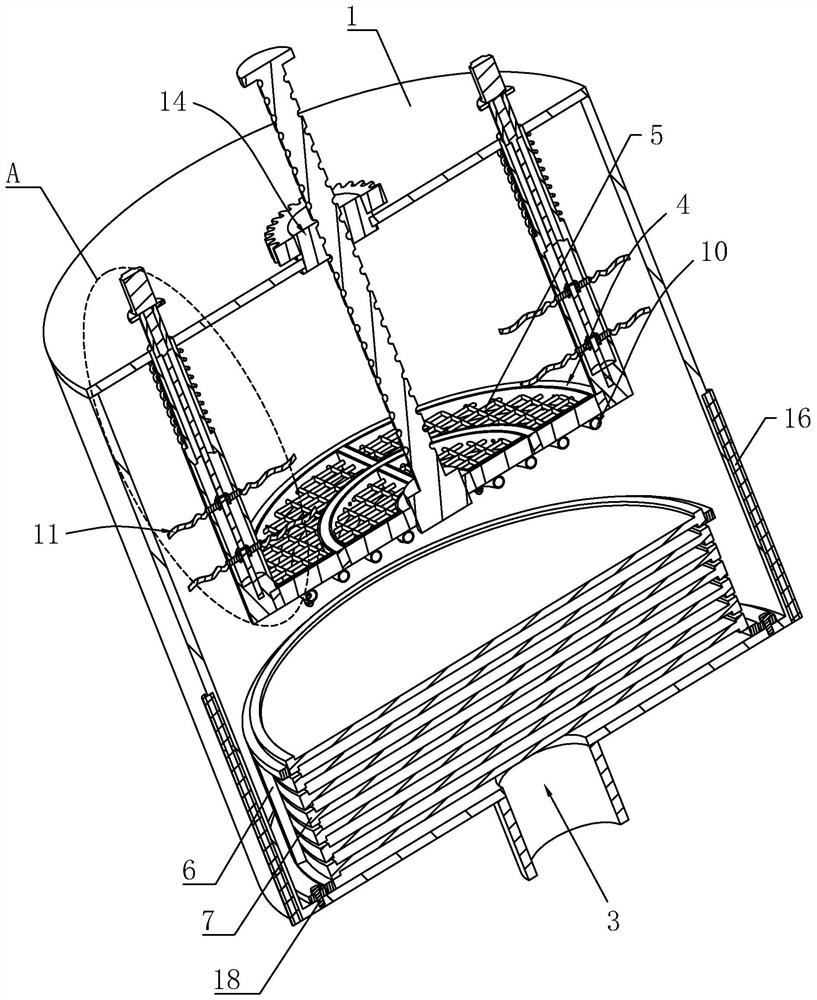

Agricultural intensive irrigation equipment with multi-angle adjusting function

ActiveCN113383693AAchieve angle adjustmentAchieving Stirring and MixingWatering devicesSpraying apparatusWater storageAgricultural science

The invention discloses agricultural intensive irrigation equipment with a multi-angle adjusting function. The equipment comprises a water storage cylinder, a central fixing column is fixedly arranged in the middle of the upper end of the water storage cylinder, and a rotating shaft convex column is fixedly arranged in the middle of the top end of the central fixing column. According to the agricultural intensive irrigation equipment, an eccentric fixed shaft rotates by taking an output shaft of a reciprocating motor as the axis, and accordingly a reciprocating rotating ring is driven to rotate back and forth by taking the rotating shaft convex column as an axis; an external thread is arranged and meshed with a worm gear, so that the angles of the worm gear and a water outlet pipe are adjusted, and the effect that sprayed water can uniformly cover surrounding crops is achieved; alternating current is sequentially introduced through an arranged coil winding, magnetic fields with sequentially changed directions are generated in the water storage cylinder, and a magnet disc generates sequentially changed directions, so that a stirring rotating shaft, a rotating shaft stirring rod and the magnet disc rotate, and water and pesticide in the water storage cylinder are stirred and mixed through the rotating shaft stirring rod; the technical problems proposed in the technical background are solved.

Owner:上海其图科技发展有限公司

Disinfectant preparation machine with pre-blending function and preparation method

InactiveCN112844181AAvoid affecting the effect of subsequent preparationsRealize deliveryRotary stirring mixersTransportation and packagingElectric machineProcess engineering

The invention discloses a disinfectant preparation machine with a pre-blending function and a preparation method. The disinfectant preparation machine comprises a bottom plate, a first motor, a second motor, a third motor, a mixing box, a crushing box, an electric push rod, a heating groove and supporting legs, the first motor rotates to drive the crushing blades on the crushing rotating shaft to rotate so as to crush and pre-mix the solid or powdery raw materials, and meanwhile, the situation that the subsequent preparation effect is affected due to the fact that solid particles are too large or the powdery raw materials are caked is avoided; and an electric push rod is used for driving a push rod to extend, so that a push plate is pushed to move, raw materials falling from a sieve plate are pushed to enter a barrel, a second motor rotates to drive spiral conveying blades on a conveying rotating shaft to rotate, the raw materials are conveyed, the raw materials further enter a mixing box through a discharging pipe, manual feeding is not needed, a large amount of manpower is saved, and the feeding efficiency is high.

Owner:柯林瑟弗(苏州)智能科技有限公司

Electrocatalytic oxidation treatment method for foam discharge gas recovery wastewater

PendingCN114044605AImprove the mixing effectImprove decomposition effectFatty/oily/floating substances removal devicesSpecific water treatment objectivesGravity separationFoam drainage

The invention relates to the technical field of foam drainage wastewater treatment, and discloses an electrocatalytic oxidation treatment method for foam drainage gas production wastewater, which comprises the following steps: s1, collecting the foam drainage gas production wastewater into a collecting tank, and then carrying out precipitation treatment; s2, a homogeneous receiving tank: introducing the settled sewage into the homogeneous receiving tank, recovering free oil obtained at the upper part through gravity separation, storing the free oil in a dirty oil recovery tank, and collecting other bubble drainage water; s3, coagulating sedimentation: introducing the treated foam drainage water into a coagulation device for coagulation treatment; and s4, treatment with an electrolytic oxidation pond. According to the method, high-salt-tolerance microorganisms are adopted to carry out biochemical treatment on the soaking drainage water. The treatment process is simple, the energy consumption is low, and various substances in the bubble drainage water can be thoroughly treated. In addition, through cooperative use of a poke rod and a spiral sheet, stirring and mixing of mixed wastewater are realized, and the mixing effect of the device is improved.

Owner:PUYANG TIANDIREN ENVIRONMENTAL PROTECTION TECH CO LTD

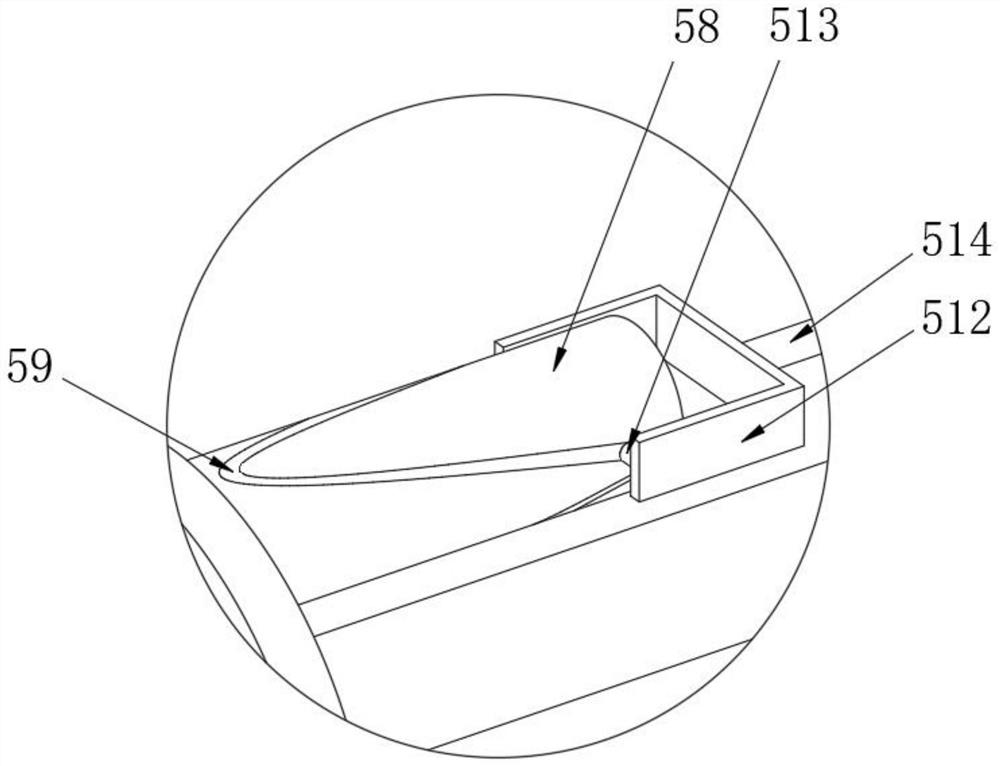

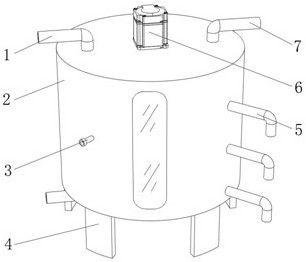

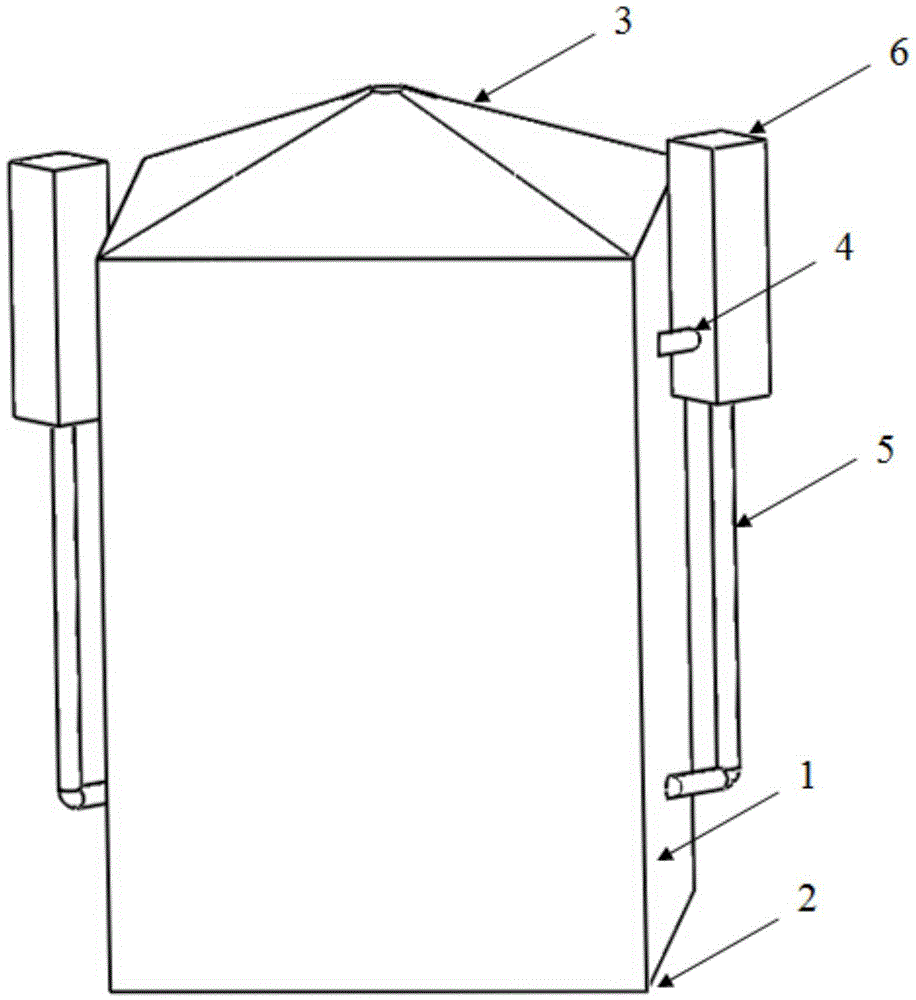

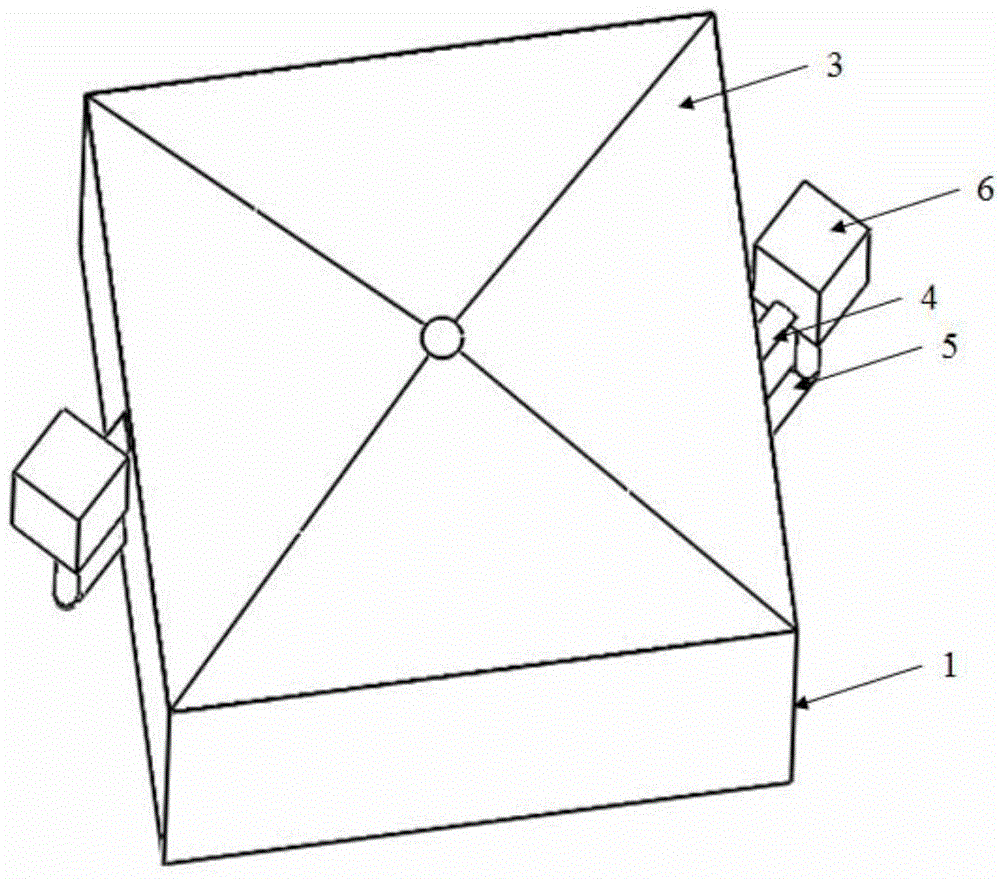

Side-arranged biogas slurry external-circulation rotational-flow stirring biogas pool

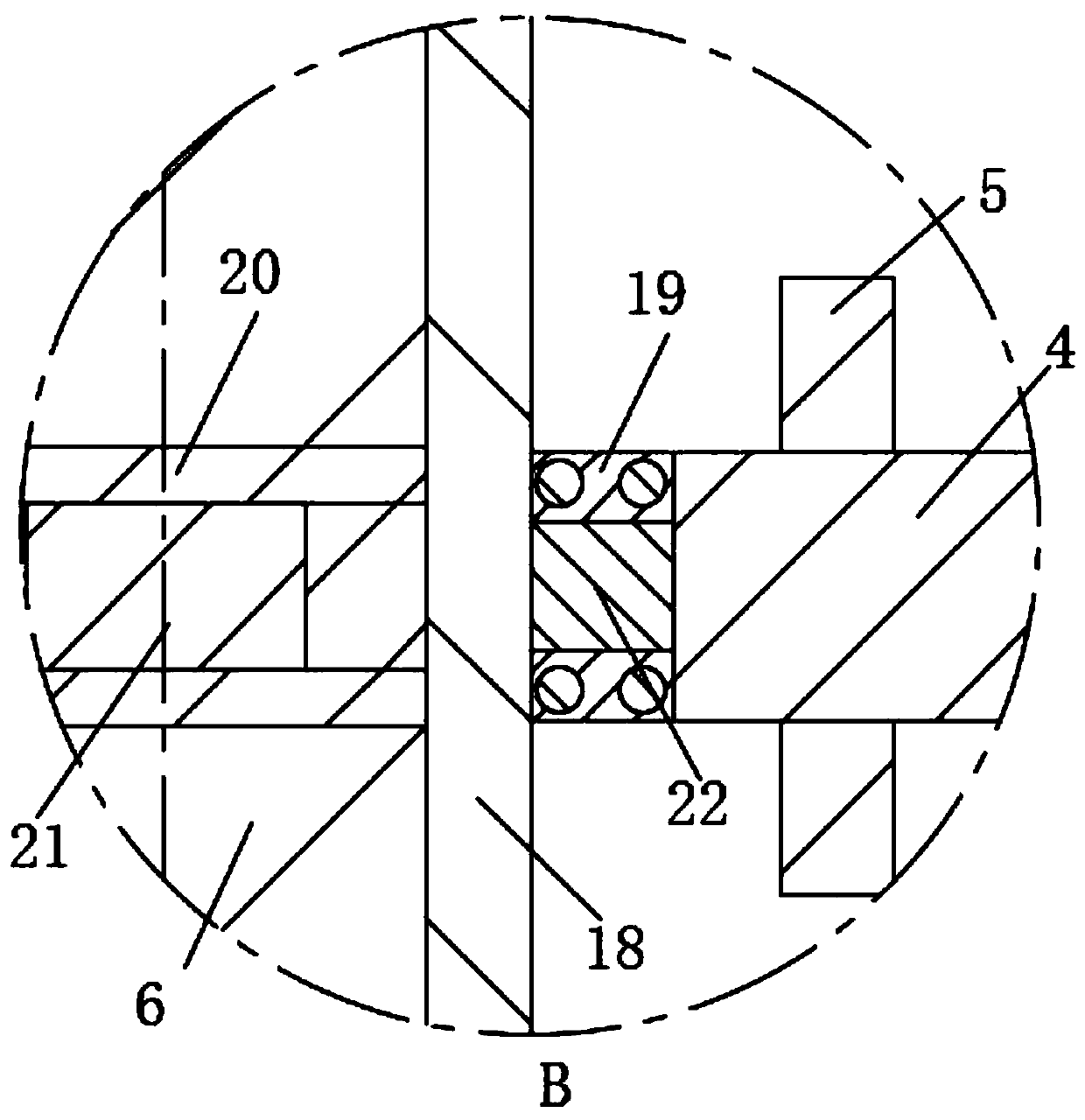

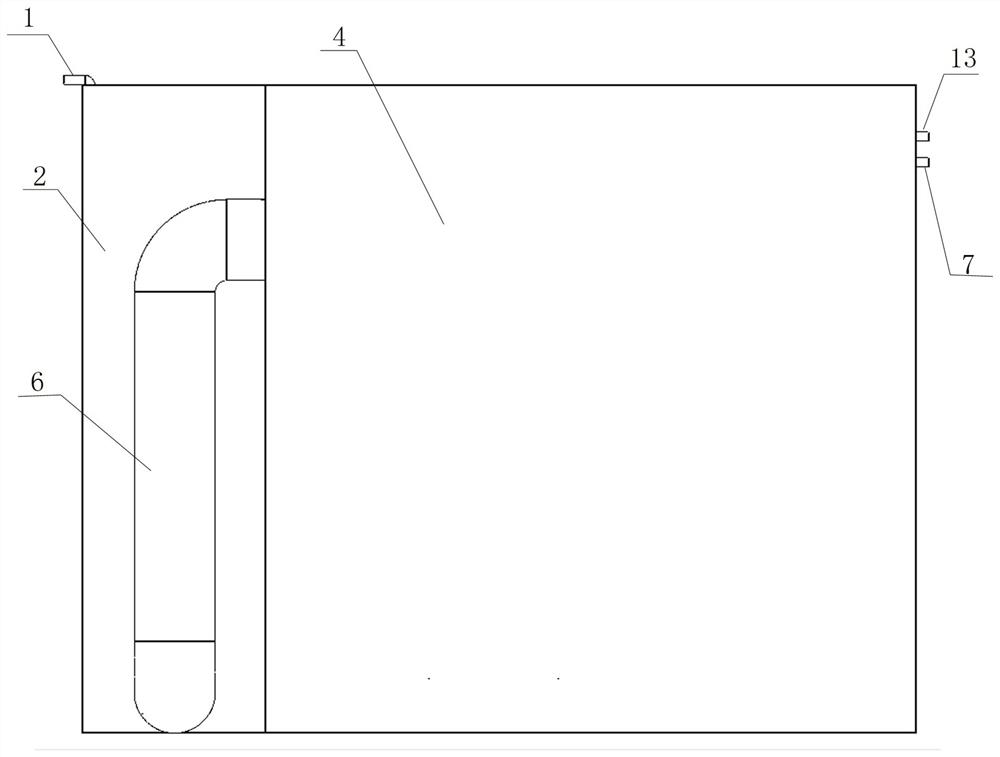

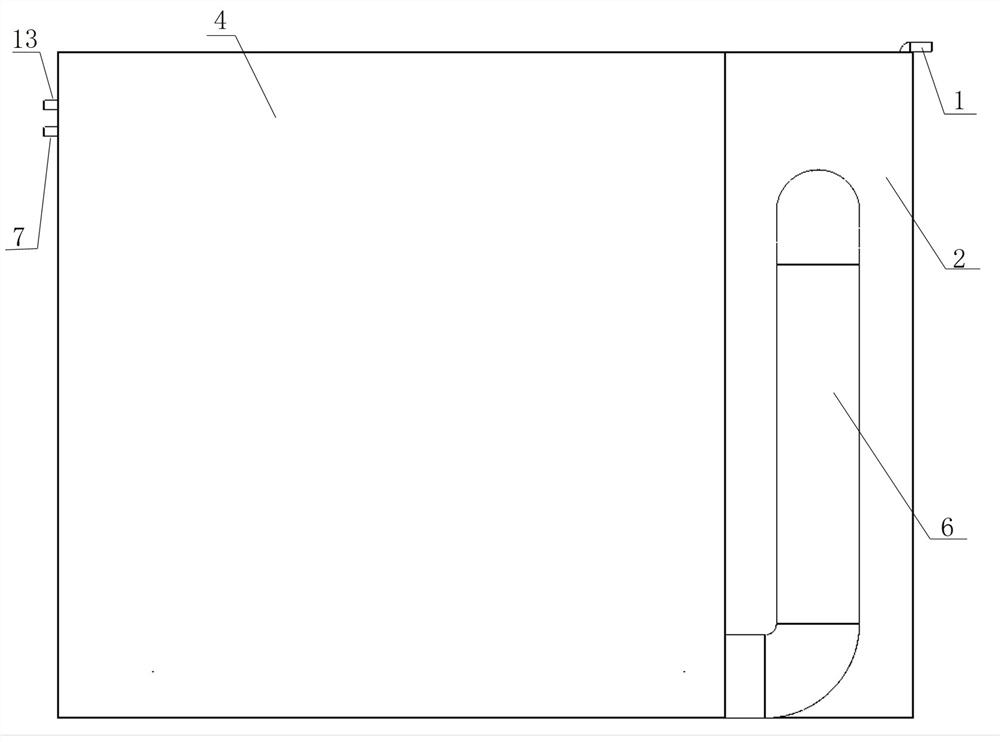

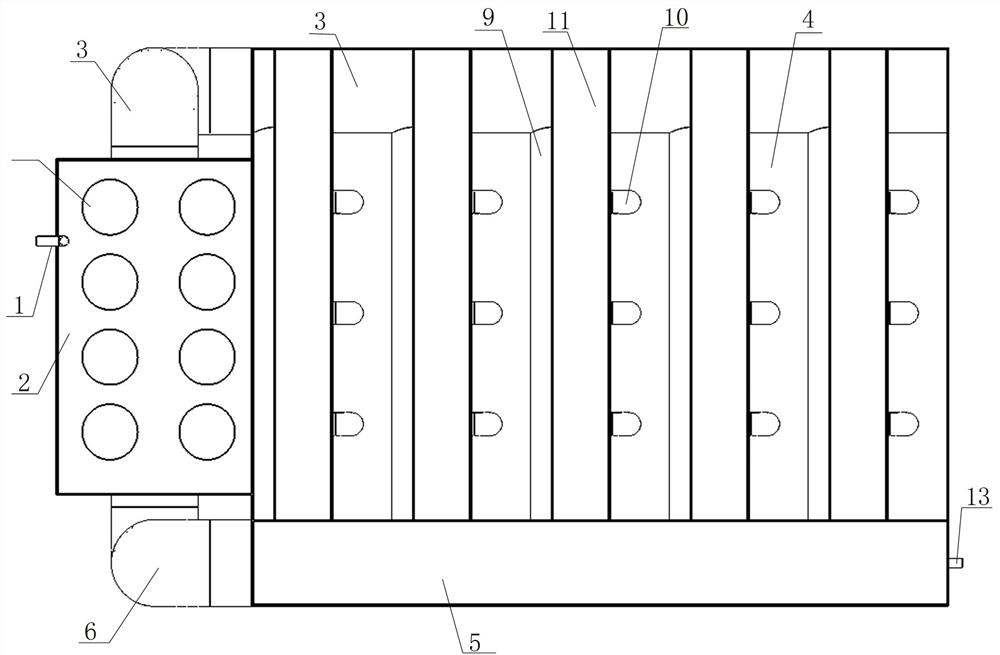

InactiveCN104531507AEffectively breakEfficient releaseBioreactor/fermenter combinationsBiological substance pretreatmentsMarine engineeringSlurry

The invention discloses a side-arranged biogas slurry external-circulation rotational-flow stirring biogas pool including a pool wall (1), a pool bottom (2), a top gas collecting hood (3) and two groups of external-circulation pipelines; the pool bottom (2) and the top gas collecting hood (3) are connected through the pool wall (1); two groups of external-circulation pipelines are respectively located at two opposite side faces of the pool wall (1), and each group of external-circulation pipeline comprises a horizontal pipeline (4) and an elbow pipe (5), each horizontal pipeline (4) is connected with the side face of the pool wall (1) and is located at the upper end of the side face of the pool wall (1), and each elbow pipe (5) is located at the lower end of the side face of the pool wall (1) and is connected with the side face of the pool wall (1); a circulation pump is connected with each horizontal pipeline (4) and each elbow pipe (5); a circulation pump protecting hood (6) is located outside each circulation pump. The biogas pool has the advantages of being simple in structure of the pool body, convenient to install, convenient to transport, suitable for rural areas, and easy to popularize.

Owner:TONGJI UNIV

Novel sand mold casting equipment and casting method thereof

PendingCN113305271AAchieving Stirring and MixingEasy to fill sandMoulding toolsMould handling/dressing devicesElectric machineryProcess engineering

The invention belongs to the technical field of sand mold casting devices, especially relates to novel sand mold casting equipment and a casting method thereof, and aims at solving the problems that in the prior art, a large amount of manual labor and production time cost are consumed, the working efficiency is low, the casting mold precision is poor, moroever, a corresponding proportioning function is lacked, so that sand filling is troublesome, and meanwhile, excessive molding sand overflowing during sand filling is troublesome to recycle, so that the utilization rate of waste sand is reduced. The following scheme is disclosed: the novel sand mold casting equipment comprises a casting sand box, wherein supporting legs are arranged at the four corners of the outer wall of the bottom of the casting sand box, a sand discharging pipe is arranged at the bottom of the casting sand box, and a sand discharging valve is installed on the sand discharging pipe. According to the invention, by starting a stirring motor, the function of stirring a proportioning box can be realized, so that proportioning is facilitated, and during sand filling, a sieve screen can be driven to move back and forth at the same time, and a vibration effect is realized, so that refining for molding sand is facilitated, a high automation degree is achieved, the manual operation intensity is reduced, and the casting precision is improved.

Owner:毛飞飞

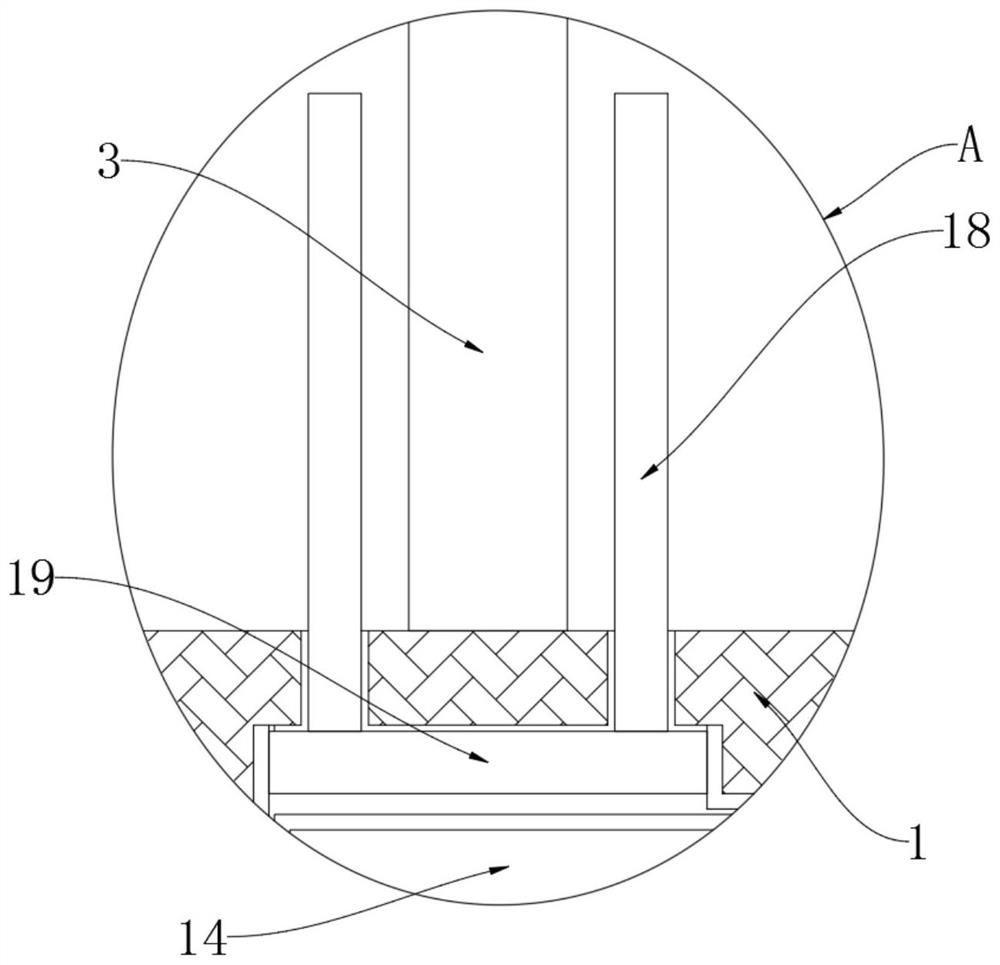

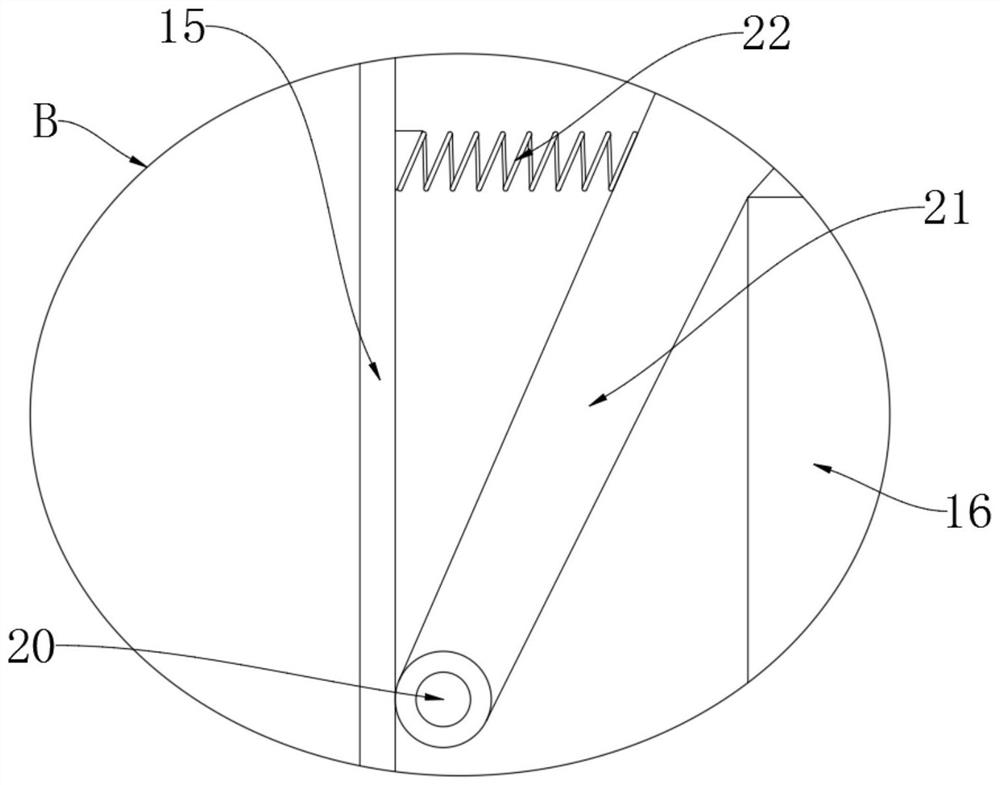

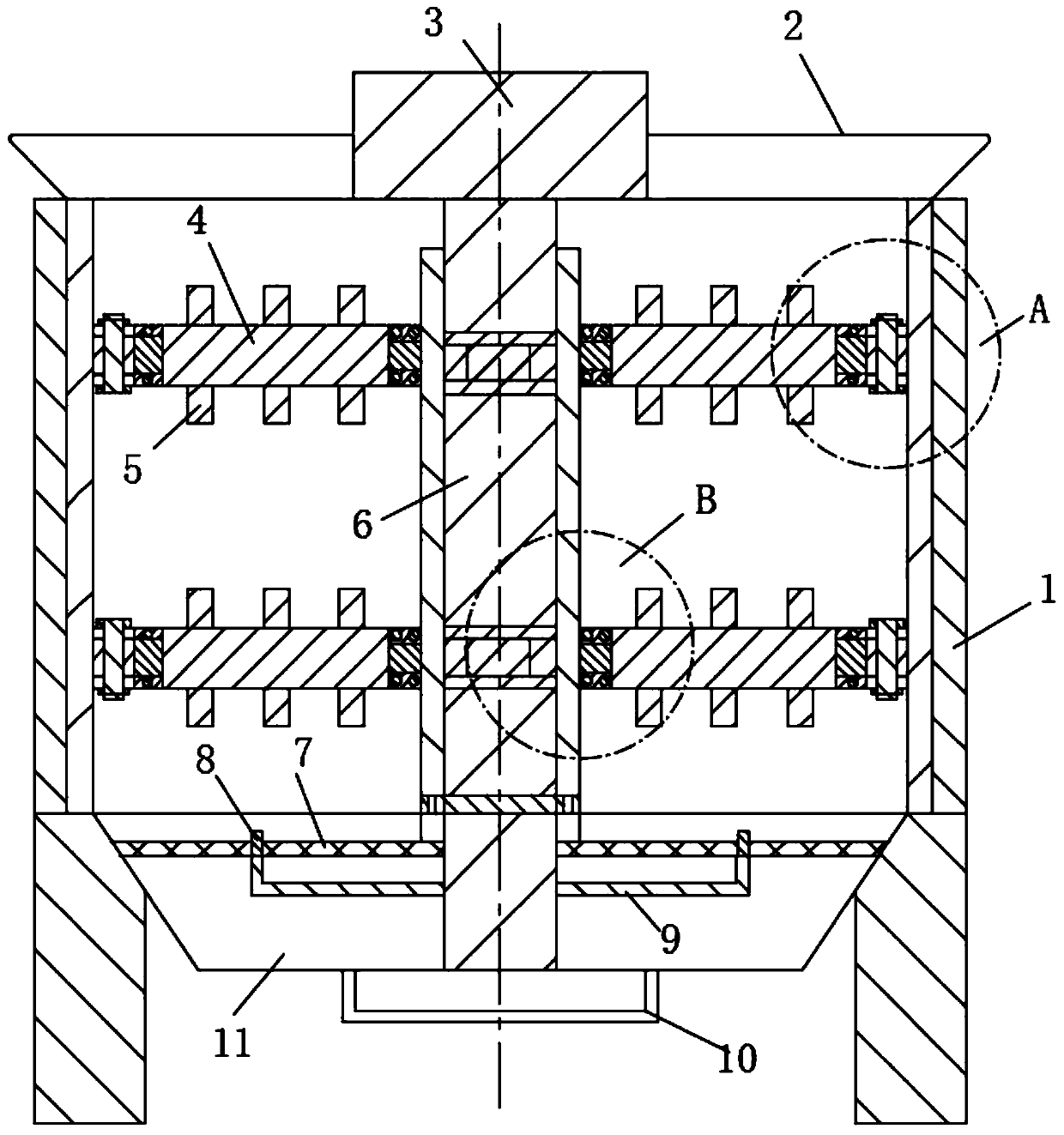

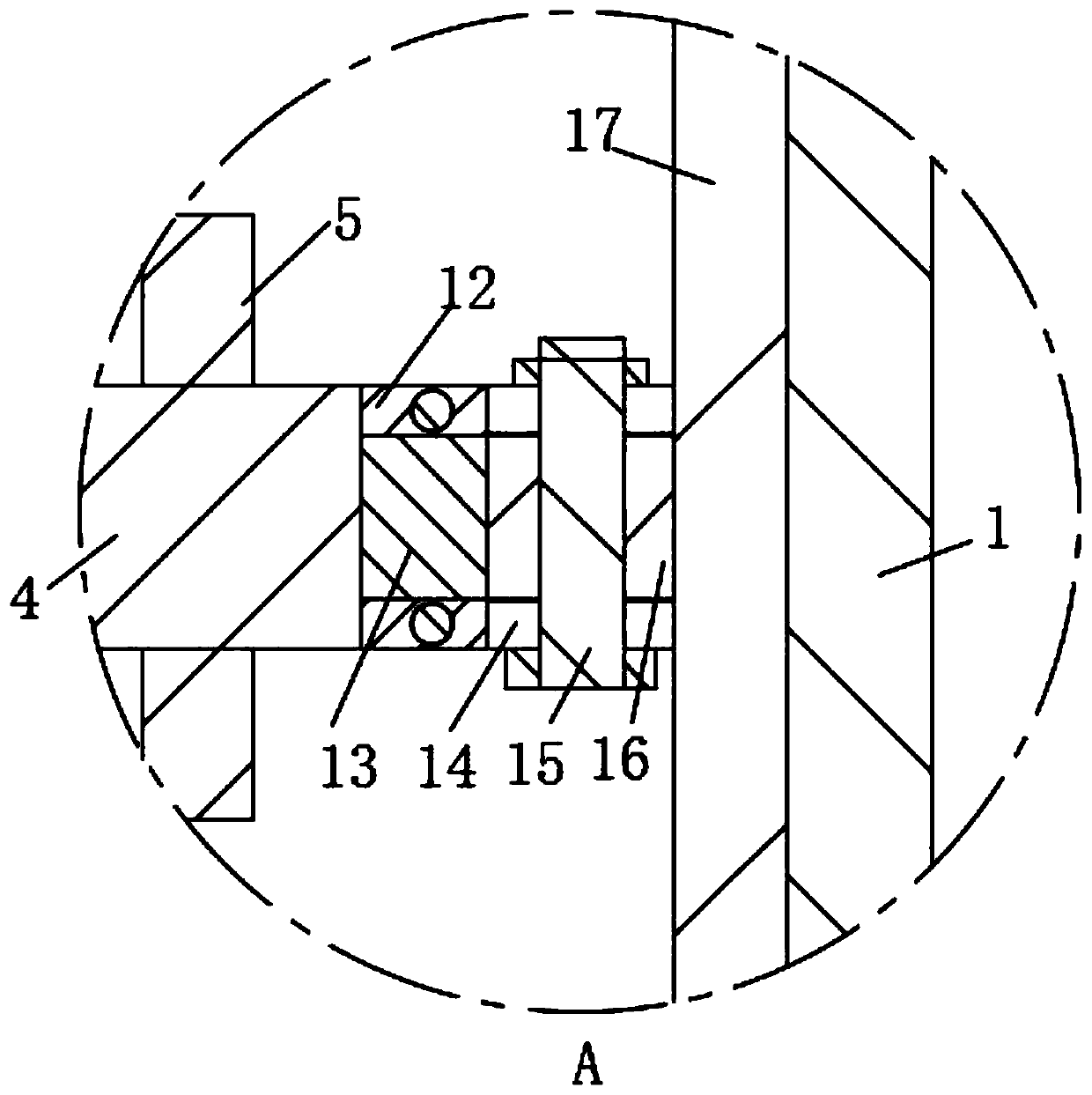

Matrix mixing device for breeding earthworms

PendingCN114797644AStir wellImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionEngineering

The invention discloses a matrix mixing device for breeding earthworms, relates to the technical field of mixing devices, and aims to provide a matrix mixing device for breeding earthworms, which can fully stir materials between upper and lower stirring blades and improve the mixing effect. The stirring mechanism is used for stirring materials so that the materials can be fully mixed, the stirring mechanism comprises a rotating part and a stirring part, the rotating part is arranged below the stirring part, and the transmission mechanism is used for driving the stirring mechanism to rotate at a high speed and driving the stirring part or the rotating part to do reciprocating motion in the vertical direction. The device has the technical effects that the limiting stirring mechanism comprises the rotating component and the stirring component, the long hole is formed in the rotating rod of the rotating component, and the stirring blade of the stirring component can penetrate through the long hole to extend outwards, so that when one component rotates, the other component can be lifted, and the stirring efficiency is improved. And materials between the upper stirring blade and the lower stirring blade can be fully stirred.

Owner:JIANGSU VOCATION & TECHNICAL COLLEGE OF FINANCE & ECONOMICS

Efficient and environmentally-friendly agricultural seed processing equipment and processing technology

PendingCN112449788AEfficient and environmentally friendly processabilityEfficient and environmentally friendly processDirt cleaningSeed coating/dressingAgricultural scienceAgricultural engineering

The invention discloses efficient and environmentally-friendly agricultural seed processing equipment and processing technology. The processing equipment comprises a bottom box and a stirring box which is fixedly connected to the top of the bottom box, an impurity clearing mechanism is arranged on one side of the top of the stirring box, the impurity clearing mechanism comprises a clearing box, the bottom of the clearing box is fixedly connected to one side of the top of the stirring box, a dust collector is fixedly connected to one side of the top of the clearing box, a fixing frame is fixedly connected to one side of the bottom of the inner wall of the clearing box, in addition, fixing grooves are formed in the two sides of the top of the fixing frame, and electric push rods are fixedlyconnected to the bottoms of the inner walls of the fixing grooves. The invention relates to the technical field of agricultural seed processing equipment. According to the efficient and environmentally-friendly agricultural seed processing equipment and processing technology, impurities such as soil and sweeps remaining in seeds can be filtered and removed before seed coating, the problems that aseed coating agent is wrapped around the seeds carrying the impurities, consequently the seed coating agent is wasted, and wrapping is uneven can be solved, and therefore the seed coating quality is improved.

Owner:李琴

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com