Pneumatic stirring mixing sludge automatic reflux domestic sewage purification treatment device

A technology of mixing sludge and automatic return flow, which is applied in water/sludge/sewage treatment, biological treatment equipment, biological water/sewage treatment, etc., to achieve the effects of easy promotion, simple operation and maintenance, and simplified structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

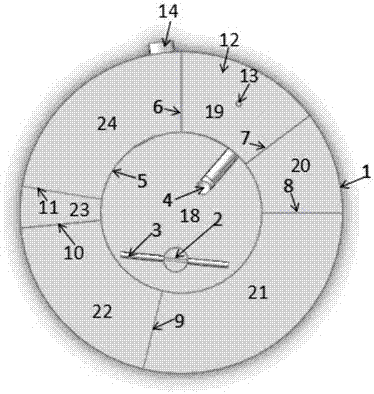

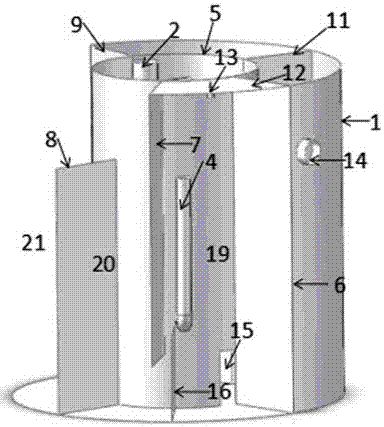

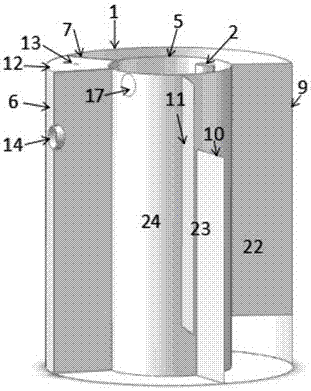

[0023] A pneumatic mixed sludge automatic backflow domestic sewage purification treatment device adopts a cylindrical cylindrical structure device, such as figure 1 As shown, it includes a cylindrical outer wall 1, the inner center of the outer wall 1 is provided with an inner cylinder 5, and the annular groove between the inner cylinder 5 and the outer wall 1 is provided with six partitions, namely the first partition 6, the second partition Plate 7, third partition 8, fourth partition 9, fifth partition 10 and sixth partition 11, the six partitions divide the annular groove into anaerobic tank 19, anoxic tank 20, aerobic tank in turn 21. The sedimentation tank 22, the dosing tank 23 and the clear water tank 24, the interior of the inner cylinder 5 is the water inlet tank 18, and the lower end of the water inlet tank 18 has a water inlet 15 that communicates with the anaerobic tank 19, and the water inlet 15 is far away from the anoxic tank 20. At one end, the anaerobic tank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com