Method and device for improving primary conversion rate of methanol in synthesized chloromethane

A technology for methyl chloride and conversion rate, which is applied in the field of improving the primary conversion rate of methanol in the synthesis of methyl chloride, can solve the problems of low single-pot production capacity, low primary conversion rate of raw methanol, etc., so as to improve the primary conversion rate and eliminate reactor death. area, the effect of reducing the unit consumption of methanol

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

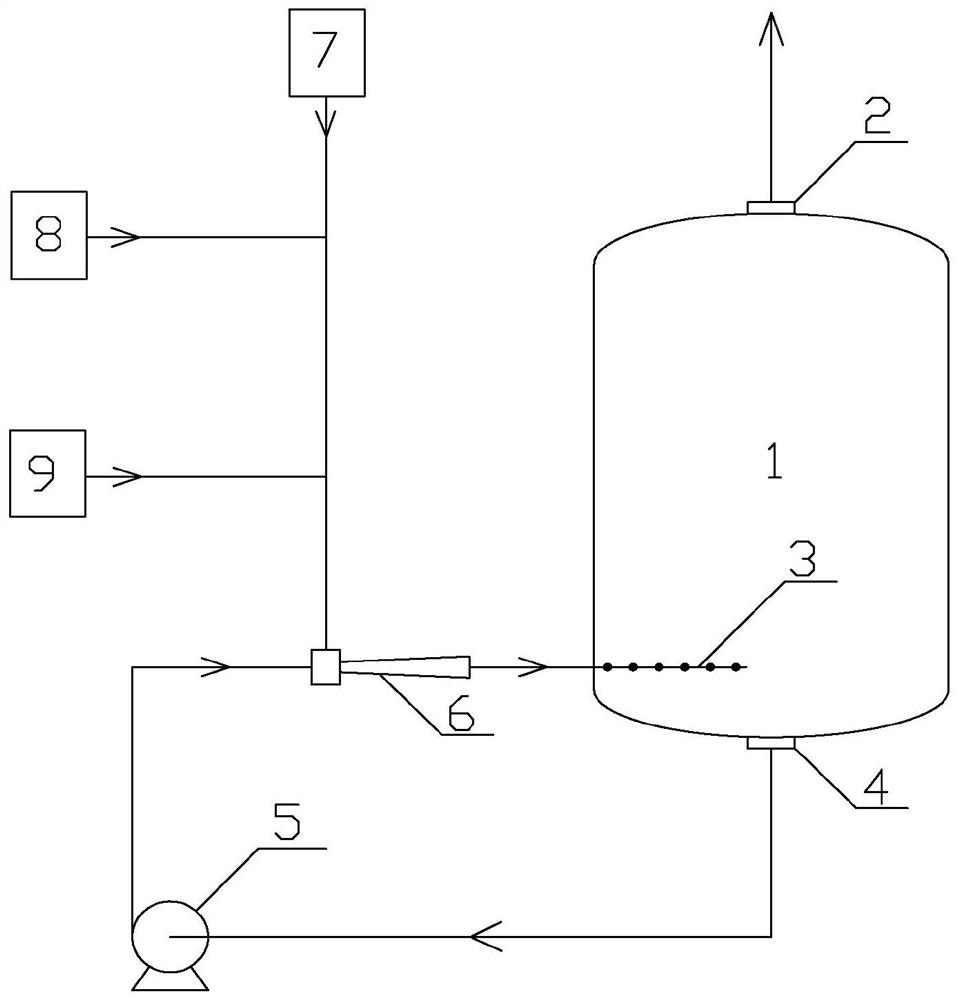

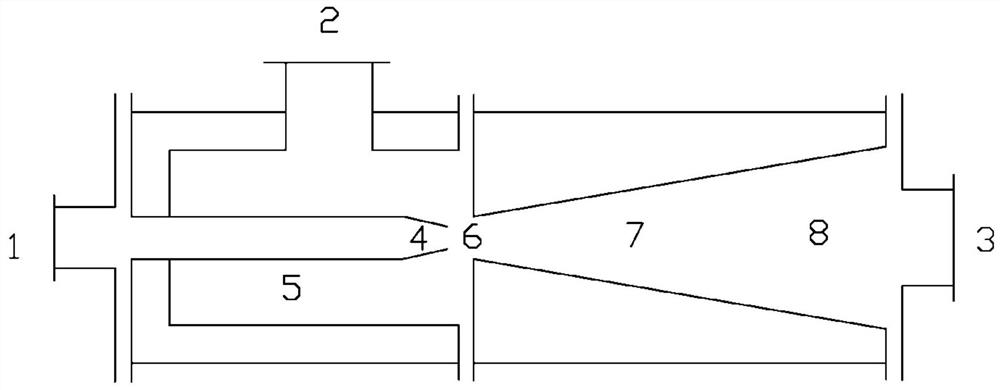

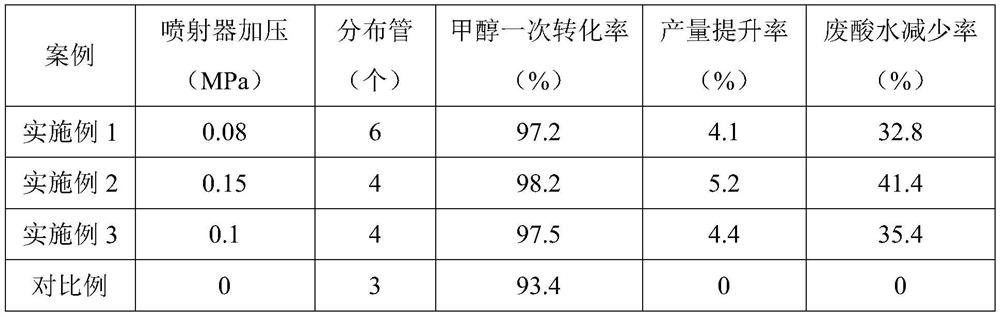

Embodiment 1

[0037] Embodiment 1 The method process for improving the primary conversion rate of methanol in the synthesis of methyl chloride by methanol hydrochlorination is as follows: After the excess gas phase hydrogen chloride is mixed with fresh methanol and recovered methanol (the molar ratio of hydrogen chloride to methanol is 1.05:1), enter the injector, inject The working medium of the reactor is a high-temperature zinc chloride solution catalyst (150°C) in the reactor, which is circulated through a graphite pump, and hydrogen chloride, fresh methanol and recovered methanol are further heated, vaporized, mixed, and pressurized ( After increasing by 0.08MPa), it enters the reactor through 6 feed distribution pipes.

[0038] Through the method of this embodiment, the primary conversion rate of methanol is increased from 93.4% to 97.2%.

Embodiment 2

[0040] Example 2 The method flow for improving the primary conversion rate of methanol in the synthesis of methyl chloride by methanol hydrochlorination is as follows: After the excess gas phase hydrogen chloride is mixed with fresh methanol and recovered methanol (the molar ratio of hydrogen chloride to methanol is 1.05:1), it enters the injector, injects The working medium of the reactor is a high-temperature zinc chloride solution catalyst (150°C) in the reactor, which is circulated through a graphite pump, and hydrogen chloride, fresh methanol and recovered methanol are further heated, vaporized, mixed, and pressurized ( After increasing by 0.15MPa), it enters the reactor through 4 feed distribution pipes.

[0041] Through the method of this embodiment, the primary conversion rate of methanol is increased from 93.4% to 98.2%.

Embodiment 3

[0043] Embodiment 3 The method process for improving the primary conversion rate of methanol in the synthesis of methyl chloride by methanol hydrochlorination is as follows: After the excess gas phase hydrogen chloride is mixed with fresh methanol and recovered methanol (the molar ratio of hydrogen chloride to methanol is 1.05:1), enter the injector, inject The working medium of the reactor is a high-temperature zinc chloride solution catalyst (150°C) in the reactor, which is circulated through a graphite pump, and hydrogen chloride, fresh methanol and recovered methanol are further heated, vaporized, mixed, and pressurized ( After increasing by 0.1MPa), it enters the reactor through 4 feed distribution pipes.

[0044] Through the method of this example, the primary conversion rate of methanol was increased from 93.4% to 97.5%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com