Novel sand mold casting equipment and casting method thereof

A sand casting, a new type of technology, applied in the direction of casting molding equipment, metal processing equipment, molding machines, etc., can solve the problems of low work efficiency, troublesome sand filling, poor mold precision, etc., to improve automation, reduce cleaning intensity, The effect of improving uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

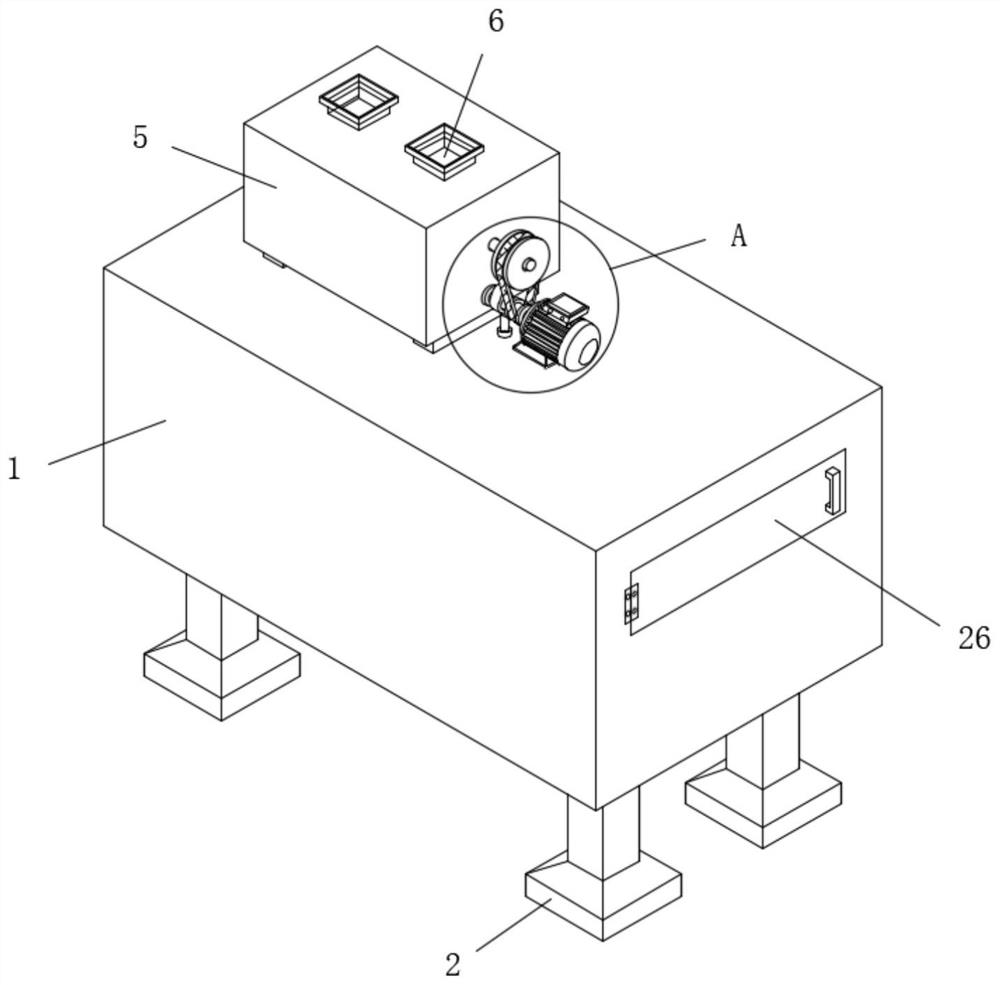

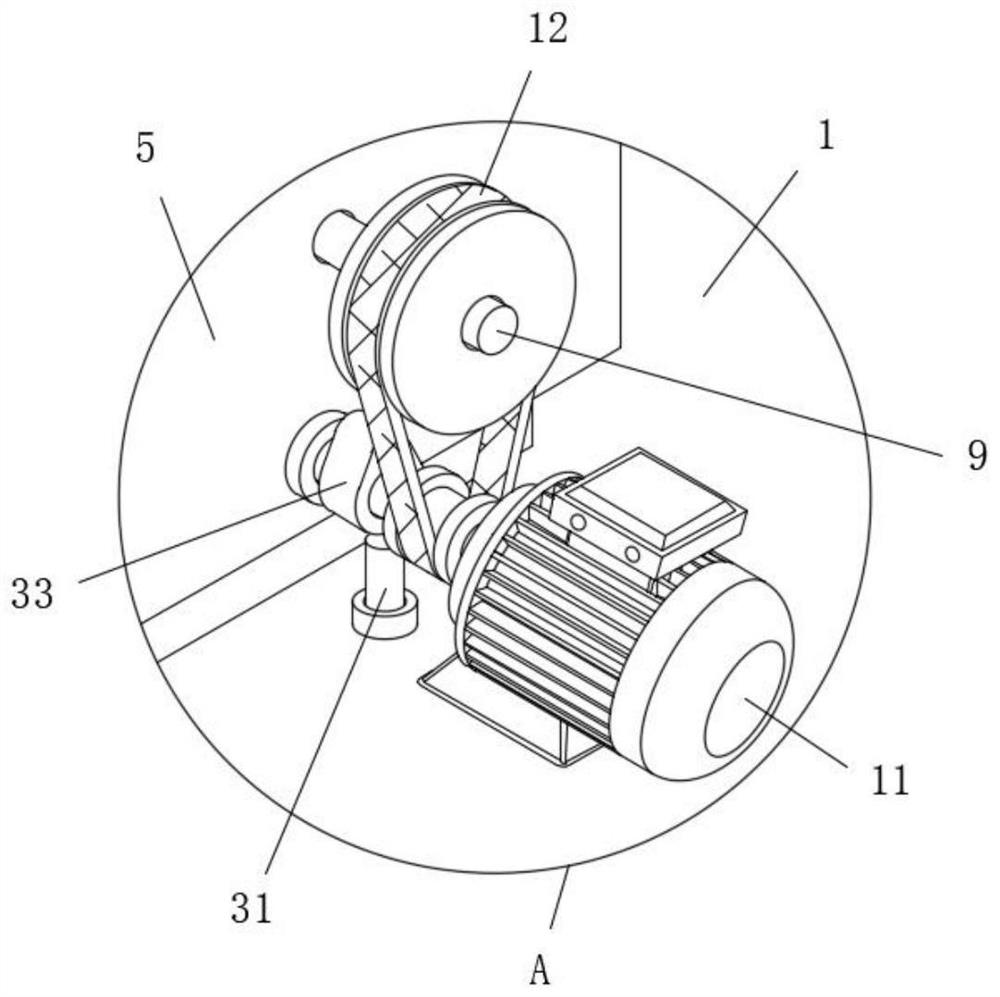

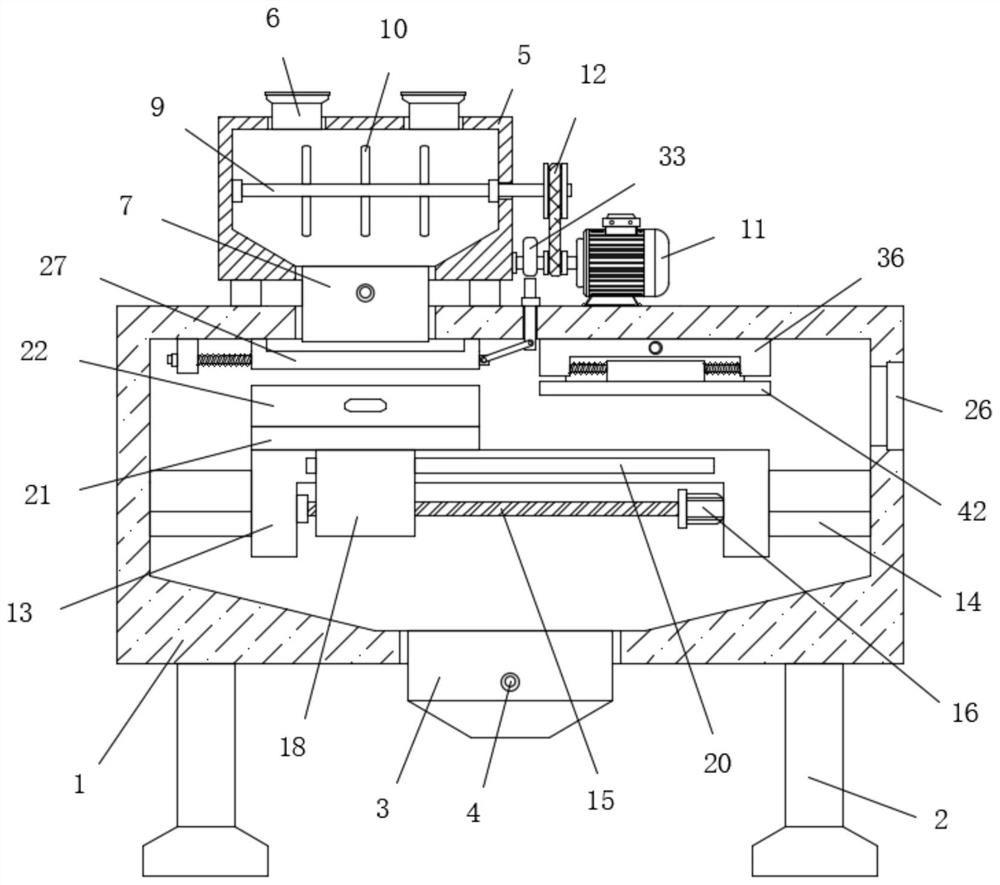

[0038] refer to Figure 1-10 , a new type of sand casting equipment and casting method thereof, comprising a sand casting box 1, the four corners of the bottom outer wall of the sand casting box 1 are provided with support legs 2, the bottom of the sand casting box 1 is provided with a sand discharge pipe 3, and the sand discharge A sand unloading valve 4 is installed on the pipe 3, and one side of the top outer wall of the casting sand box 1 is fixedly connected with a batching box 5 through a pad. There is a sand delivery pipe 7, and the bottom end of the sand delivery pipe 7 runs through the top of the sand casting box 1, a sand delivery valve 8 is installed on the sand delivery pipe 7, a stirring assembly is arranged inside the batching box 5, and the sand casting boxes 1 are far away from each other Two connecting blocks 14 are symmetrically fixedly connected to the inner wall of one side of the two connecting blocks 14, and the same U-shaped fixing seat 13 is fixedly con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com