Matrix mixing device for breeding earthworms

A mixing device and matrix technology, which is applied to mixers with rotating stirring devices, mixers, shaking/oscillating/vibrating mixers, etc., can solve the problem that the stirring blade materials cannot be stirred sufficiently, affect the mixing effect of the matrix, and have poor sludge fluidity, etc. problems, to achieve the effect of ingenious structural design, improved mixing efficiency, and enhanced mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

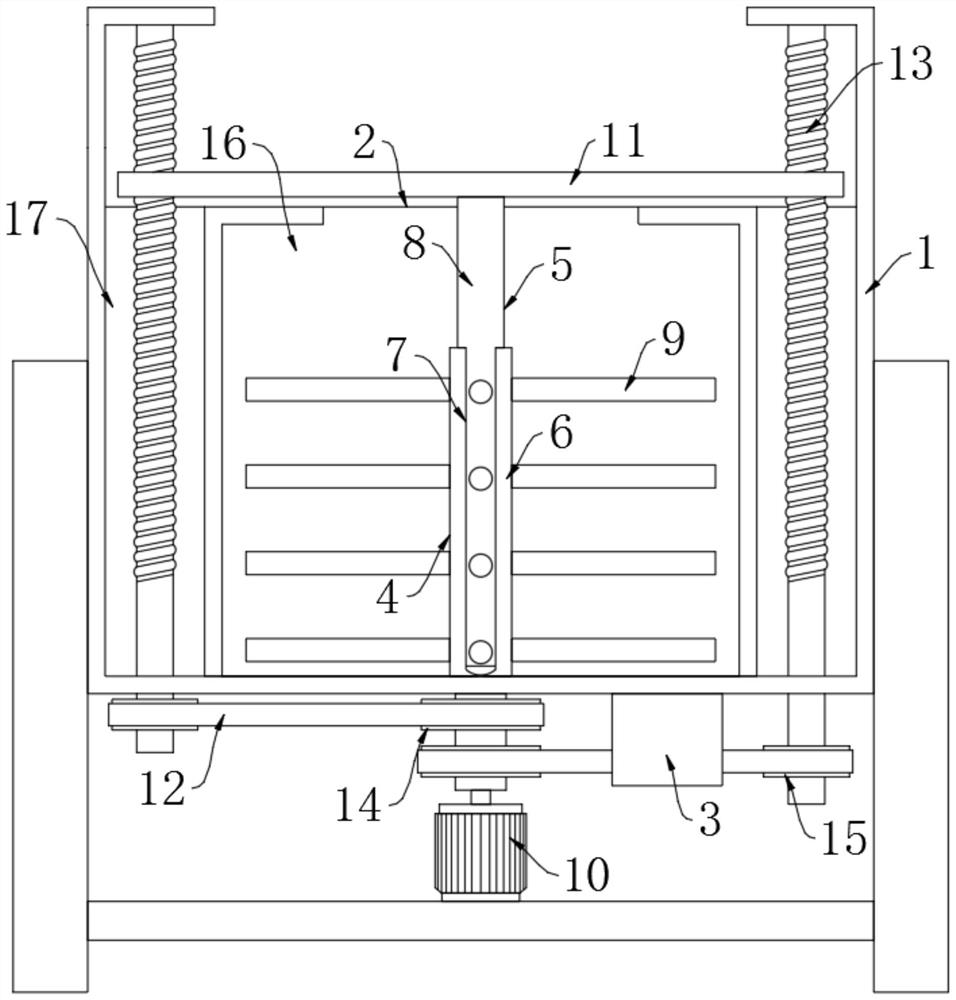

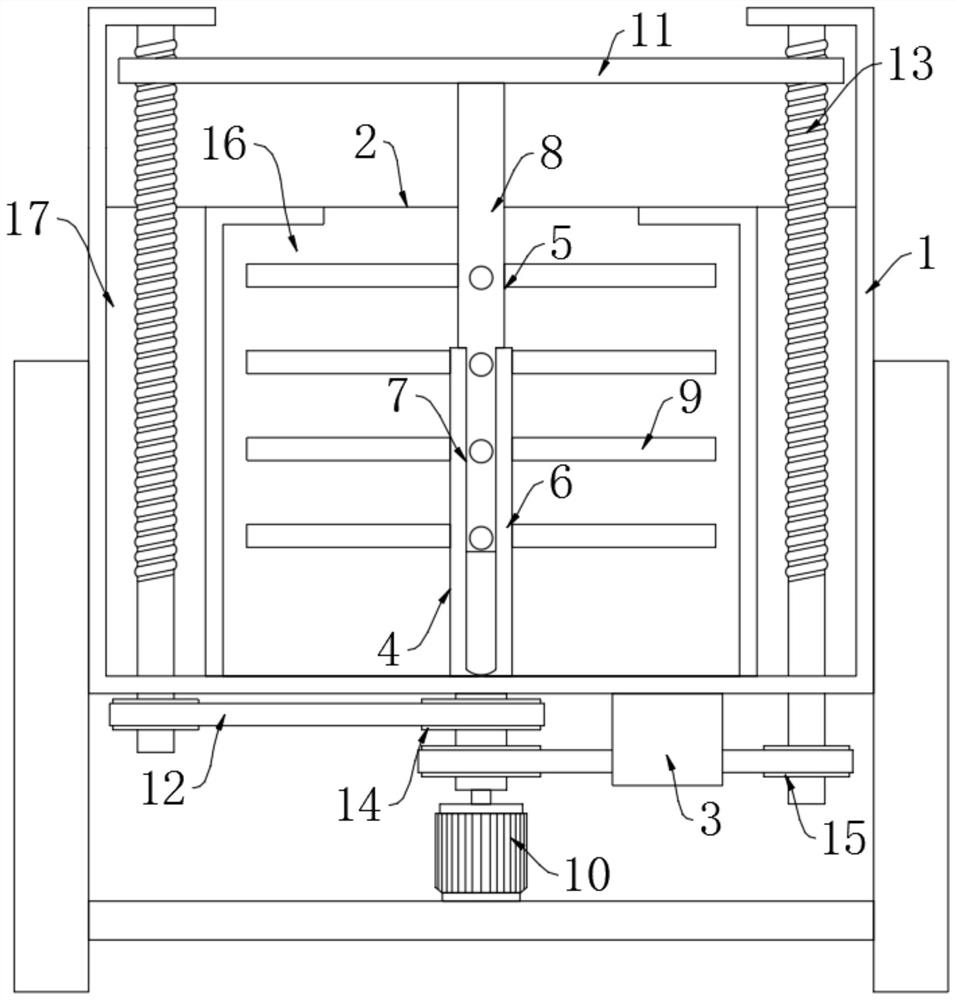

[0034] Please refer to Figure 1-Figure 2 , a substrate mixing device for cultivating earthworms, comprising a mixing box 1, the mixing box 1 is provided with a feeding port 2 and a feeding port 3, and it is characterized in that, the device also includes:

[0035] a stirring mechanism, the stirring mechanism is used to stir the material to make it fully mixed, and the stirring mechanism includes a rotating part 4 and a stirring part 5, and the rotating part 4 is arranged below the stirring part 5;

[0036] The rotating part 4 includes a rotating rod 6, and the rotating rod 6 is provided with an elongated hole 7, and the elongated hole 7 penetrates the top end of the rotating rod 6;

[0037] The stirring member 5 includes a stirring rod 8, and the stirring rod 8 is slidably sleeved with the rotating rod 6, and a stirring blade 9 is installed on the stirring rod 8, and the stirring blade 9 extends through the elongated hole 7 to the outside of the rotating member 4;

[0038] T...

Embodiment 2

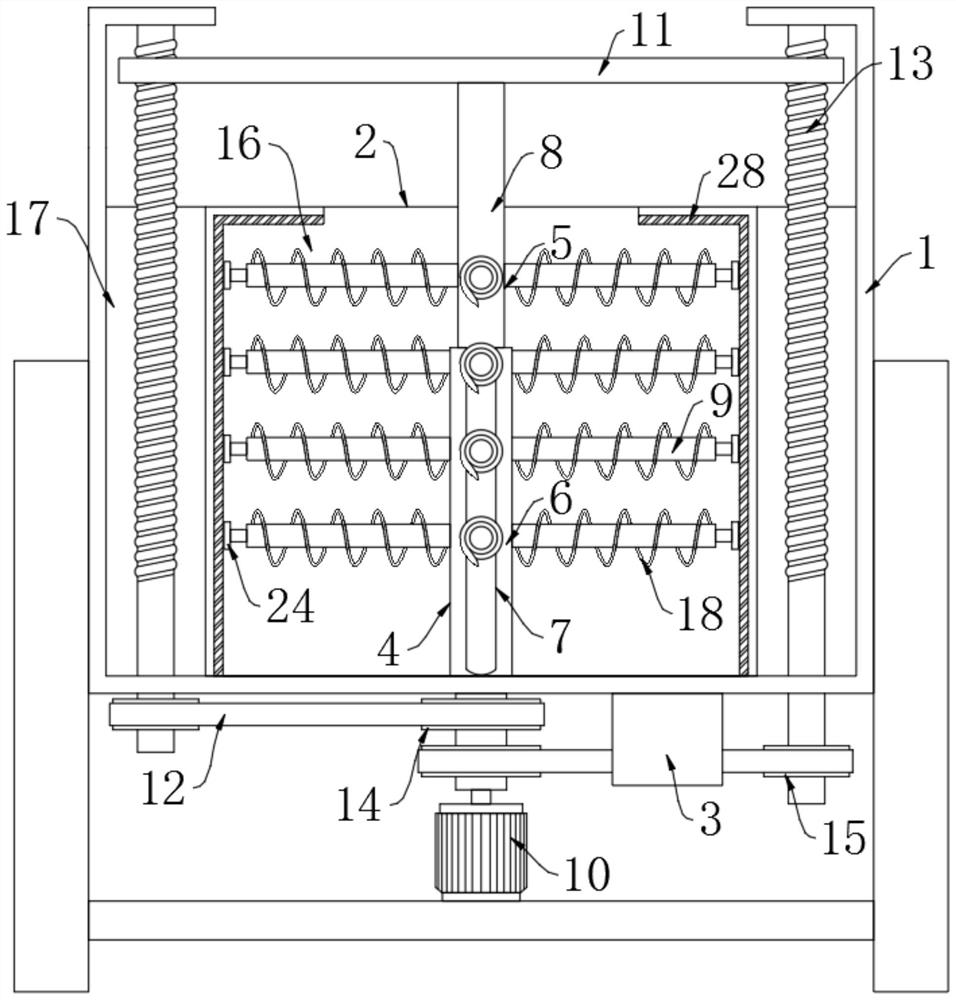

[0048]In the prior art, the stirring blades 9 of the stirring mechanism have a spiral shape, and are generally installed horizontally. In the vertical mixing box 1, most of the stirring blades 9 of the stirring mechanism have a simple structure, in order to enhance the stirring effect on the material. Most of the prior art combines the two, that is, a plurality of stirring zones are arranged, the stirring zones are arranged in the vertical direction, and different stirring blades 9 are arranged in different stirring zones. Although the stirring effect is strengthened, the two stirring methods cannot simultaneously The materials at the same level are stirred at the same time, which prolongs the stirring time, and the stirring effect is still unsatisfactory.

[0049] Therefore, the present invention further provides another embodiment:

[0050] Specifically, refer to image 3 The stirring blade 9 is provided with a helical blade 18, a mounting cavity 19 is provided inside the s...

Embodiment 3

[0055] Due to the presence of sludge in the matrix, the mixing box 1 needs to be washed after the mixing is completed, but there may be some sludge on the wall surface that is difficult to fall off, so further, the present invention provides another embodiment:

[0056] Specifically, refer to image 3 and Figure 4 , a scraper 24 is detachably installed at the end of the stirring blade 9 , and the scraper 24 slides along the inner wall of the mixing chamber 16 .

[0057] When washing the mixing box 1 , the scraper 24 rotates along its inner wall, which can enhance the cleaning effect of the mixing box 1 .

[0058] Further, the scraper 24 and the stirring blade 9 are connected by a telescopic piece 25. The telescopic piece 25 includes a telescopic spring 26 and a connecting column 27. The telescopic spring 26 is installed in the inner cavity of the stirring blade 9, and one end of the connecting column 27 is connected to the scraper. 24 is fixedly connected, and the other end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com