Patents

Literature

48results about How to "Guaranteed axial movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

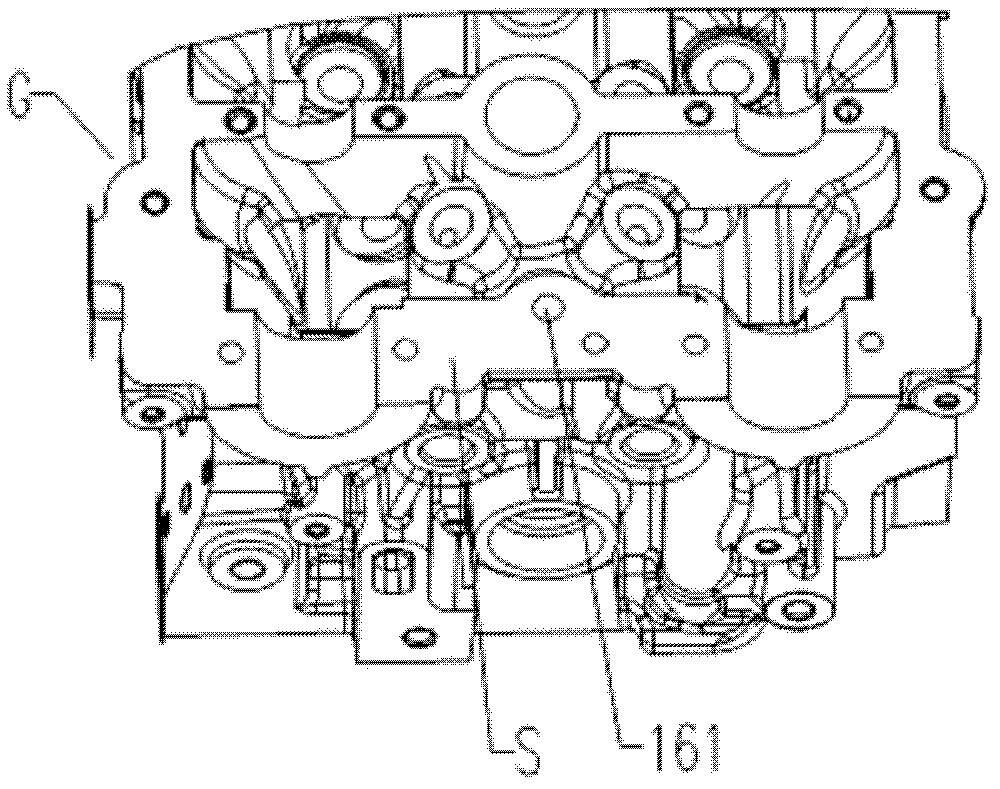

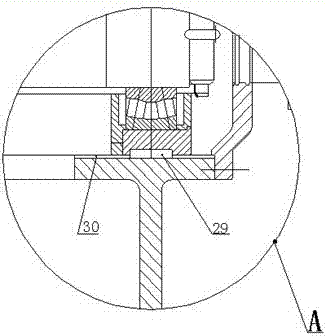

First bearing cover of engine cylinder cover

ActiveCN102425464AGuaranteed axial movementReduce processing stepsValve arrangementsLubrication of auxillariesVariable valve timingThrust bearing

The invention relates to a first bearing cover of an engine cylinder cover, which is characterized in that: a bolt hole is arranged on the bearing cover, and is used for fixing the bearing cover onto the cylinder cover. An air inlet bearing and an exhaust bearing are connected with each other into a whole through a cross arm. At the same time, two oil holes which are arranged on the upper end of an air inlet cam shaft bearing are communicated with an oil passage of a variable valve timing (VVT) control valve through an external pipeline. An oil storage trough and the oil passage are cast on the lower surface of the first bearing cover, and the casting of the oil passage can greatly reduce the mechanical processing difficulty. The first bearing cover of the engine cylinder cover has simple design, is easy to arrange, is simple to process, and can effectively reduce the processing difficulty.

Owner:CHERY AUTOMOBILE CO LTD

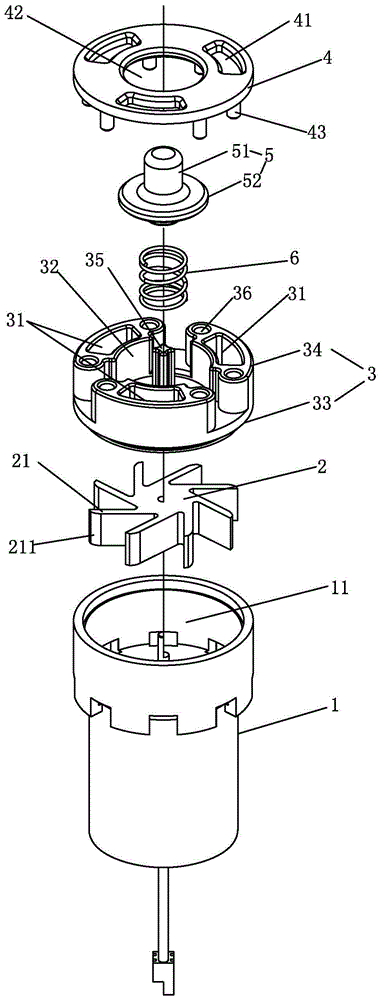

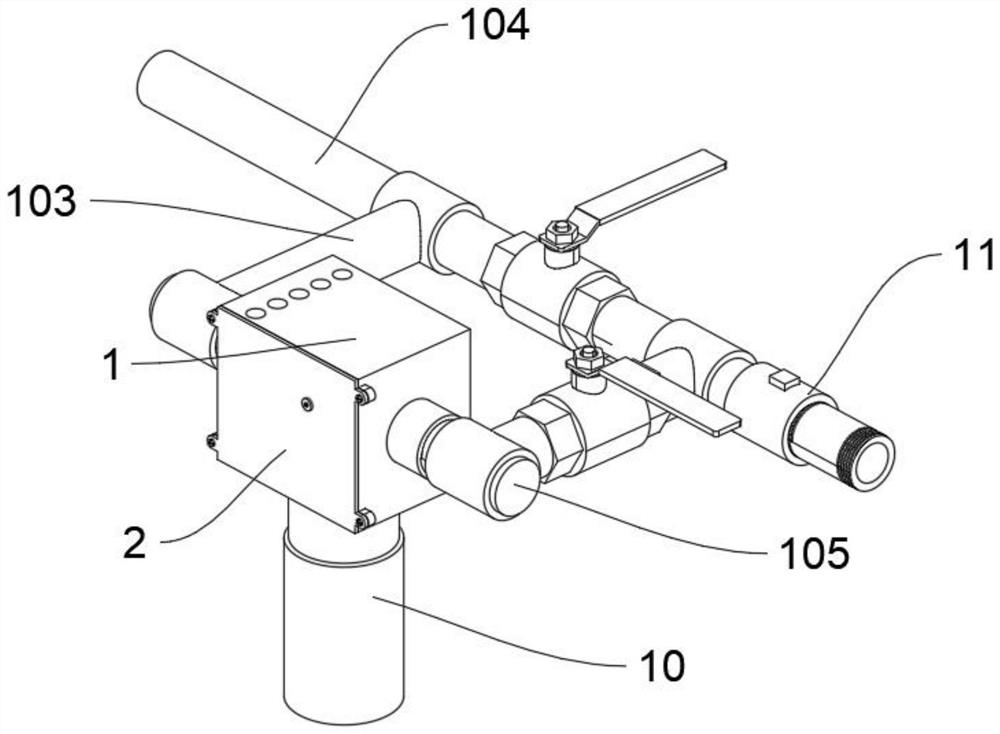

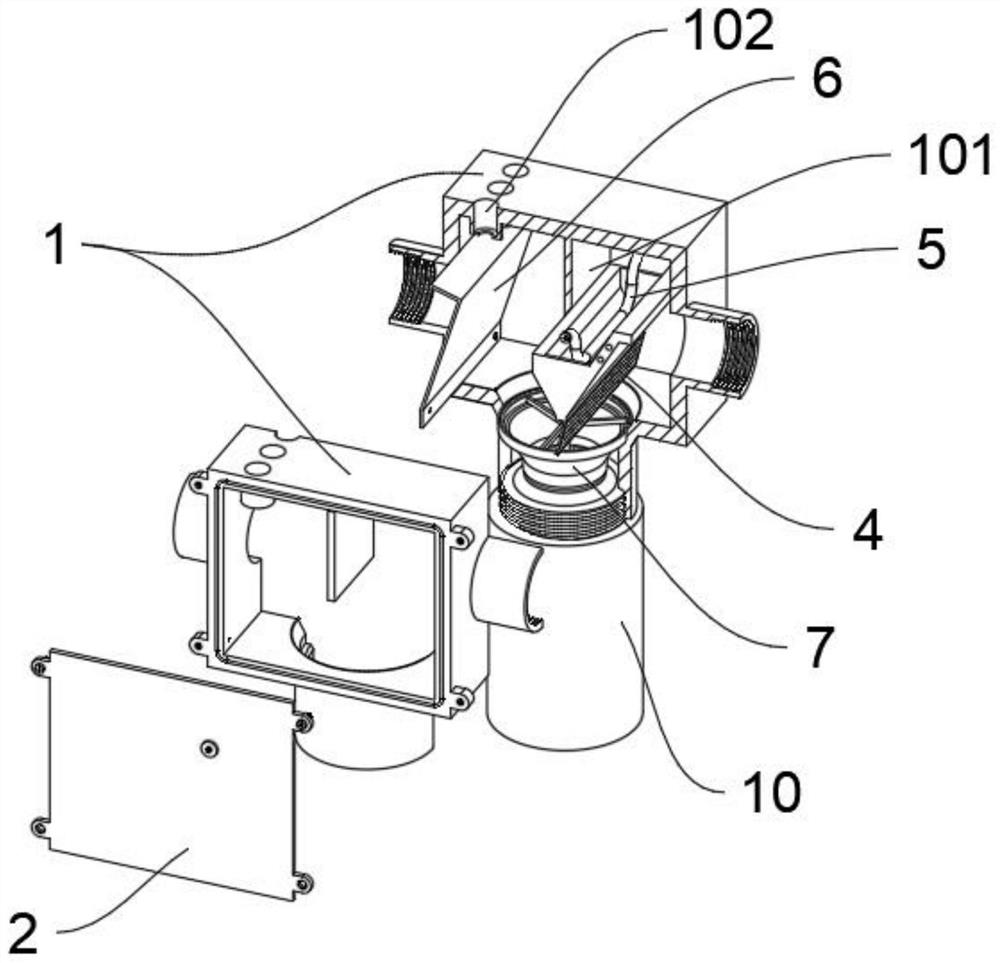

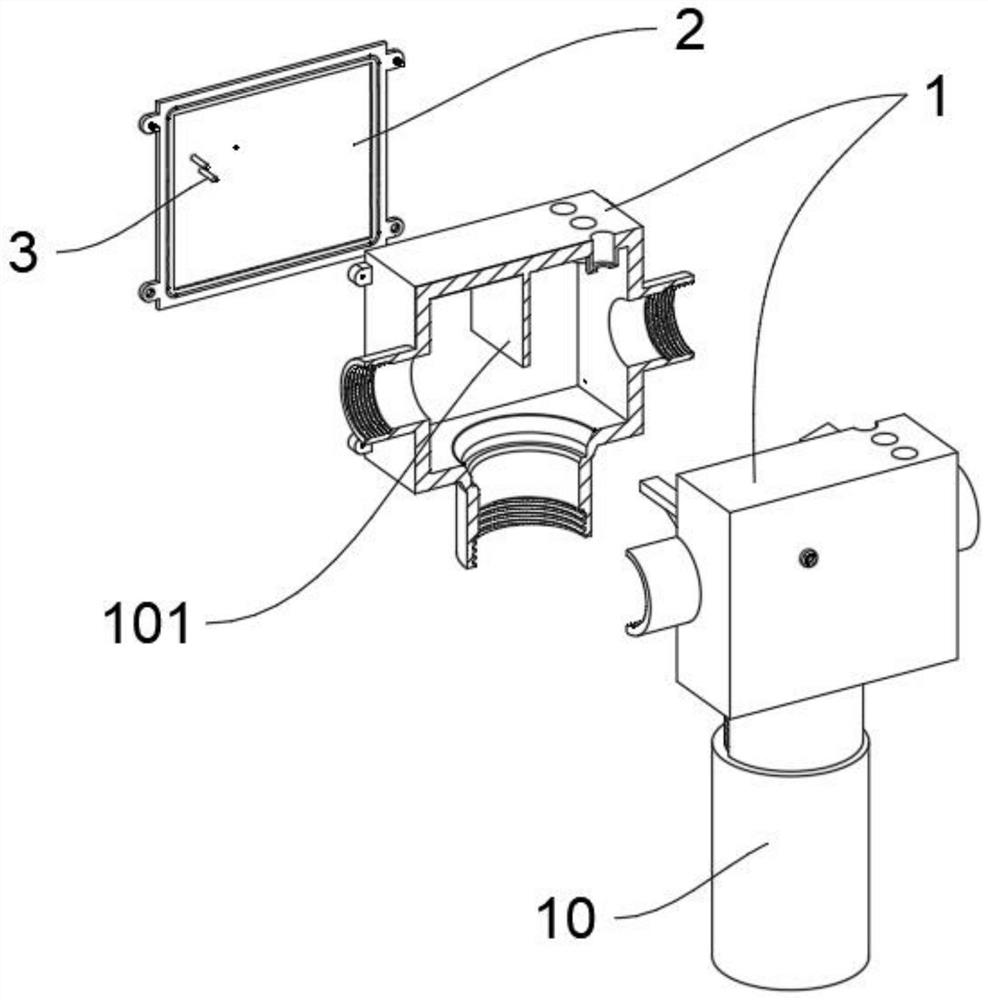

Hydroelectric generator with flow control function, and shower faucet

ActiveCN105782560AWill not hinder normal circulationLow costHydro energy generationReaction enginesImpellerWater flow

The invention discloses a hydroelectric generator with a flow control function, and a shower faucet. The hydroelectric generator comprises an electric generator body and a valve. The valve is provided with a first runner and a second runner which are capable of being communicated with a same water supply pipeline. The first runner is communicated with an impeller cavity of the electric generator body. Through the first runner, water flow is pressurized and conveyed into the impeller cavity of the electric generator body so as to drive an impeller to rotate. The impeller cavity is provided with a water outlet. The valve is provided with a control valve body which is controlled by water supply pressure and can be reset. The control valve body controls the second runner to discharge water or not. According to the hydroelectric generator and the shower faucet, under the low water pressure condition, water can be made to flow the impeller cavity of the electric generator body completely, and power generation of the electric generator body is not influenced; and under the high water pressure condition, part of water flows out through the second runner and provides efficient flow for the rear end together with water flowing out from the impeller cavity, so that normal flowing of the water flow is not hindered. The hydroelectric generator and the shower faucet further have the characteristics of being simple in structure, convenient to produce and assemble, low in cost and the like.

Owner:JOMOO KITCHEN & BATHROOM

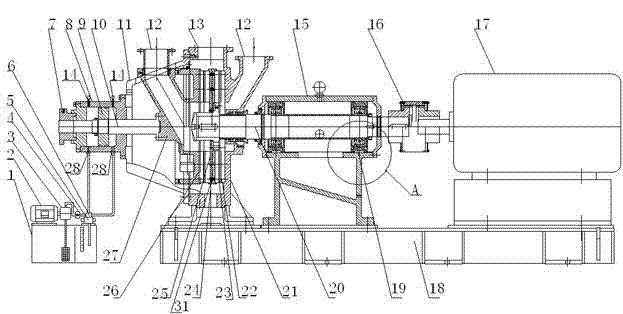

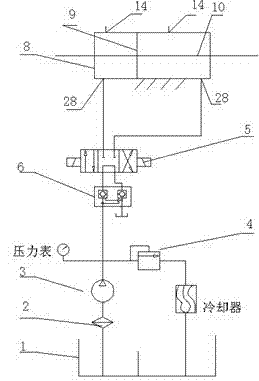

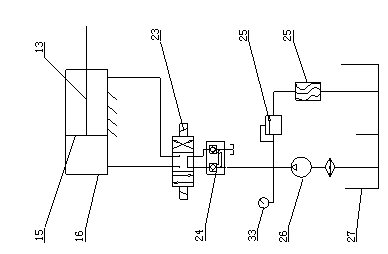

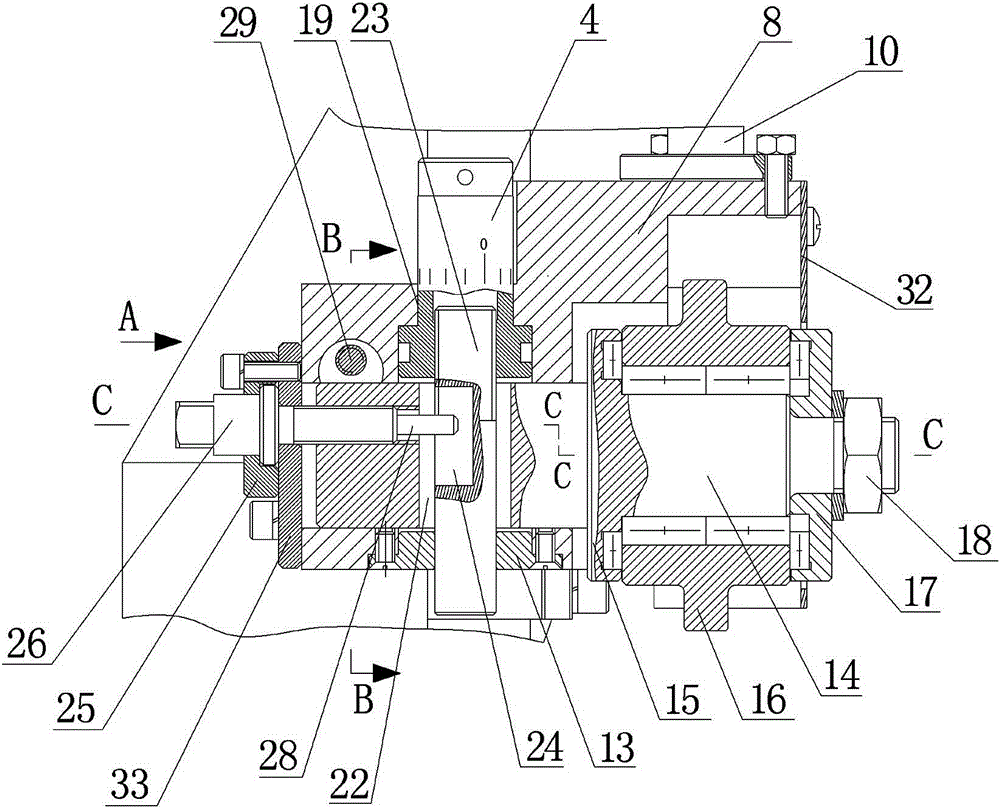

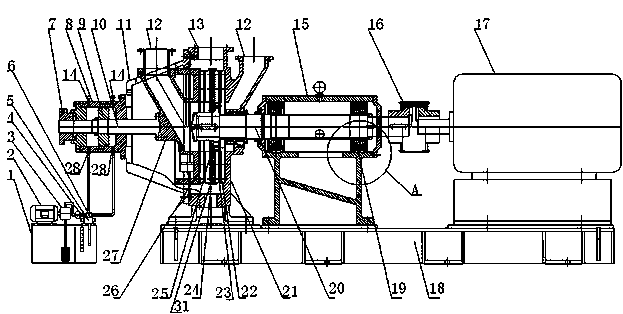

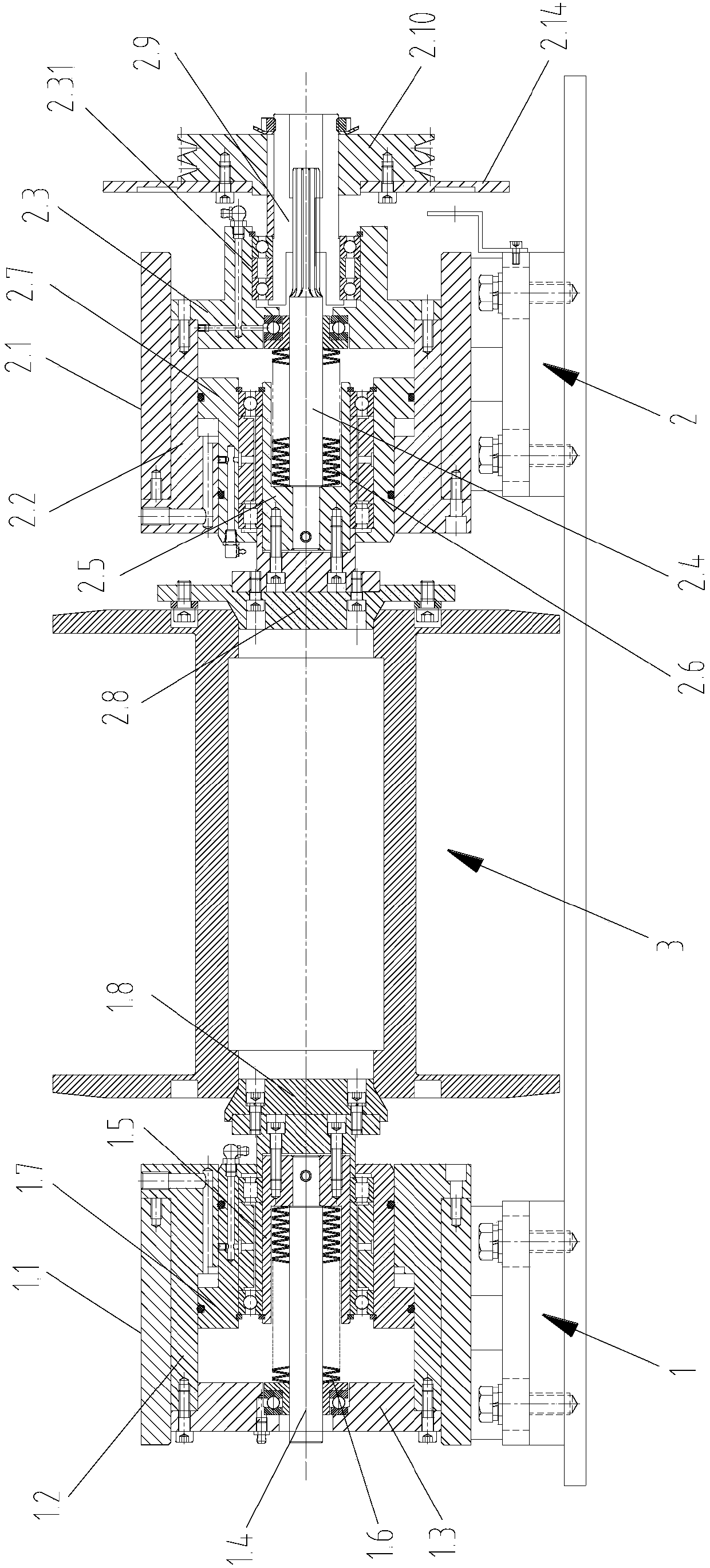

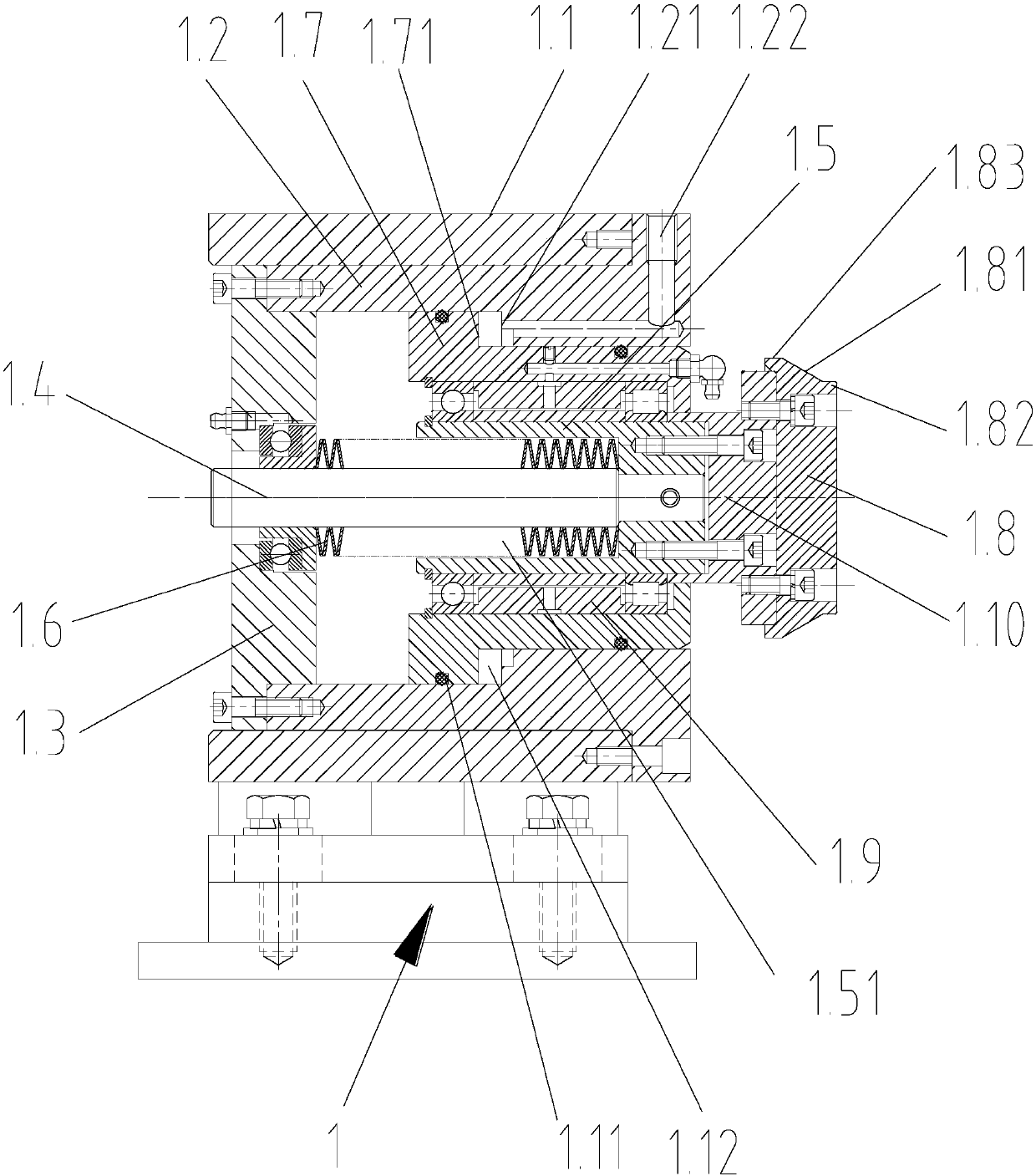

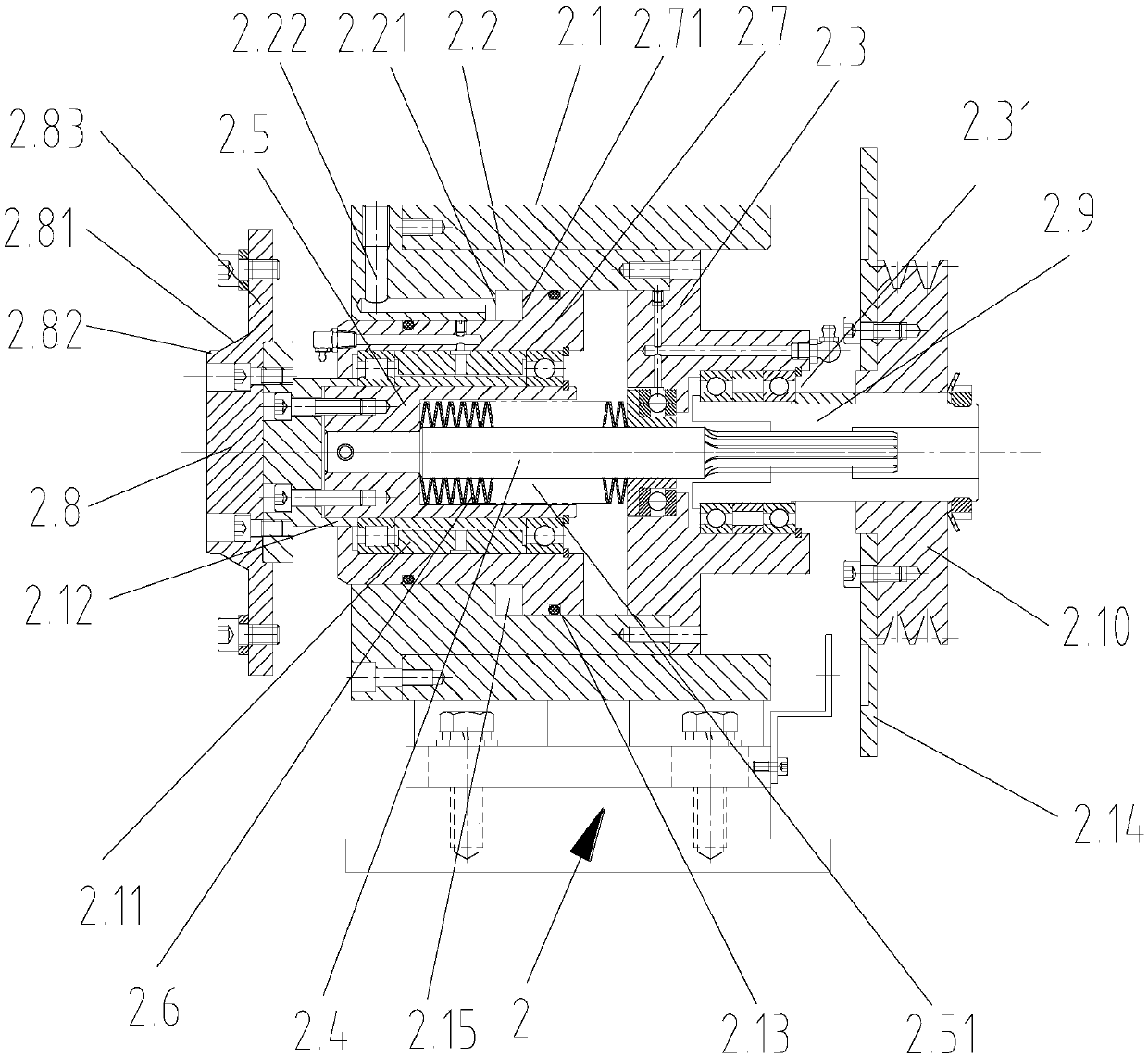

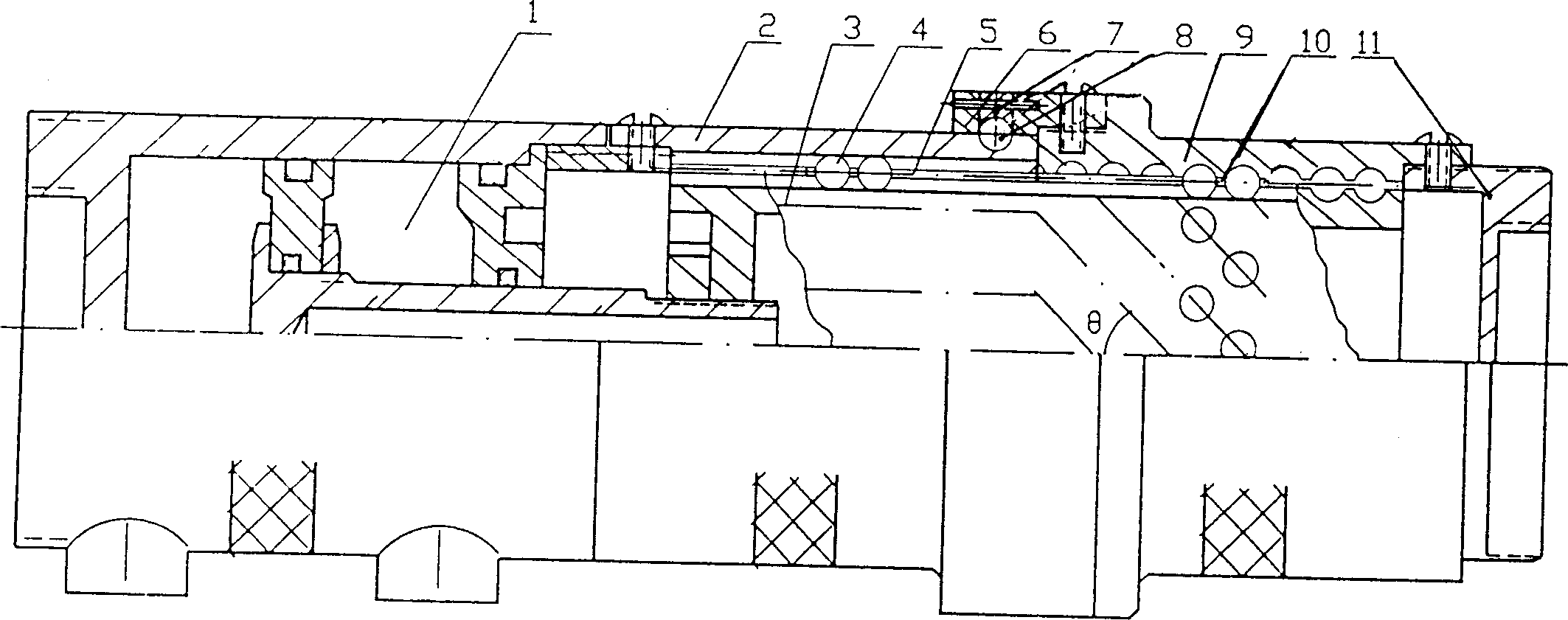

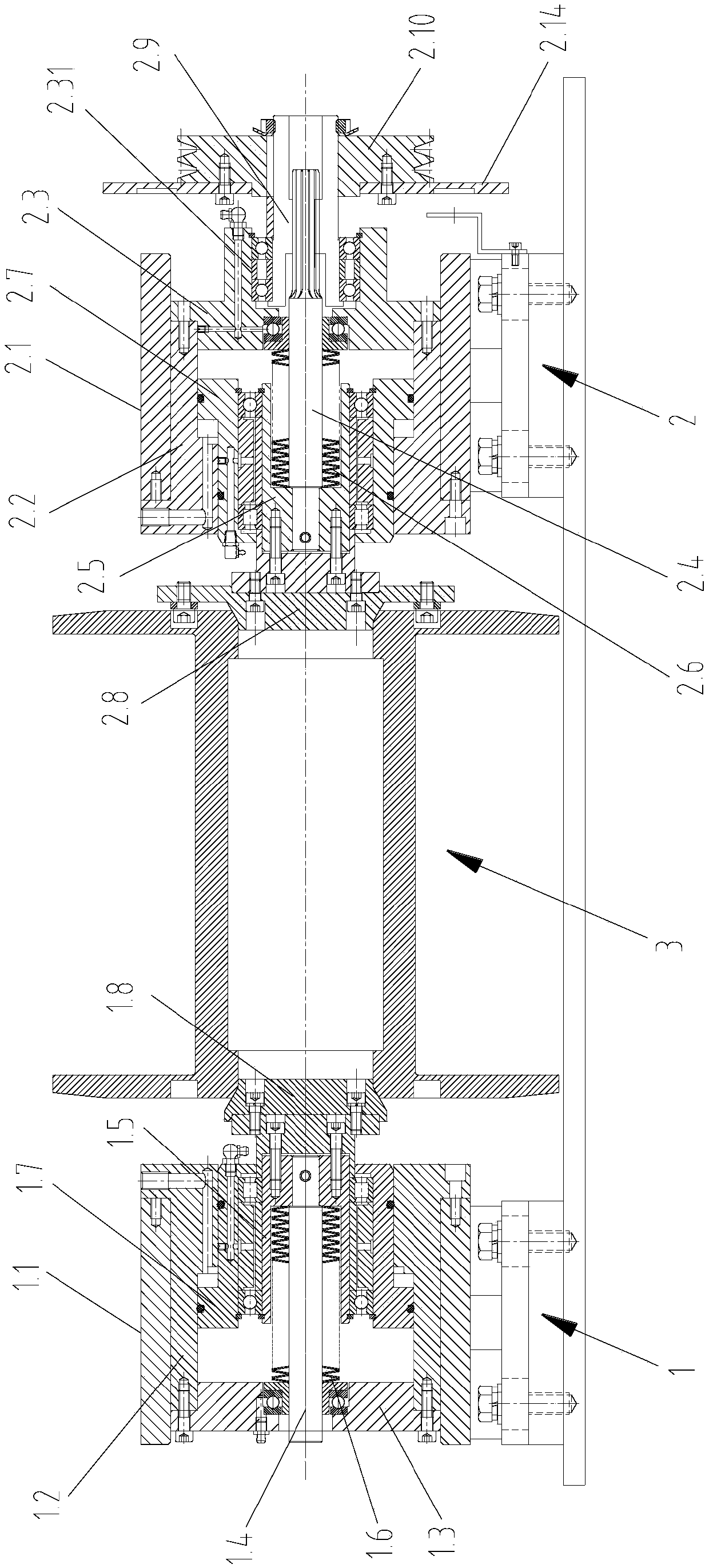

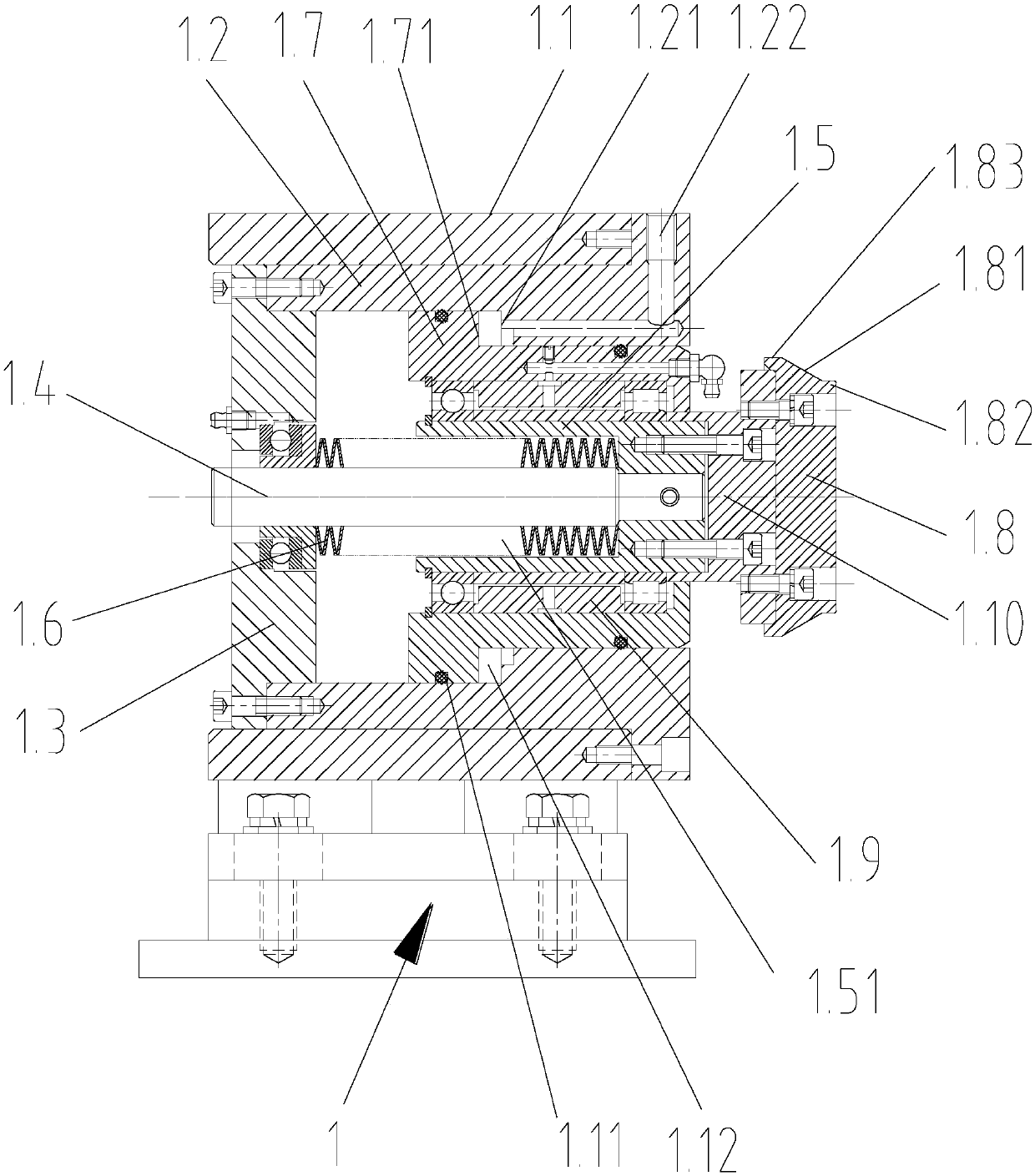

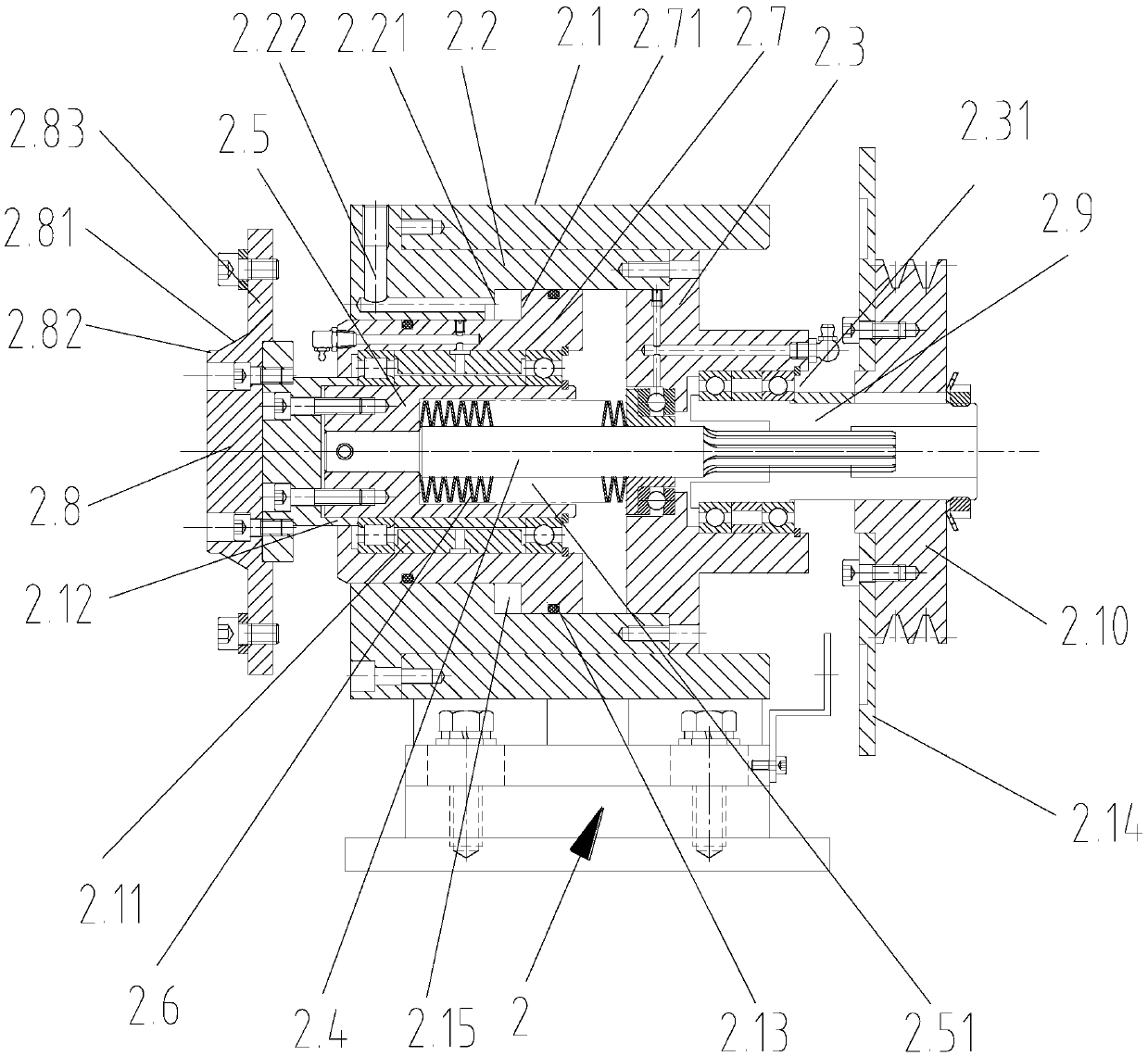

Medium concentration hydraulic double disc stuff grinder

ActiveCN102400406AEasy to adjustConvenient beating specific pressurePulp beating/refining methodsHydraulic cylinderHydraulic pump

The invention discloses a medium concentration hydraulic double disc stuff grinder, comprising a hydraulic adjusting unit and a medium concentration double disc stuff grinder body. The hydraulic adjusting unit consists of a hydraulic cylinder, an electromagnetic direction valve, a pressure retaining valve, a hydraulic pump, an oil pump motor and an oil tank connected orderly by pipelines. The oil tank is further connected with a cooler, a pressure adjusting valve and a pipeline of a pressure gauge; the medium concentration double disc stuff grinder body consists of a double shell and a shell cover, a coupler, a motor, a bearing body suspension and a bearing body, a shaft, a left fixed disc base and left and right fixed discs, left and right rotary discs and a rotary disc base. The hydraulic cylinder is fixed on the shell cover. One end of the piston rod is fixed on the left fixed disc base while the other end is provided with a mechanism limiting fine-adjusting nut. The left fixed disc is fixed on the left fixed disc base and the right fixed disc is fixed on the shell. The left and right rotary discs are fixed respectively at both sides of the rotary disc base. Tangential stock inlets are arranged on the left fixed disc base and the shell. The shell is provided with a stock outlet. The invention adjusts the definitely proportional pressure of the millstone which feeds and discharges through the pressure retaining valve to pulp in medium concentration, thereby improving the pulping quality and efficiency thereof.

Owner:SOUTH CHINA UNIV OF TECH

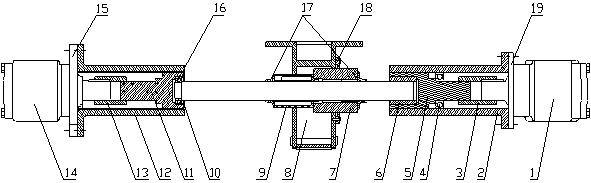

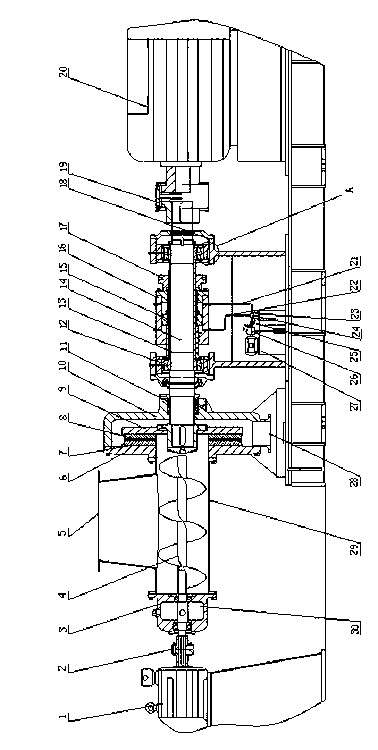

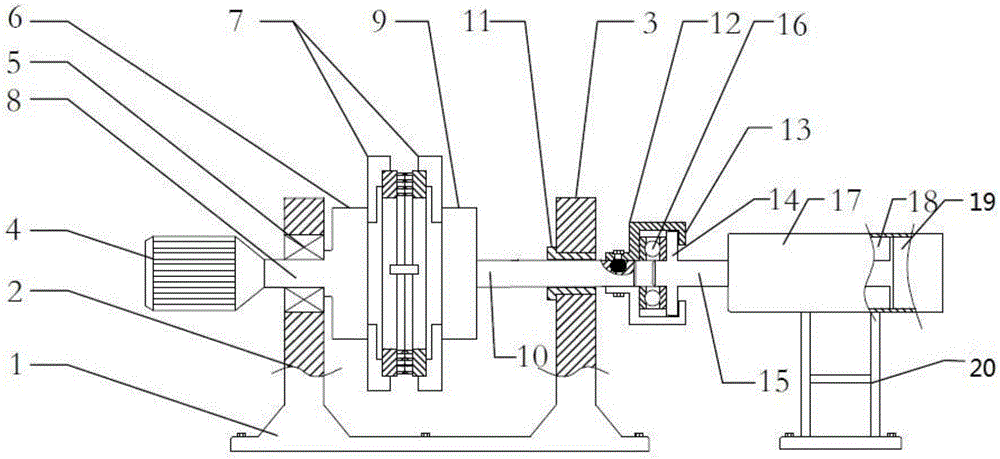

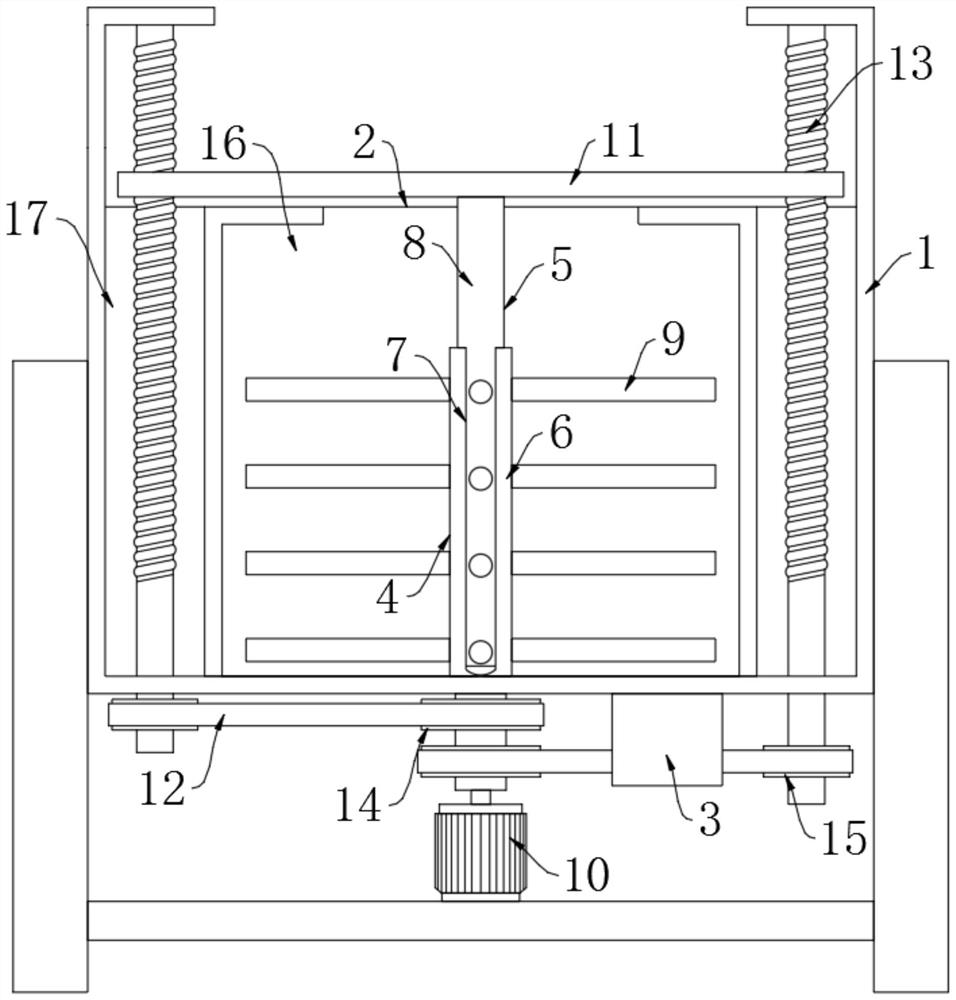

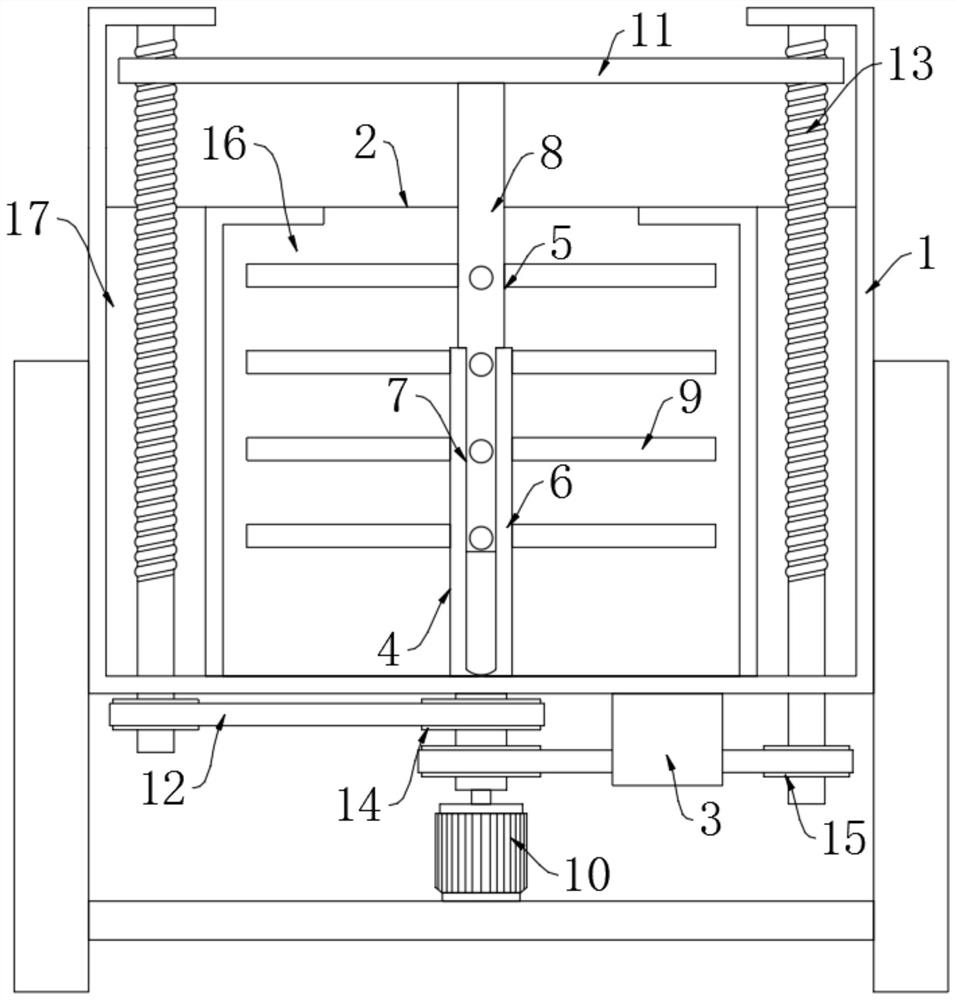

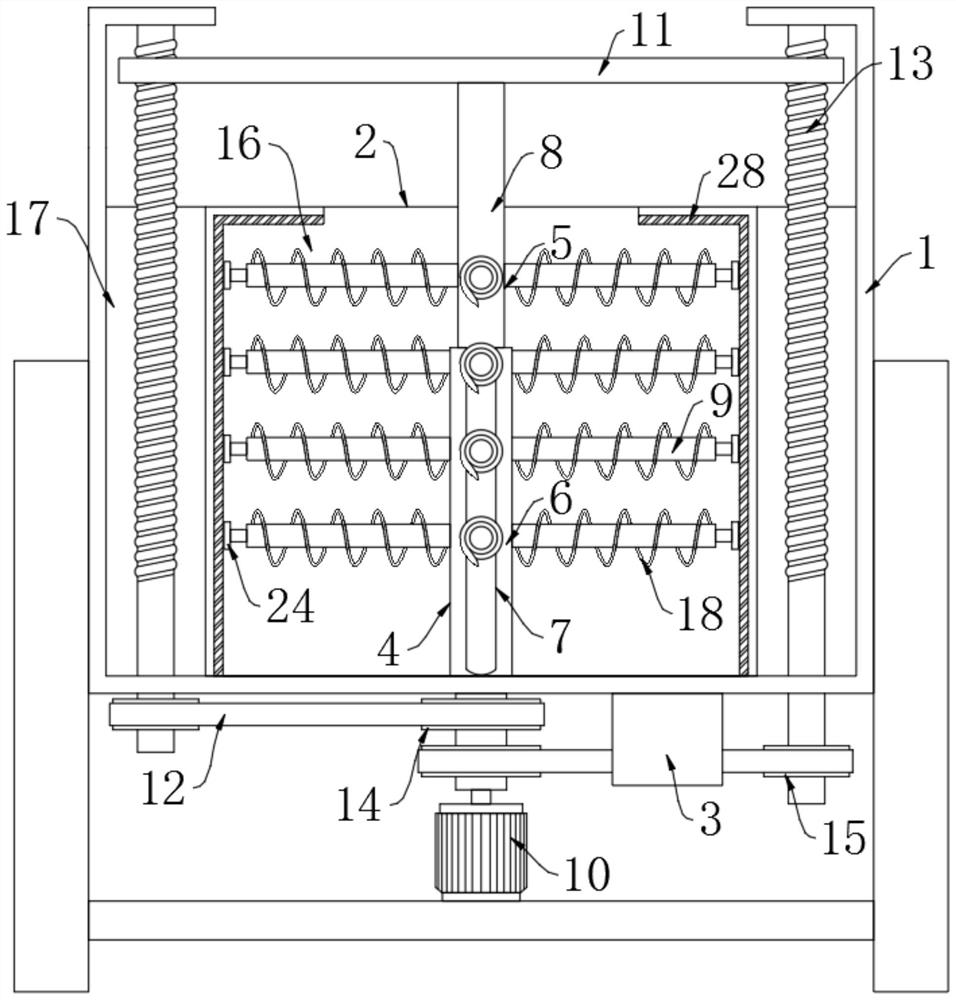

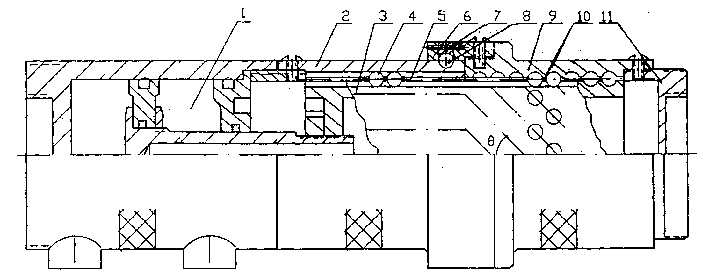

Rotary speed and opening degree double-adjustment device for fertilizer discharging shaft of variable fertilizer applicator

InactiveCN104380897AIncrease or decrease effective working lengthReduce the effective working lengthFertiliser distributersAgriculture gas emission reductionAgricultural engineeringControl theory

The invention relates to a rotary speed and opening degree double-adjustment device for a fertilizer discharging shaft of a variable fertilizer applicator. The rotary speed and opening degree double-adjustment device comprises a rack, a rotary speed adjusting mechanism, an opening degree adjusting mechanism and fertilizer discharging devices, and is characterized in that the rotary speed adjusting mechanism is arranged at the right side of the rack; the opening degree adjusting mechanism is arranged at the left side of the rack; and the fertilizer discharging devices are uniformly distributed between the rotary speed adjusting mechanism and the opening degree adjusting mechanism according to specific farmland plant planting line spacing and the width of the variable fertilizer applicator. The rotary speed adjusting mechanism is composed of a rotary speed motor, a rotary speed motor seat, a rotary speed sleeve, a rotary speed shaft coupler, a supporting bearing, a rotary speed connection piece and a spline; the opening degree adjusting mechanism is composed of an opening degree motor, an opening degree motor seat, an opening degree sleeve, an opening degree shaft coupler, an opening degree connection piece and a rotary bearing; and each fertilizer discharging device is composed of a fertilizer discharging box, a groove wheel, a fertilizer discharging stopping shaft, a clamping device and a follow-up baffle. The adjustment device can be used for adjusting the rotary speed and the opening degree of a fertilizer discharging main shaft at the same time so that the working efficiency is improved, and the influences in fertilization uniformity, caused by fertilizer discharging pulsatility in a fertilizer discharging process are reduced.

Owner:SHIHEZI BOLI ELECTROMECHANICAL TECH

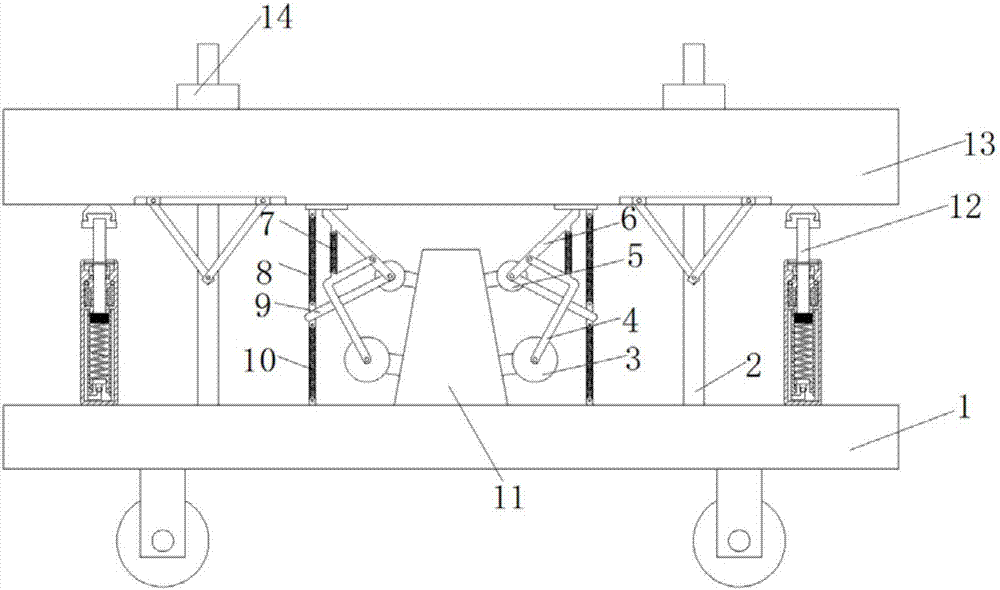

Damping device of base of drawing robot

InactiveCN107504123AReduced service lifePrevent overflowSpringsNon-rotating vibration suppressionEngineeringRobot

The invention discloses a shock absorbing device for the base of a painting robot, which comprises a bottom plate, on which a plurality of limit posts are arranged symmetrically, on which a base is sheathed together on the limit posts, and on which a fixed block is arranged on the bottom plate , the lower surface of the base is symmetrically provided with two support plates, and the fixed block is symmetrically provided with two first mounting frames and two second mounting frames, and the first mounting frame is rotatably connected with a first connecting frame. rod and the second connecting rod, the second mounting bracket is rotatably connected with an L-shaped connecting rod, the first spring is connected between the first connecting rod and the L-shaped connecting rod, and the support plate and the second connecting rod A second spring is connected between them, a third spring is connected between the second connecting rod and the bottom plate, and four sleeves are symmetrically arranged on the bottom plate. The invention is simple in structure, convenient to use, multiple shock absorbing modes can absorb shock at the same time, greatly improves the shock absorbing effect of the whole device, does not affect the work of the painting robot, and is worth popularizing.

Owner:重庆胡柚塔文化传播有限公司

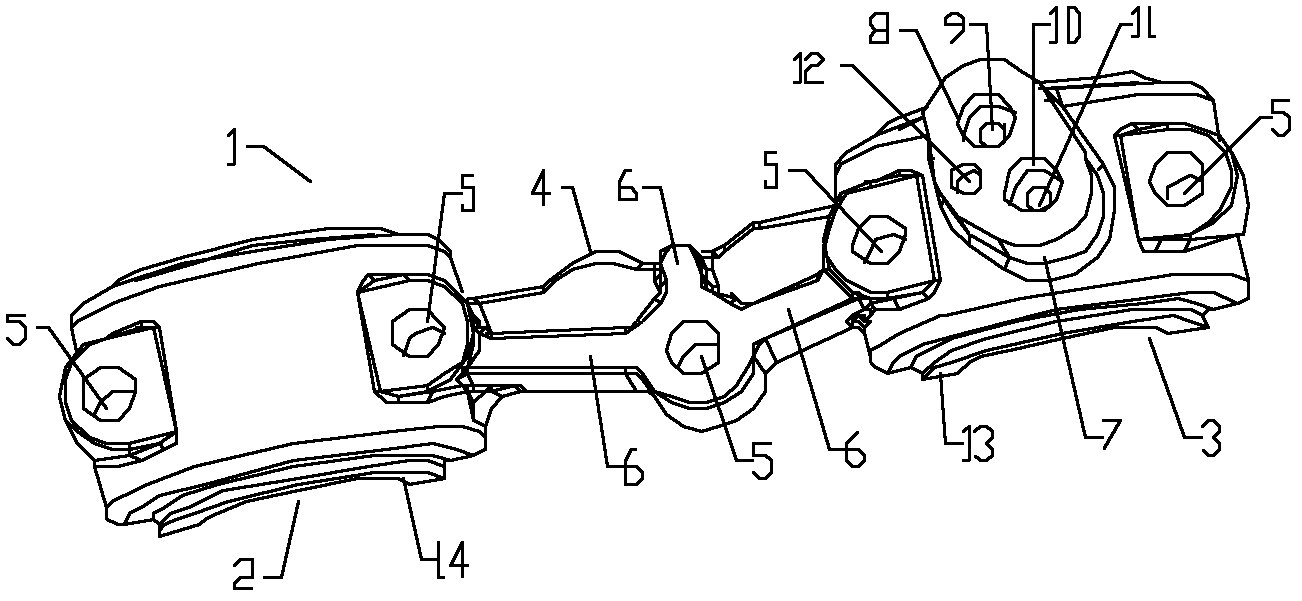

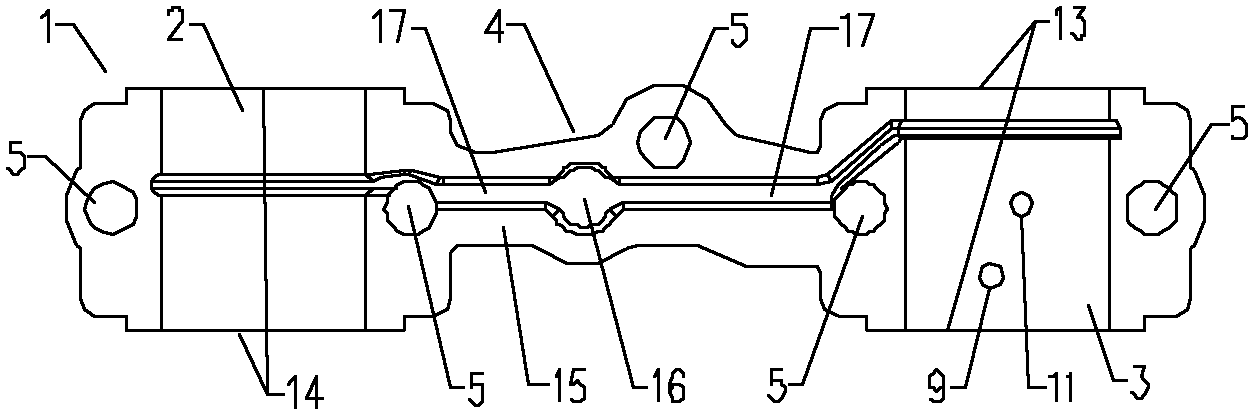

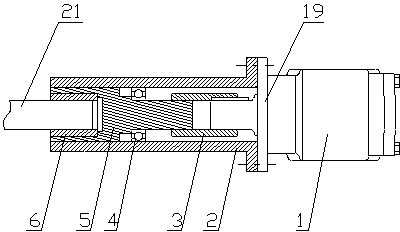

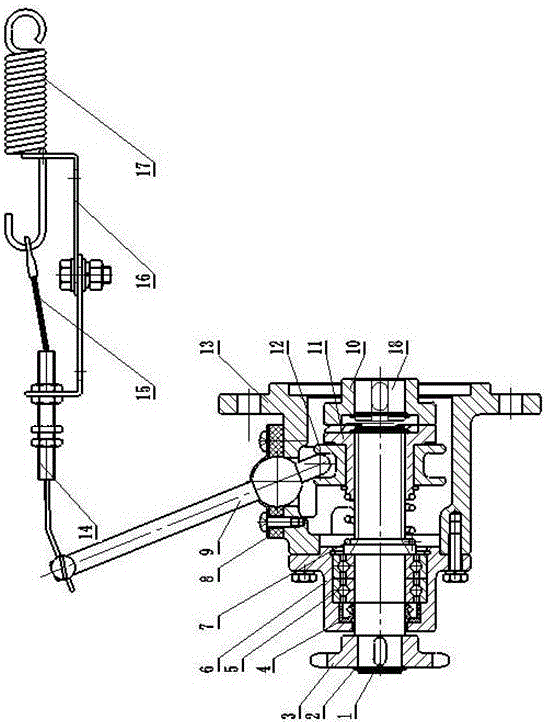

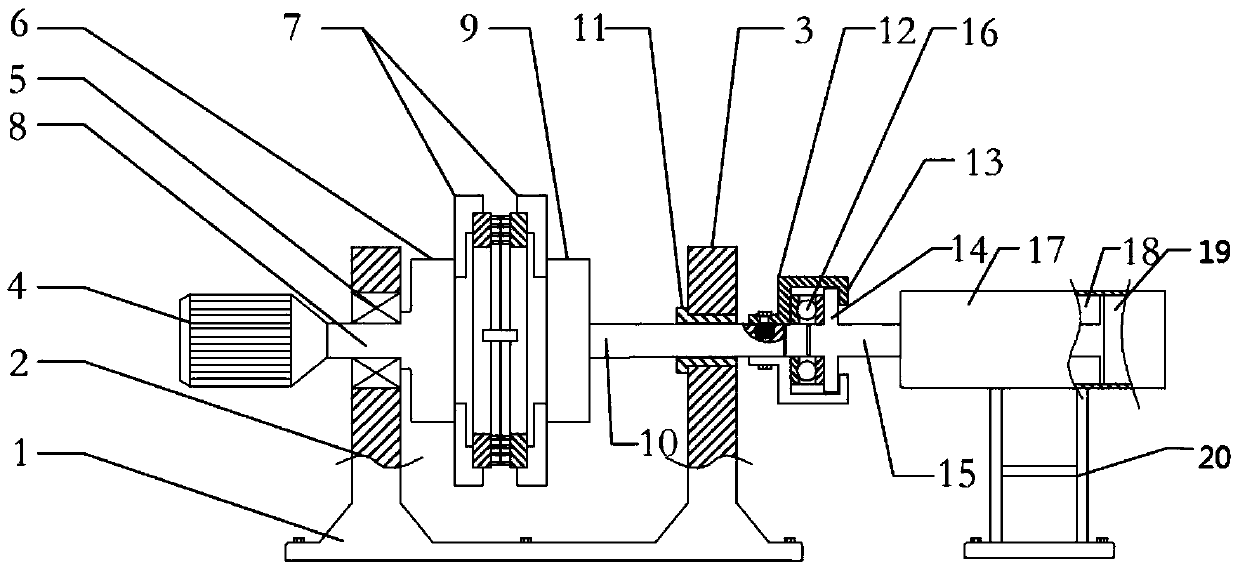

Mechanical clutch transmission device for combined seed and fertilizer drill

InactiveCN105156488AImprove the quality of sowing and fertilizingReduce wasteInterengaging clutchesFertiliser equipmentsDrive shaftSprocket

The invention discloses a mechanical clutch device for a combined seed and fertilizer mill. The mechanical clutch device comprises a clutch flange. One end of the clutch flange is fixedly provided with a main drive shaft through a semi-clutch A. The end, opposite to the above end, of the clutch flange is fixedly provided with a spline shaft through a semi-clutch B. The semi-clutch A and the semi-clutch B which are provided with teeth on the opposite end faces form a jaw clutch. The spline shaft is fixed to the clutch flange through cascading connection of a bearing and a bearing seat. The free end of the spline shaft is fixedly provided with a chain wheel through a clamp spring. A spline shaft body is axially provided with a compression spring. The semi-clutch B is connected with the semi-clutch A under the action of the compression spring. A shifting fork ring is circumferentially arranged on the semi-clutch B. A shifting fork bar is correspondingly arranged in the shifting fork ring and fixed into the clutch flange through a guide cover. The free end of the shifting fork bar is connected with a control end through a wiring assembly. The mechanical clutch device is stable, reliable and easy to operate, avoids seedling missing and excessive seeding, reduces waste and guarantees that production and income of crops are increased.

Owner:金湖小青青机电设备有限公司

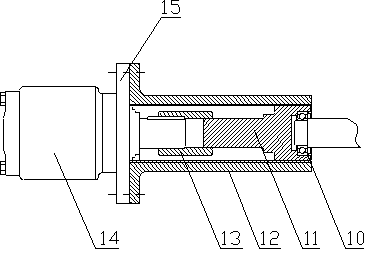

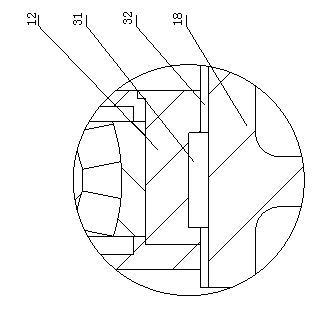

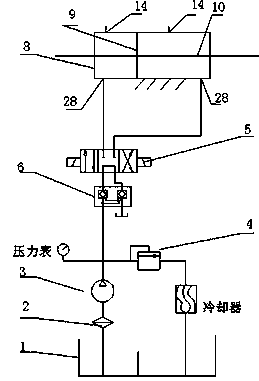

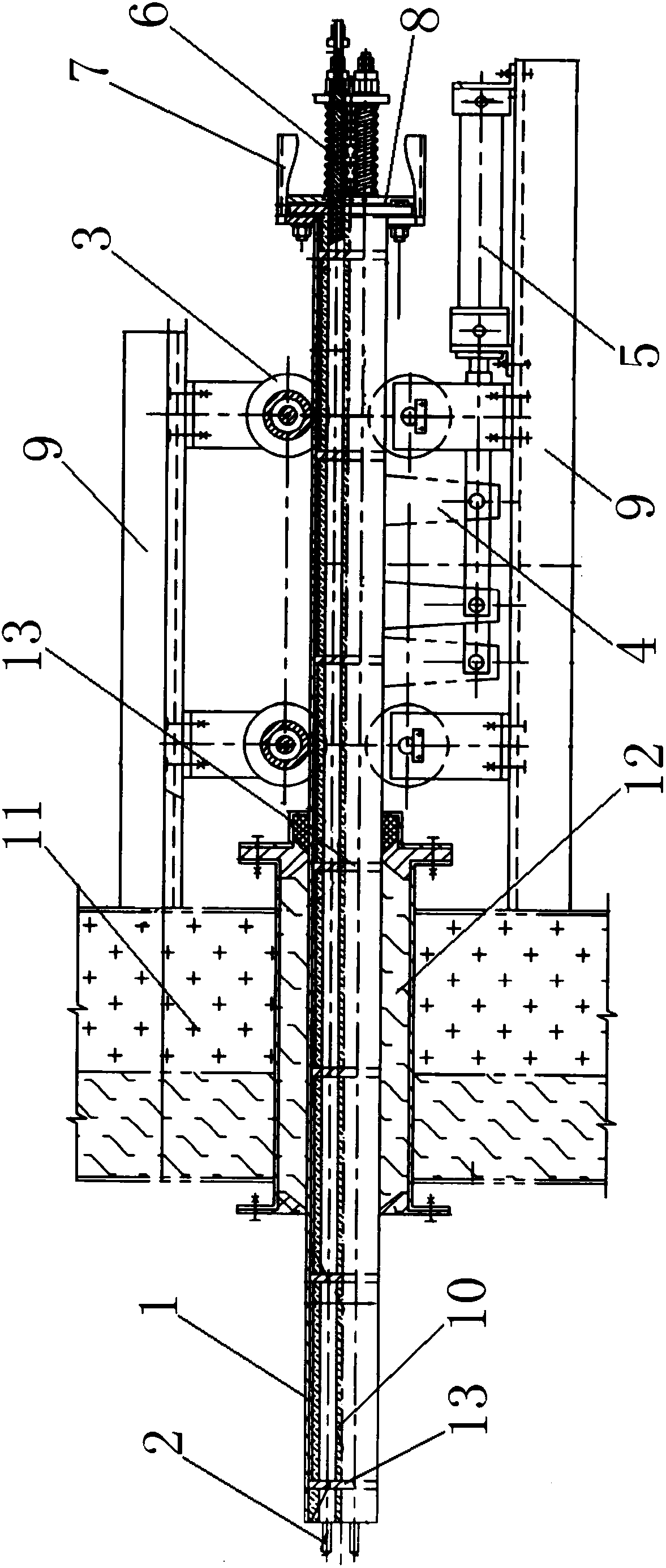

High-consistency hydraulic disc mill

InactiveCN103255667AEasy to adjustConvenient refining specific pressurePulp beating/refining methodsHydraulic cylinderDisc mill

A high-consistency hydraulic disc mill comprises a spiral feed unit, a hydraulic adjusting unit and a high-consistency disc mill body, wherein the rotating speed of a conveying screw is adjusted by a variable-frequency and variable-speed motor, and feed quantity of the high-consistency disc mill is matched with the defibrination output of the high-consistency disc mill. The hydraulic adjusting unit is composed of an oil tank, a hydraulic pump, a solenoid directional valve, a pressure regulating valve, a pressure retaining valve, a hydraulic cylinder, a piston, a thrust cylinder, a cooler, the pressure regulating valve and a pressure gauge, wherein the hydraulic cylinder is fixed on a bearing body suspended frame, the piston is fixed on the thrust cylinder, one end of the thrust cylinder is fixed on an front bearing cover, and a mechanical limiting fine tuning nut is arranged at the other end of the thrust cylinder. The high-consistency disc mill body is composed of a machine shell, a machine cover, a fixed disc, a rotating disc, the bearing body suspending frame, a bearing body, a shaft, a coupler and a motor, wherein the fixed disc is fixed on the machine cover and the rotating disc is fixed on the shaft. Due to the fact that the hydraulic regulating unit which is provided with a pressure retaining return circuit regulates the advancing and the retreating of a knife and defibrination specific pressure, producing of high-consistency milled defibrination with the fixed specific pressure is achieved, energy is saved, and defibrination efficiency is improved.

Owner:SOUTH CHINA UNIV OF TECH

Medical infusion machine

InactiveCN106215277ALow costImprove reliabilityMedical devicesPressure infusionEngineeringMechanical engineering

The invention discloses a medical infusion machine which comprises an intelligent control system, an alarming device, a driving device and a piston reciprocating pump. The alarming device, the driving device and the piston reciprocating pump are connected with the intelligent control system respectively, the piston reciprocating pump comprises a pump body and a piston body mounted on the side face of the pump body, a pump cavity is arranged in the pump body and communicated with a piston cavity of the piston body, a piston rod is arranged in the piston body, and a sealing ring is arranged between the piston body and the piston rod. The medical infusion machine is more accurate in infusion flow control, capable of realizing infusion with different flows for different patients and different medicine liquids, more durable and higher in reliability.

Owner:鲁绍荣

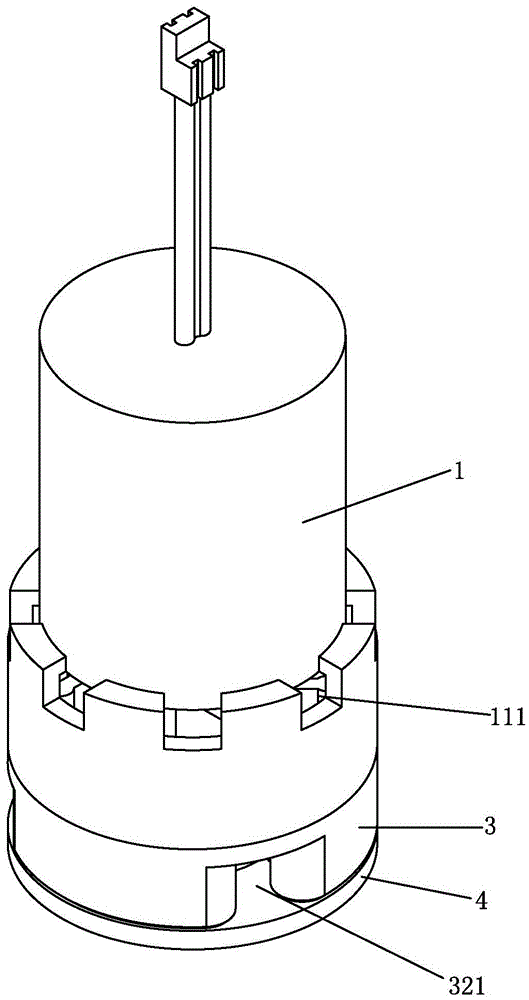

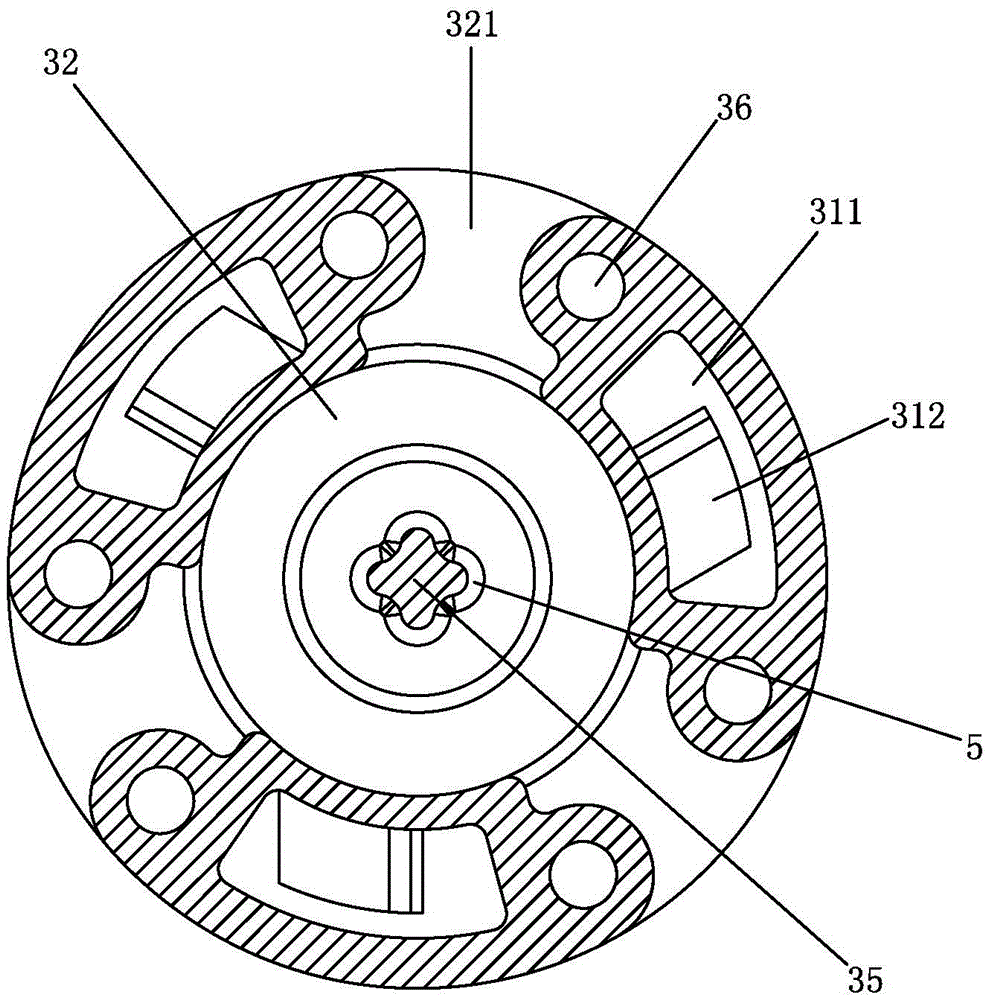

Rotor, motor, water pump and vehicle

InactiveCN109921530AStable and reliable sealingThere will be no displacement or even prolapseMagnetic circuit rotating partsManufacturing stator/rotor bodiesFastener

Owner:GUANGDONG WELLING AUTO PARTS CO LTD

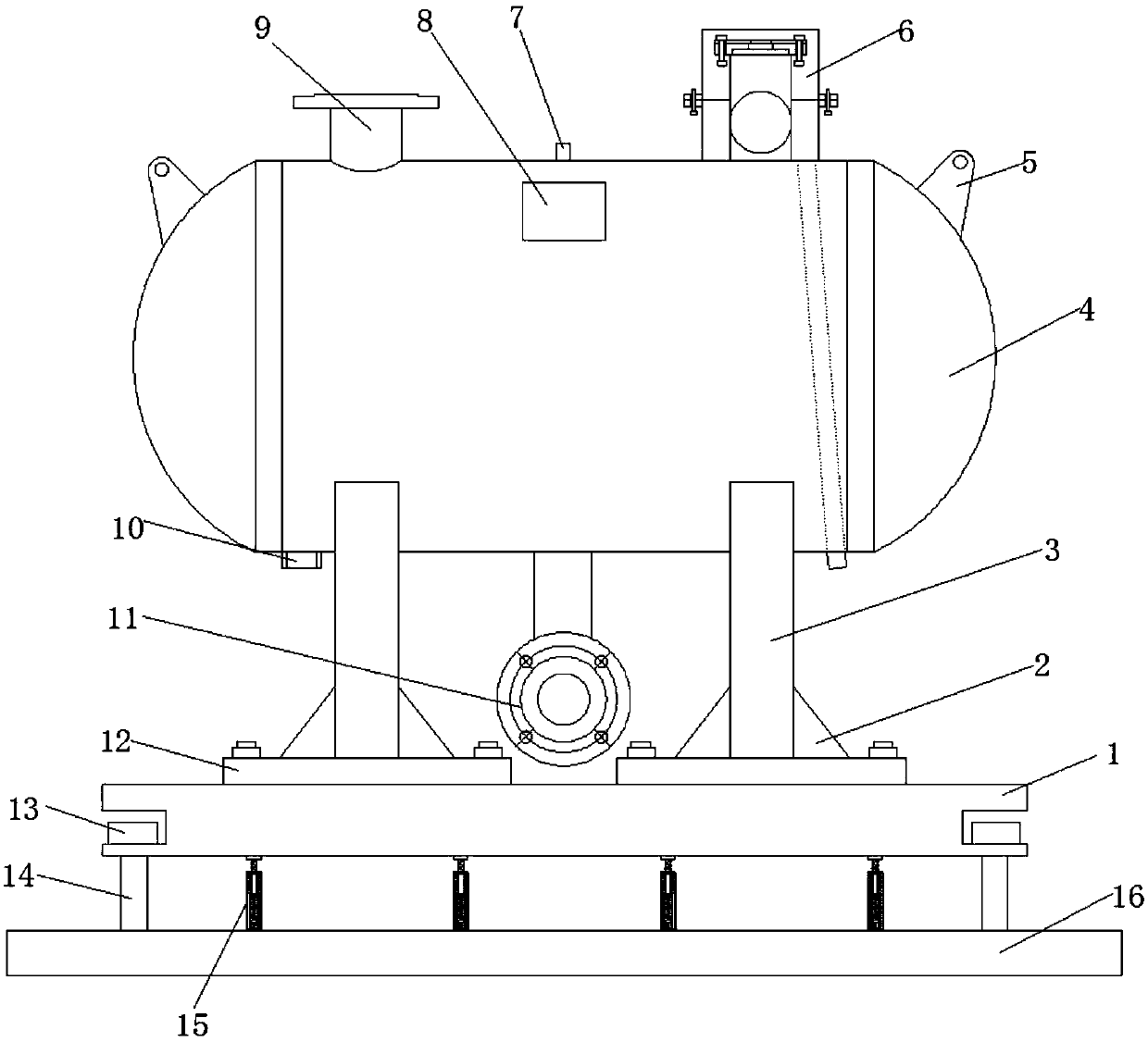

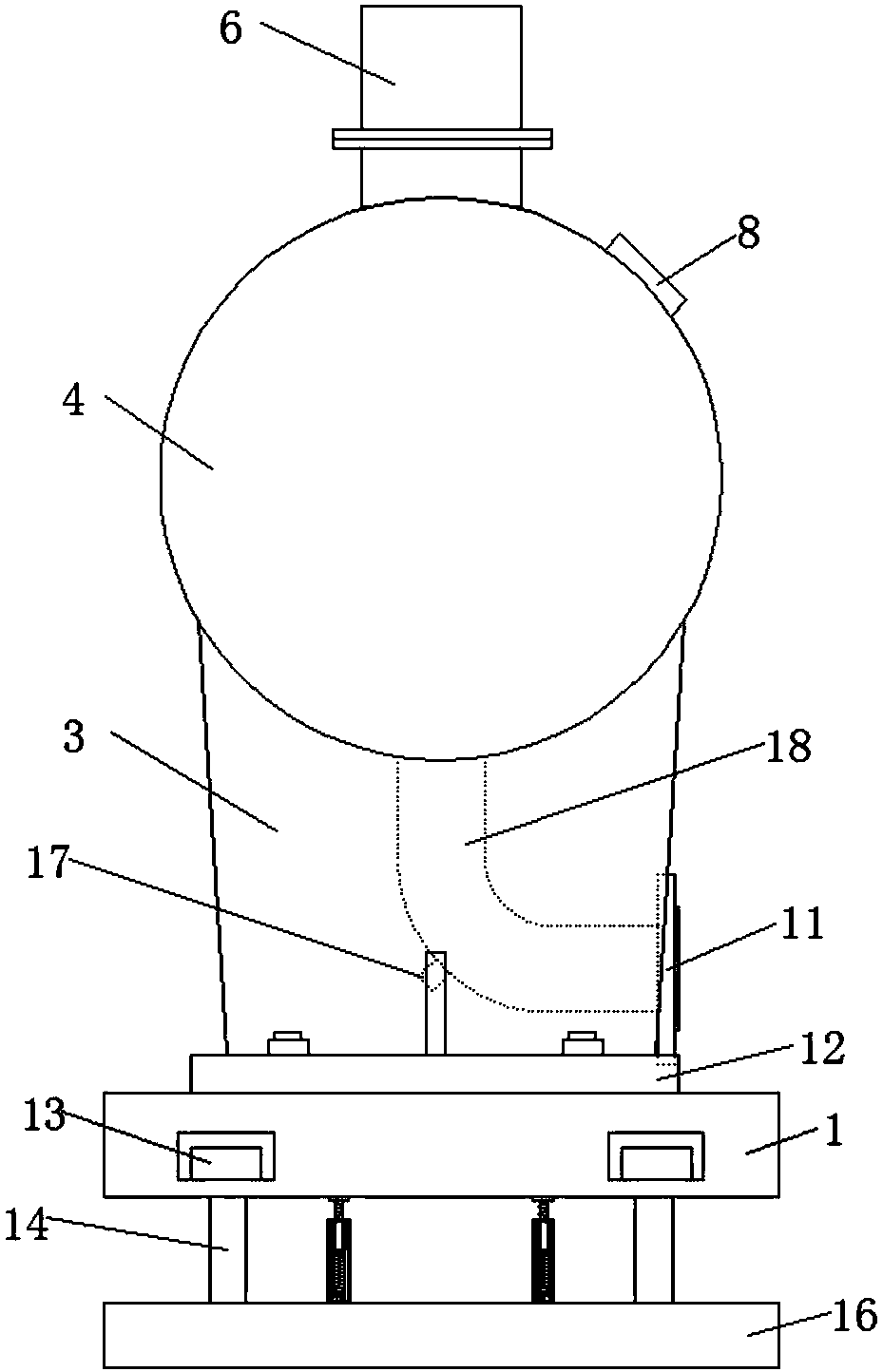

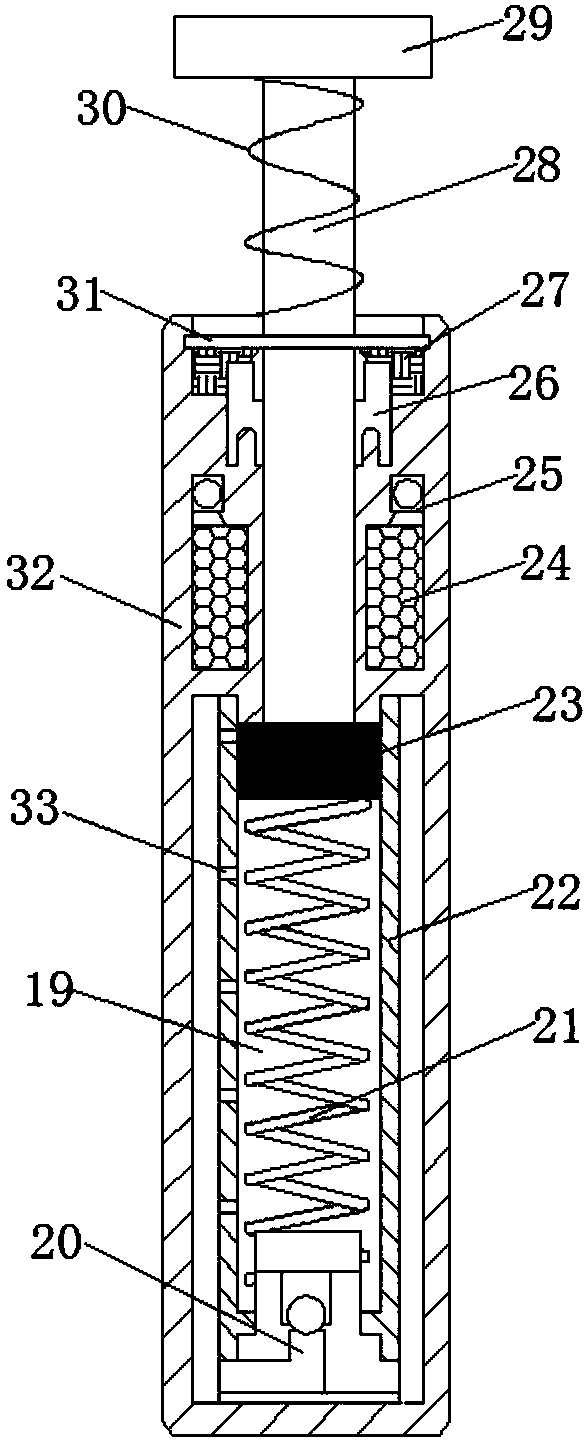

Non-vacuum water supply device steady flow compensator

PendingCN107700599APrevent overflowAvoid enteringWater supply tanksWater conservationAbsorption effectWater pipe

The invention discloses a non-vacuum water supply device steady flow compensator. The non-vacuum water supply device steady flow compensator includes a base; a plurality of cavities are symmetricallyformed in the base; limiting blocks are arranged in the cavities; each limiting block is fixedly connected to a limiting column, and the lower end of the limiting column passes through the base and has a bottom plate; a plurality of shock absorbers are evenly arranged between the base and the bottom plate; two supporting seats are symmetrically arranged on the base through locking screws; each supporting seat is fixedly connected to a support; a tank is arranged on the two supports; a water inlet pipe and a lower breathing type vacuum suppressor are arranged on the tank; a water shortage protection pipe and a water outlet pipe are welded onto the tank; a blowoff pipe is arranged on the water outlet pipe; and two lifting lugs are symmetrically welded onto the tank. The non-vacuum water supply device steady flow compensator is simple in structure, is easy to use, is table in structure, is good in shock absorption effect, can reduce shock during working, can reduce damage to parts of thedevice, can prolong the service life, and is worthy of promotion.

Owner:XINGAN ANHUI ELECTRIC LTD BY SHARE LTD

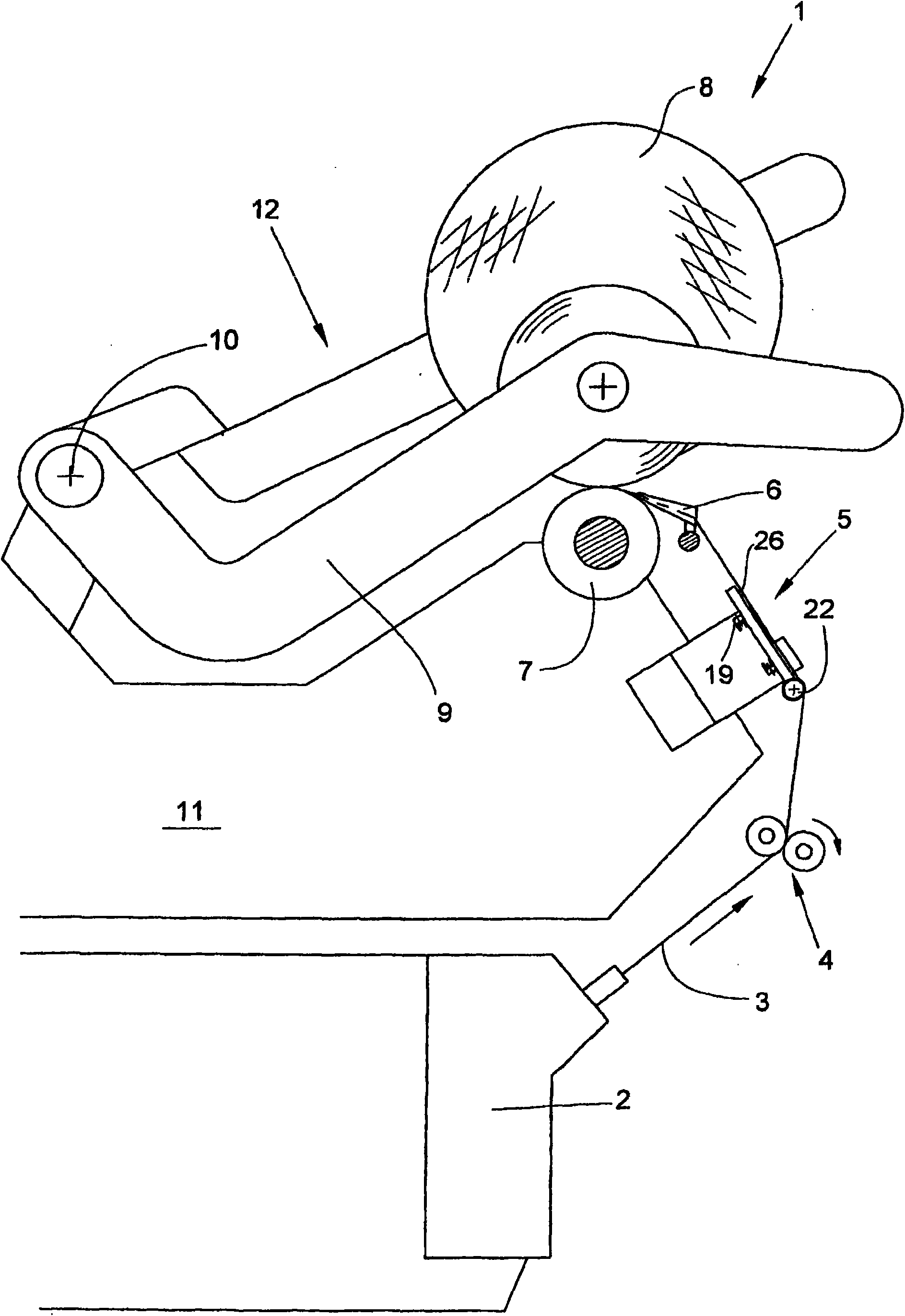

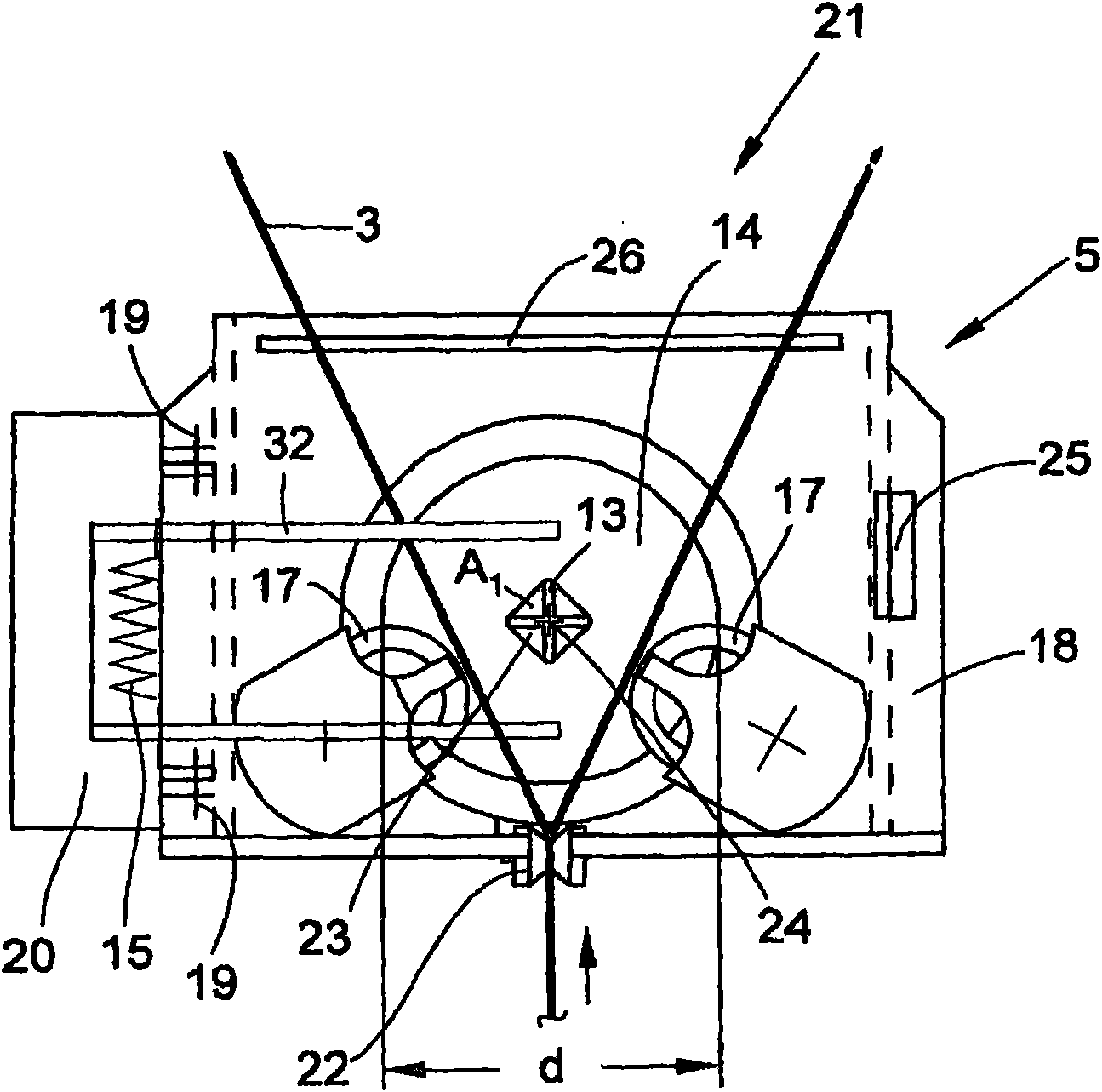

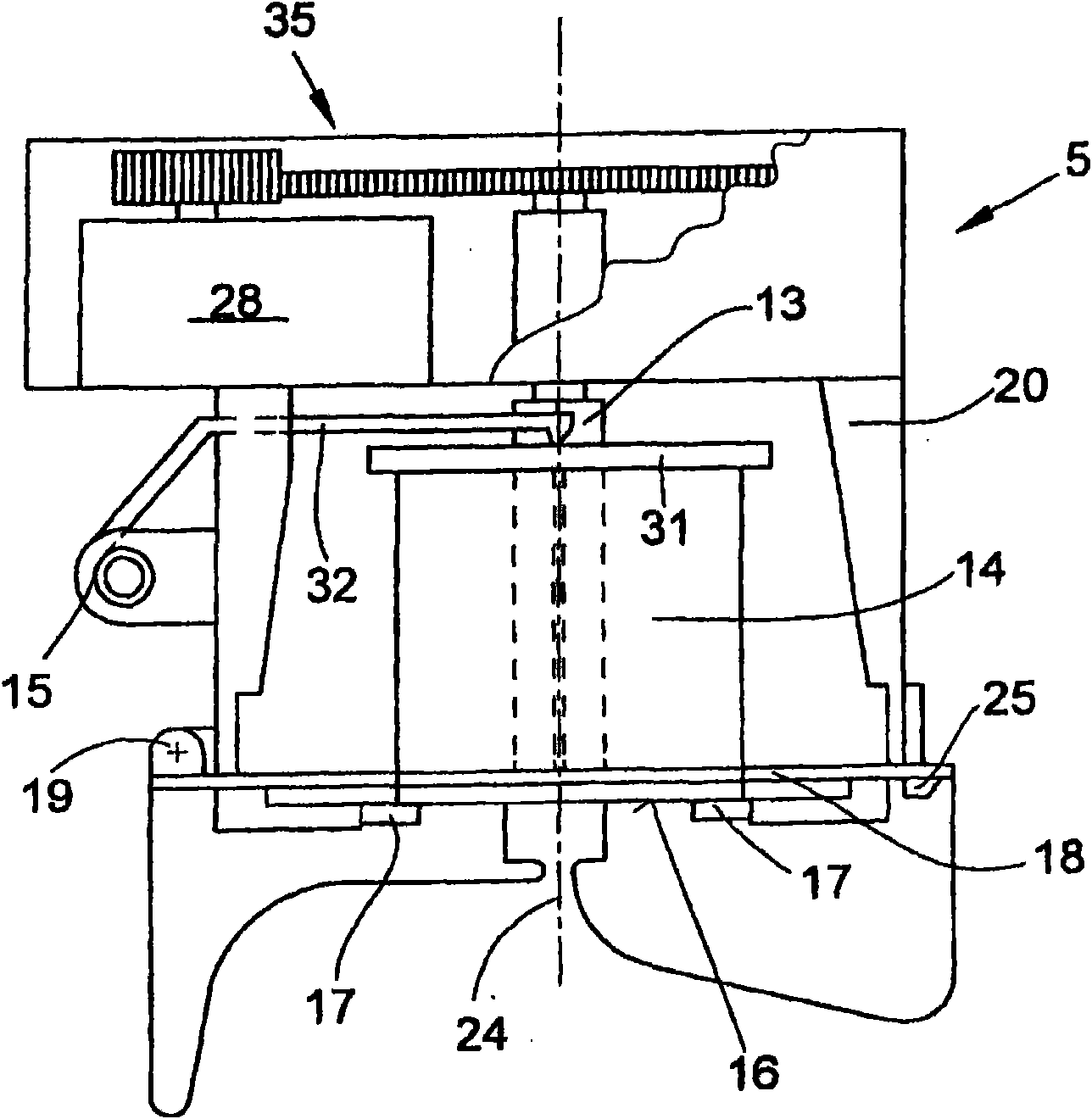

Paraffin-treatment device for a workstation on a textile machine producing cross-wound bobbins

InactiveCN101657373APromote conversionChange cross sectionFilament handlingTextiles and paperBobbinEngineering

The invention relates to a paraffin-treatment device (5) for a workstation (1) on a textile machine producing cross-wound bobbins, having a drive and bearing shaft (13) that can be rotationally movedand on which a paraffin body (14) is supported in a rotationally fixed, but axially displaceable manner, having a receiving opening (23) in the region of the central longitudinal axis (35) thereof. According to the invention, in a first embodiment, the drive and bearing shaft (13) has a bearing region (27) designed such that a paraffin body (14) of a first type can be slid onto it, having a receiving opening (23) having a first cross section (A1), and that the bearing region (27) of the drive and bearing shaft (13) is expandable in the dimension thereof such that the expanded bearing region (27) can support a paraffin body (14A) of a second type, the receiving opening (23A) thereof having a second cross section (A2).

Owner:SAURER GERMANY GMBH & CO KG

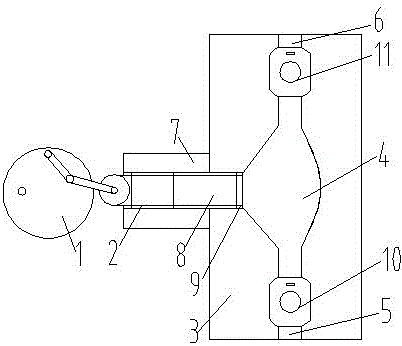

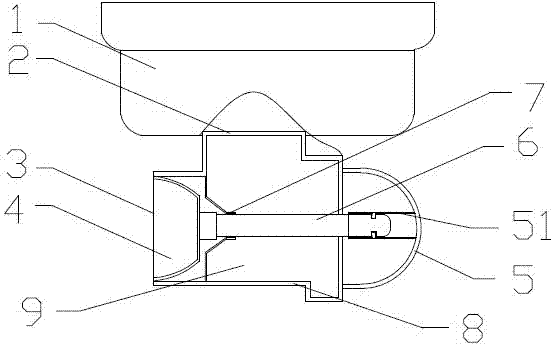

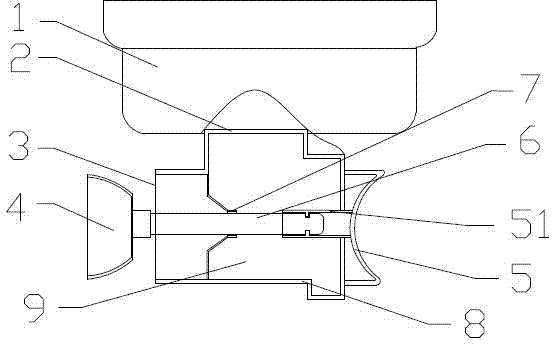

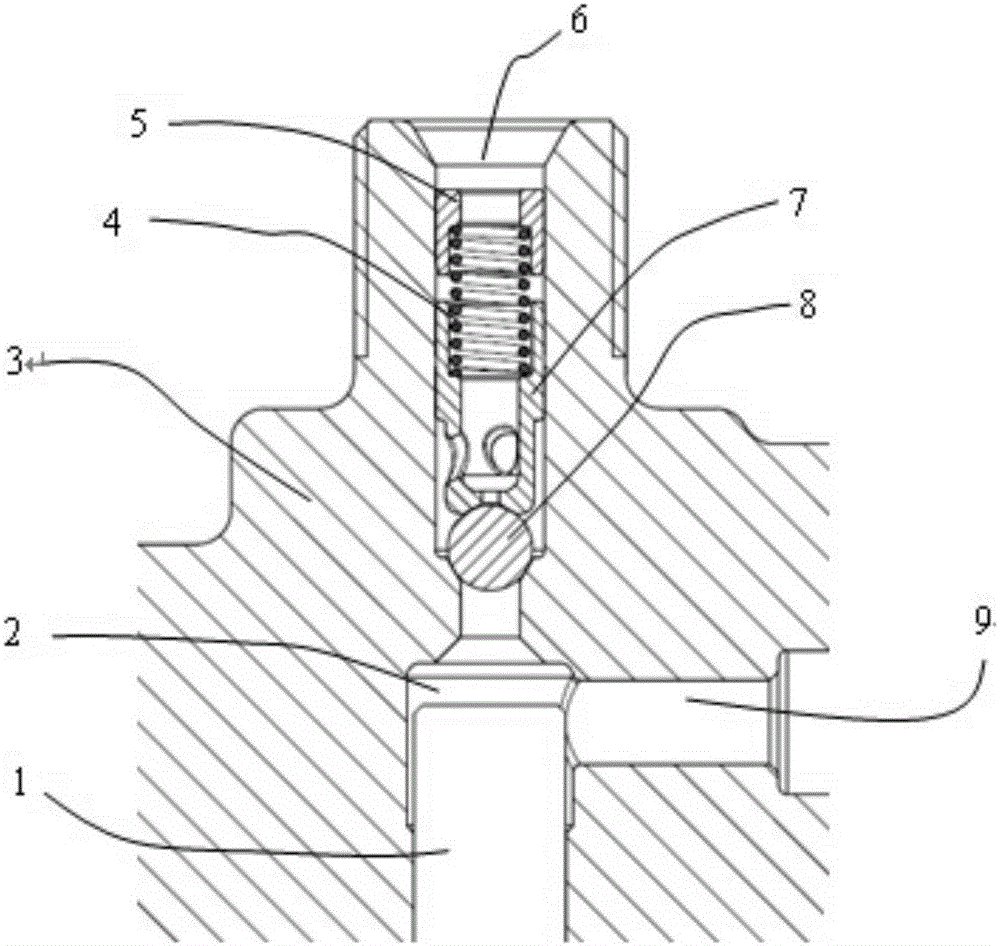

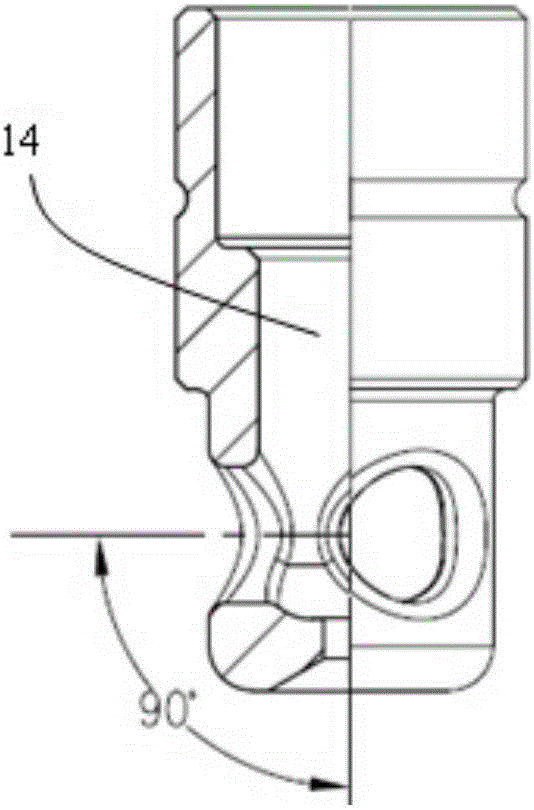

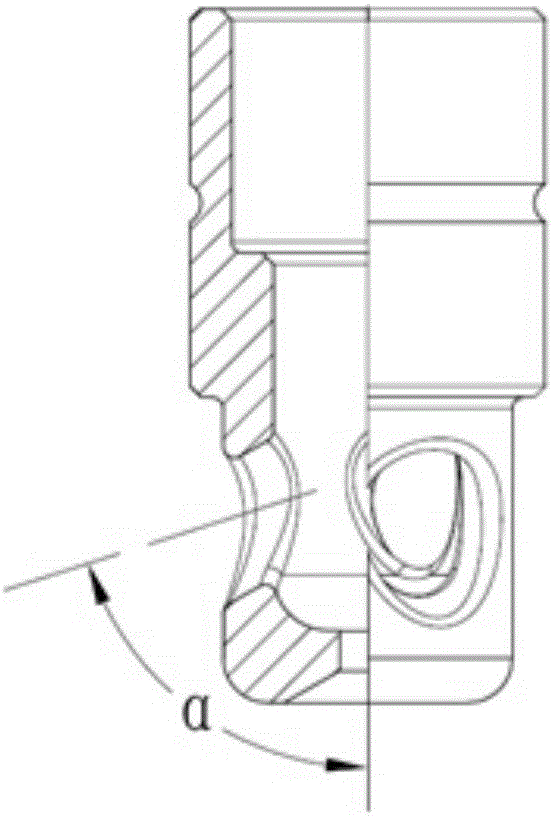

Liquid valve

InactiveCN102313032AOpen quicklyQuick closeOperating means/releasing devices for valvesSlide valveVolume bodyEngineering

The invention discloses a liquid valve, which comprises a connecting cover (1), a valve body (8), a liquid inlet (2), a liquid outlet (3), a passage, a sealing valve plate (4), an elastic gland (5) and a connecting rod (6), wherein the connecting cover (1) is connected with a volume body; the valve body (8) is fixedly connected with the connecting cover (1); the liquid inlet (2) is formed at the junction of the connecting cover (1) and the valve body (8); the liquid outlet (3) is formed on the valve body (8); the passage is used for communicating the liquid inlet (2) with the liquid outlet (3); the sealing valve plate (4) is matched with the liquid outlet (3); the elastic gland (5) is axially limited and sealed with the valve body (8) and is arranged on the valve body (8) at the other end away from the liquid outlet (3); and the connecting rod (6) is connected with the sealing valve plate (4) and the elastic gland (5). The liquid valve has the advantages of quickness in opening and closing, simple structure, convenience in operation and low in manufacturing cost.

Owner:宁波市鄞州华邦电子有限公司

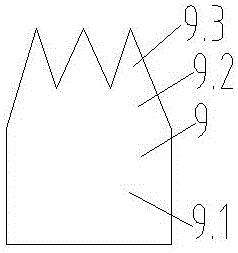

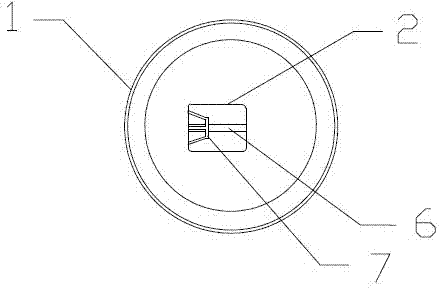

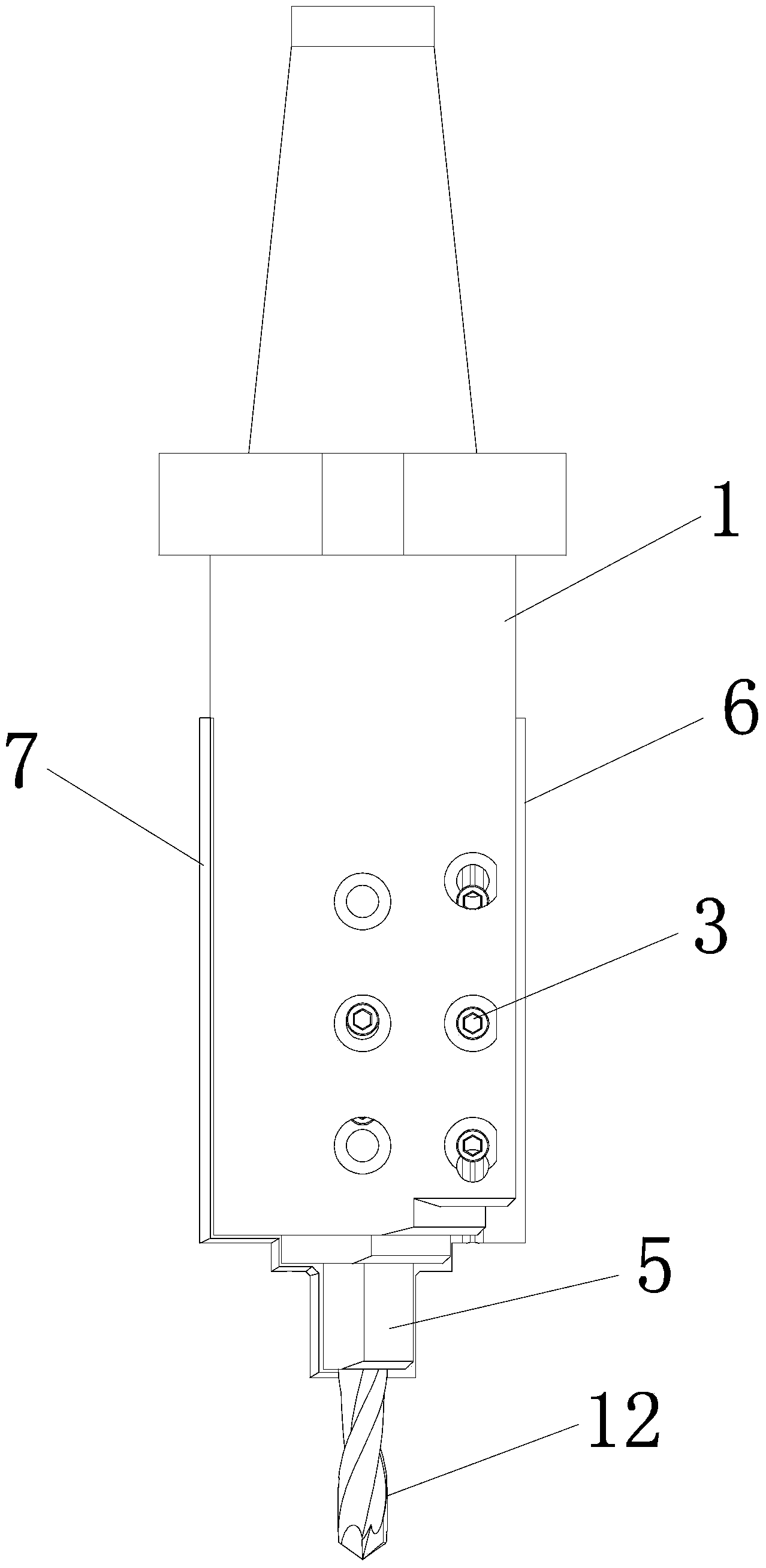

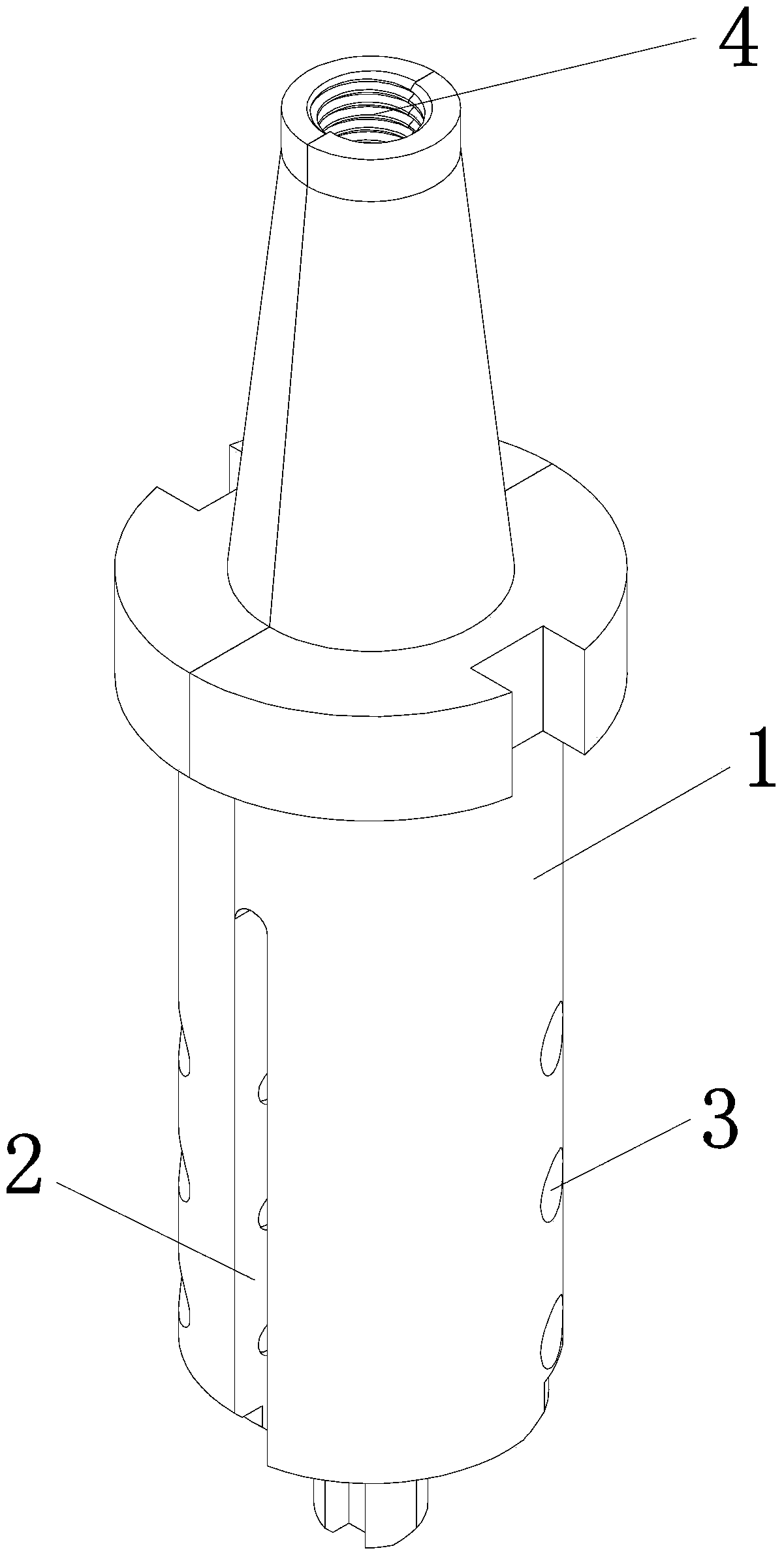

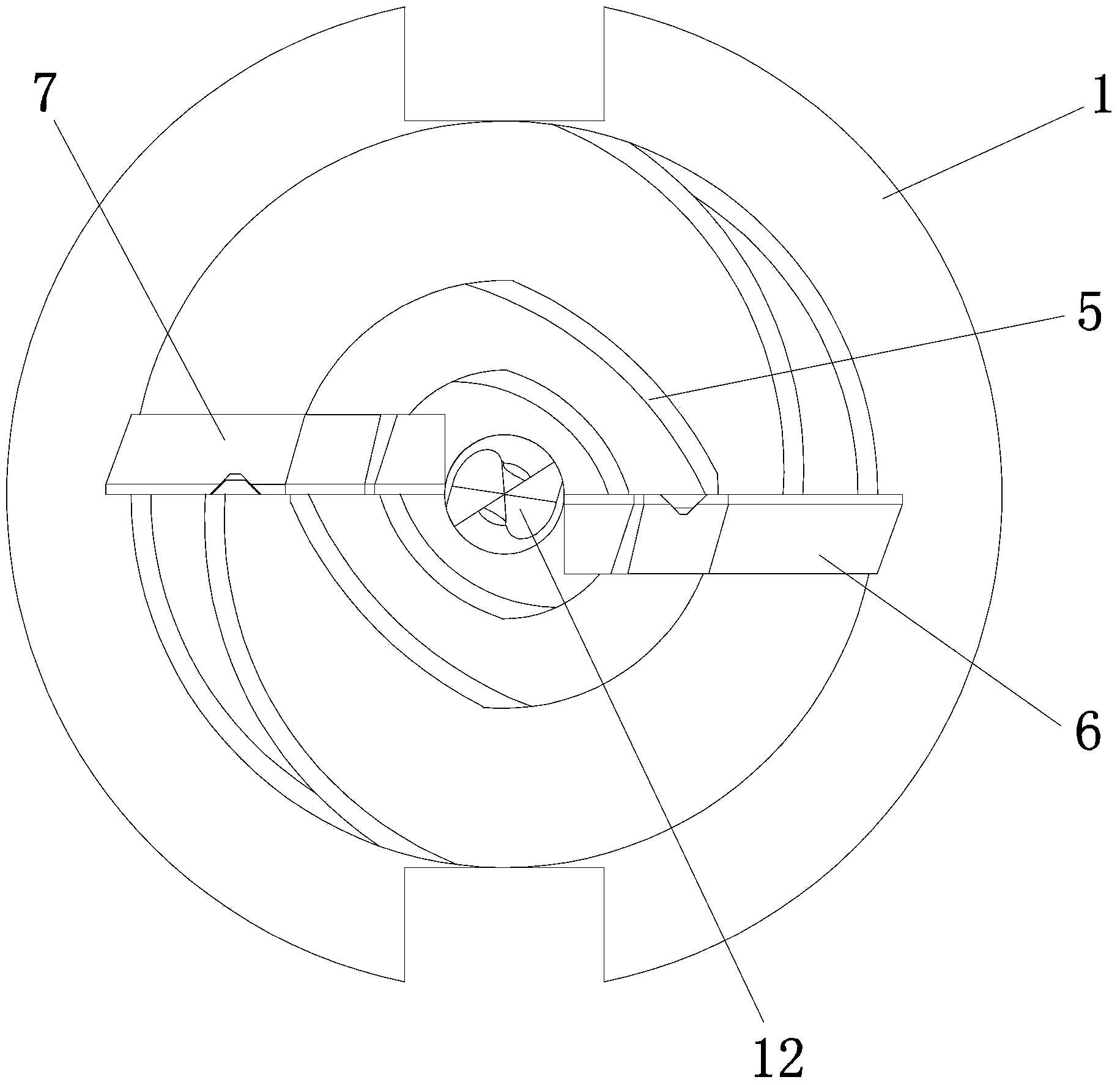

Multifunctional combined tool special for machining of stepped holes

InactiveCN103447592AEasy to processReduce workloadTransportation and packagingTrepanning drillsMachine toolMachining

The invention relates to a machining tool, in particular to a multifunctional combined tool special for machining of stepped holes. The multifunctional combined tool special for machining of stepped holes comprises a tool holder and blades. The blades include an end machining blade and a radial machining blade. One end of the end machining blade and one end of the radial machining blade are provided with stepped hole machining teeth in step forms. The end of the tool holder is provided with a clamping channel and a bit positioning hole. A bit is disposed inside the bit positioning hole. The clamping channel comprises a first clamping part used for clamping the end machining blade and a second clamping part used for clamping the radial machining blade. The first clamping part locates on the diametric section of the tool holder. The lower end face of the second clamping part and the upper end face of the first clamping part locate in a same plane. One end of the end machining blade, close to the radial machining blade, is parallel to the axis of the tool holder. The multifunctional combined tool has the advantages that the diametric part of each segment of a stepped hole can be machined once, and the end face and diametric part of the stepped hole can be machined at the same time.

Owner:ZHEJIANG GEELY POWERTRAIN CO LTD +3

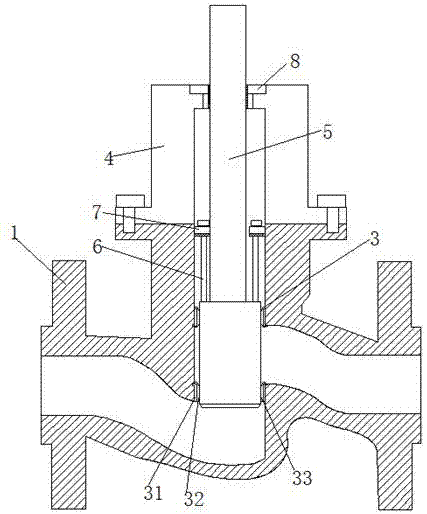

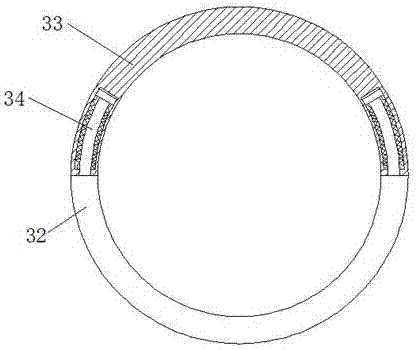

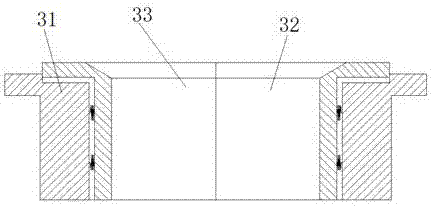

High-pressure-resistant regulating valve

InactiveCN107101008AAvoid offsideGuaranteed axial movementLift valveValve housingsHigh pressureValve seat

The invention discloses a high-pressure-resistant regulating valve. The high-pressure-resistant regulating valve comprises a valve body. A valve body inlet and a valve body outlet are formed in the two sides of the valve body correspondingly. A valve element is arranged at the junction of the valve body inlet and the valve body outlet. A valve seat matched with the valve element is arranged on the valve body. A mounting base is fixed to the valve body, and a first sealing plate and a second sealing plate are connected to the inner side of the mounting base through springs. Limiting plates are arranged at the two ends of the first sealing plate correspondingly. A sliding clamp block is arranged at the end, away from the first sealing plate, of each limiting plate. A valve deck is arranged on the upper side of the valve body. A valve rod is perpendicularly arranged at the center of the side, close to the valve deck, of the valve element. Two guide rods which are perpendicularly mounted on the valve element are arranged on the outer side of the valve rod. Two supporting plates in symmetrical positions are arranged on the inner wall of the valve body. Guide through holes which are matched with the guide rods are formed in the supporting plate. The high-pressure-resistant regulating valve is simple in structure and good in airtightness, abrasion of the regulating valve is effectively reduced, and the service life of the valve is prolonged.

Owner:YANCHENG WEILE VALVE MFG CO LTD

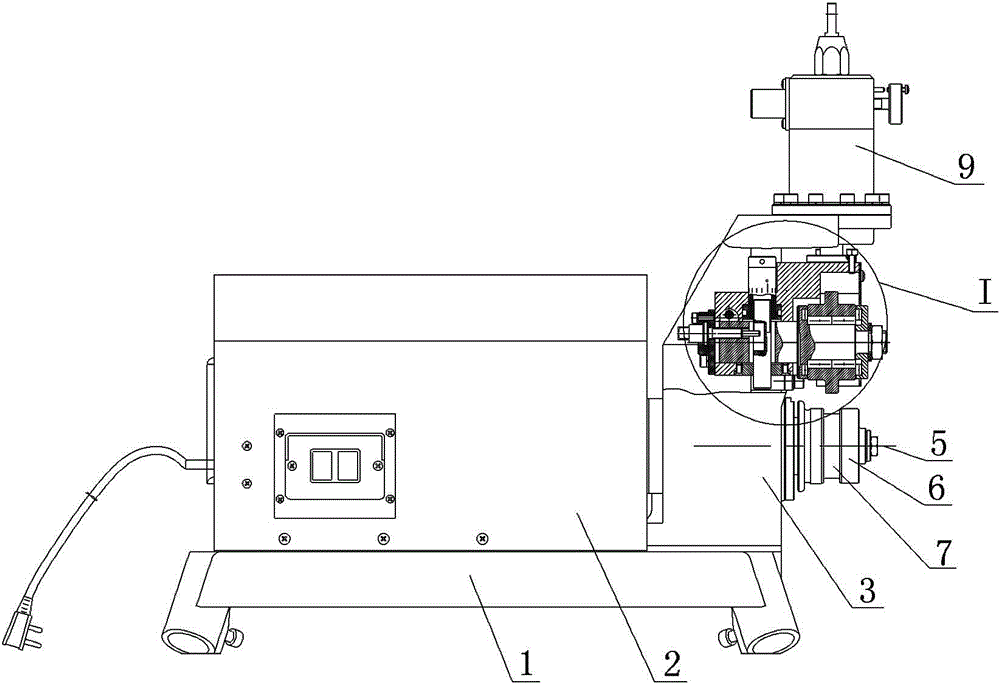

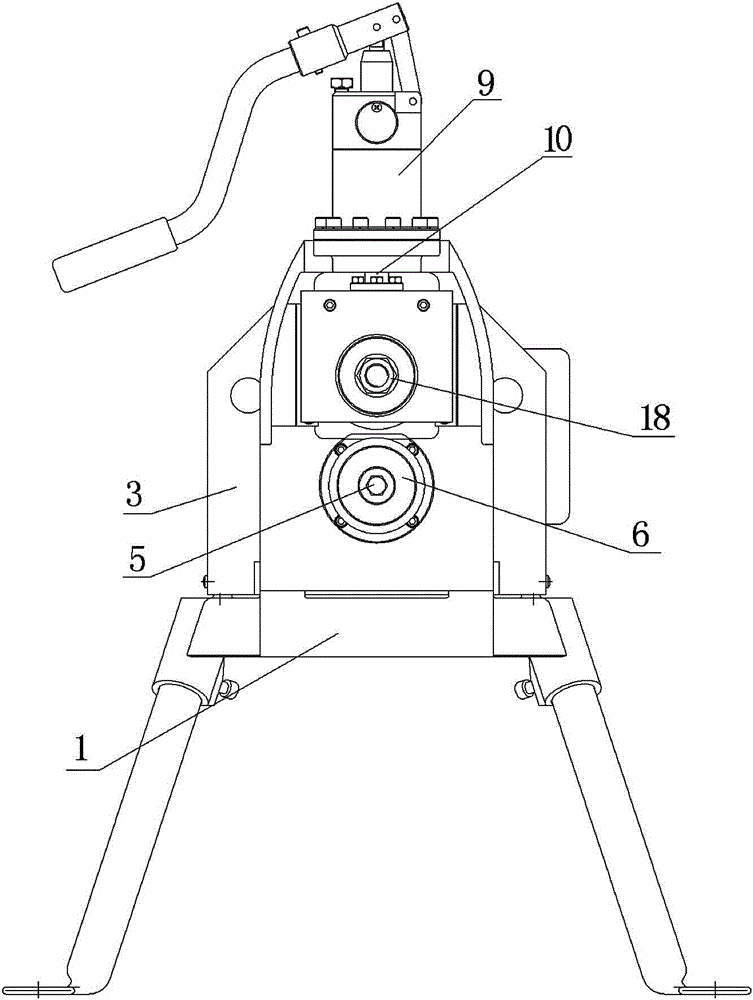

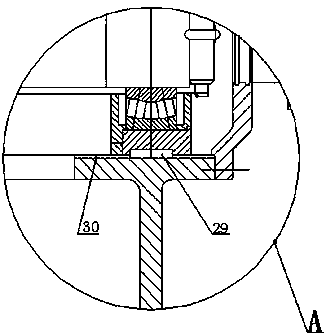

Channeling machine

The invention discloses a channeling machine. The channeling machine comprises a platform (1), a dial (4), a main shaft (5), a machine case (2) and a framework (3) arranged on the platform (1) and a motor and a speed reducer arranged in the machine case (2), wherein the motor is connected with the speed reducer; the main shaft (5) is provided with a knurl wheel (6) with a flange plate at an exposed side of the framework (3); rectangular guide rails (11) are respectively mounted at two sides of a right side plane of the framework (3) through bolts; the top end of a supporting rod is in threaded fit with the dial (4); the lower part of the supporting rod is matched with an end cover A (13) mounted on the bottom of the slide base (8), and extends out of the end cover A (13); the left end of a pressure wheel shaft (14) is provided with a threaded hole (27); a screw (26) is screwed into the threaded hole (27) in the tail part of the pressure wheel shaft (14); the right side of the screw (26) is provided with a cylinder (28); and the cylinder (28) extends into a long circular slot (24). The channeling machine has the beneficial effects of a long service life, convenience in replacing the pressure wheel, and simple operation.

Owner:CEC JINJIANG INFO IND

Assembly welding tool for wheel disc body and application method

ActiveCN106736209AButt seamlessAvoid deformationWelding/cutting auxillary devicesAuxillary welding devicesInterference fitRolling-element bearing

The invention discloses an assembly welding tool for a wheel disc body and an application method. The assembly welding tool comprises a support seat, a left support upright, a right support upright, a stepping motor, a rolling bearing, a driving chuck, a short shaft, a long clamping jaw, a driven chuck, a long shaft, a bearing sleeve, a return shaft sleeve, a return pull disc, a push pull disc, a push shaft, a thrust bearing, an air cylinder, a working air chamber, a return air chamber and an air cylinder bracket, wherein the support seat comprises the left and right support uprights; the short shaft is in interference fit connection with the left support upright through the rolling bearing; the long shaft is in clearance fit connection with the bearing sleeve; the bearing sleeve is in interference fit connection with the right support column; and the long clamping jaw is embedded in the driving chuck and driven chuck. The technical scheme disclosed by the invention overcomes the deformation problem of free quenching of the wheel disc body, solves the cracking problem caused by pressure quenching and increases the product yield.

Owner:LEADRUN MAODA CASTING JIANGSU +1

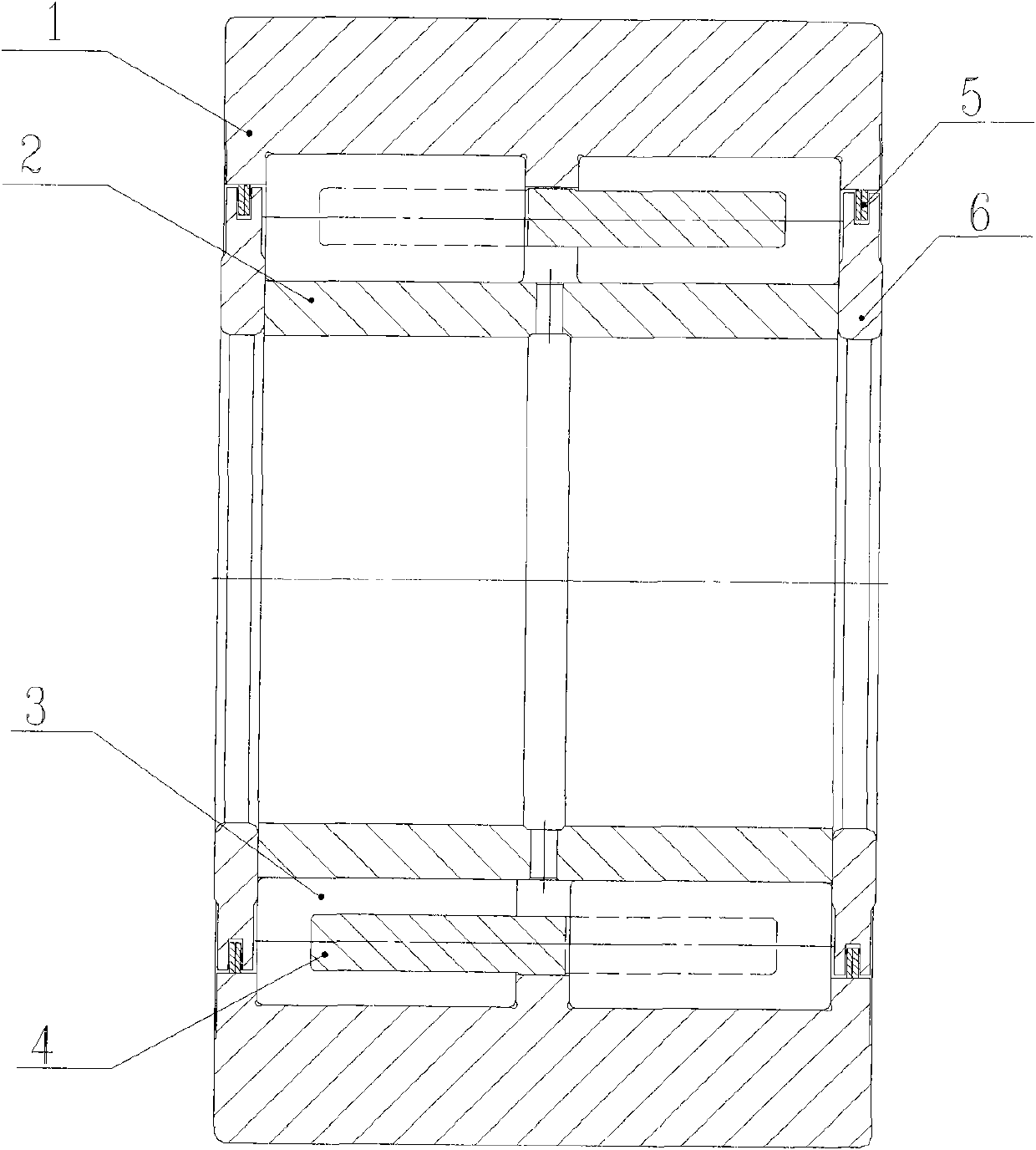

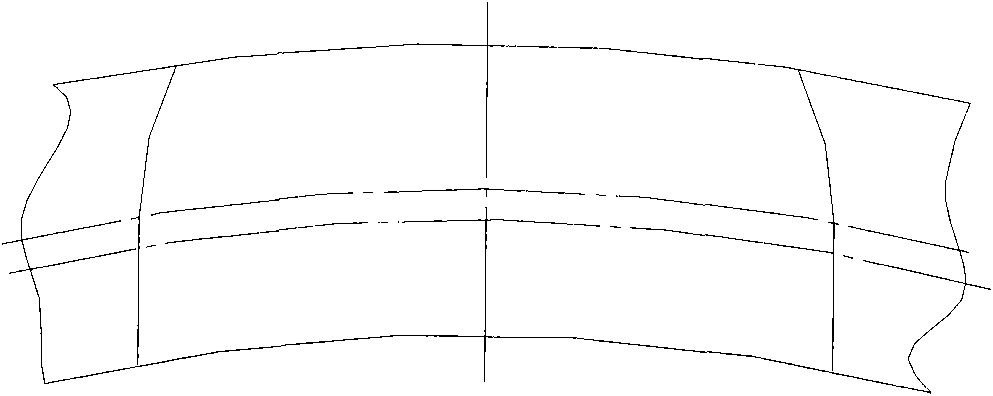

Comb retainer for Sendzimir bearing

The invention belongs to the technical field of bearings, in particular to a comb retainer for a Sendzimir bearing. The retainer is in a retainer pocket structure shape of a double-segment type comprising an arc and a line and is in the combined type of a part of arc shape and a part of line shape instead of the shape of simple arc pockets, and the depths of the pockets adopt an alternate arrangement mode that one is deep and another is shallow. The invention has the advantages that (1) the common single arc pocket structure of the retainer is changed into the combined type of an arc and a line so that a roll to be assembled can be mounted from the internal diameter of the retainer to avoid scratching a bearing roll and further ensure the accuracy and the service life of the bearing; and (2) the depths of the pockets adopt the alternate arrangement mode that one is deep and another is shallow so as to ensure the axial cascading of the retainer, more importantly improve the lubrication, avoid abrasion and overhigh temperature rise in the high-speed rotation of the bearing and improve the service life and the stability of the bearing.

Owner:WAFANGDIAN BEARING GRP CO LTD

Matrix mixing device for breeding earthworms

PendingCN114797644AStir wellImprove the mixing effectShaking/oscillating/vibrating mixersTransportation and packagingReciprocating motionEngineering

The invention discloses a matrix mixing device for breeding earthworms, relates to the technical field of mixing devices, and aims to provide a matrix mixing device for breeding earthworms, which can fully stir materials between upper and lower stirring blades and improve the mixing effect. The stirring mechanism is used for stirring materials so that the materials can be fully mixed, the stirring mechanism comprises a rotating part and a stirring part, the rotating part is arranged below the stirring part, and the transmission mechanism is used for driving the stirring mechanism to rotate at a high speed and driving the stirring part or the rotating part to do reciprocating motion in the vertical direction. The device has the technical effects that the limiting stirring mechanism comprises the rotating component and the stirring component, the long hole is formed in the rotating rod of the rotating component, and the stirring blade of the stirring component can penetrate through the long hole to extend outwards, so that when one component rotates, the other component can be lifted, and the stirring efficiency is improved. And materials between the upper stirring blade and the lower stirring blade can be fully stirred.

Owner:JIANGSU VOCATION & TECHNICAL COLLEGE OF FINANCE & ECONOMICS

Medium concentration hydraulic double disc stuff grinder

ActiveCN102400406BEasy to adjustConvenient beating specific pressurePulp beating/refining methodsHydraulic cylinderElectric machinery

The invention discloses a medium concentration hydraulic double disc stuff grinder, comprising a hydraulic adjusting unit and a medium concentration double disc stuff grinder body. The hydraulic adjusting unit consists of a hydraulic cylinder, an electromagnetic direction valve, a pressure retaining valve, a hydraulic pump, an oil pump motor and an oil tank connected orderly by pipelines. The oil tank is further connected with a cooler, a pressure adjusting valve and a pipeline of a pressure gauge; the medium concentration double disc stuff grinder body consists of a double shell and a shell cover, a coupler, a motor, a bearing body suspension and a bearing body, a shaft, a left fixed disc base and left and right fixed discs, left and right rotary discs and a rotary disc base. The hydraulic cylinder is fixed on the shell cover. One end of the piston rod is fixed on the left fixed disc base while the other end is provided with a mechanism limiting fine-adjusting nut. The left fixed disc is fixed on the left fixed disc base and the right fixed disc is fixed on the shell. The left and right rotary discs are fixed respectively at both sides of the rotary disc base. Tangential stock inlets are arranged on the left fixed disc base and the shell. The shell is provided with a stock outlet. The invention adjusts the definitely proportional pressure of the millstone which feeds and discharges through the pressure retaining valve to pulp in medium concentration, thereby improving the pulping quality and efficiency thereof.

Owner:SOUTH CHINA UNIV OF TECH

H-shaped wheel tightening device for water tank wire-drawing machine

The invention discloses an H-shaped wheel tightening device for a water tank wire-drawing machine. The tightening device comprises a first disc spring tightening mechanism and a second disc spring tightening mechanism which are symmetrically arranged at two ends of an H-shaped wheel in the axial direction. The first disc spring tightening mechanism comprises a first cylindrical mounting seat, a first fixing sleeve, a first end cap and a first sliding shaft; the first fixing sleeve is annularly arranged on a cavity of the first mounting seat and is attached to the inner wall of the cavity; thefirst end cap is arranged at one end of the cavity of the first mounting seat; the first end cap and the first fixing sleeve are fixed in the circumferential direction; and the first sliding shaft penetrates in the middle of the cavity of the first mounting seat in the axial direction. The second disc spring tightening mechanism comprises a second cylindrical mounting seat, a second fixing sleeve,a second end cap and a second sliding shaft, wherein the second fixing sleeve is annularly arranged on a cavity of the second mounting seat and is attached to the inner wall of the second mounting seat; the second end cap is arranged at one end of the cavity of the second mounting seat; the second end cap and the second fixing sleeve are fixed in the circumferential direction; and the second sliding shaft penetrates in the middle of the cavity of the second mounting seat in the axial direction. The H-shaped wheel tightening device for the water tank wire-drawing machine is simple in structure, and is safe and reliable, and thus, the working efficiency of rolling of steel cords is ensured.

Owner:湖北三江航天江北机械工程有限公司

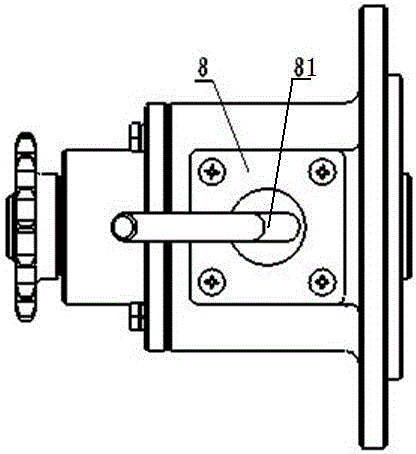

Fuel pump valve element

InactiveCN106523229AGuaranteed axial movementGuaranteed smooth outflowMachines/enginesFuel injecting pumpsSteel ballEngineering

The invention relates to a fuel pump delivery valve, and particularly relates to a fuel pump valve element. The fuel pump valve element comprises a plunger bushing, wherein a plunger cavity and an outlet channel are axially formed in the plunger bushing, the plunger cavity communicates with the outlet channel through a step round hole, a guide sleeve is arranged in the outlet channel, a spherical valve element is arranged between the lower end of the guide sleeve and the upper end surface of the step round hole, a return spring is arranged in an inner hole which is formed in the upper end of the guide sleeve, the lower end of the return spring is limited and fixed by virtue of a step formed by the inner hole of the guide sleeve, the upper end of the return spring is limited and fixed by virtue of a delivery valve spring seat, and the delivery valve spring seat is fixed to the interior of the outlet channel. According to the fuel pump valve element, a steel ball is matched with a conical surface at an outlet of the plunger bushing, so that the processing requirement is reduced. Compared with a traditional ball valve, the guide sleeve structure is designed in the fuel pump valve element, so that the axial movement of the return spring and the ball is guaranteed.

Owner:CHINA FIRST AUTOMOBILE

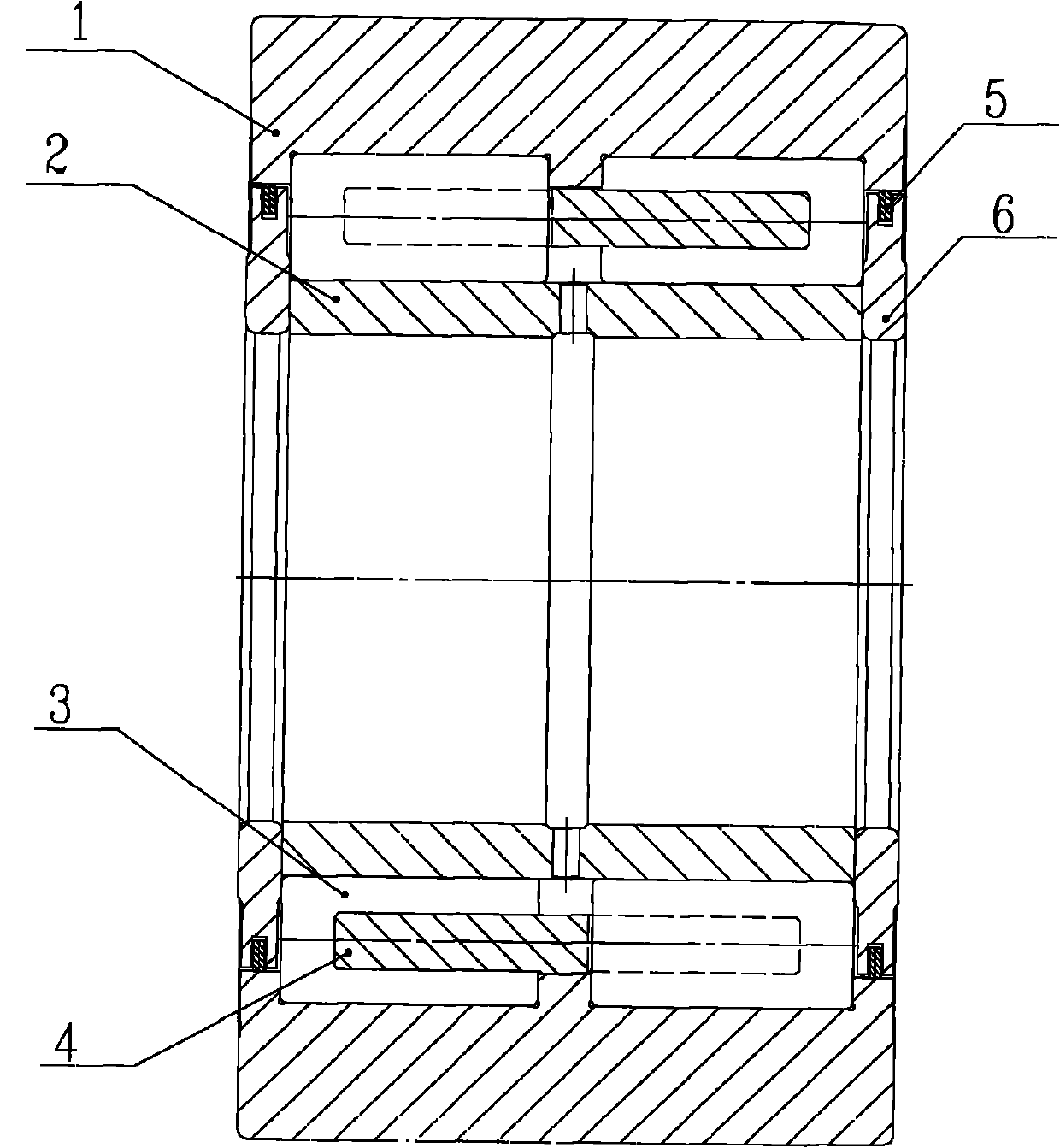

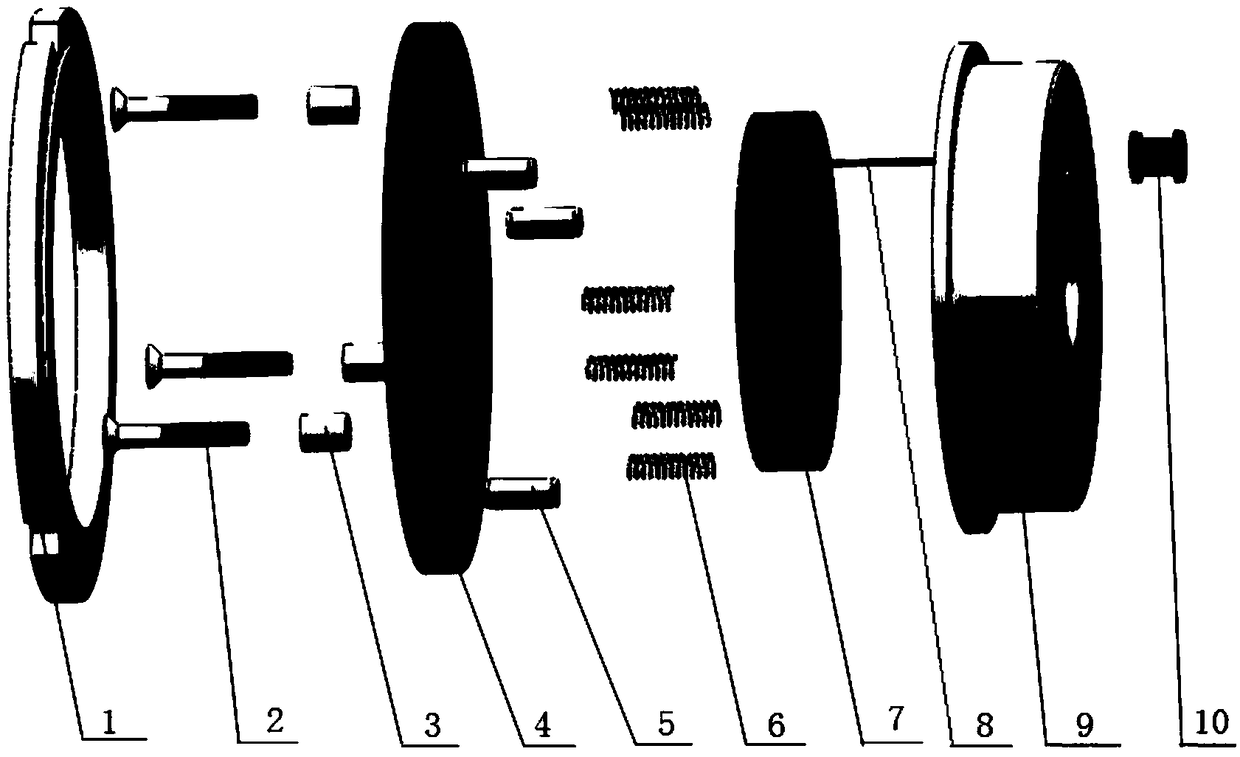

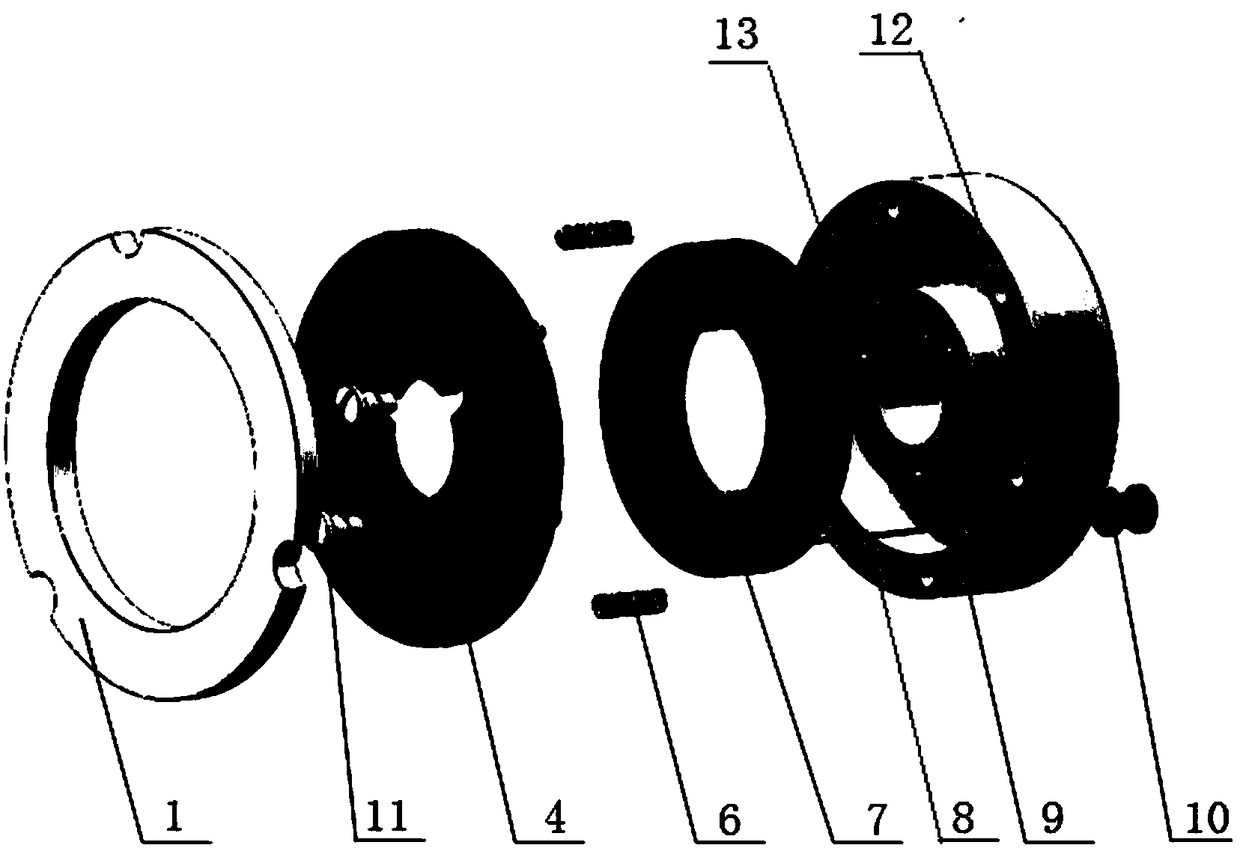

Magnetic motor brake

PendingCN108233611AGuaranteed fixed effectGuaranteed axial movementMechanical energy handlingMagnetic tension forceEngineering

The invention discloses a magnetic motor brake. The magnetic motor brake comprises a magnetic brake seat, a magnetic coil, reset springs, a rotor / stator combined plate and a friction ring and is characterized in that an annular groove is arranged inside the magnetic brake seat, the outer edge of the inner side of the magnetic brake seat is evenly provided with positioning holes, and the middle ofthe inner side of the magnetic brake seat is evenly provided with threaded holes; the magnetic coil is arranged in the annular groove of the inner cavity of the magnetic brake seat and connected witha switch; the magnetic coils are correspondingly arranged in the positioning holes; the rotor / stator combined plate is coordinated with the threaded holes in the magnetic brake seat through fastenersand connected with the magnetic brake seat to guarantee circumferential fixing and axial movement of the rotor / stator combined plate; the friction ring is arranged on the outer side of the rotor / stator combined plate and connected with the end cover of a motor. The magnetic motor brake is simple and optimized in overall structure, easy to assemble, convenient to maintain, wide in application rangeand suitable for being widely produced and used.

Owner:NANJING KANGNI SMART TECH CO LTD

Hydraulic spiral longitudinal joint of robot

The present invention relates to longitudinal robot joint, which includes oil cylinder for driving, multiple rollling screw pair, rolling spline pair and output terminal. The longitudinal robot joint features that the rolling spline pair has spline shaft connected to the piston rod of the oil cylinder and spline hoursing connected to the oil cylinder liner to make the spline possess only axial motion and bear the counteractive force moment; that the multiple rolling spline pair has screw shaft integrated with the spline shaft and screw housing connected to the outer terminal to complete the conversion from the linear motion of oil cylinder to rotation motion; and that these is a thrust bearing pair between the spline housing and the screw housing to make the screw housing capable of swinging only around its axis.

Owner:CHONGQING UNIV

Material temperature measuring device for soaking furnace

InactiveCN108254095AEasy to replaceIsolated and lostThermometers using electric/magnetic elementsUsing electrical meansReciprocating motionSilicon alloy

The invention discloses a material temperature measuring device for a soaking furnace. The material temperature measuring device comprises a cylinder passing through a furnace wall, a guiding mechanism, and a driving mechanism. Four metal rods penetrate the cylinder; and two of the four metal rods are nickel-chromium alloy rods and the other two rods are nickel-silicon alloy rods. Guiding wheels are fixed on a rack and are in contact with the outer surface of the cylinder. The driving mechanism drives the cylinder to make axial reciprocating motion. A longitudinal insulating plate is arrangedinside the cylinder along the axial direction and separates the four metal rods mutually. A plurality of horizontal insulating plates are arranged inside the cylinder along the direction perpendicularto the axial direction and are distributed at intervals; and the horizontal insulating plates and the longitudinal insulating plate are fixed mutually. Lead screws are arranged at the tails of the metal rods. A limiting plate protruding radially is arranged at the shaft end of one side of the cylinder; and internal threads cooperating with the lead screws are formed in the limiting plates. Therefore, the temperature of the aluminum alloy ingot in the furnace can be measured accurately; the material temperature measuring device can be utilized repeatedly; and the temperature measuring is donequickly and efficiently.

Owner:SUZHOU BONENG FURNACE TECH CO LTD

Tooling for assembly and welding of roulette body and method of use

ActiveCN106736209BIncreasing the thicknessButt seamlessWelding/cutting auxillary devicesAuxillary welding devicesInterference fitRolling-element bearing

Owner:LEADRUN MAODA CASTING JIANGSU +1

I-shaped wheel jacking device for water tank wire drawing machine

The invention discloses an H-shaped wheel tightening device for a water tank wire-drawing machine. The tightening device comprises a first disc spring tightening mechanism and a second disc spring tightening mechanism which are symmetrically arranged at two ends of an H-shaped wheel in the axial direction. The first disc spring tightening mechanism comprises a first cylindrical mounting seat, a first fixing sleeve, a first end cap and a first sliding shaft; the first fixing sleeve is annularly arranged on a cavity of the first mounting seat and is attached to the inner wall of the cavity; thefirst end cap is arranged at one end of the cavity of the first mounting seat; the first end cap and the first fixing sleeve are fixed in the circumferential direction; and the first sliding shaft penetrates in the middle of the cavity of the first mounting seat in the axial direction. The second disc spring tightening mechanism comprises a second cylindrical mounting seat, a second fixing sleeve,a second end cap and a second sliding shaft, wherein the second fixing sleeve is annularly arranged on a cavity of the second mounting seat and is attached to the inner wall of the second mounting seat; the second end cap is arranged at one end of the cavity of the second mounting seat; the second end cap and the second fixing sleeve are fixed in the circumferential direction; and the second sliding shaft penetrates in the middle of the cavity of the second mounting seat in the axial direction. The H-shaped wheel tightening device for the water tank wire-drawing machine is simple in structure, and is safe and reliable, and thus, the working efficiency of rolling of steel cords is ensured.

Owner:湖北三江航天江北机械工程有限公司

Compliance detection device for exhaust gas emission

ActiveCN110940775BMove fastGuaranteed uniformityWithdrawing sample devicesExhaust gas emissionsExhaust fumes

The invention provides a standard detection device for waste gas discharge, which relates to the technical field of waste gas discharge, and solves the problem that the original detection device has a high degree of automation in the detection mode and may have uneven detection, and does not have the ability to detect waste residues and easily polymerized substances in the waste gas. For the function of sampling, it is inconvenient to set different sensors at the same time for the function of real-time detection; it includes the housing; the outer side of the housing is fixed with a side cover by bolts; the sensor installation hole is provided to provide a sensor for the detection device It can flexibly change and select devices according to different exhaust gas components for real-time detection. Real-time detection can ensure the uniformity of sampling. At the same time, the detection device is set as a branch, which can close the passage when not in use. The device can assist in accelerating the moving speed of exhaust gas for detection.

Owner:山东省碳中和科技发展集团有限公司

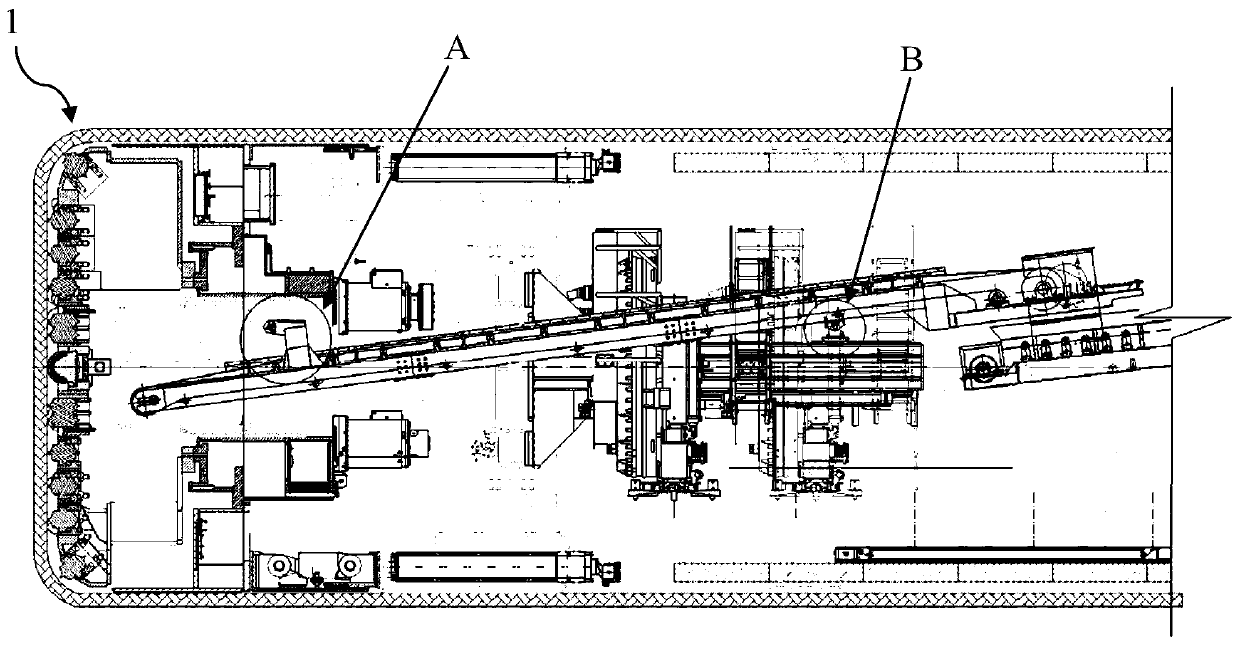

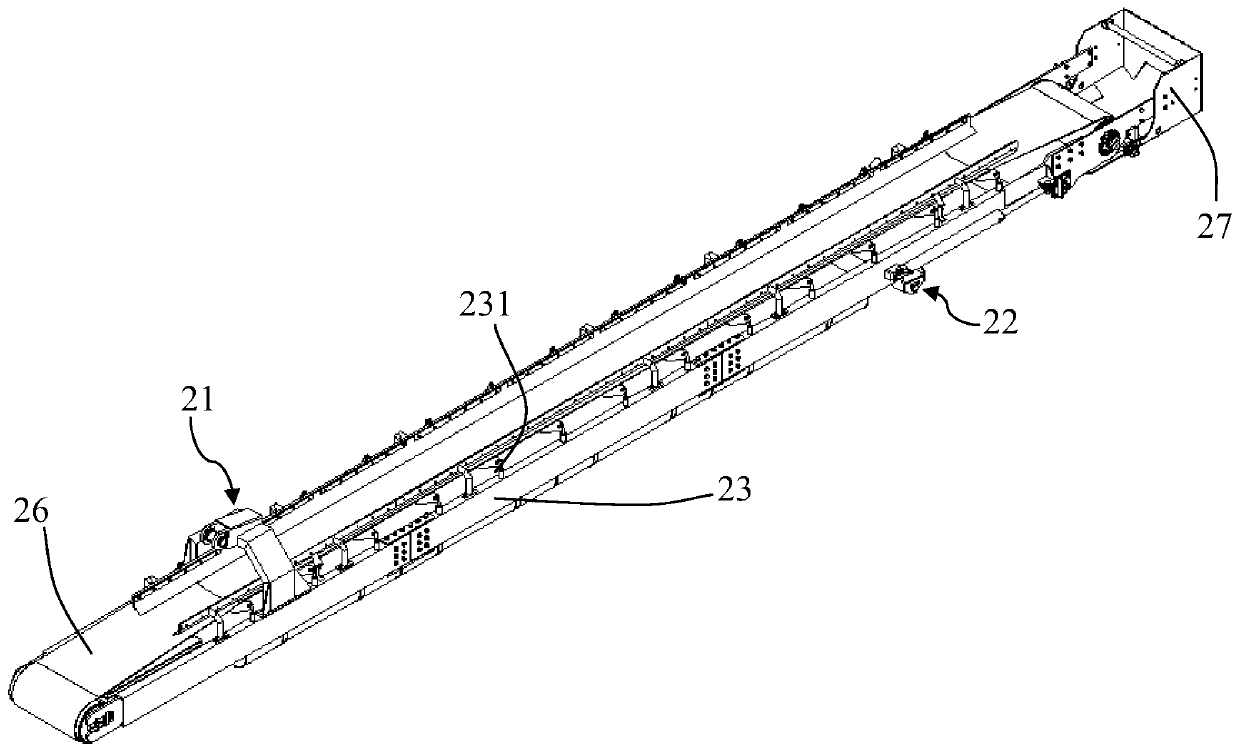

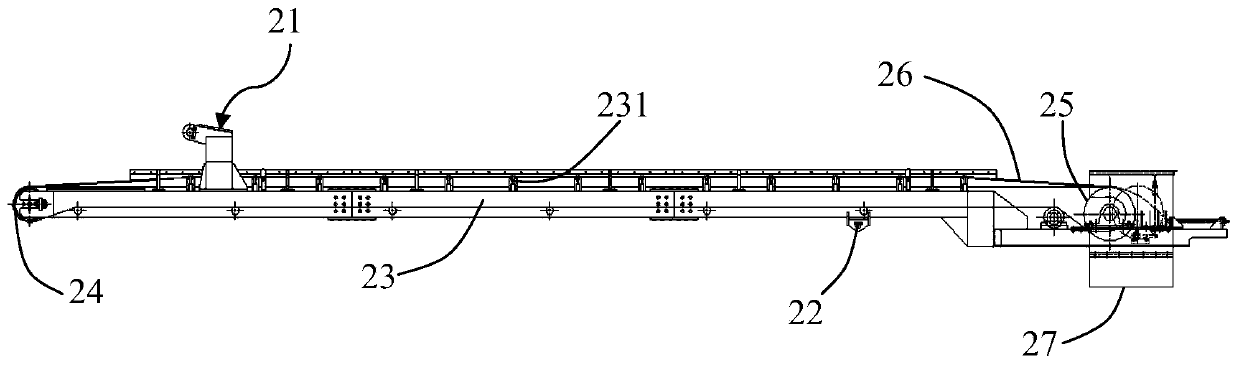

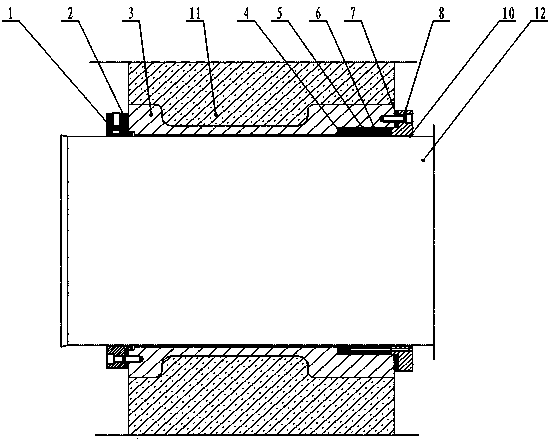

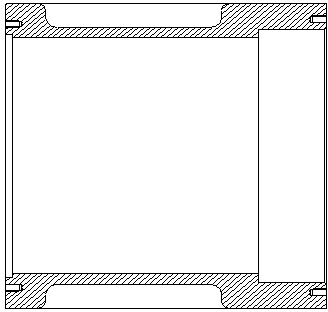

An Axially Translatable Conveyor

ActiveCN108374671BGuaranteed axial movementSolve the space problem that cannot move axiallyTunnelsEngineeringShield tunneling

The invention provides a conveyor capable of achieving axial translation. The conveyor comprises a conveyor body, a head component used for being connected with the soil collecting ring of a shield tunneling machine, and a support, wherein the head component is mounted on the frame of the conveyor body, and the support is provided with a slide face for supporting the frame. The conveyor has the advantages that the conveyor can axially move along with the soil collecting ring, and the problem that the soil collecting ring cannot move axially due to the fact that the conveyor is fixedly mountedon the frame of the shield tunneling machine and occupies the axial moving space of the soil collecting ring during shield tunneling is solved effectively.

Owner:SHANGHAI TUNNEL ENG CO LTD +1

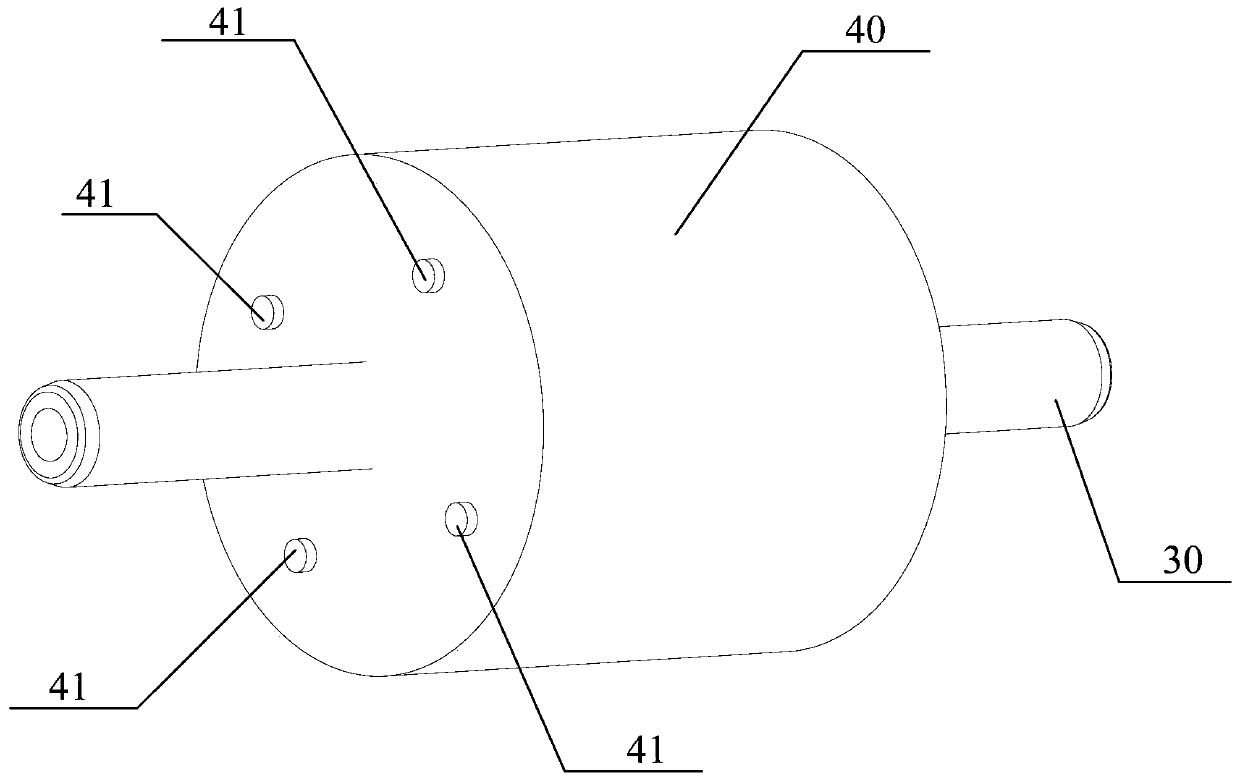

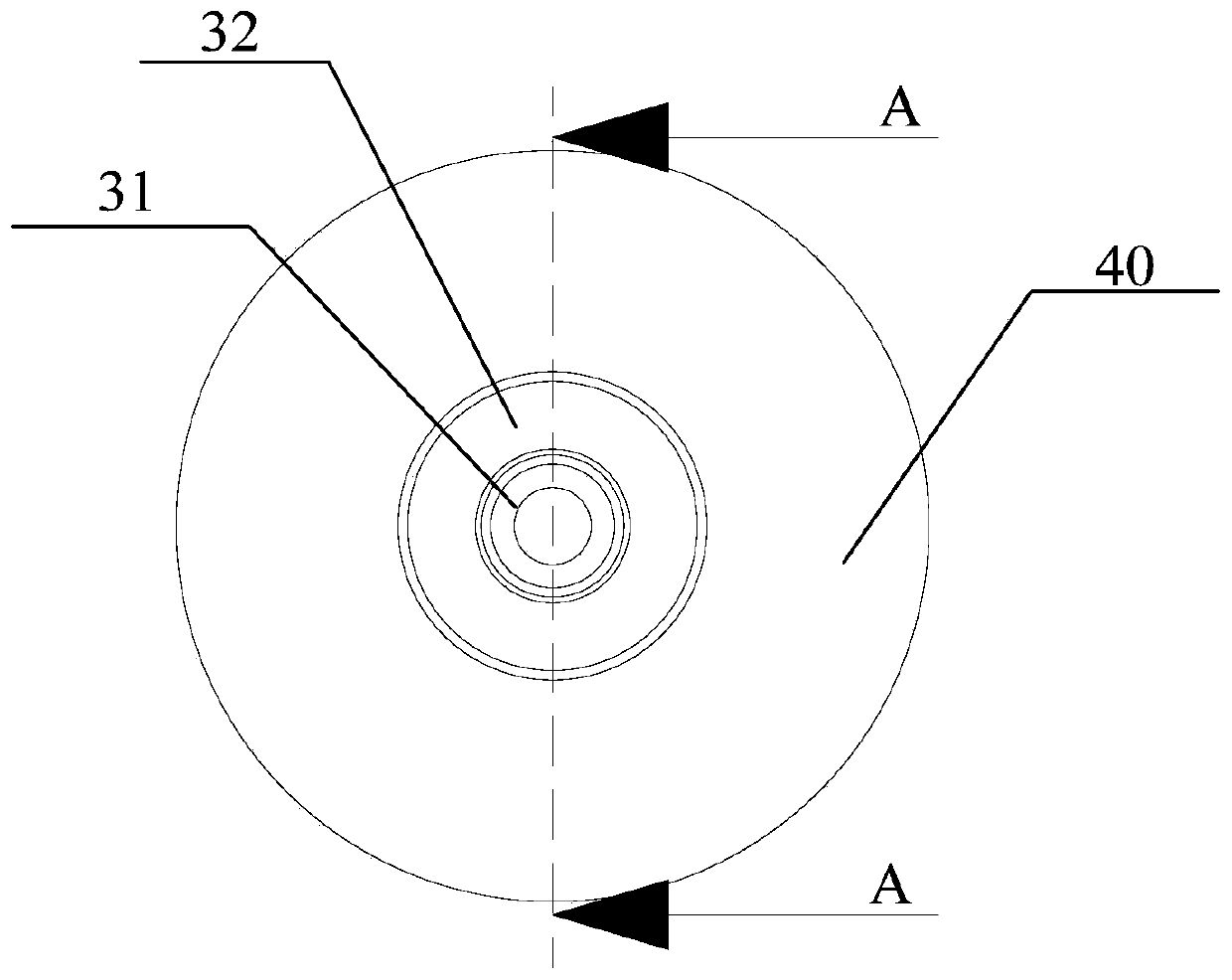

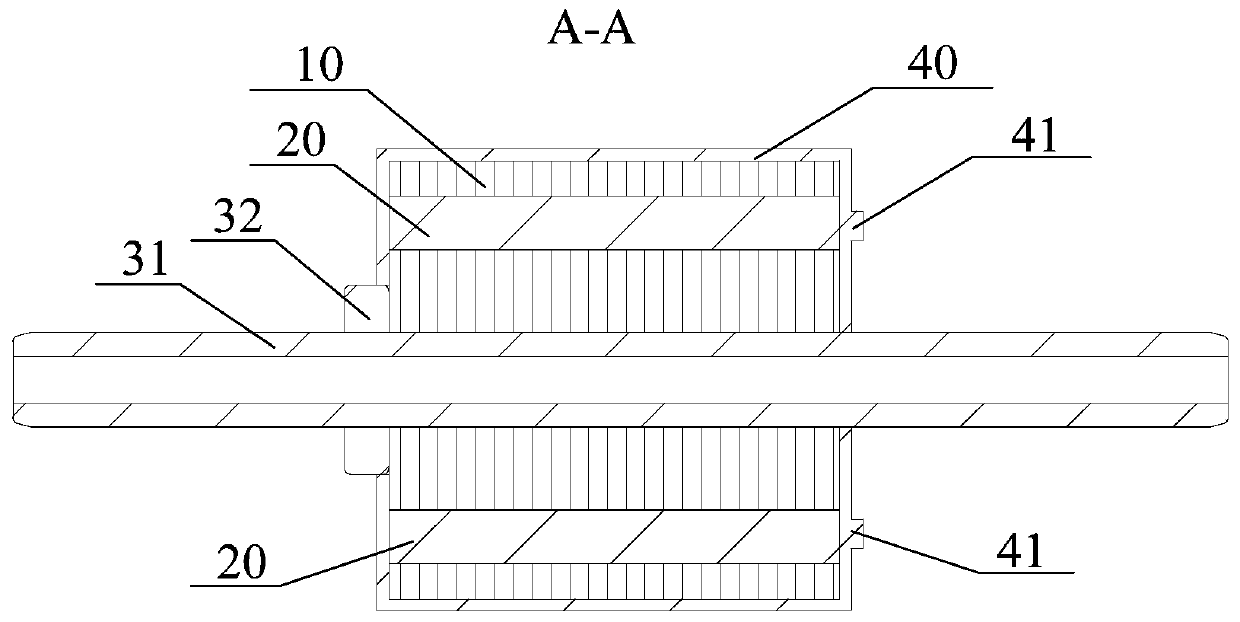

Driving tube adapter for large explosive wave simulator

InactiveCN103868794AGuaranteed axial movementProtection bufferShock testingStrength propertiesEngineeringFlange

The invention relates to a driving tube adapter for a large explosive wave simulator. The driving tube adapter for the large explosive wave simulator comprises a sealing body (3) used as an adapter main body, wherein the sealing body (3) is in a sleeve type structure, the sealing body (3) is sheathed on a driving tube (12) and is fixed in a buttress type reaction wall (11), the inner wall surface of the sealing body (3) is provided with a groove, a locating sleeve (6) is arranged between the groove on the inner wall surface of the sealing body (3) and the driving tube (12), a front end cover (8) and a rear end cover (1) are fixed at two ends of the sealing body (3) respectively, the rear end cover (1) comprises a rear end cover flange (13) and locating mechanisms, and a plurality of groups of locating mechanisms are arranged in the rear end cover flange (13). The driving tube adapter has the characteristics of good sealing, shock-insulation and damping effects and stable performance, and can accurately control the driving tube to buffer and reset, and has important significance on ensuring the safe and normal operation of the driver in the large explosive wave simulator.

Owner:THE THIRD ENG CORPS RES INST OF THE HEADQUARTERS OF GENERAL STAFF PLA

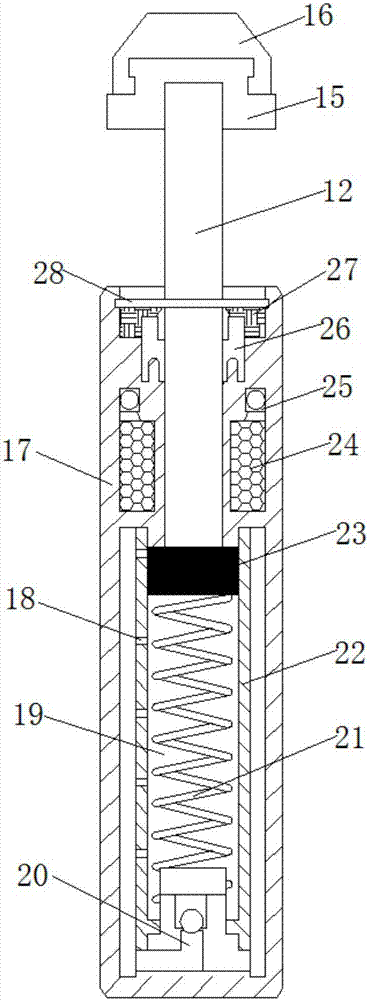

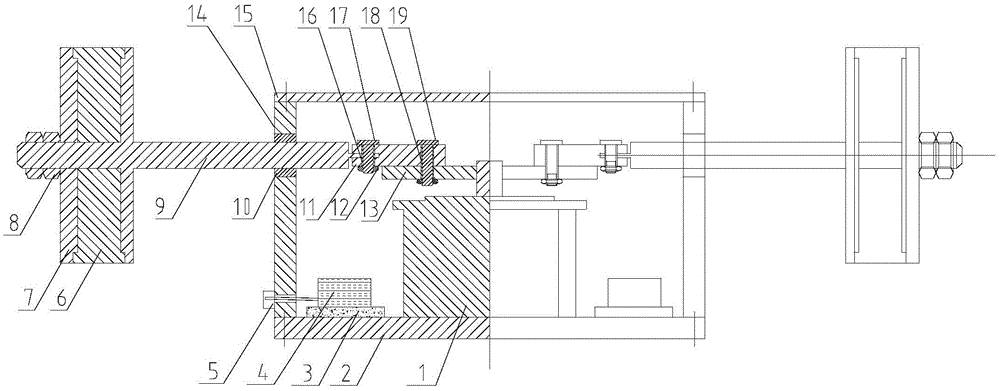

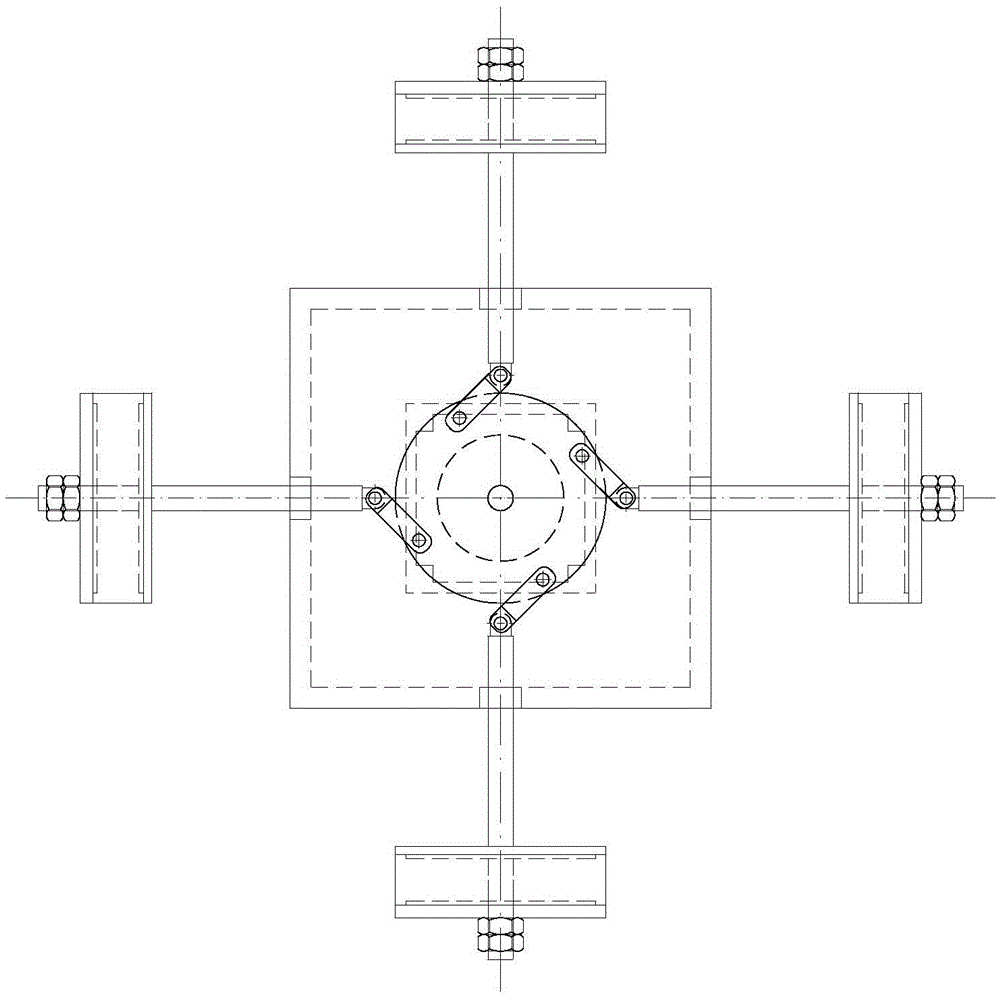

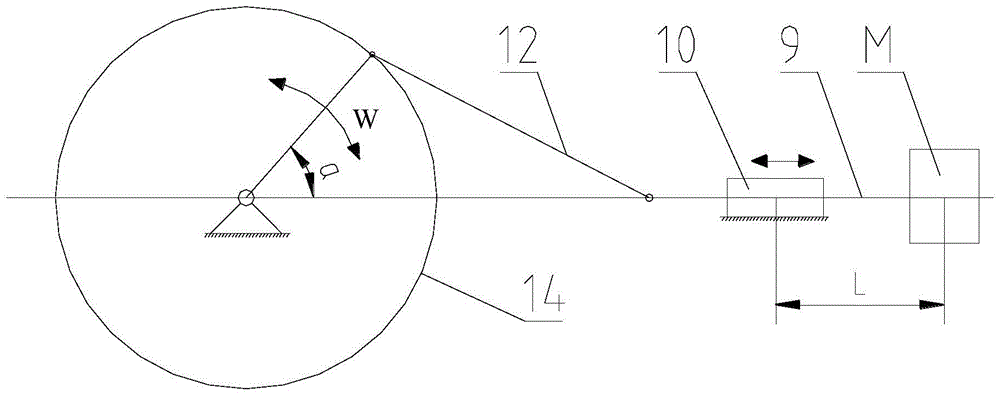

An adaptive frequency modulation dynamic vibration absorber

InactiveCN104154172BEasy to assemble and disassembleWith anti-loose functionVibration suppression adjustmentsNoise controlElectric machine

The invention discloses an adaptive frequency-modulation type dynamic vibration absorber, and belongs to the technical field of vibration noise controlling. The vibration absorber comprises a stepping motor, a rotary table, a connecting rod, a guiding rod, an adjusting mass block, a fixed mass block, a stepping motor controlling system, an elastic element, a wiring terminal, a top plate, a bottom plate, a wiring terminal, a linear bearing, a hinge pin, a nut and a shell, wherein the rotary table, the connecting rod, the guiding rod and the linear bearing inlaid in the shell form a connecting rod system; the turning direction and the step size of the stepping motor are controlled by the stepping motor controlling system; the rotary table is driven to rotate; the rotary table rotates to drive the connecting rod system to work so that the guiding rod upwards moves on the linear bearing; the length of the guiding rod is adjusted; the rigidity of the vibration absorber is changed; and the purpose of modulating frequency is achieved. The change of the revolving speed of a controlled object can be automatically tracked; the frequency of the vibration absorber is automatically modulated; and the vibration absorbing effect of controlled equipment is ensured under variable working conditions or during revolving speed drifting.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com