Magnetic motor brake

A magnetic brake and magnetic brake seat technology, applied in the field of motor magnetic brakes, can solve the problems of narrow application area of a single product, inconvenient product maintenance, low product cost performance, etc., and achieve the effects of low cost, easy maintenance, and simple maintenance process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

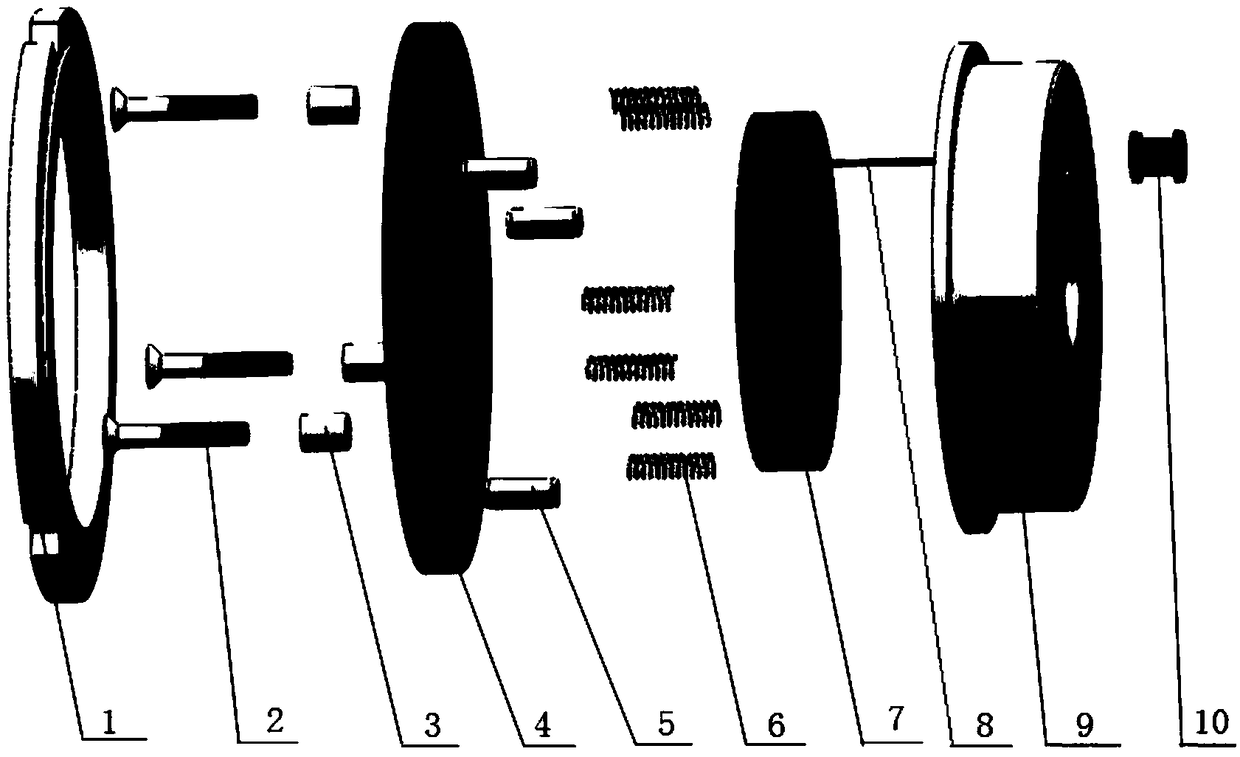

[0020] Embodiment 1: A kind of motor magnetic brake, such as figure 1 As shown, it includes a magnetic brake seat 9, a magnetic coil 7, a return spring 6, a moving plate / fixed plate combination plate 4, a screw 2, a spacer 3, a pin 5 and a friction ring 1.

[0021] The magnetic brake seat 9 is fixed with the motor shaft through the keyway of the inner hole and the key pin, so as to keep the circumferential positioning of the magnetic brake seat 9; The units contact to form the axial positioning of the magnetic brake seat 9. The inside of the magnetic brake seat 9 is provided with an annular groove, and the inner surface and outer edge of the magnetic brake seat 9 are evenly provided with positioning holes 12, and the inner surface of the magnetic brake seat 9 is evenly provided with threaded holes 13 at the middle position. An outgoing line protection ring 10 is provided on the outer surface of the magnetic brake seat 9 .

[0022] The positioning hole 12 is correspondingly p...

Embodiment 2

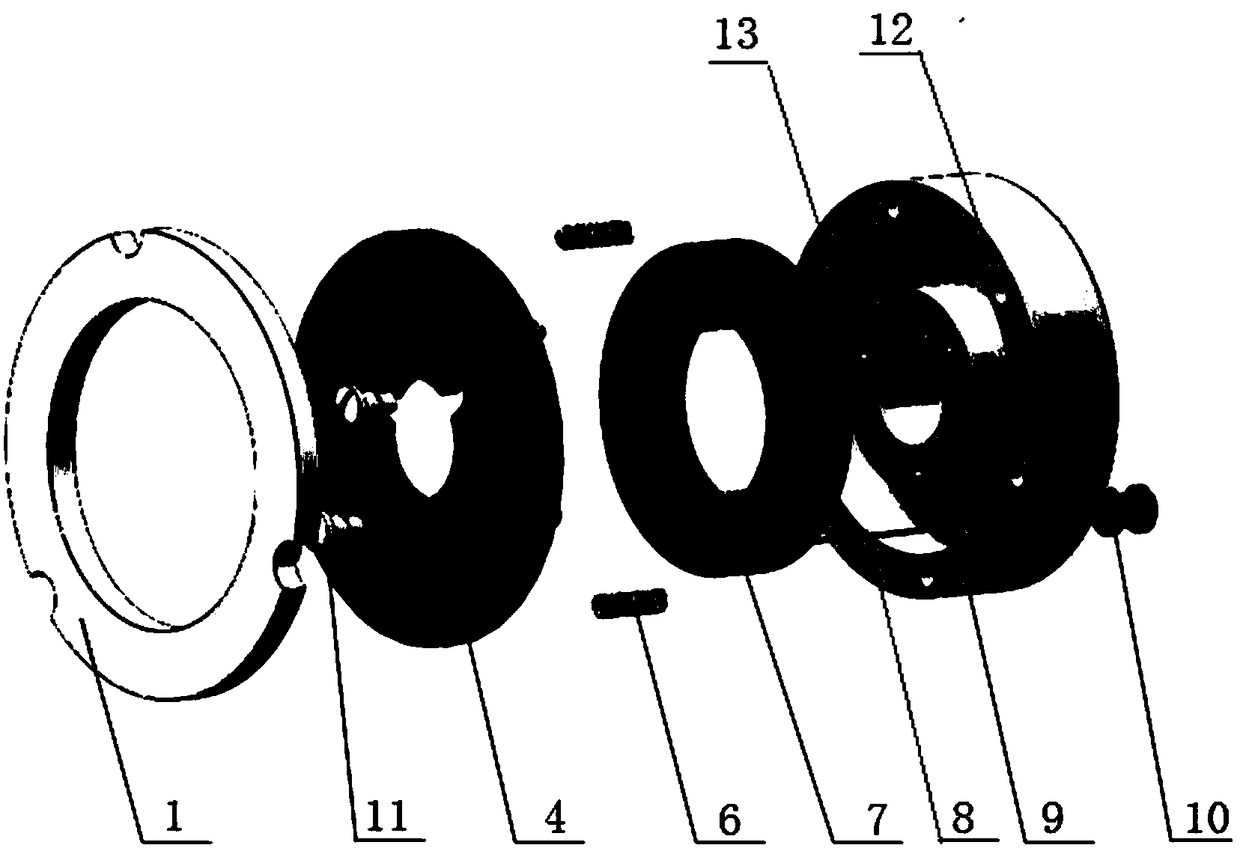

[0026] Embodiment 2: a kind of motor magnetic brake, such as figure 2 As shown, it includes a magnetic brake seat 9, a magnetic coil 7, a return spring 6, a moving plate / fixed plate combination plate 4, a shaft screw 11 and a friction ring 1.

[0027] The magnetic brake seat 9 is fixed with the motor shaft through the keyway of the inner hole and the key pin, so as to keep the circumferential positioning of the magnetic brake seat 9; The units contact to form the axial positioning of the magnetic brake seat 9. The inside of the magnetic brake seat 9 is provided with an annular groove, and the inner surface and outer edge of the magnetic brake seat 9 are evenly provided with positioning holes 12, and the inner surface of the magnetic brake seat 9 is evenly provided with threaded holes 13 at the middle position. An outgoing line protection ring 10 is provided on the outer surface of the magnetic brake seat 9 .

[0028] The positioning hole 12 is correspondingly provided with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com