High-consistency hydraulic disc mill

A disc refiner and high-consistency disc technology, which is applied in textile and papermaking, pulp beating/refining method, fiber raw material processing and other directions, can solve problems such as poor refining adaptability, achieve stable quality, simple adjustment structure, and convenient operation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments.

[0029] It should be noted that the drawings are only for illustrative purposes and should not be construed as limitations on this patent; for those skilled in the art, it is understandable that some known structures and their descriptions in the drawings may be omitted.

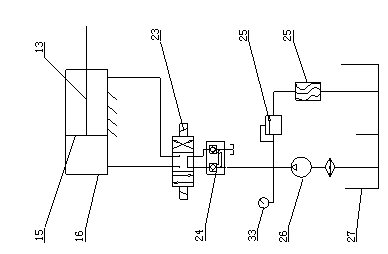

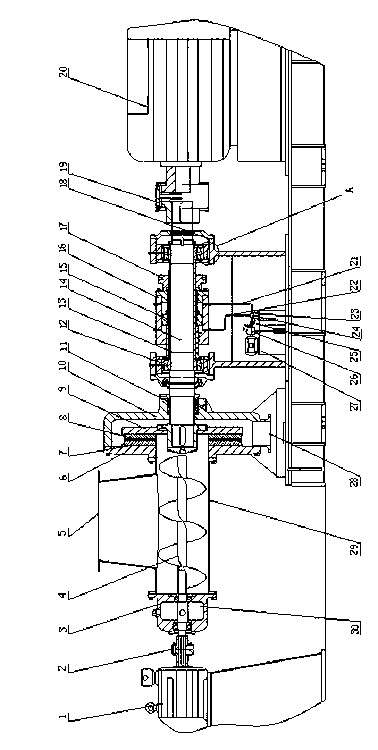

[0030] Such as figure 1 As shown, a high-consistency hydraulic disc refiner that uses hydraulic pressure to adjust the refining pressure includes a screw feeding unit, a hydraulic adjustment unit and a high-consistency disc refiner body.

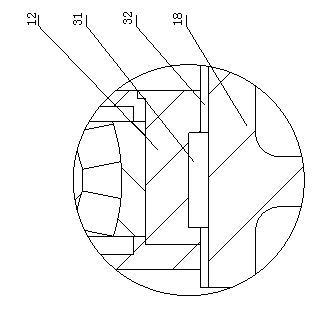

[0031] The high-concentration disc mill body includes a casing 10, a machine cover 6, a fixed disk 7, a rotating disk 8, a bearing body suspension 18, a bearing body 12, a shaft 14, a second shaft coupling 19, and a motor 20. The machine cover 6 is connected with the machine casing 10 to form a grinding chamber, the fixed plate 7 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com