Patents

Literature

69results about How to "Affect normal movement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

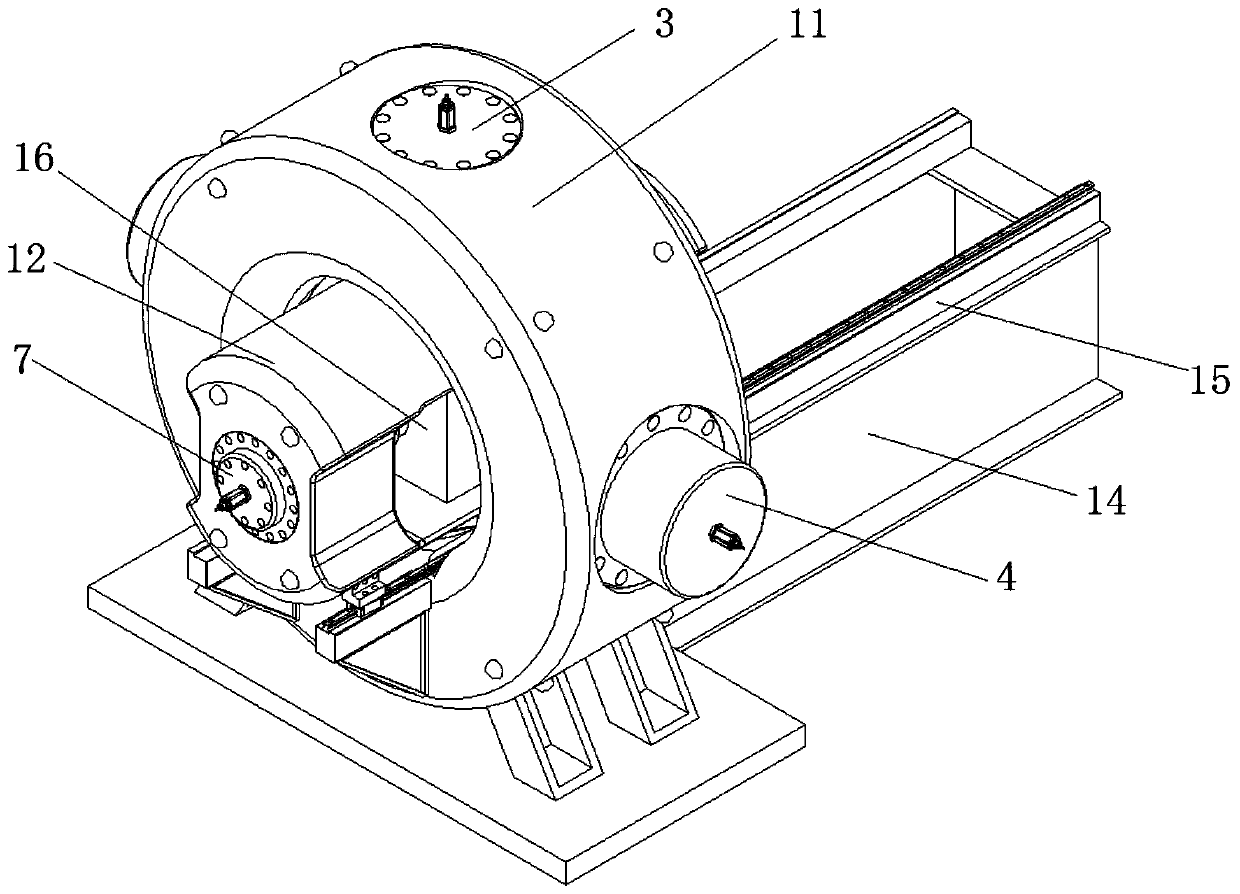

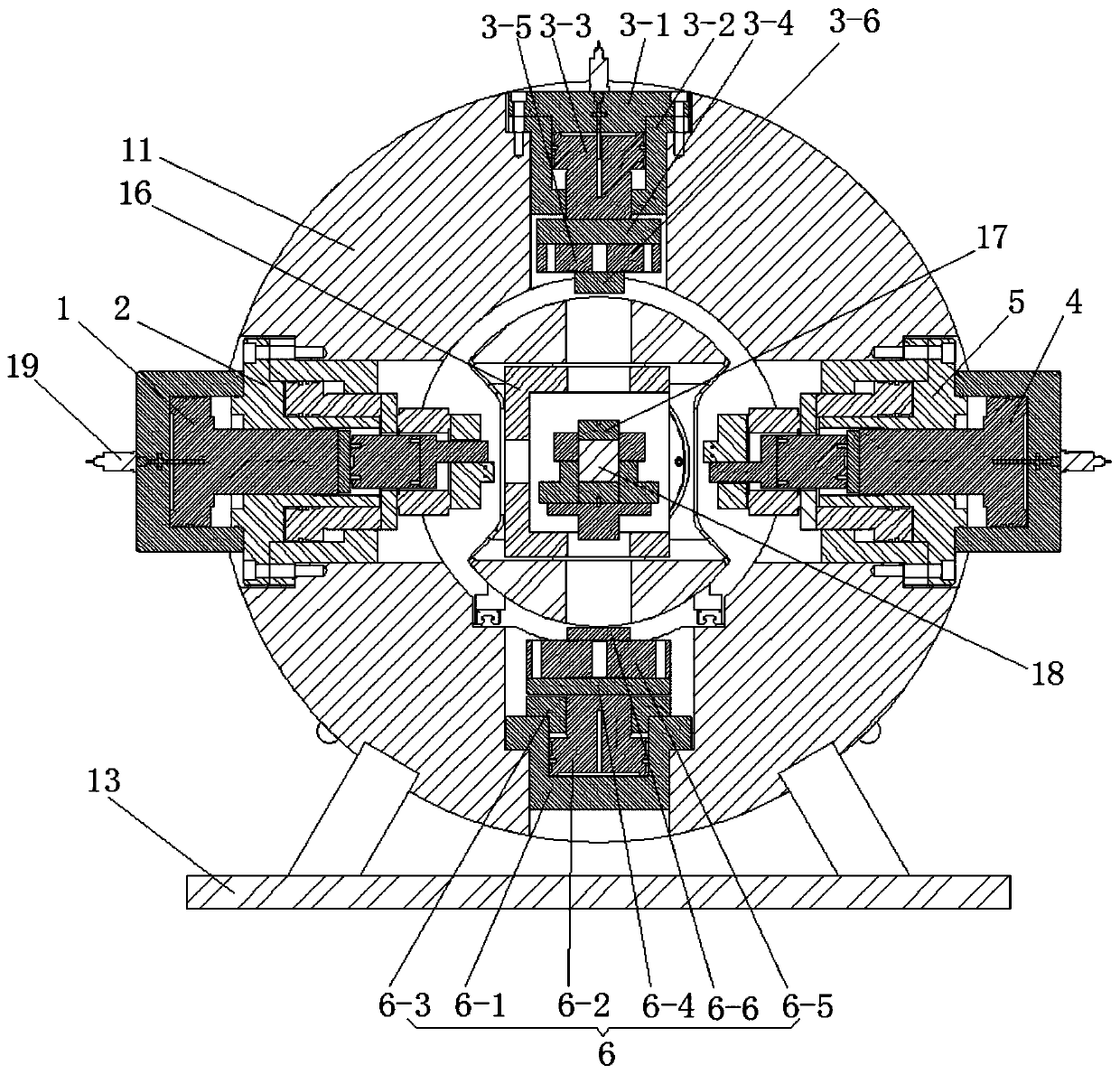

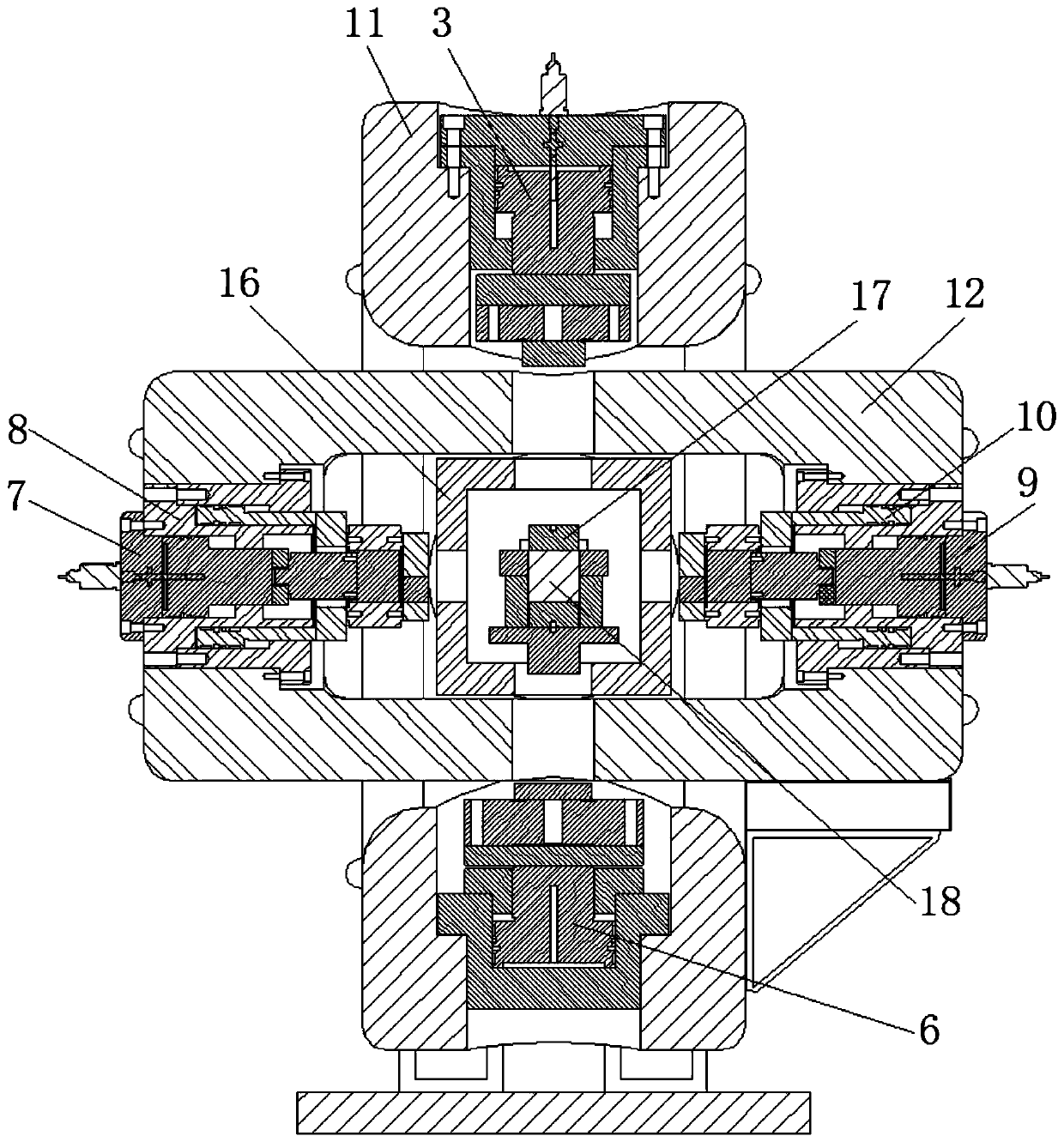

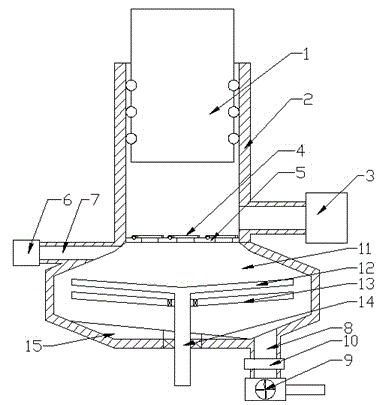

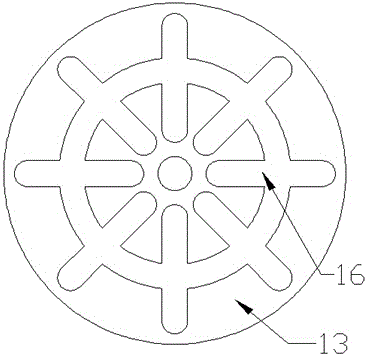

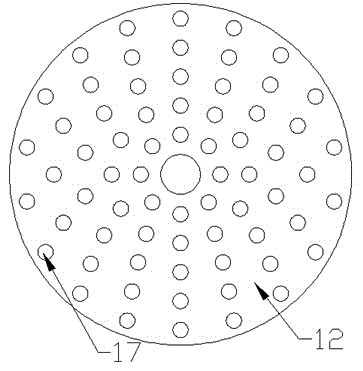

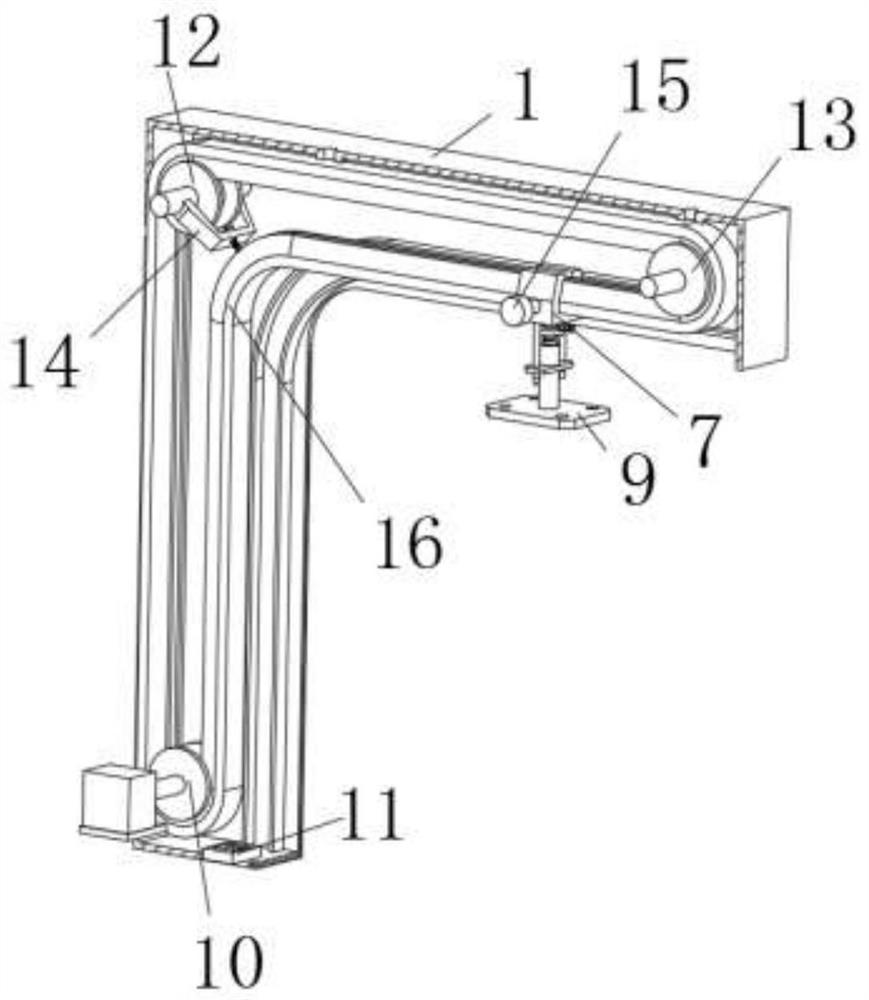

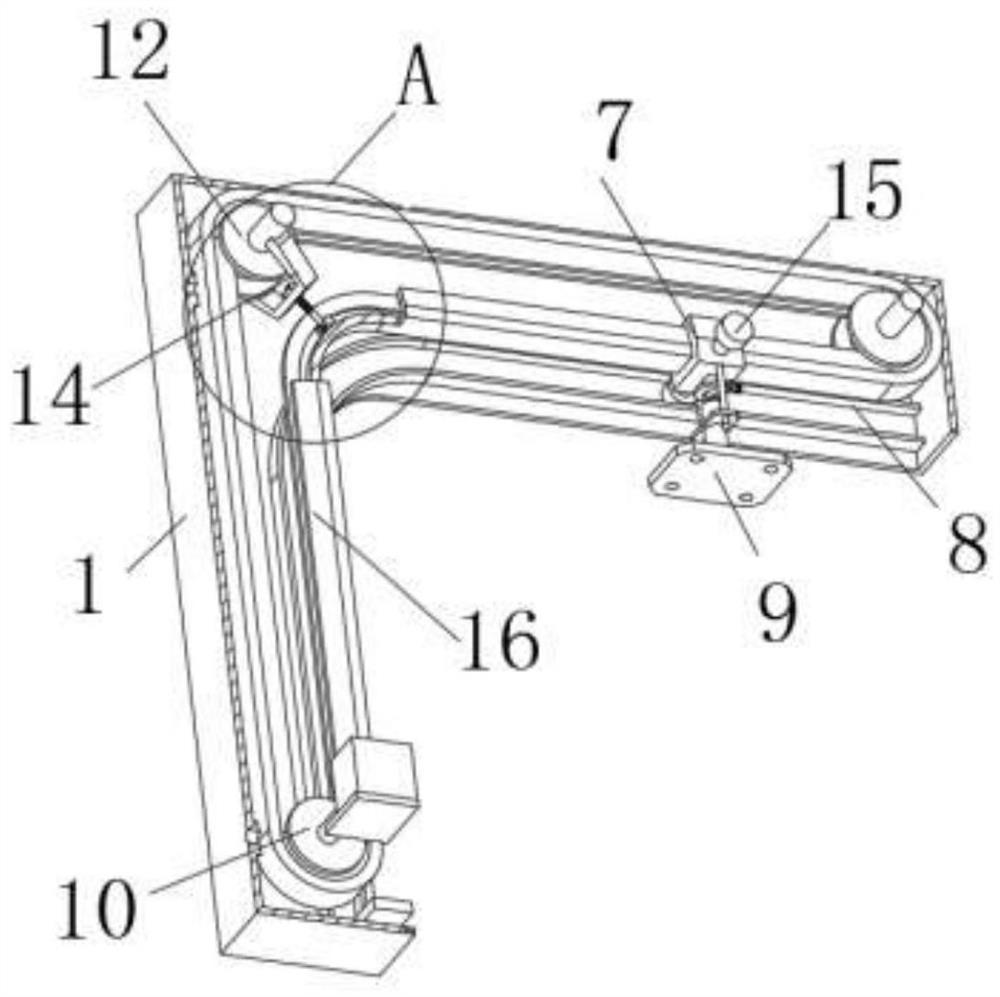

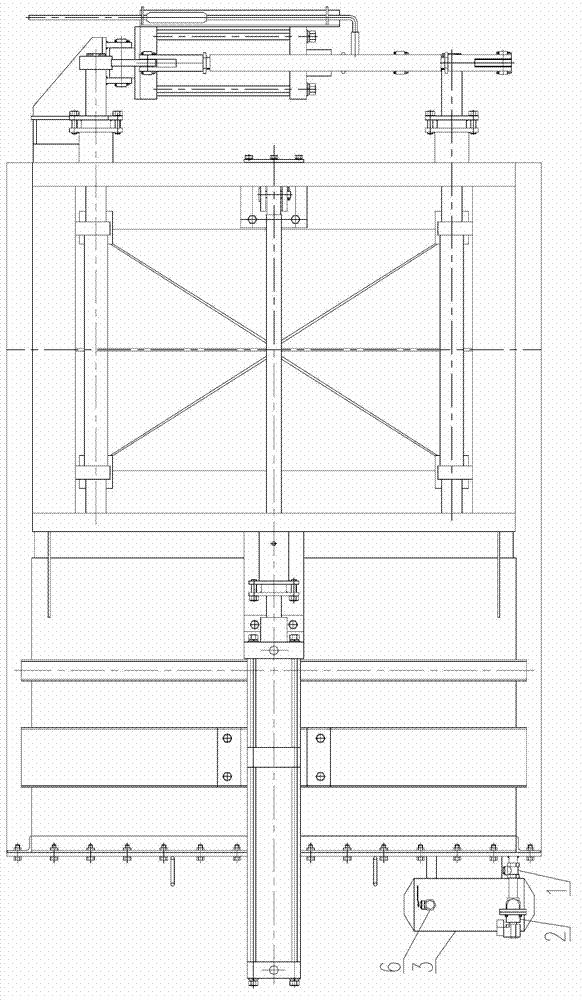

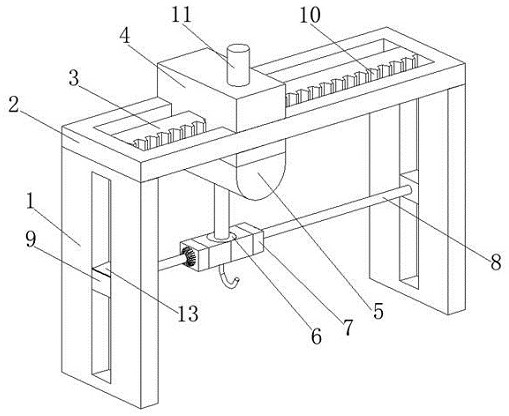

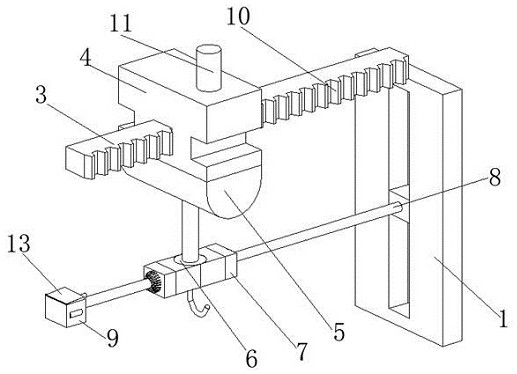

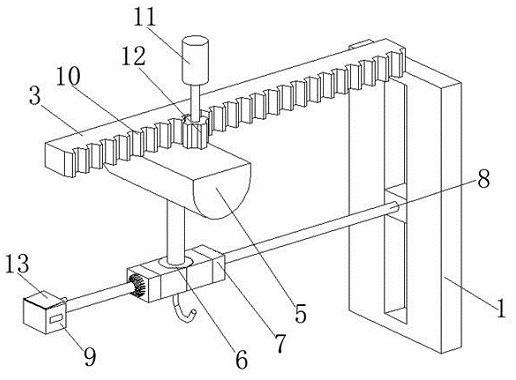

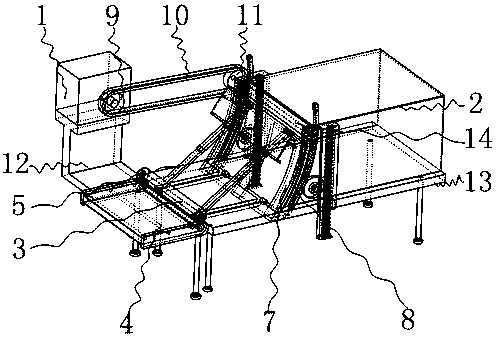

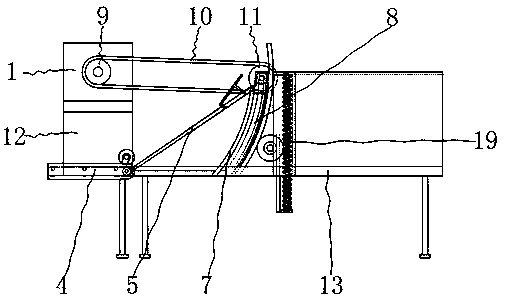

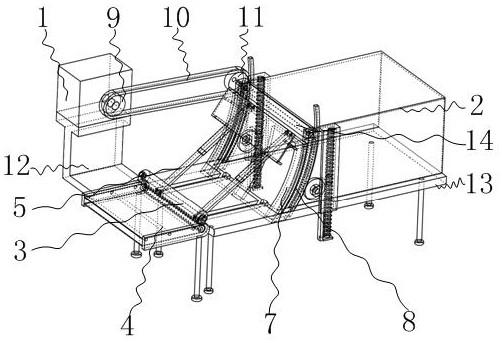

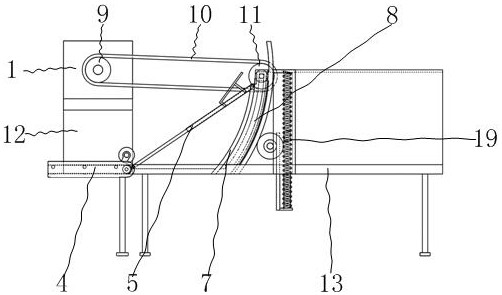

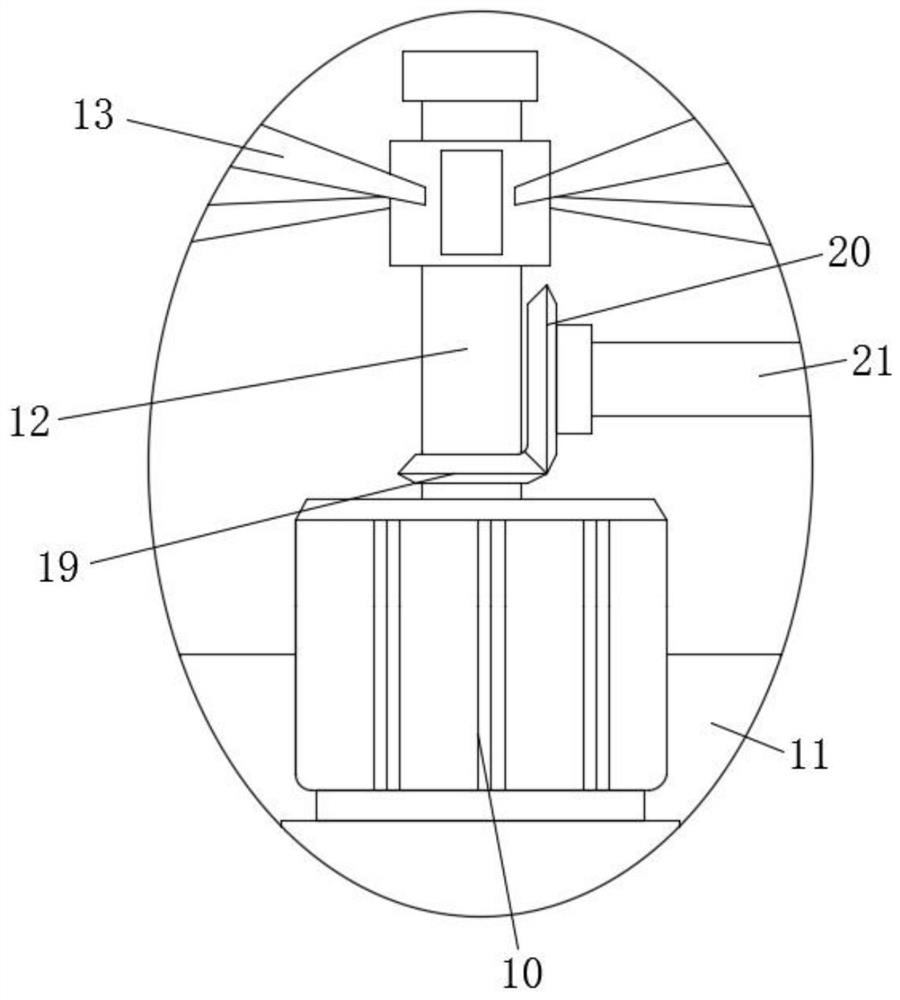

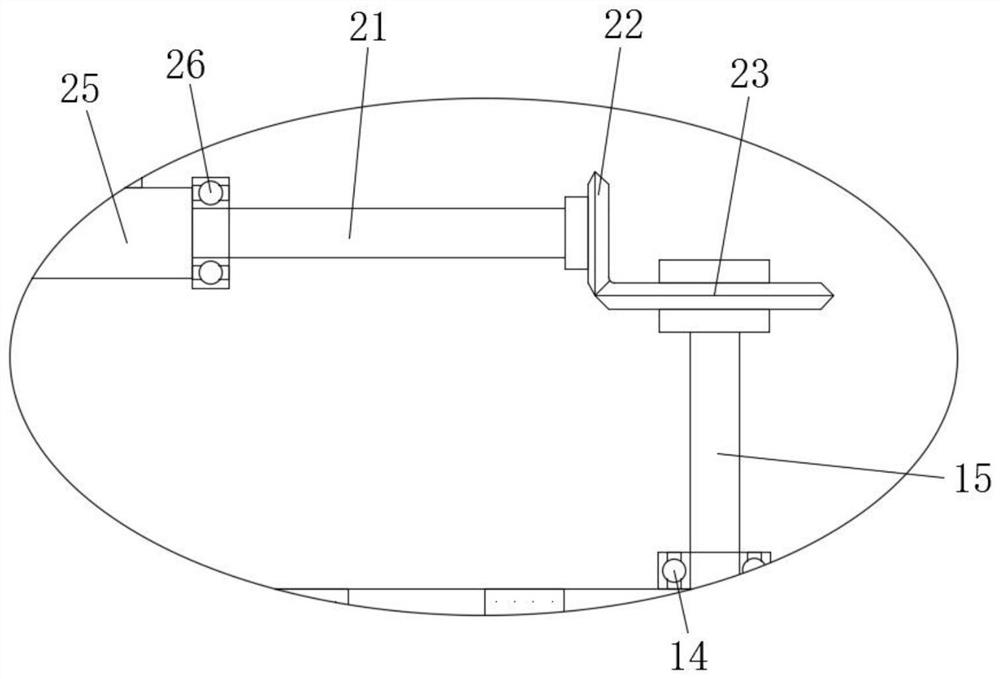

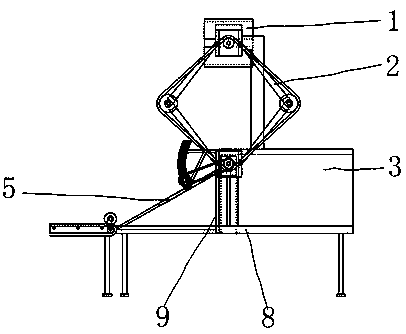

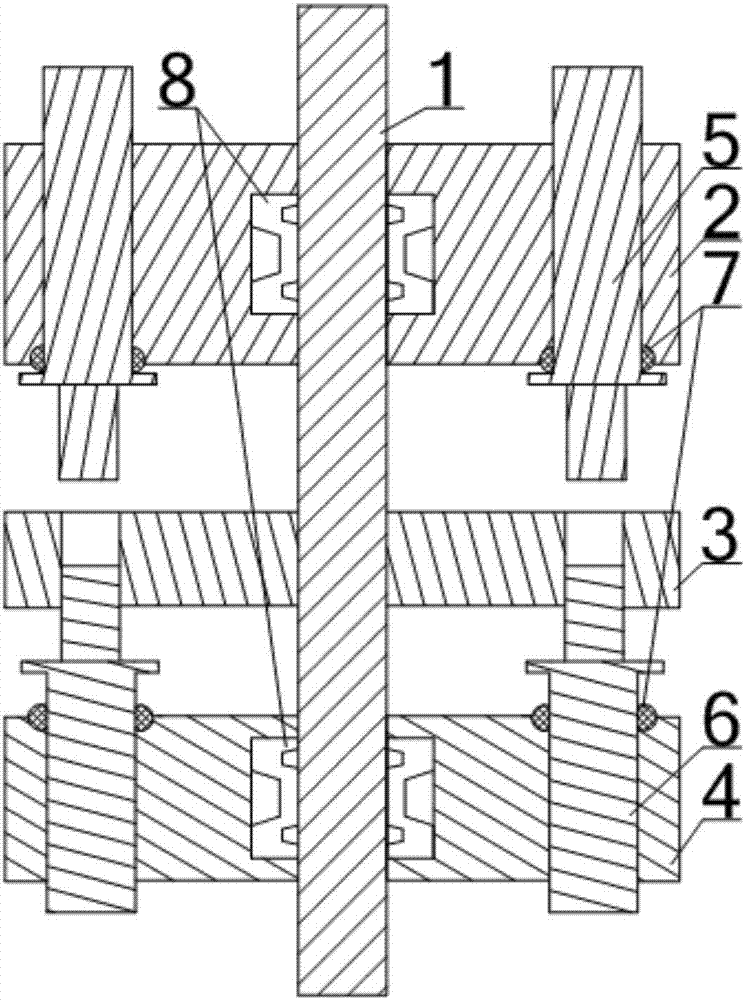

True triaxial multifunctional shearing test device and method for high-temperature and high-pressure hard rock

ActiveCN110658085AMake sure to loadAffect normal movementMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesTriaxial shear testStructural engineering

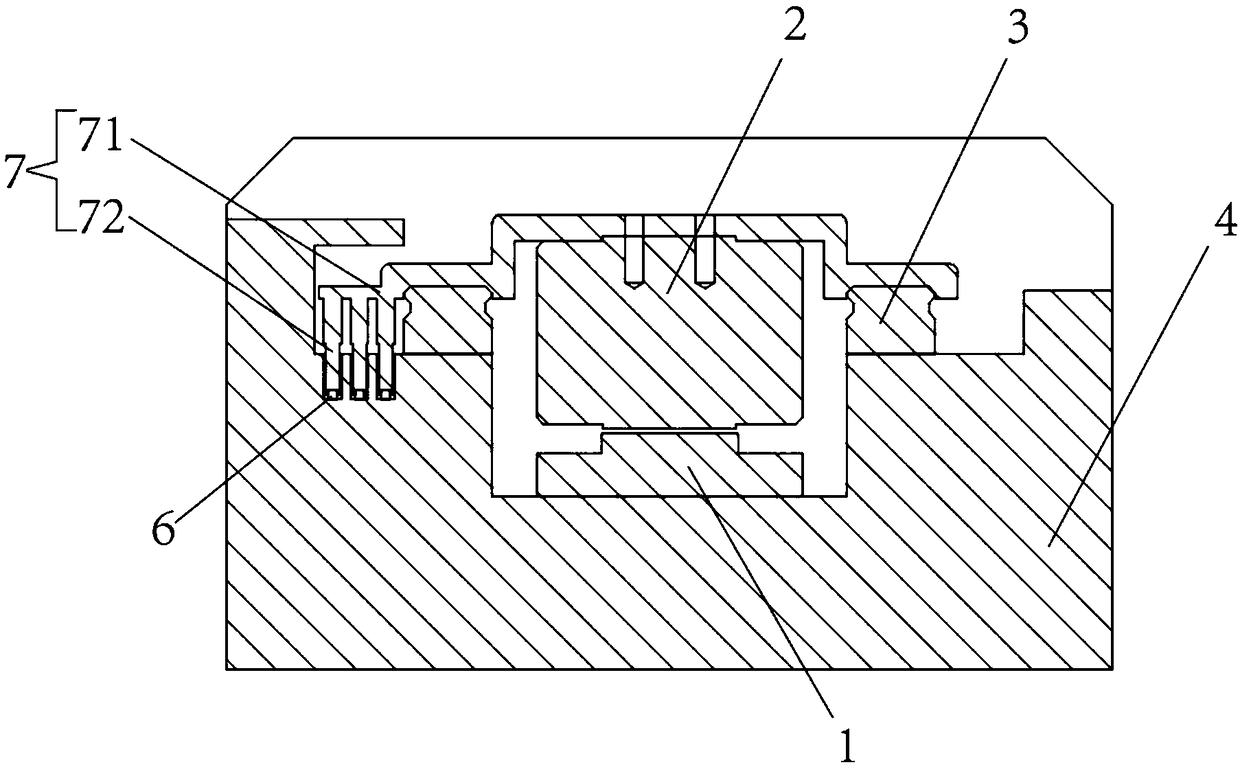

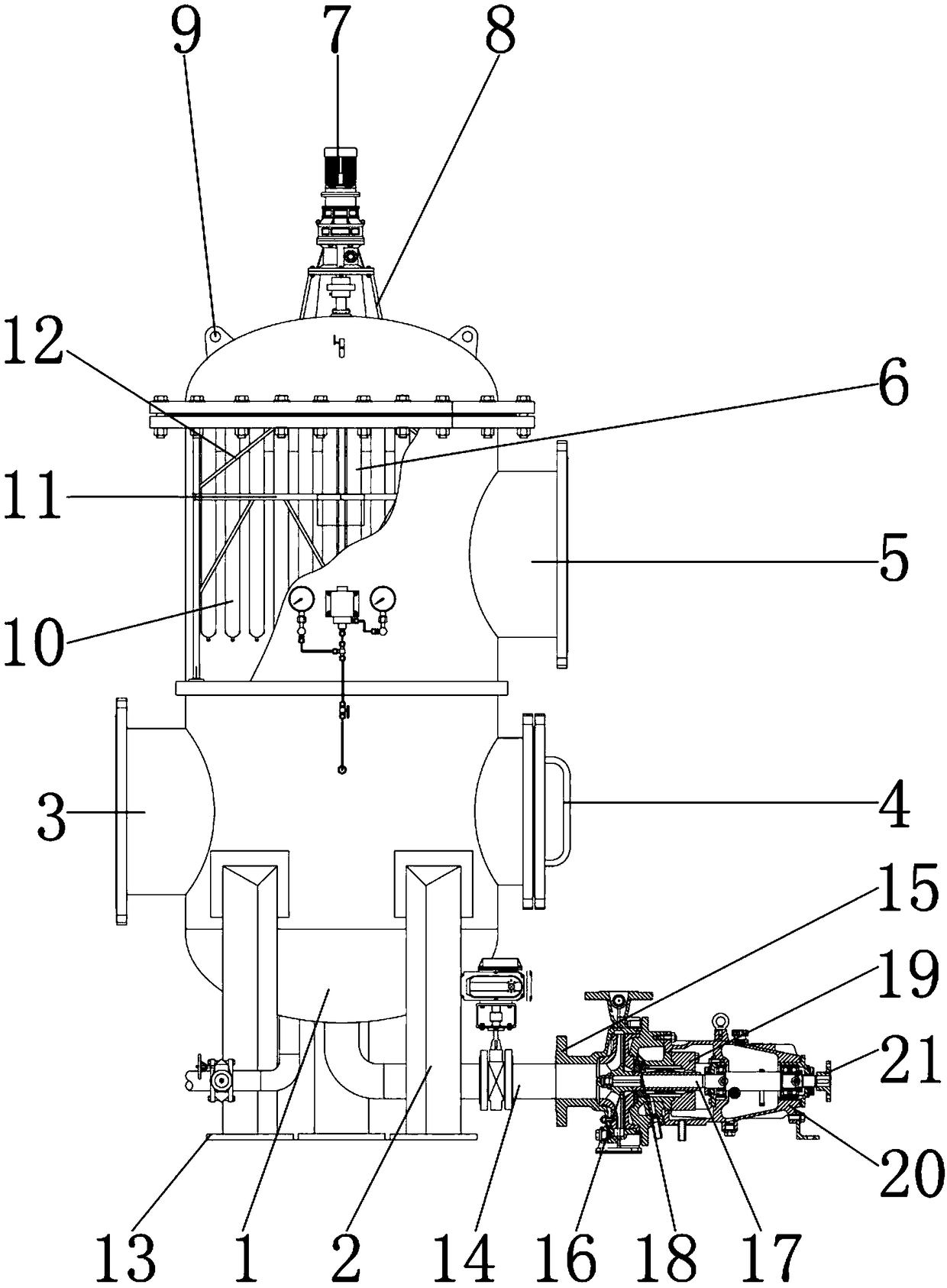

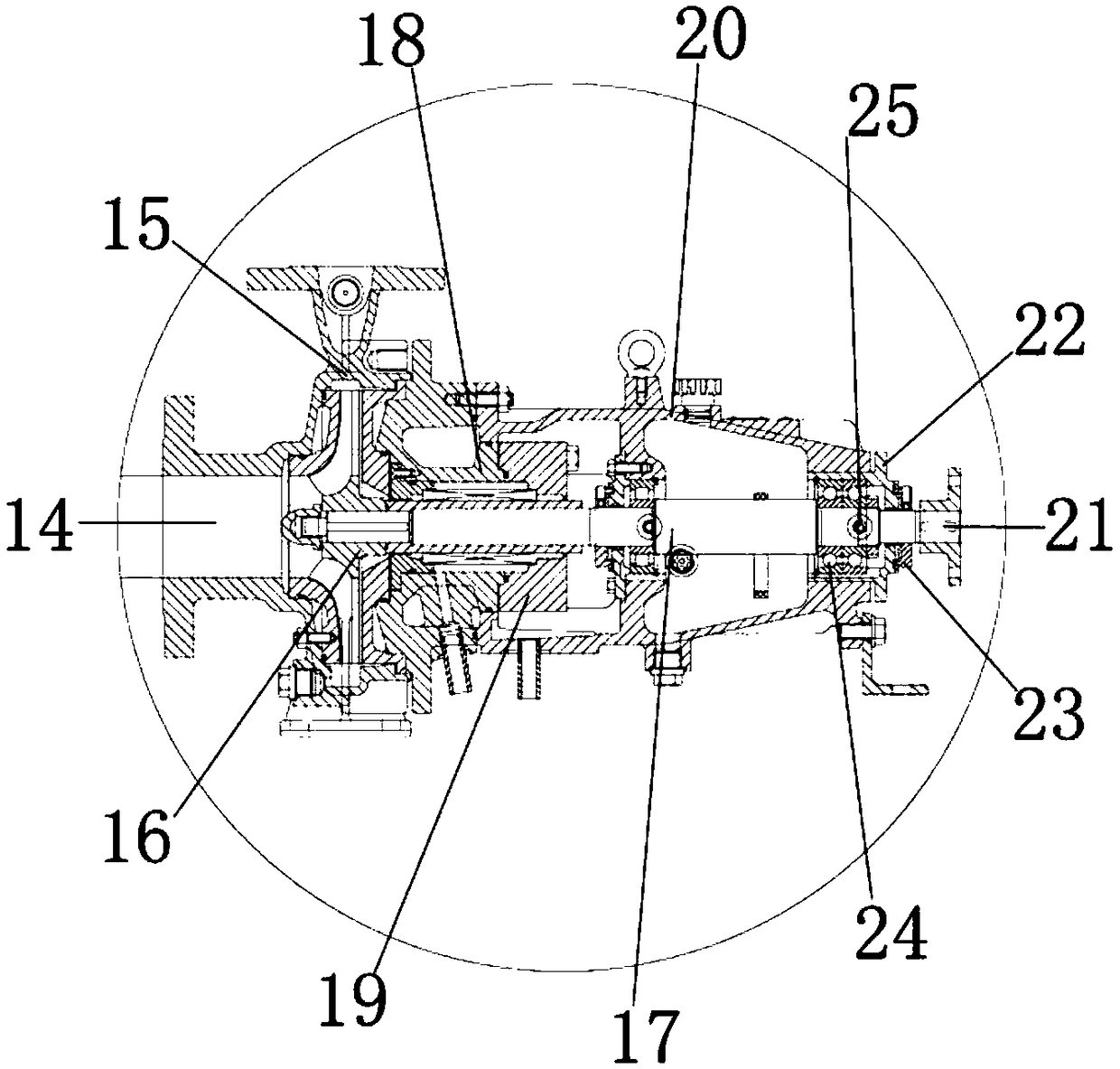

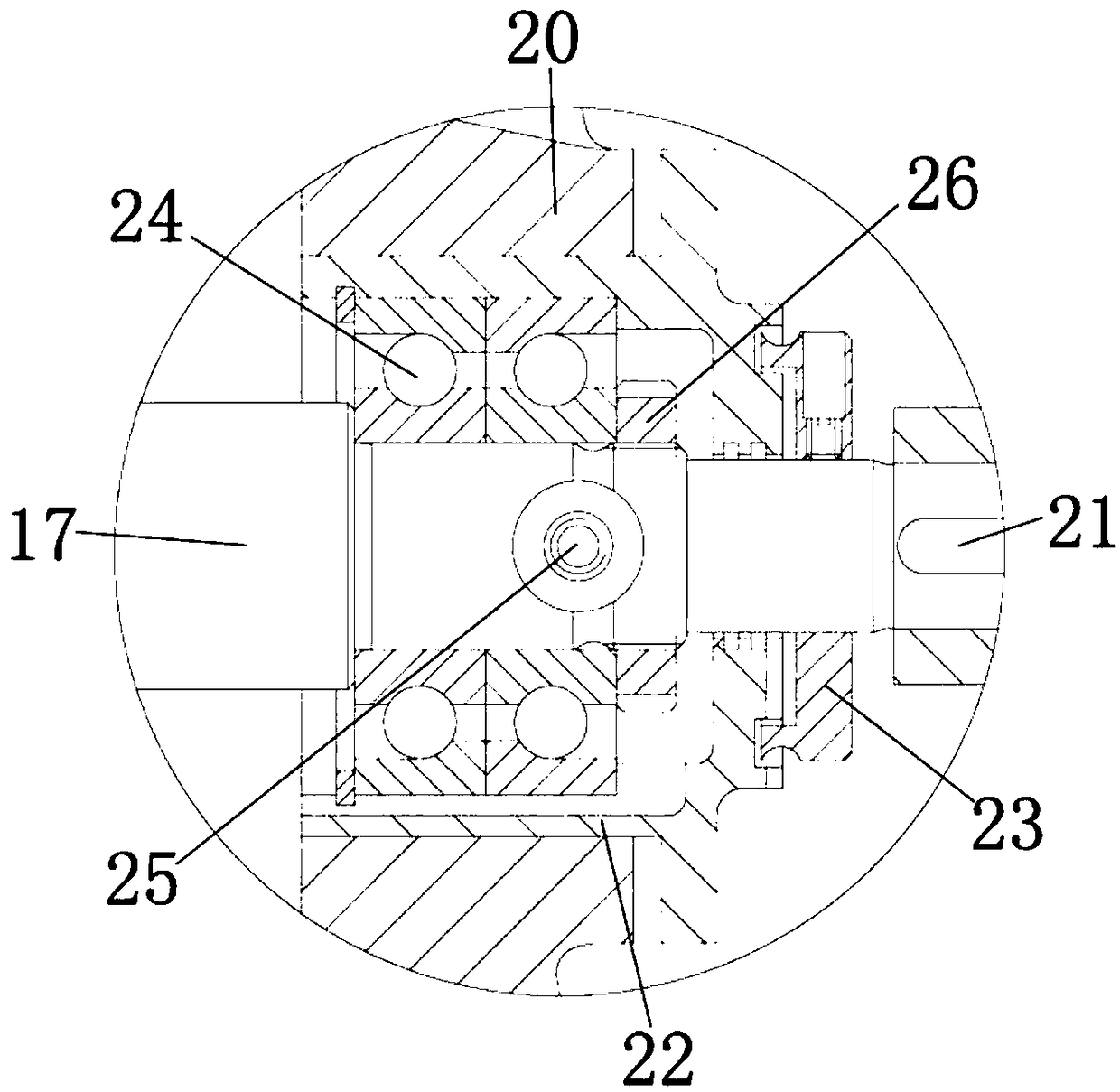

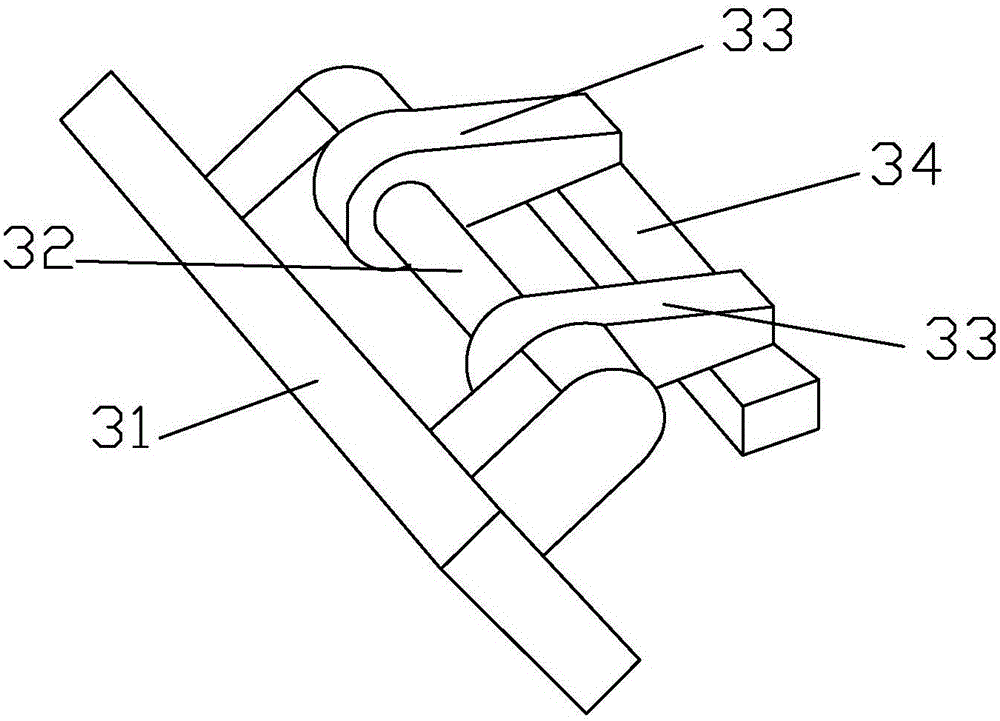

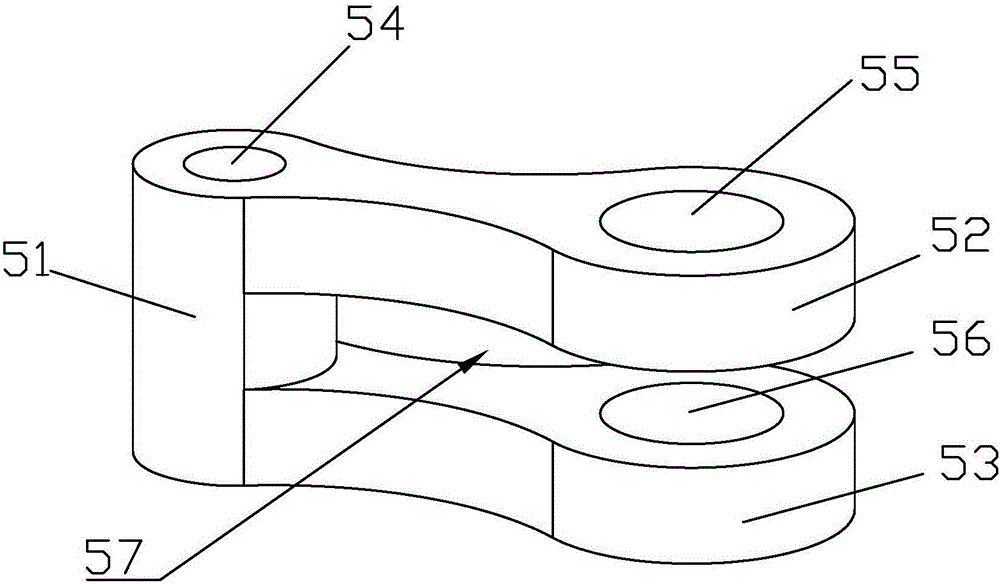

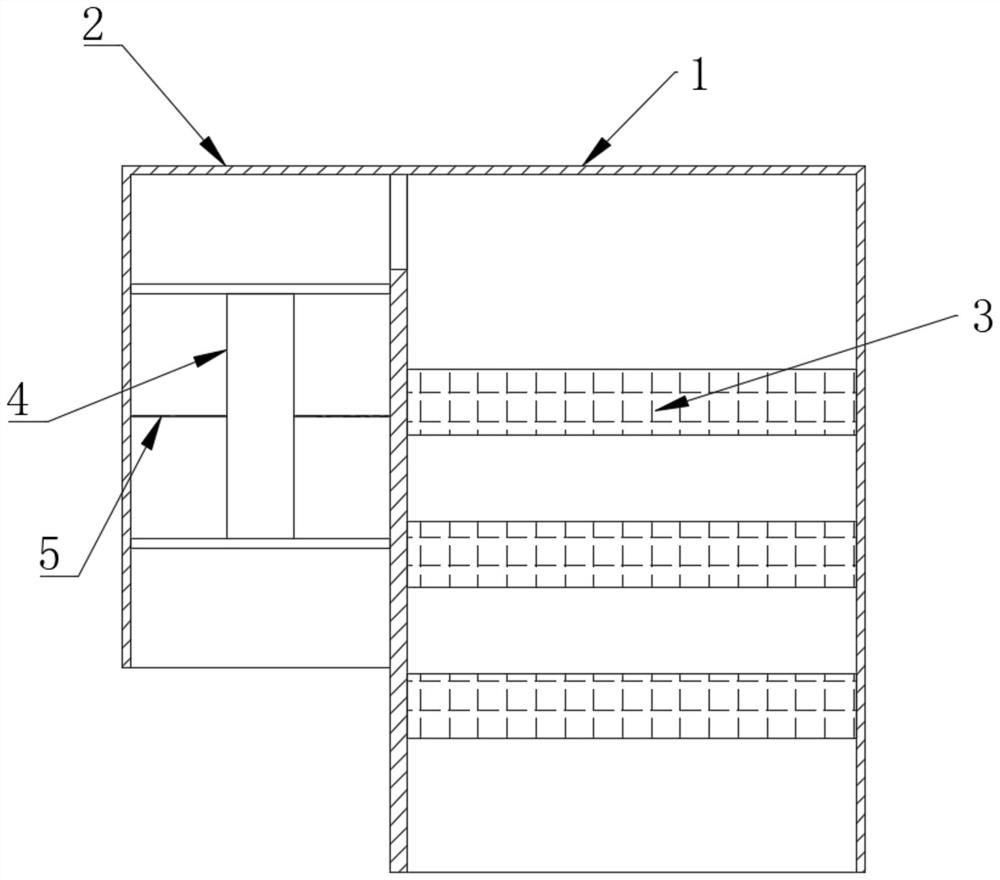

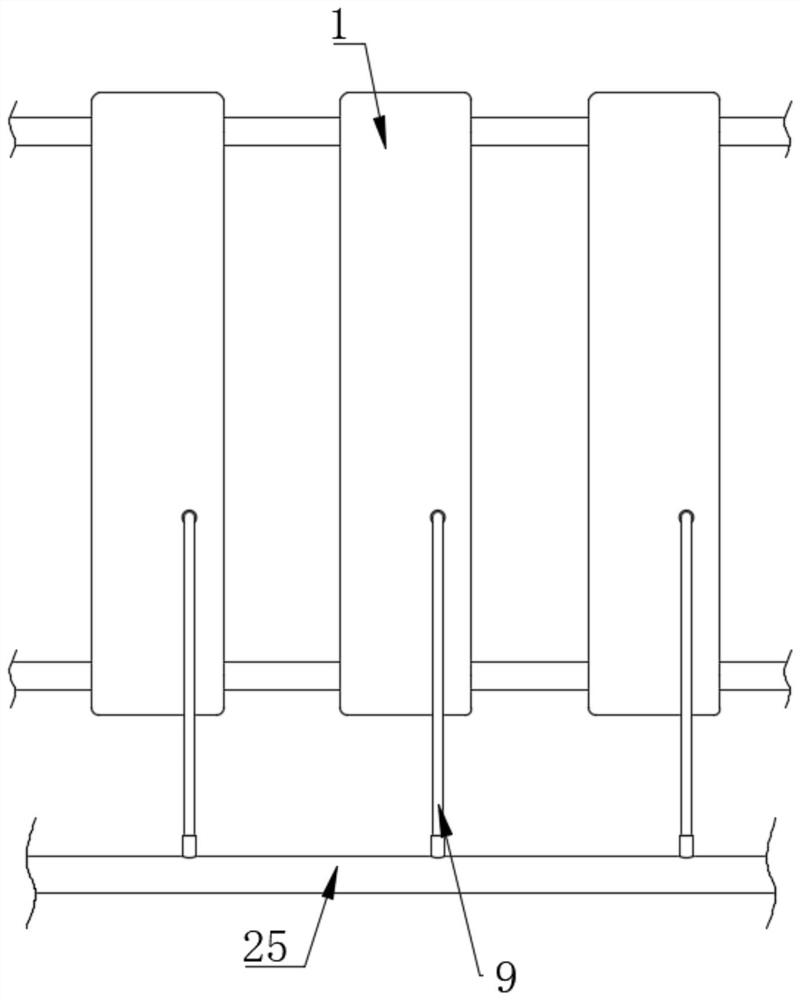

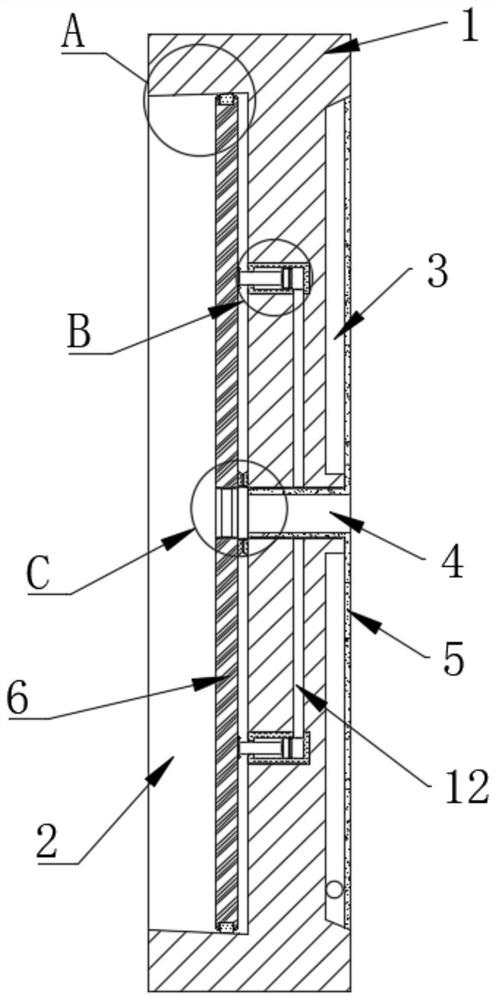

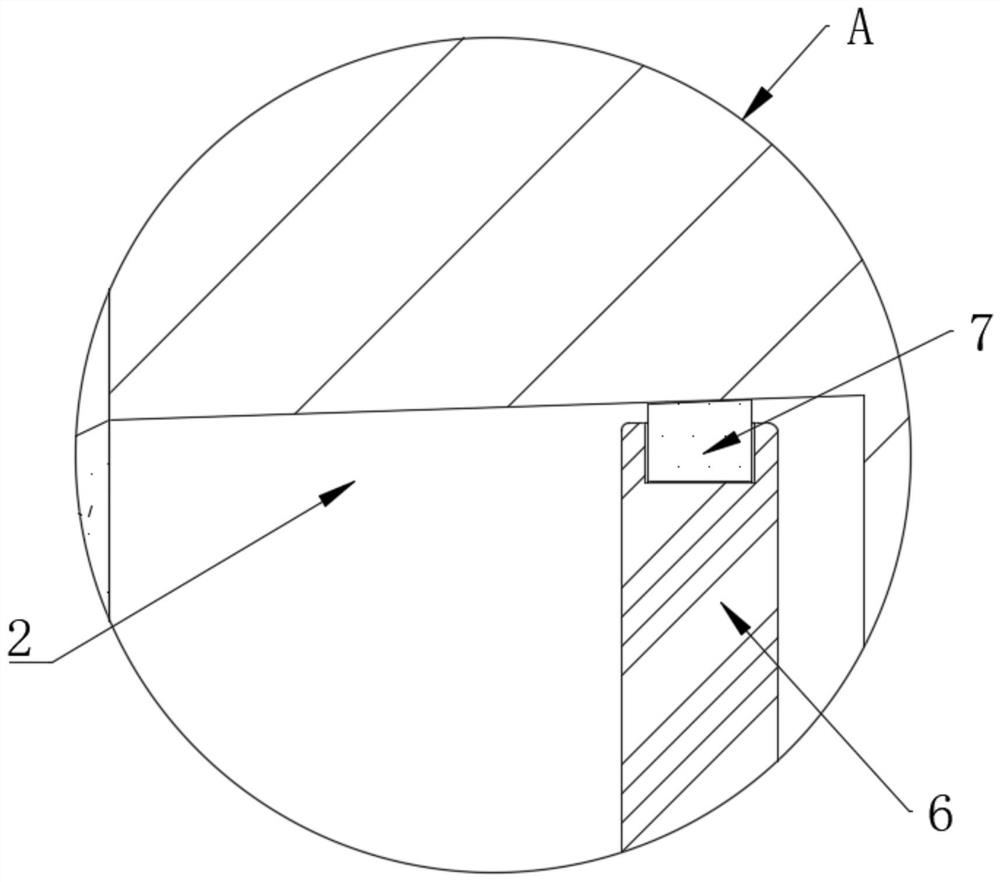

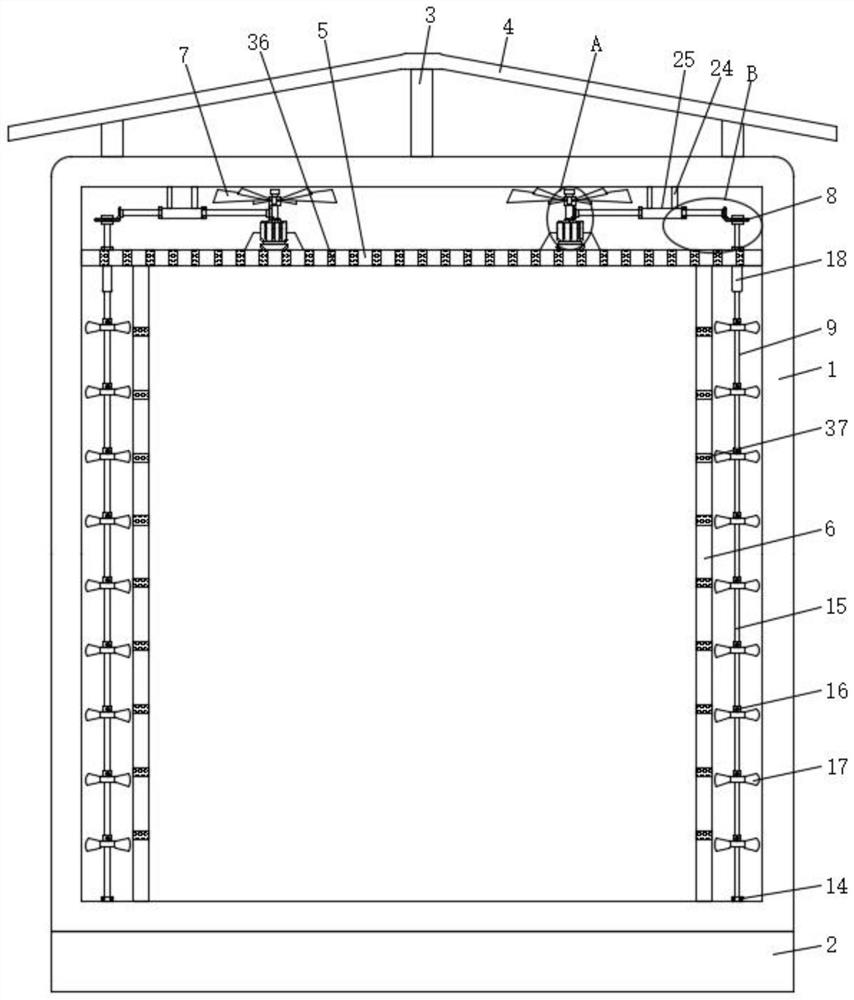

The invention relates to a true triaxial multifunctional shearing test device and method for a high-temperature and high-pressure hard rock, and belongs to the technical field of rock indoor loading experience. The true triaxial multifunctional shearing test device comprises a hydraulic system, a left-end combination tangential loading oil cylinder, a right-end combination tangential loading oil cylinder, a front-end combination lateral loading oil cylinder, a rear-end combination lateral loading oil cylinder, an upper normal loading oil cylinder, a lower normal loading oil cylinder, an annular framework, a lateral auxiliary push-pull framework, an annular framework support platform, a horizontal support plate and an experiment box. Shearing test of the hard rock under a true triaxial condition is initially achieved. In order to meet true triaxial test under the true triaxial condition, the invention designs the loading frameworks and the oil cylinders which have brand-new structures.The integral rigidity of equipment is improved, and meanwhile, a full-section stress coverage loading mode of a rock sample during the true three-way shearing process is ensured; and by improving a front-end cooling mode of the oil cylinder, and the situation that the temperature of hydraulic oil in the oil cylinder is raised at a high temperature reaching 300 DEG C to affect normal motion of an actuator can be prevented.

Owner:NORTHEASTERN UNIV LIAONING

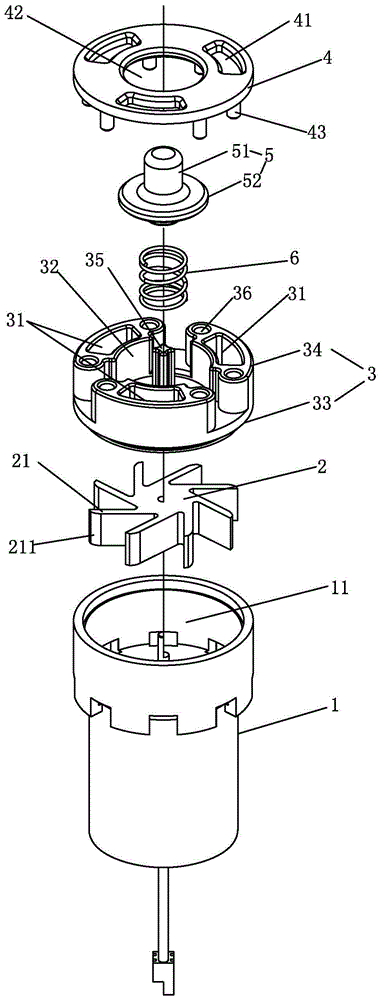

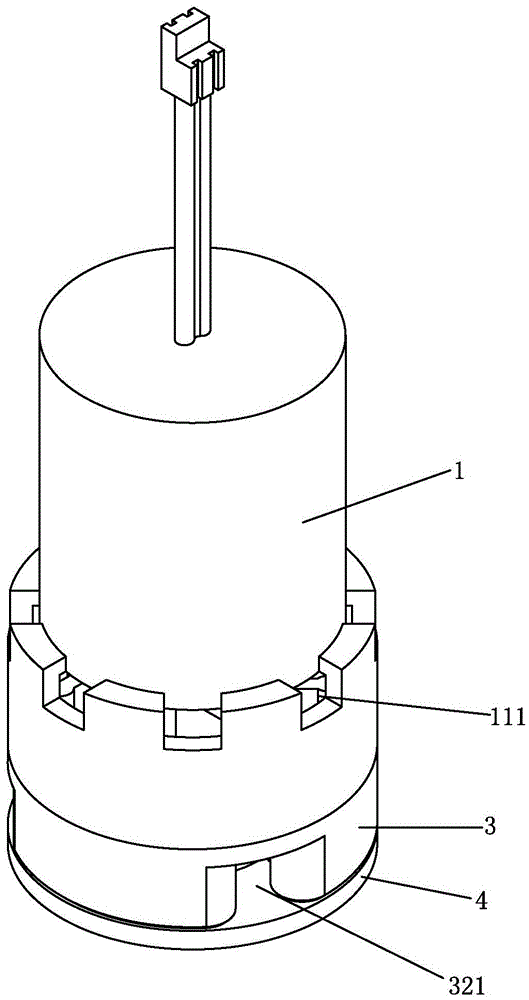

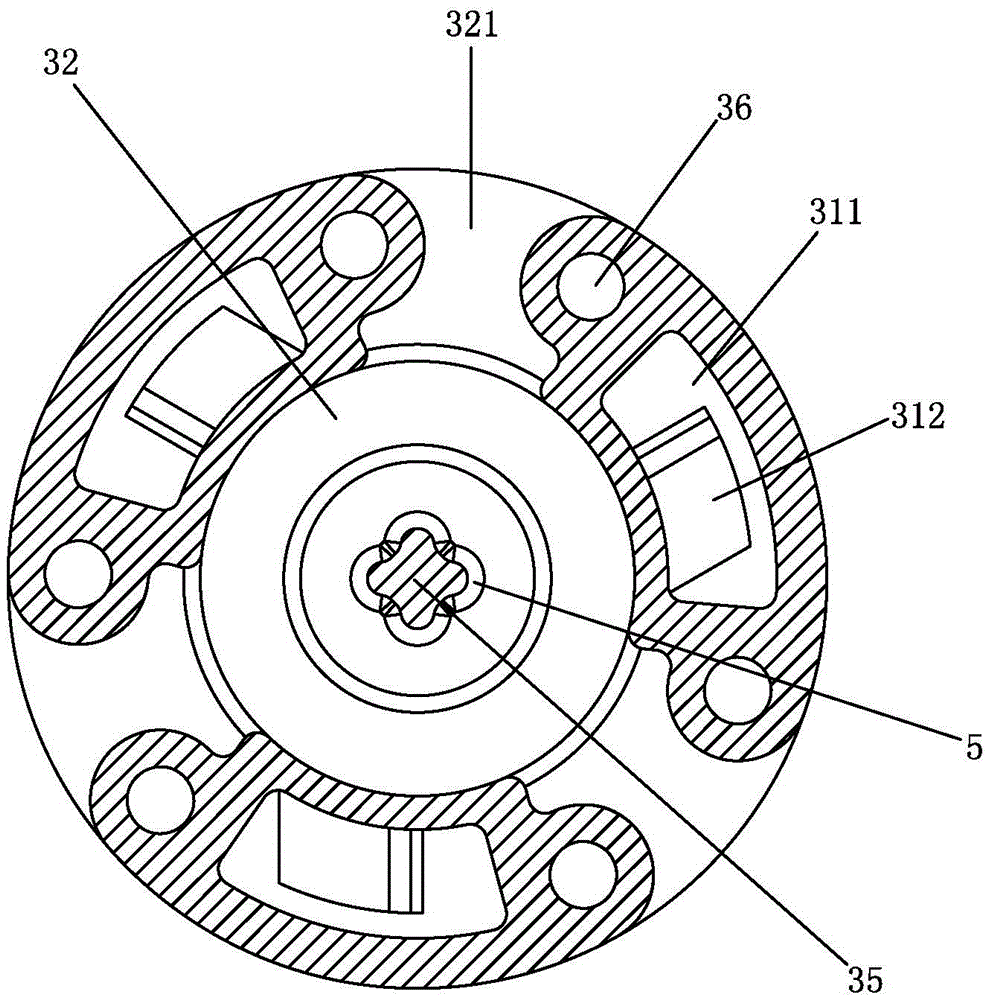

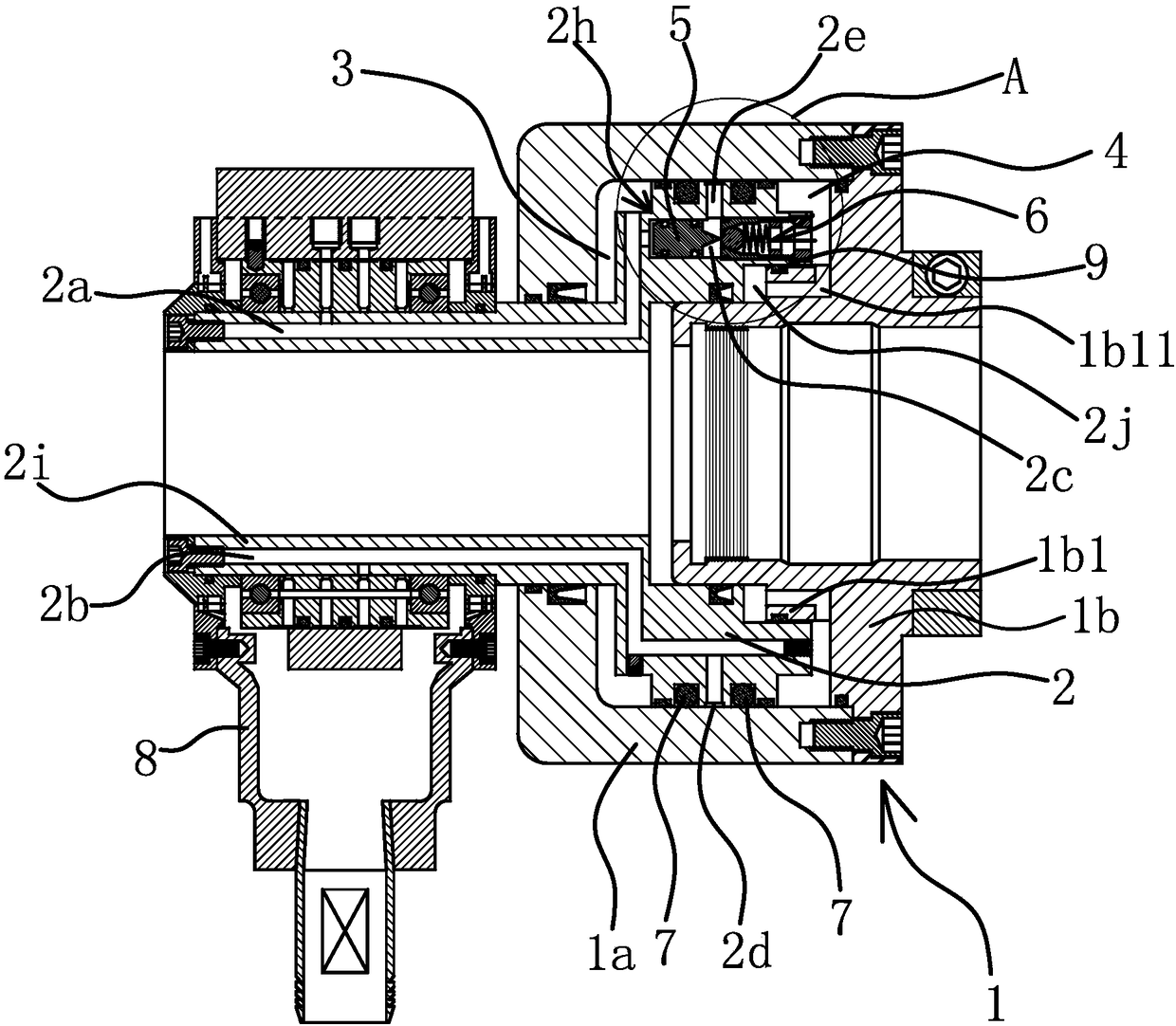

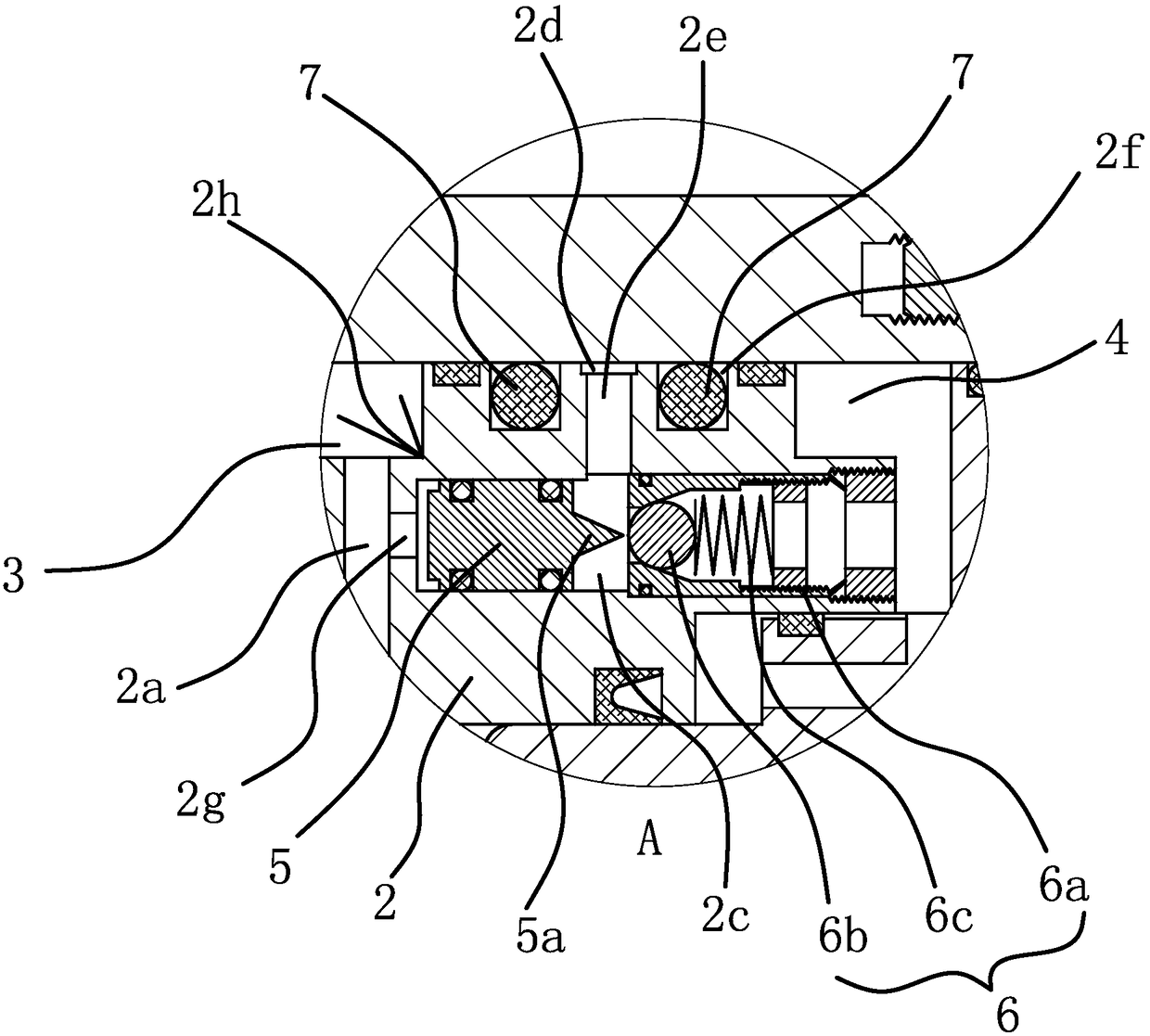

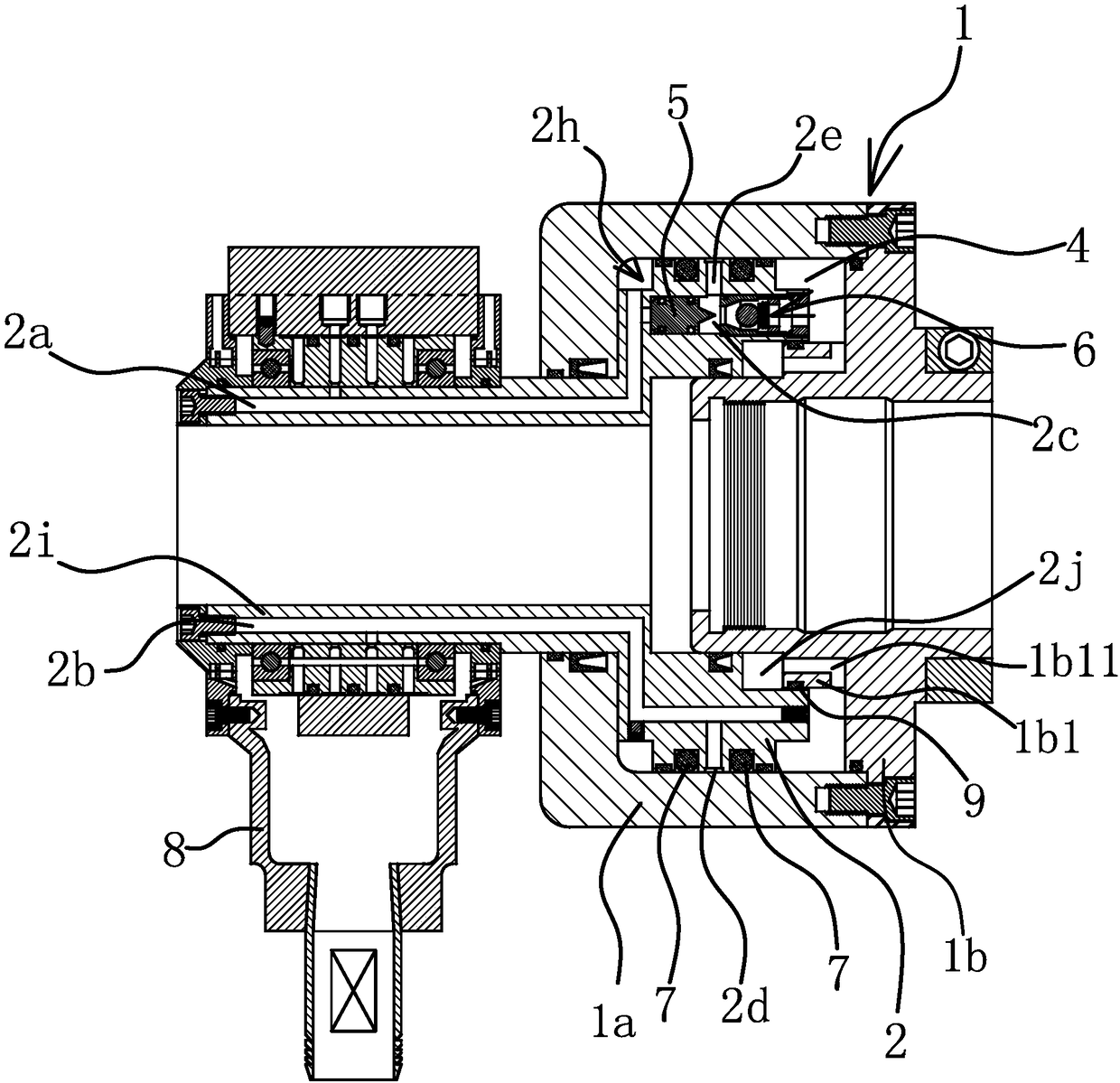

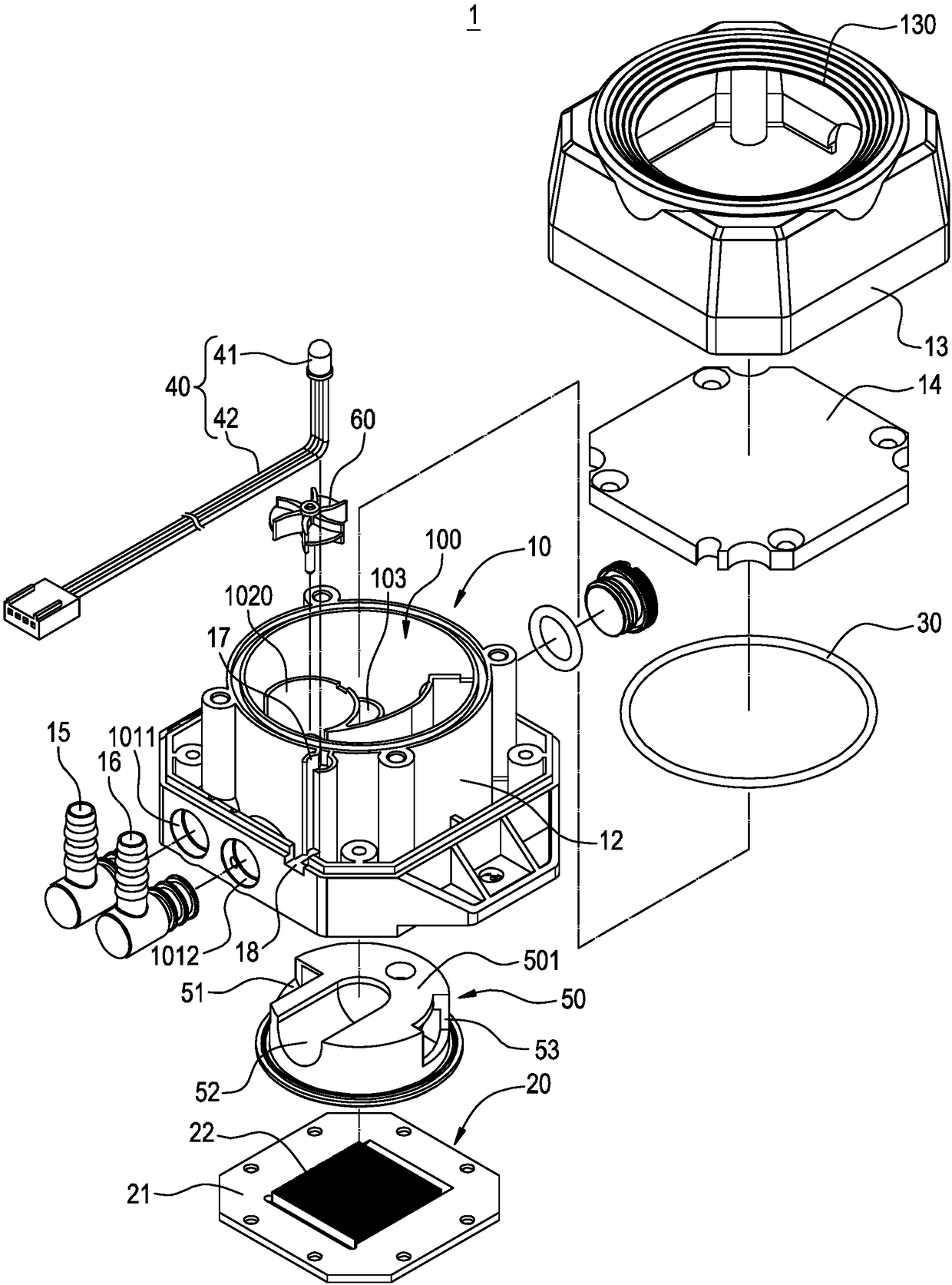

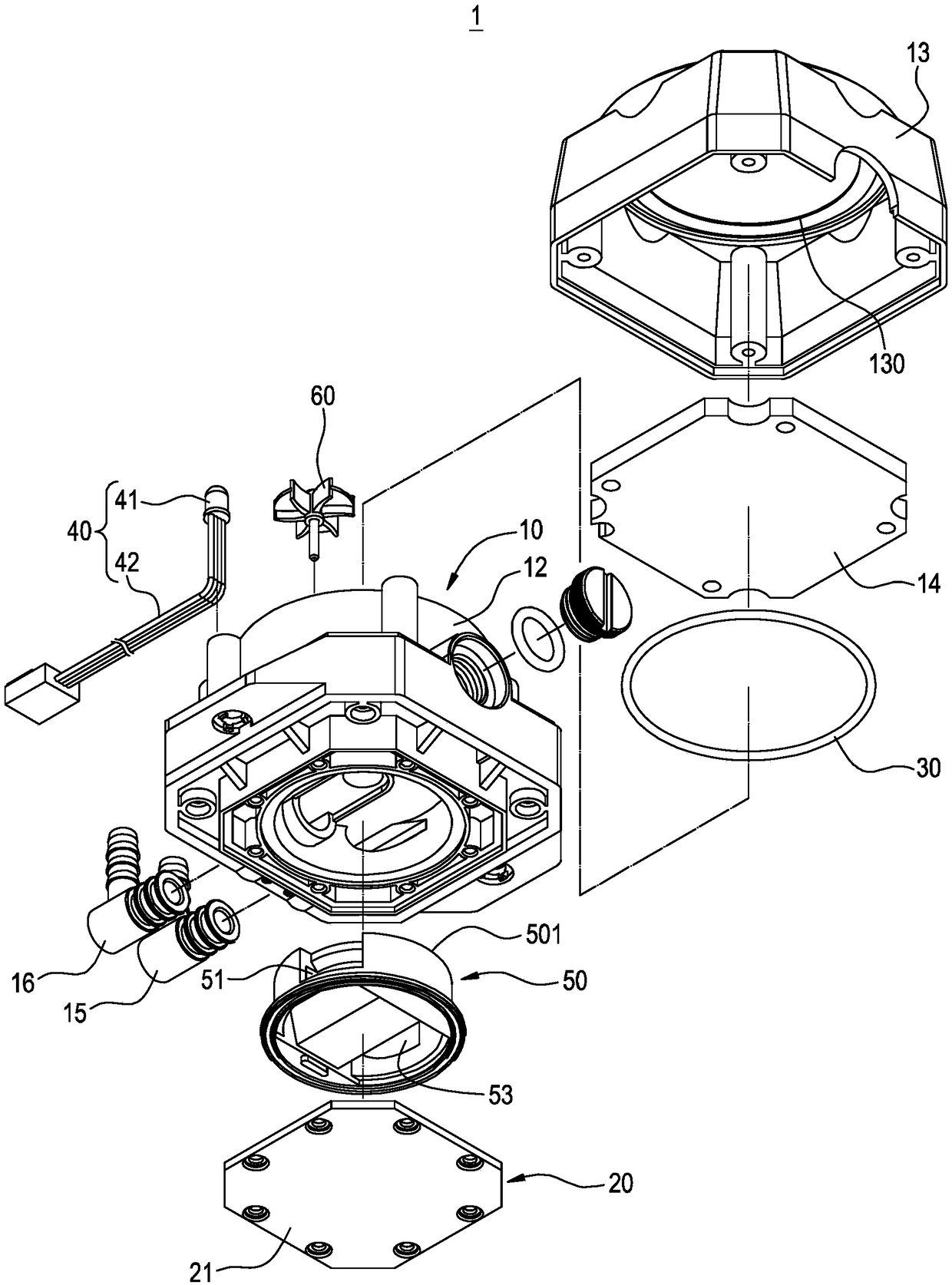

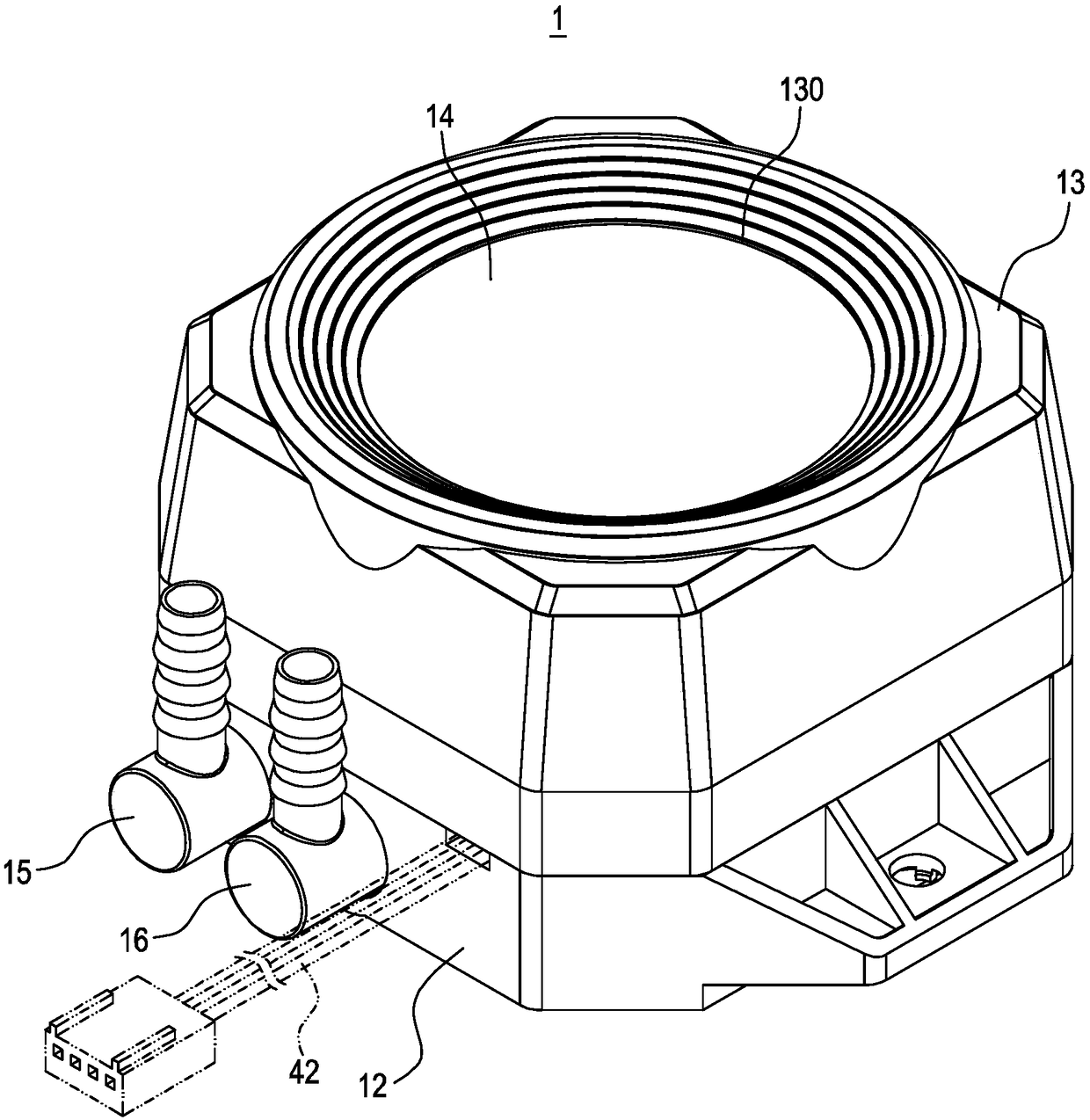

Hydroelectric generator with flow control function, and shower faucet

ActiveCN105782560AWill not hinder normal circulationLow costHydro energy generationReaction enginesImpellerWater flow

The invention discloses a hydroelectric generator with a flow control function, and a shower faucet. The hydroelectric generator comprises an electric generator body and a valve. The valve is provided with a first runner and a second runner which are capable of being communicated with a same water supply pipeline. The first runner is communicated with an impeller cavity of the electric generator body. Through the first runner, water flow is pressurized and conveyed into the impeller cavity of the electric generator body so as to drive an impeller to rotate. The impeller cavity is provided with a water outlet. The valve is provided with a control valve body which is controlled by water supply pressure and can be reset. The control valve body controls the second runner to discharge water or not. According to the hydroelectric generator and the shower faucet, under the low water pressure condition, water can be made to flow the impeller cavity of the electric generator body completely, and power generation of the electric generator body is not influenced; and under the high water pressure condition, part of water flows out through the second runner and provides efficient flow for the rear end together with water flowing out from the impeller cavity, so that normal flowing of the water flow is not hindered. The hydroelectric generator and the shower faucet further have the characteristics of being simple in structure, convenient to produce and assemble, low in cost and the like.

Owner:JOMOO KITCHEN & BATHROOM

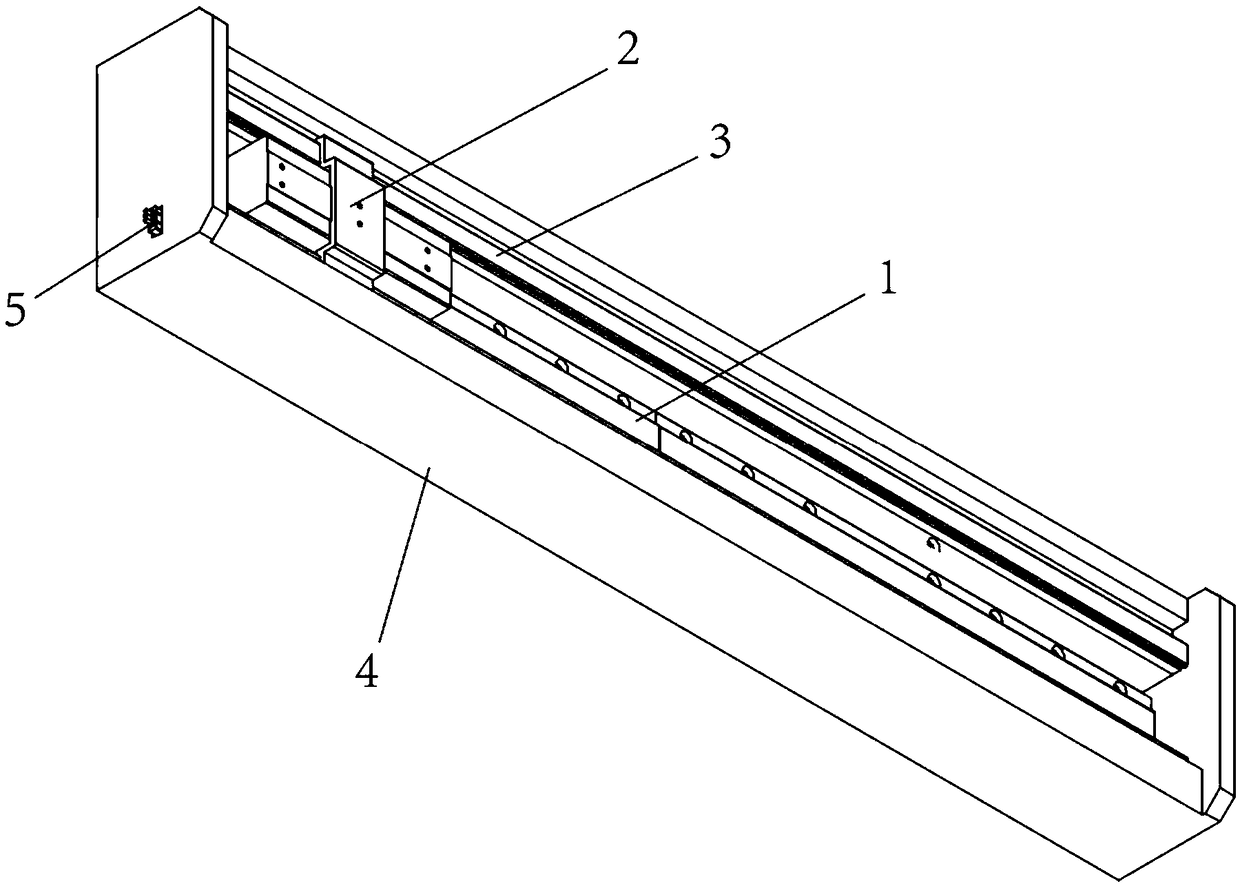

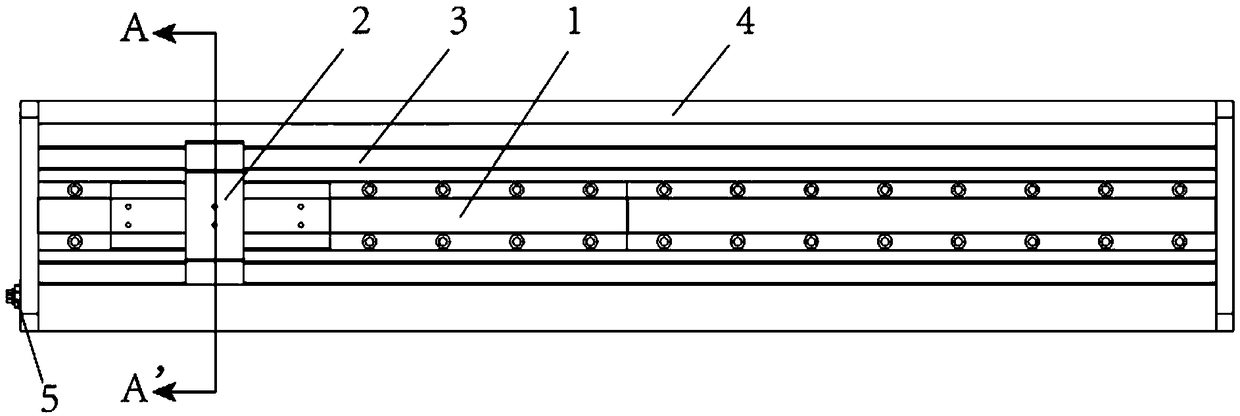

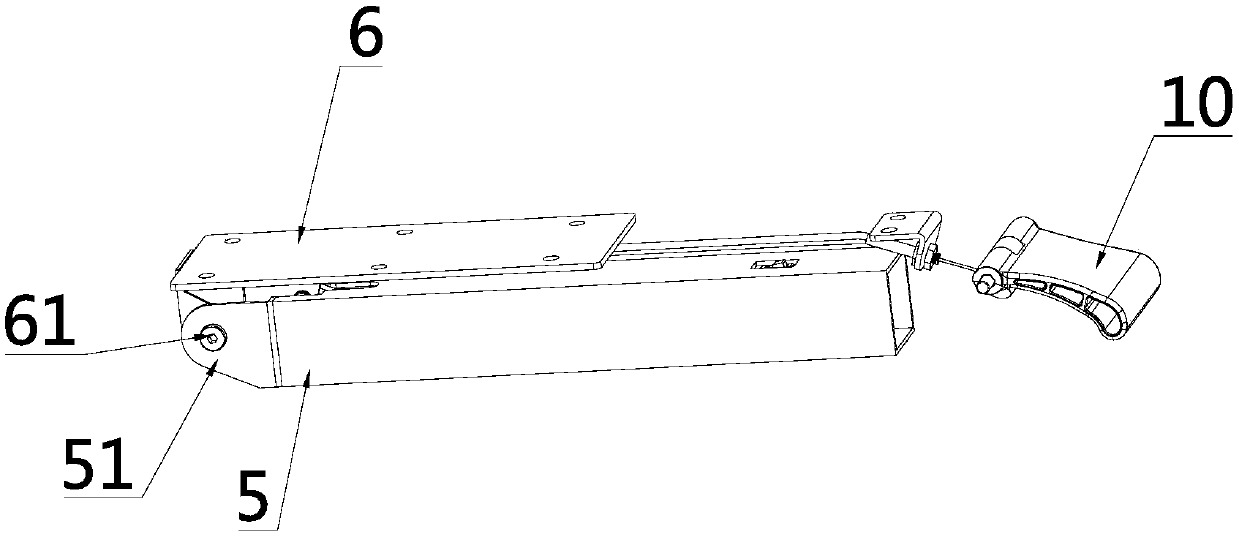

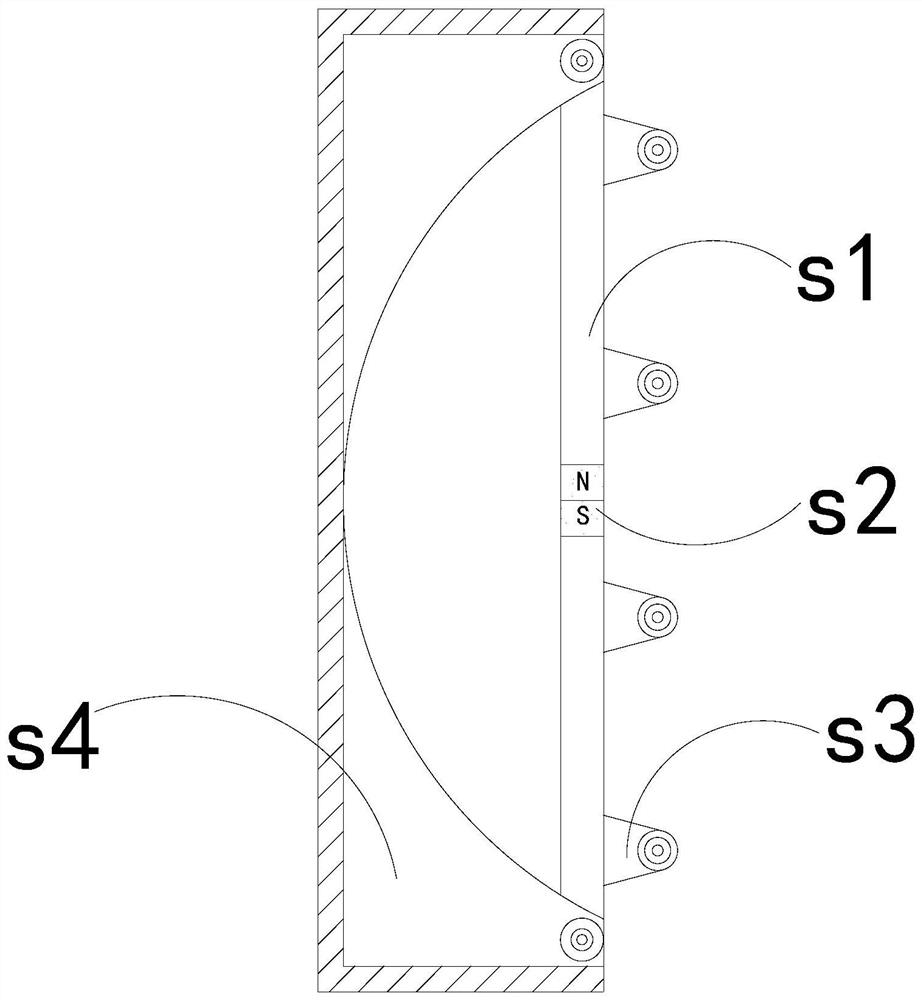

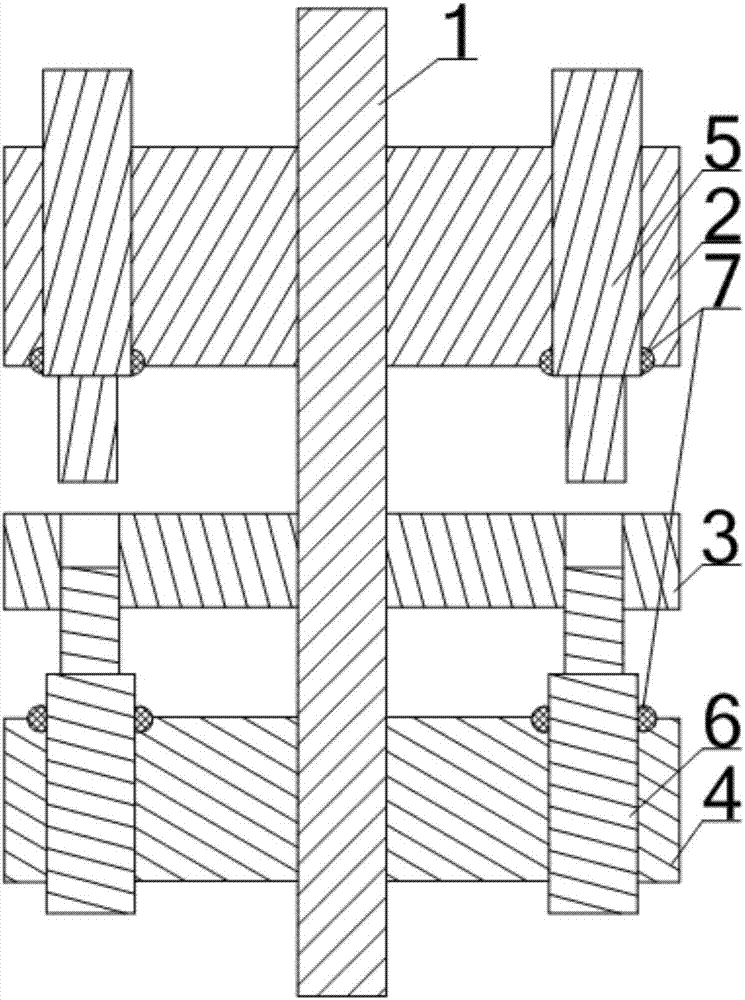

A linear motor

PendingCN109104067AAvoid fatigue damageSmall footprintNon-rotary current collectorPropulsion systemsCable carrierPower cord

The invention provides a linear motor, which relates to the technical field of the motor. The linear motor comprises a stator magnetic plate, a mover and a power supply sliding rail, wherein the moveris arranged above the stator magnetic plate, a gap is arranged between the mover and the stator magnetic plate, the power supply sliding rail is parallel to the moving direction of the mover, and a conductive component is arranged on the mover, and the conductive component is in contact with the power supply sliding rail. The linear motor provided by the invention, when in operation, the power supply sliding rail is kept stationary, only the conductive component on the mover moves together with the mover, and does not need to be bent in the movement process, and only needs to be kept in contact with the power supply guide rail. The power cord does not need to be moved all the way to avoid fatigue damage caused by multiple bending. It also avoids that the aging of the chain affects the normal motion of the mover during the movement. The power guide takes up less space than the towed chain.

Owner:GREE ELECTRIC APPLIANCES INC OF ZHUHAI

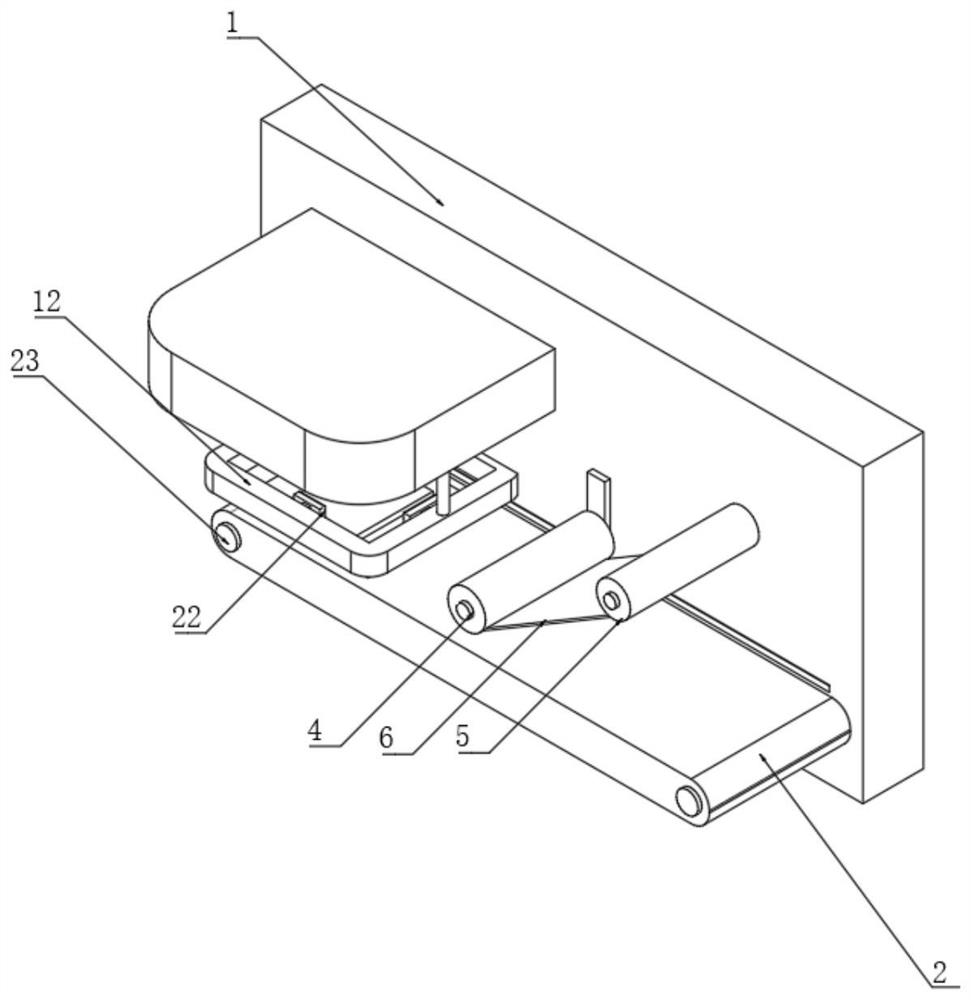

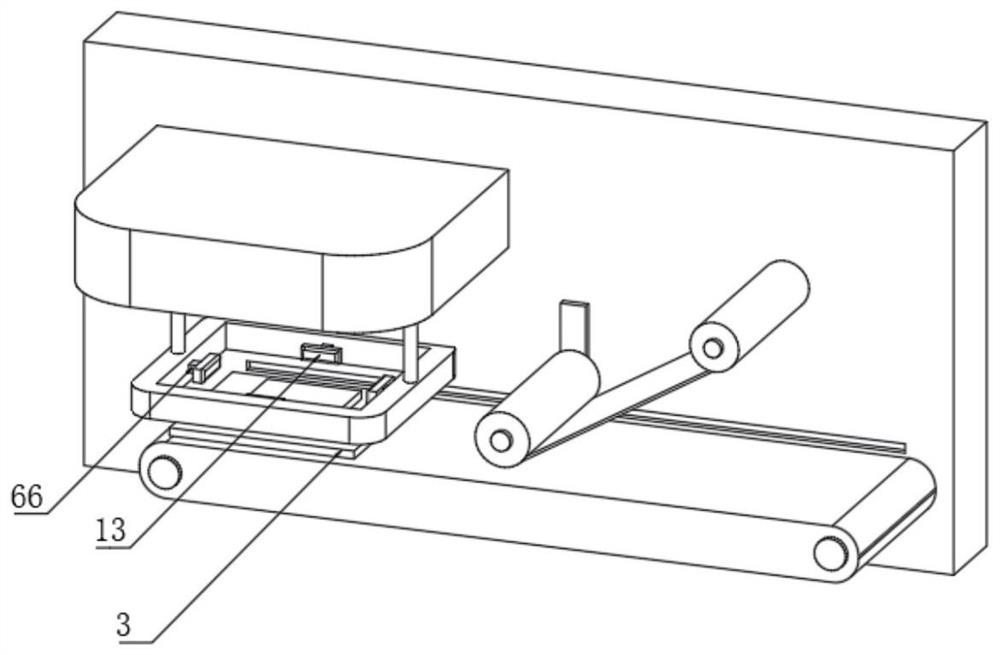

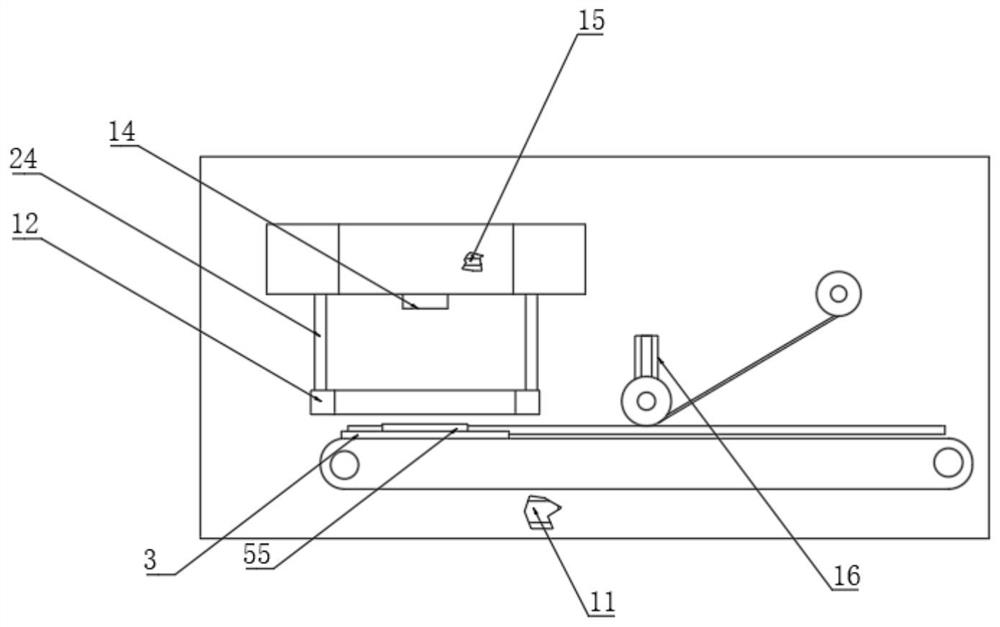

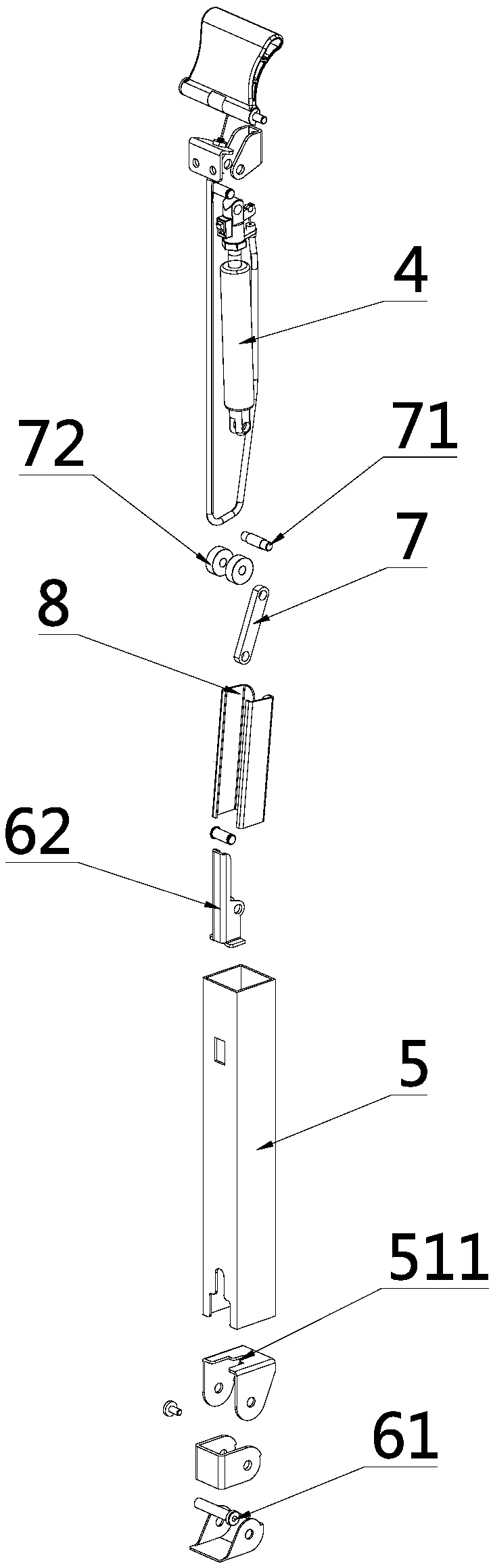

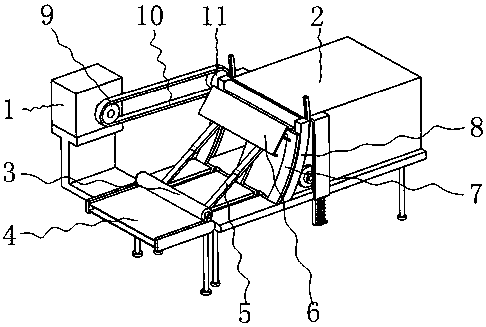

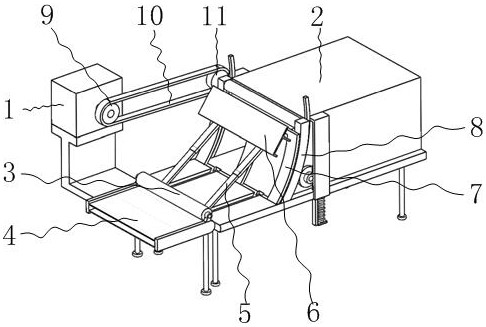

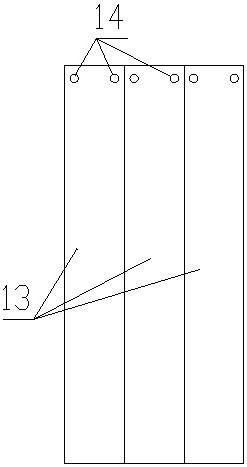

Film positioning and laminating device for film laminating machine

InactiveCN112158568AImprove pass rateAffect normal movementConveyorsControl devices for conveyorsThin membraneEngineering

The invention discloses a film positioning and laminating device for a film laminating machine, and particularly relates to the technical field of film laminating equipment. The film positioning and laminating device comprises a film laminating machine body, a conveying belt is arranged on the film laminating machine body, a positioning plate is fixedly arranged on the conveying belt, a pressing roller is further arranged on the conveying belt, a conveying roller is arranged above the pressing roller, and a thin film is wound between the pressing roller and the conveying roller; and rectangular array grooves are formed in the top of the positioning plate, an adsorption hole is formed in each rectangular array groove, and an electromagnetic valve is arranged in each adsorption hole. According to the film positioning and laminating device, through the arrangement of the rectangular array grooves, a camera can shoot the positions of workpieces in the rectangular array grooves, shot imagesare compared with workpiece image data which are shot and positioned in advance in a memory through a controller, comparison can be more accurate through the rectangular array, and the attaching precision is greatly improved; and different workpiece positioning image information is stored in advance, so that workpieces of different specifications are automatically positioned, and the applicability is high.

Owner:昆山德美恒业电子有限公司

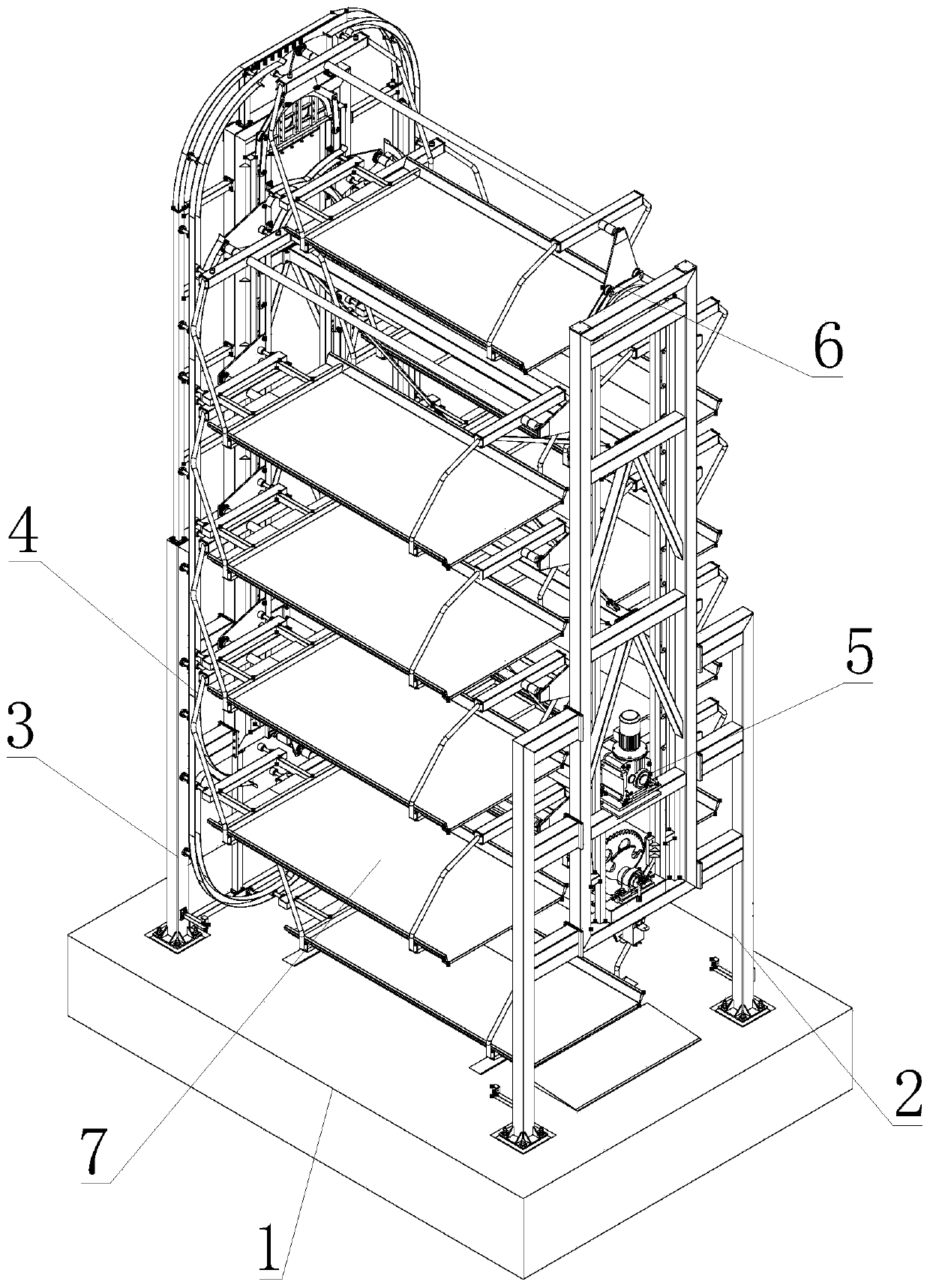

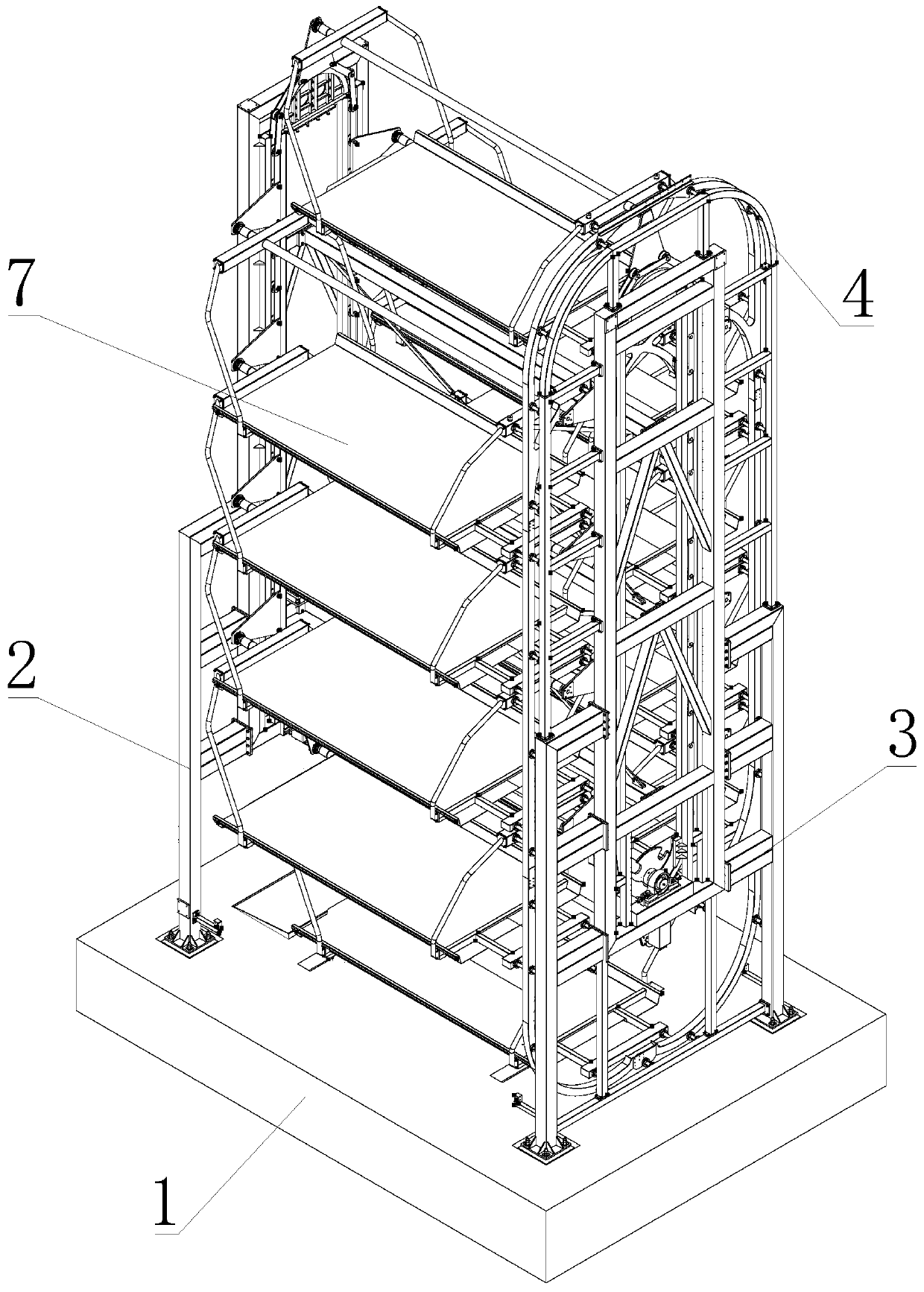

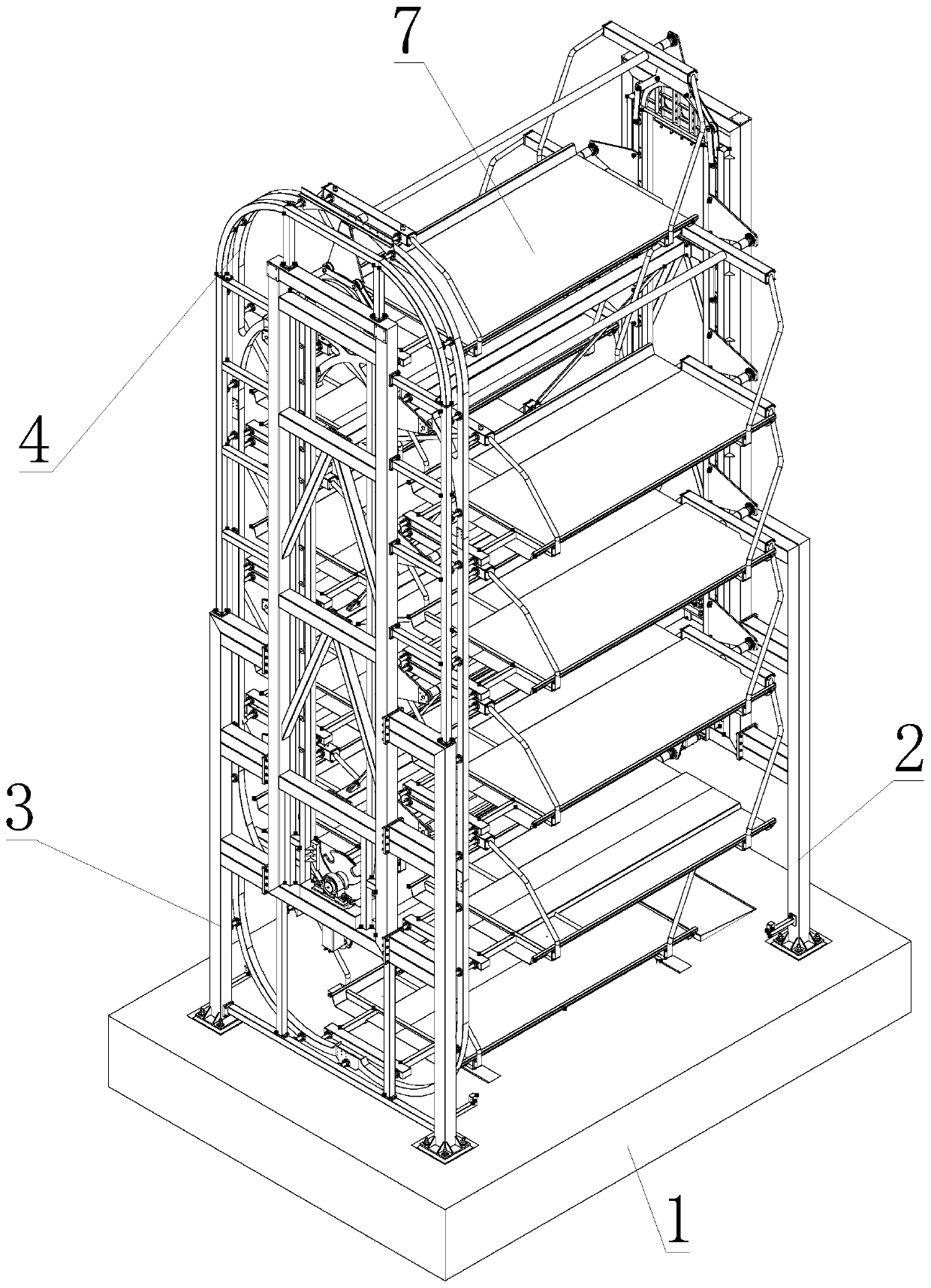

Vertical circulating garage for vehicle parking and using method thereof

The invention discloses a vertical circulating garbage for vehicle parking and a using method thereof. A first garbage bracket and a second garbage bracket are fixedly mounted on a garbage base station in parallel; a drive mechanism comprises a drive motor, a speed reducer, a drive chain, a driven chain wheel, a drive shaft and bearings with seats; the drive motor is mounted on the speed reducer;the speed reducer is fixedly mounted on the first garbage bracket; a drive chain wheel is connected on the speed reducer; the drive chain wheel is connected to the driven chain wheel through the drivechain; the driven chain wheel is fixedly mounted on the drive shaft; the two ends of the drive shaft are fixedly equipped with drive wheels; the two ends of the drive shaft are rotatably connected tothe bearings with the seats; and the bearings with the seats are fixedly mounted on the first garbage bracket and the second garbage bracket. The vehicle circulating garbage has the advantages of being simple in control, small in floor space, convenient to operate, high in vehicle taking speed, economical and reliable.

Owner:合肥市春华起重机械有限公司

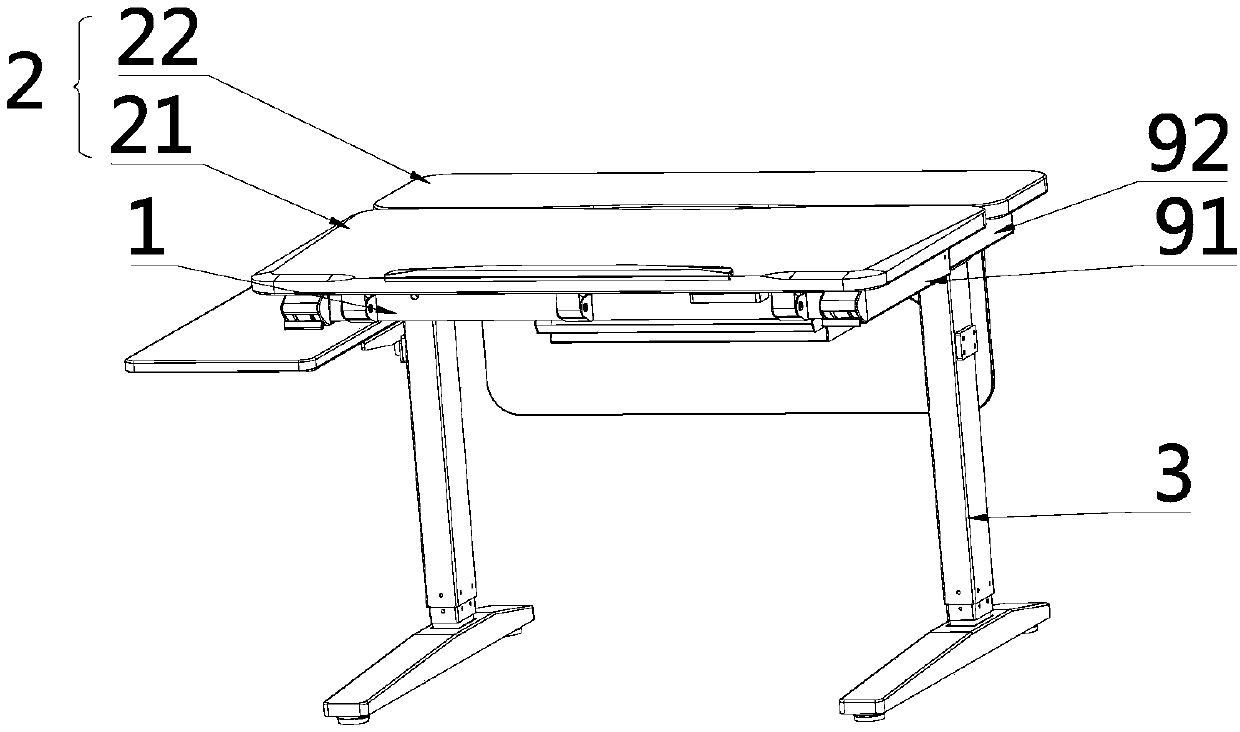

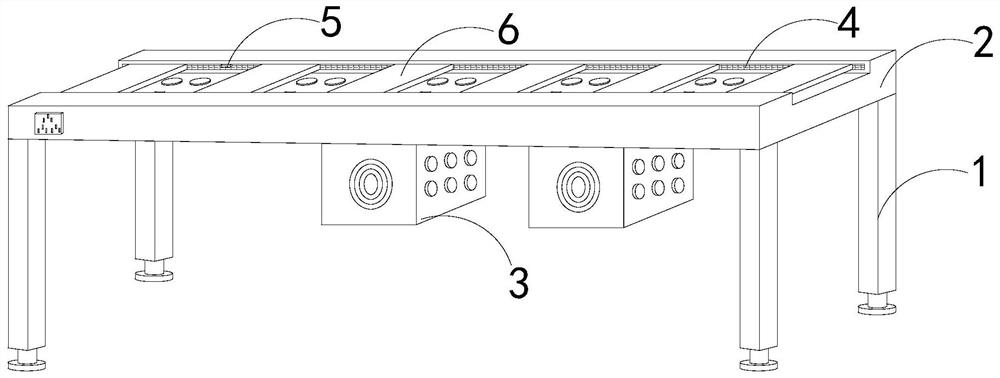

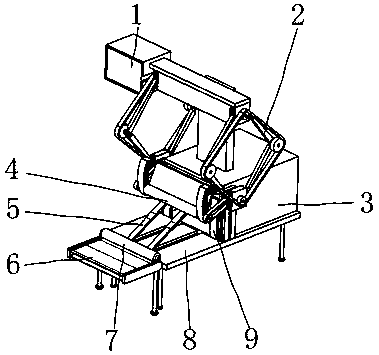

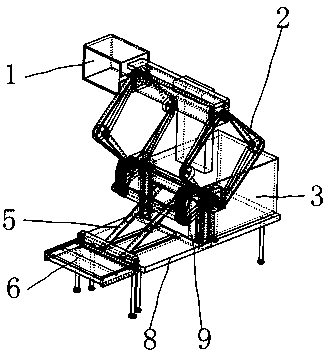

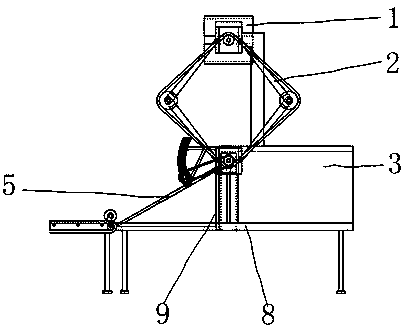

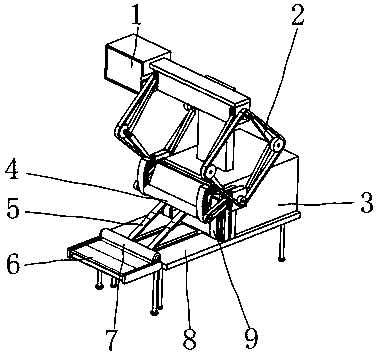

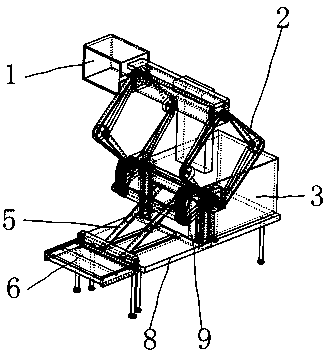

Learning table with automatic overturning table board

PendingCN107550022AAffect normal movementImprove stabilityFurniture partsSchool benchesStructural engineeringMechanical engineering

Owner:ZHEJIANG JUYOU INTELLIGENT TECH CO LTD

Speed chain assembly line

The invention discloses a speed chain assembly line. The speed chain assembly line structurally comprises a supporting frame, a workbench, a distribution box, a chain, a stop block and a tool plate, wherein the workbench is fixed to the top of the supporting frame, the distribution box is installed at the bottom of the workbench, due to fact that conveying speed of the assembly line is changed andexteriors of a part of parts are smooth and round, conveying speed of the tool plate is increased, when tool plate suddenly stops when passing through the stop block and collides with the stop block,the stop blocks stop and clamp the parts, so that the situation that the parts move forwards under the action of inertia force and are likely to be disengaged from the surface of the tool plate to fall off, the surfaces of the parts collide, the shapes are changed, and assembling of the parts is affected is reduced, a check block is limited through a side block and clamping teeth in an opening, the situation that when a part collides with the check block, normal clamping and blocking of the part are affected due to the fact that the position of the check block is prone to being changed is relieved, and the situation that the position of the check block is changed due to collision force, and normal movement of the tool plate is affected is reduced.

Owner:泉州市启明电子设备有限公司

Combined air purification method having self-cleaning function

InactiveCN109091993AAdjust the rotation speedAdjustable speedCombination devicesDispersed particle filtrationEngineeringAir purification

The invention discloses a combined air purification method having a self-cleaning function. Supporting legs are mounted on the outer wall of a barrel, the inner walls of the supporting legs are connected with the outer wall of the barrel, the left side outer wall of the barrel is provided with an air outlet, the outer wall of the air outlet is connected with the inner wall of the barrel, the rightside outer wall of the barrel is provided with an air inlet, the inner wall of the air inlet is connected with the outer wall of the barrel, and a machine frame is mounted at the top end of the outerwall of the barrel. According to a combined air purification device having the self-cleaning function, through a motor and a rotating shaft and the cooperation between the motor and the rotating shaft, under the action of a filter core, the existing combined air purification method having the self-cleaning function can receive more acceptance on the market, the product quality of the combined airpurification method having the self-cleaning function is improved, a user's procurement cost is reduced, resource waste of the combined air purification device having the self-cleaning function is avoided, and the combined air purification device is suitable for popularization.

Owner:冯浩杰

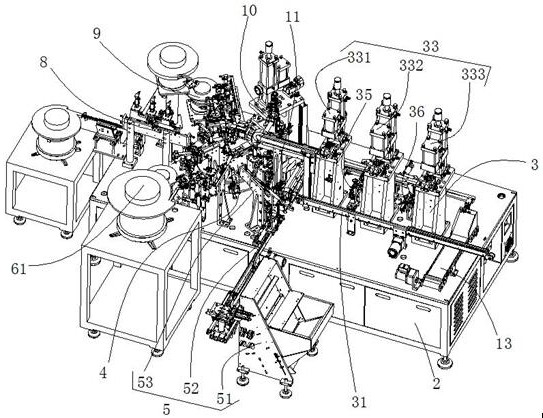

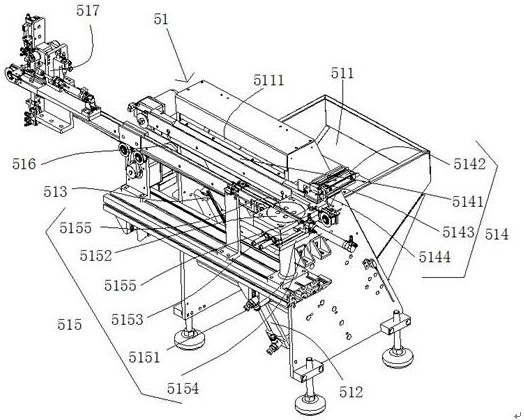

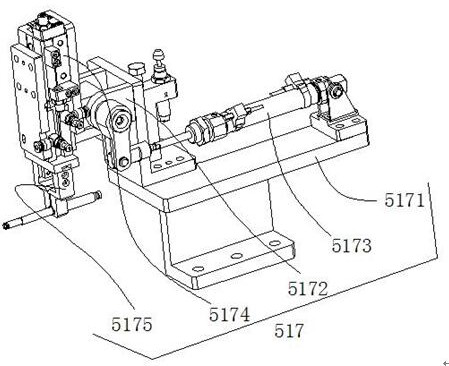

Latch bolt assembly machine

PendingCN111992626AHigh degree of automationLabor savingMetal-working feeding devicesPositioning devicesStructural engineeringRobot hand

The invention discloses a latch bolt assembly machine. The latch bolt assembly machine comprises a rack component, a shifting fork riveting and pressing component, a rotating disk component, a latch bolt rod feeding component, a long spring feeding component, a front separation blade feeding component, a support piece feeding component, a rear separation blade and short spring feeding component, arod end riveting and pressing component, a transfer discharging mechanical arm and a detection component; the rotating disk component is arranged on the rack component; along a circumferential side of a rotating direction of the rotating disk component, the latch bolt rod feeding component, the long spring feeding component, the front separation blade feeding component, the support piece feedingcomponent, the rear separation blade and short spring feeding component, the rod end riveting and pressing component and the transfer discharging mechanical arm are orderly arranged; the shifting forkriveting and pressing component is located at a right side of the rotating disk component; and the detection component is arranged on the rotating disk component. The latch bolt assembly machine provided by the invention has high automation degree, can realize regular work just by one person, and can solve a problem of too much high labor cost.

Owner:厦门致迩科技有限公司

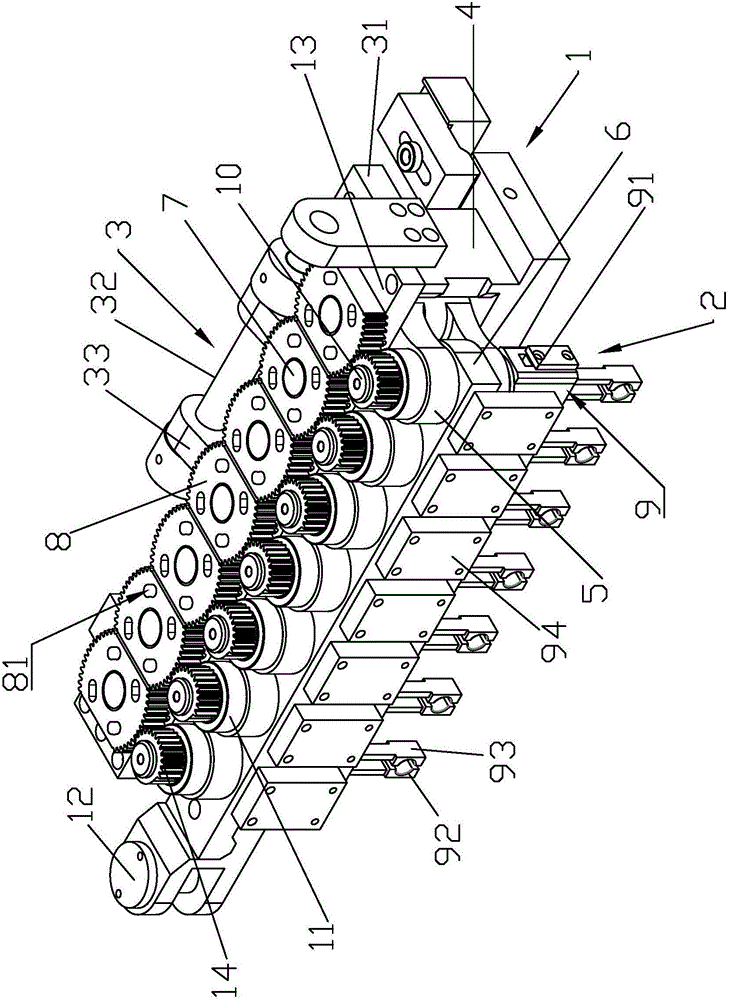

Clamping device of eight-station cold heading machine

ActiveCN105692192AReduce lateral forceRigid enoughConveyor partsWorking environmentIndustrial engineering

The invention discloses a clamping device of an eight-station cold heading machine. The clamping device comprises a clamping table mechanism and a clamping core mechanism, wherein the clamping table mechanism is connected with the clamping core mechanism, the clamping table mechanism comprises a clamp box, a clamping table connecting rod and a clamping table oscillating rod, the clamping table connecting rod is connected with the clamping table oscillating rod, the clamping table oscillating rod is installed in the clamp box, a clamping table oscillating rod shaft is connected to the clamping table oscillating rod, a guide gear is arranged on the clamping table oscillating rod shaft, the clamping core mechanism comprises a clamping core shaft and a clamping assembly, a rolling gear is arranged on the upper part of the clamping core shaft, the rolling gear is engaged with the guide gear, the clamping table connecting rod and the clamping table oscillating rod are connected to the middle of the clamping core shaft, and the clamping assembly is connected to the lower part of the clamping core shaft. The device has the advantages of simple and compact structure, high degree of automation, stable working performance and high production efficiency, both the clamping table connecting rod and the clamping table oscillating rod are wrapped in the clamp box, so that the normal movement of the clamping table mechanism is not influenced by the outside adverse working environment, and the exposed part of equipment is reduced, so that materials are saved.

Owner:浙江东雄机床有限公司

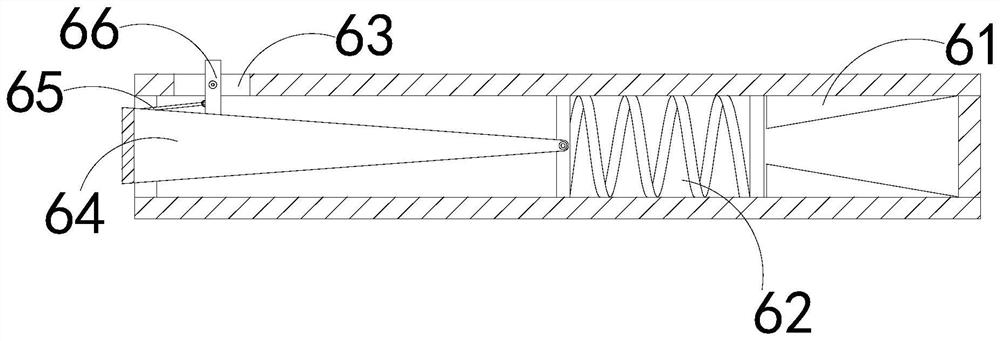

Angling cylinder with pressure maintaining function

PendingCN108533569AStay clampedAffect subsequent processing accuracyFluid-pressure actuator safetyLarge fixed membersEngineeringCylinder block

The invention provides an angling cylinder with a pressure maintaining function, belongs to the technical field of machinery and solves the problem that the conventional angling cylinder does not havethe pressure maintaining function and is poor in stability. The angling cylinder comprises a cylinder body and a big piston arranged in the cylinder body and capable of moving forwards and backwards,wherein an oil chamber I is formed by the rear end of the big piston and the inner wall of the cylinder body, an oil chamber II is formed by the front end of the big piston and the inner wall of thecylinder body, an oil channel I and an oil channel II are formed in the big piston, an outlet of the oil channel I communicates with the oil chamber I, a positioning hole is formed in the big piston,the oil channel I communicates with the positioning hole, the oil chamber II communicates with the oil channel II through the positioning hole, a check valve and a small piston are arranged in the positioning hole from front to back, the check valve is closed in front-to-back direction and can be opened when the small piston moves forwards, the communication part of the oil channel I and the positioning hole is located at the rear of the small piston, and the communication part of the oil channel II and the positioning hole is located between the small piston and the check valve. The angling cylinder has the advantages that pressure maintaining can be realized, normal work of the angling cylinder can be guaranteed, stability is good, and the like.

Owner:玉环广越机械有限公司

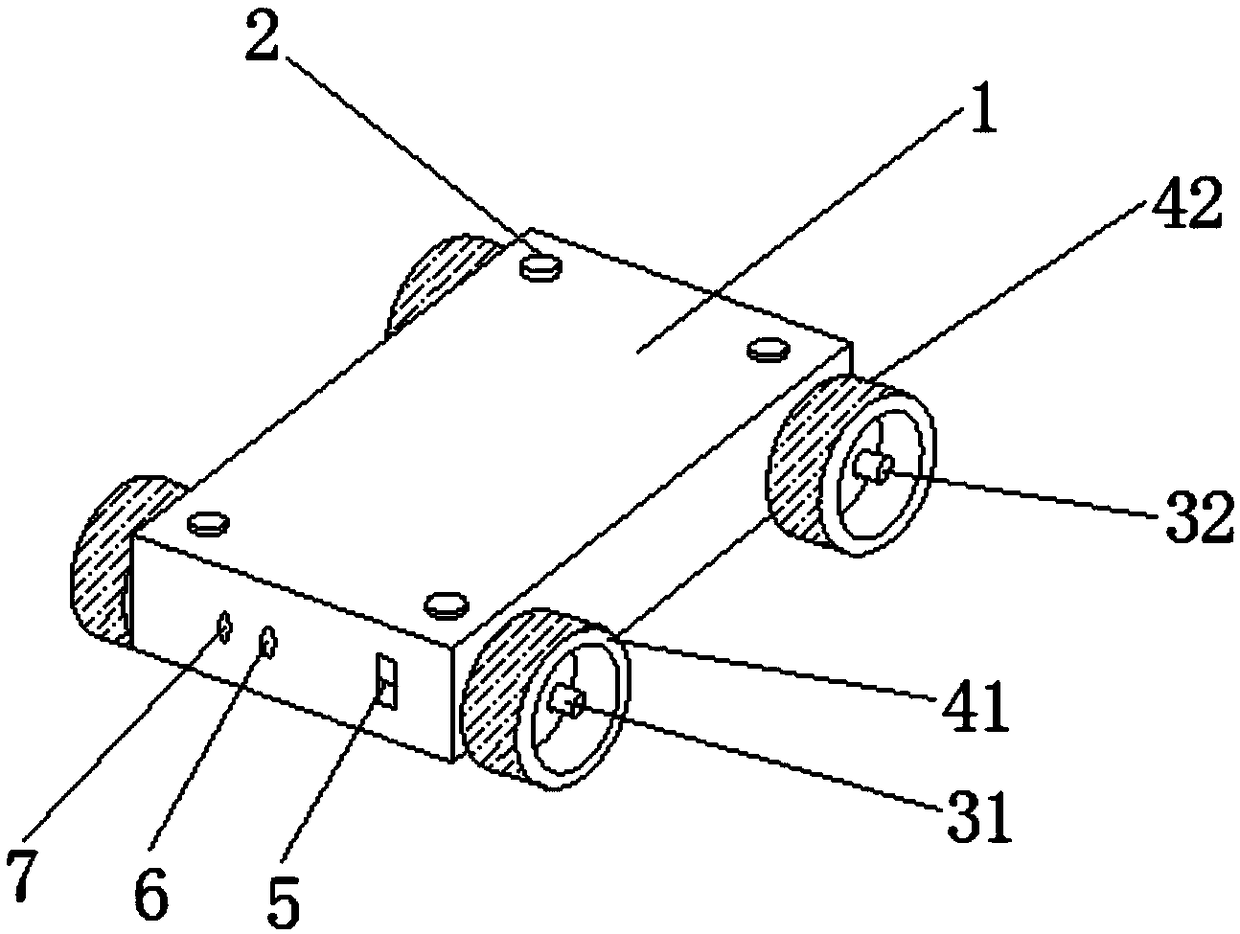

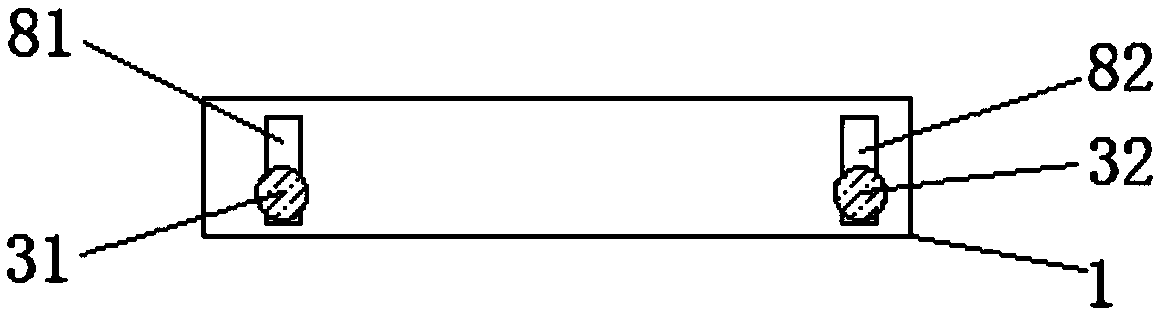

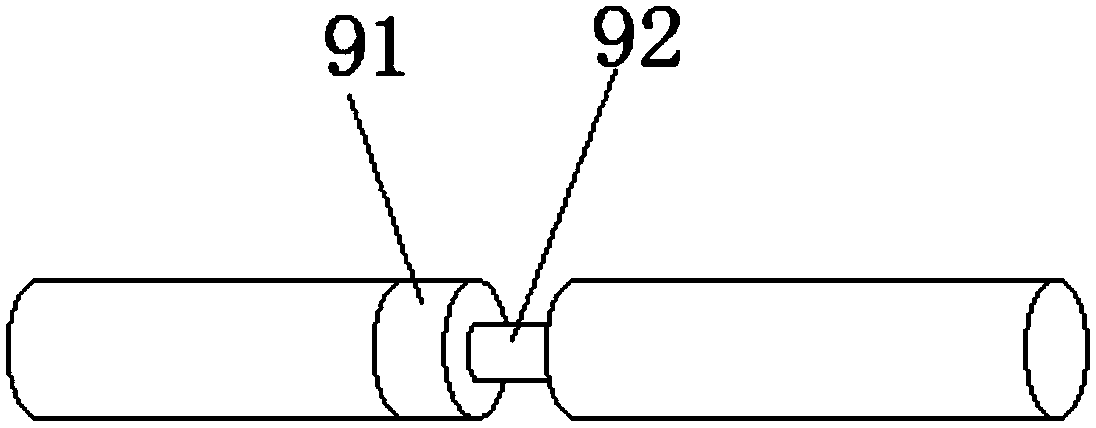

Adjustable chassis used for robot

InactiveCN109278486AImprove passabilityAffect normal movementResilient suspensionsVehicle springsControl systemEmbedded system

The invention discloses an adjustable chassis used for a robot. The adjustable chassis comprises a chassis body, a front drive axle, a rear drive axle and a chassis control system, wherein the front drive axle and the rear drive axle are separately arranged in parallel on the chassis body; two opposite sides of the chassis body are separately provided with first sliding grooves in the vertical direction; two ends of the front drive axle are separately arranged in the first sliding grooves in a clamping manner; the two opposite sides of the chassis body are also separately provided with secondsliding grooves in the vertical direction; two ends of the rear drive axle are separately arranged in the second sliding grooves in a clamping manner; the chassis control system is arranged in the chassis body; and the chassis control system can control the front drive axle to slide along the first sliding grooves and control the rear drive axle to slide along the second sliding grooves. The adjustable chassis used for the robot overcomes the problems that the height of a robot chassis in the prior art is fixed, that the chassis is prone to collide with obstacles when meeting the obstacles ifthe chassis is too low, and that the robot is reduced in stability and prone to side tumbling if the chassis is too high.

Owner:ANHUI POLYTECHNIC UNIV MECHANICAL & ELECTRICAL COLLEGE

Pulverized coal dryer

ActiveCN104668074AAchieve separationEfficient dryingDrying solid materials without heatSolid fuelsEngineeringCylinder block

The invention relates to a pulverized coal dryer. The pulverized coal dryer comprises a negative-pressure empty cavity and a drying empty cavity, wherein the negative-pressure empty cavity is arranged on the upper part of the drying empty cavity and is communicated with the drying empty cavity; the negative-pressure empty cavity comprises a piston component comprising a piston cylinder body the bottom of which is communicated with the drying empty cavity; the piston cylinder body is internally connected with a piston in a sliding mode; the side wall of the bottom of the piston cylinder body is provided with a unidirectional valve A; the drying empty cavity is internally provided with a pulverized coal grinding component; the top of the drying empty cavity is provided with a charge hopper; the bottom of the drying empty cavity is provided with a discharge hopper; the charge hopper is connected with a seal valve A; the discharge hopper is connected with a seal valve B; a plurality of discharge holes are densely distributed in a grinding plate; the drying empty cavity and the piston cylinder body are communicated via a unidirectional valve B. Water drops in the pulverized coal and other mixed gases are separated via a negative-pressure type evacuation structure, and are discharged out after separation, and the time consumption is short in the whole drying process.

Owner:苏州盛泽科技创业园发展有限公司

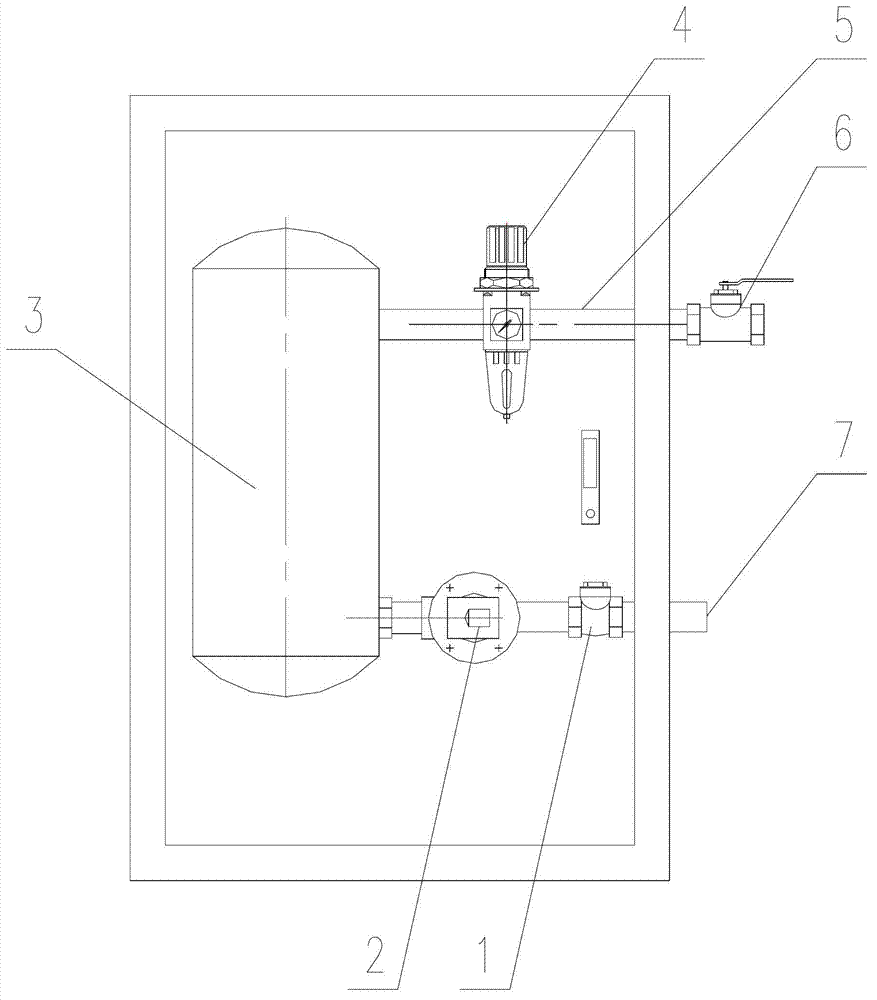

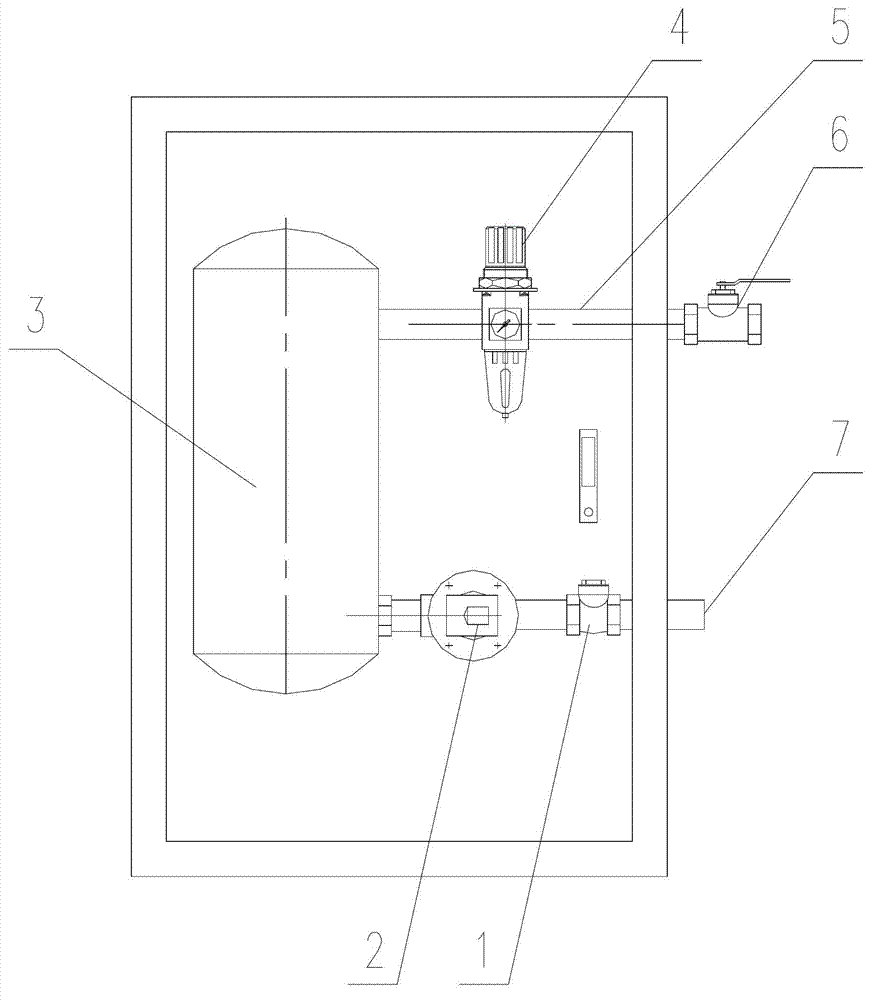

Deashing device for pneumatic plugboard isolated door

The invention relates to a deashing device for a pneumatic plugboard isolated door and belongs to the technical field of power station auxiliary equipment. The deashing device for the pneumatic plugboard isolated door comprises an air storage tank, wherein the air storage tank is provided with an air inlet pipeline and an air outlet pipeline; an air inlet valve is arranged on the air inlet pipeline; a pulse solenoid valve and a check valve are arranged on the air outlet pipeline; and the solenoid valve is positioned between the air storage tank and the check valve. When the deashing device for the pneumatic plugboard isolated door operates, the air inlet valve is opened, the compressed air enters the air storage tank through the air inlet pipeline, a control circuit controls the pulse solenoid valve to circularly blow high-pressure and high-frequency gas at regular time, deashing is conducted on a door sheet track, the check valve controls the flow direction of gas in the pipelines, the high-temperature and high-pressure gas in an air duct is prevented from flowing to the pulse solenoid valve, and the pulse solenoid valve is protected against being damaged by the high-temperature and high-pressure gas. As the improvement of the deashing device, a filter is arranged on the air intake pipeline to prevent impurities in the compressed gas from entering the deashing device to influence normal operation of the valves.

Owner:JIANGSU WEITONG ELECTRICAL EQUIP

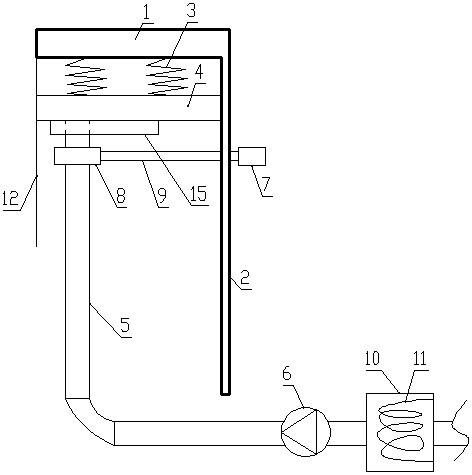

Heat dissipation water tank structure of water cooling system

ActiveCN108131877AGuaranteed heat exchangeImprove convenienceLighting and heating apparatusCooling fluid circulationEngineeringCooling fluid

The invention relates to a heat dissipation water tank structure of a water cooling system, and the structure comprises a shell seat and a water cooling plate set. The shell seat has a water inlet, awater outlet and a partition for the accommodating space to connect the accommodating space, and the partition accommodating space is a heat exchange area and a water collecting area, and the shell seat has a conveying pipe which is communicated with the heat exchange zone and the nozzle of the conveying pipe is located in the water collecting area. The water-cooling plate group is combined with the shell seat and covers one side of the heat exchange area, wherein the heat-dissipating water tank structure can cover the nozzle of the conveying pipe through the cooling liquid in the water collecting area. It is arranged at any angle or direction. Accordingly, the air does not enter the water pump connected to the radiator tank structure, and the operation can be maintained, and the convenience in setting is increased.

Owner:KUAN DING TECH

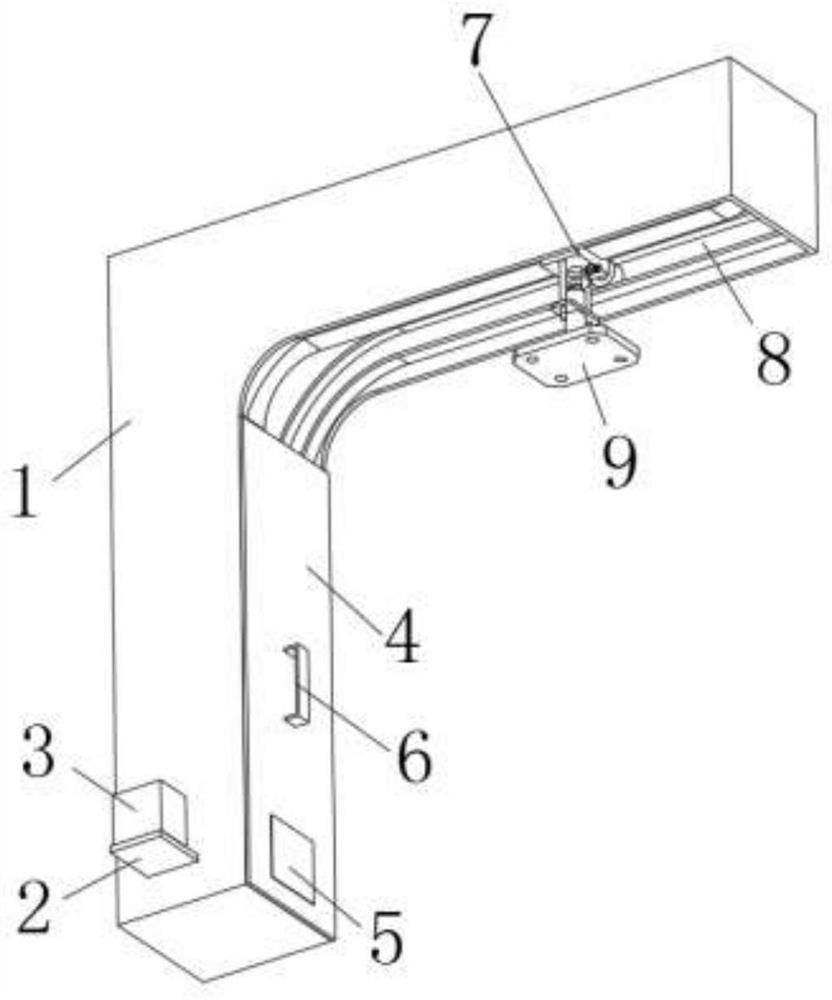

Omni-directional camera hoisting structure for tourist hotel monitoring

ActiveCN113090914AEasy to installMounted on camera for easy installationStands/trestlesCamera body detailsRotational axisControl theory

Owner:YELLOW RIVER CONSERVANCY TECHN INST

Automatic ash cleaning type pneumatic plugboard isolating door

The invention relates to an automatic ash cleaning type pneumatic plugboard isolating door and belongs to the technical field of power station auxiliary engine. The automatic ash cleaning type pneumatic plugboard isolating door comprises an ash cleaning device, wherein the ash cleaning device comprises an air storage tank, the air storage tank is provided with an air intake pipeline and an exhaust pipeline, an air intake valve is arranged on the air intake pipeline, a pulse solenoid valve and a check valve are arranged on the exhaust pipeline, and the solenoid valve is located between the air storage tank and the check valve. When the automatic ash cleaning type pneumatic plugboard isolating door disclosed by the invention is at work, the air intake valve of the ash cleaning device is opened, compressed air enters the air storage tank through the air intake pipeline, a control circuit controls the pulse solenoid valve to periodically blow high pressure and high frequency air to clean the dust on the door panel rail, the check valve controls the air flow direction of the pipeline to prevent the high temperature and high pressure air in the air channel from flowing to the pulse solenoid valve so as to protect the pulse solenoid valve from being damaged by the high temperature and high pressure air.

Owner:JIANGSU WEITONG ELECTRICAL EQUIP

Building construction crane with anti-shaking function

InactiveCN114229710AWith anti-shake functionAffect normal movementCleaning using toolsTrolley cranesBristleGear wheel

The invention relates to the technical field of cranes, and discloses a building construction crane with an anti-shaking function, which comprises a supporting column, the top of the supporting column is fixedly connected with a supporting plate, the inner wall of the supporting plate is fixedly connected with a supporting strip, the surface of the supporting strip is slidably connected with a sliding block, and the bottom of the sliding block is fixedly connected with an electric hoist. A lifting hook is fixedly connected to the output end of the electric hoist, a limiting rod is slidably connected to the inner wall of the lifting hook, moving blocks are fixedly connected to the two ends of the limiting rod, a plurality of teeth are fixedly connected to the front portion of the supporting strip, a motor is fixedly connected to the top of the sliding block, a transmission gear is fixedly connected to the output end of the motor, and a cleaning device is arranged on the surface of the lifting hook. Dust on the surface of the limiting rod can be brushed off through the cleaning device, the dust is prevented from influencing normal movement of the lifting hook, meanwhile, the cleaning mechanism can drive blades to impact bristles, the bristles vibrate, and self-cleaning of the bristles is achieved.

Owner:河南工学院 +1

Carton sheet pushing device used in packaging field

The invention belongs to the technical field of carton sheet pushing, and particularly relates to a carton sheet pushing device used in packaging field. The carton sheet pushing device comprises a speed reducing motor, a sheet storage shell, a guide telescopic plate, a conveying mechanism, a bottom plate, a sheet blocking plate and a sheet licking roller. In the case of a traditional carton sheetpushing device, carton sheets of the device are pushed out from the lower side of the sheet storage shell, and the carton sheets which are to be pushed each time is subjected to the gravity exerted from the other carton sheets located on the upper side, so that the carton sheets located on the lower side suffer big resistance. Compared with the traditional carton sheet pushing device, a pushing opening of the carton sheet pushing device used in the packaging field is located on the upper side of the sheet storage shell, so that the pushed carton sheets are not affected by other carton sheets after being pushed each time, and pushing resistance is small; and in addition, according to the designed pushing device, the pressure of the sheet licking roller exerted on the carton sheets is stable, and meanwhile a small pressure is kept, so that the normal movement of the carton sheets cannot be influenced due to overlarge pressure of the sheet licking roller on the carton sheets.

Owner:SUNKISS HEALTHCARE ZHEJIANG

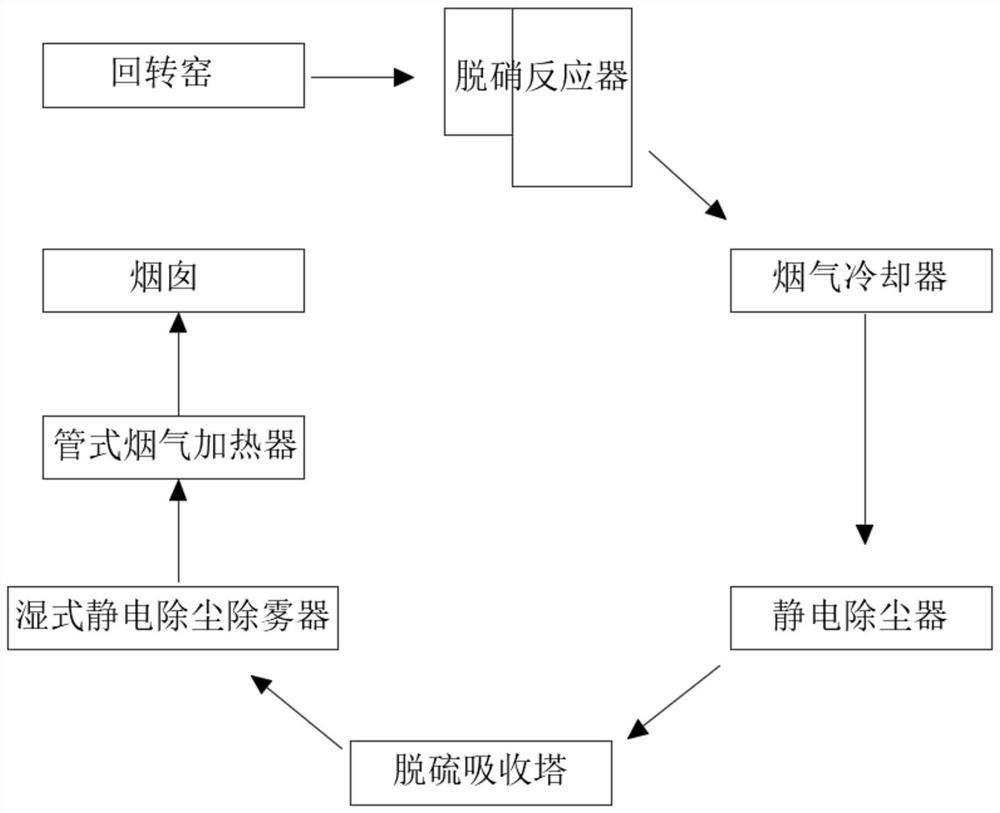

Denitration treatment system and method for pellet roasting flue gas of grate rotary kiln

InactiveCN114432882AEasy to useExtended service lifeGas treatmentDispersed particle filtrationThermodynamicsFlue gas

The invention discloses a denitration treatment system and method for pellet roasting flue gas of a grate rotary kiln, belongs to the technical field of waste gas treatment, and can be used for carrying out desulfurization and denitration treatment on flue gas generated during pellet production, when the flue gas enters a denitration reactor, dust particles in the flue gas can be intercepted by through holes in a filter plate, and the dust particles in the flue gas can be prevented from entering the denitration reactor. The catalytic plate is prevented from being blocked during use, the using effect of the catalytic plate is improved, the service life of the catalytic plate is prolonged, when the through holes are blocked, the pressure sensing film is stressed, the lifting plate can be driven to ascend under the action of a driving rope and other devices, the filter plate is shifted under the action of the shifting rod, the filter plate rebounds, and when the filter plate rebounds, the catalytic plate is prevented from being blocked. The dust particles in the through holes are vibrated off through inertia, the through holes can continuously filter smoke, the service life of the through holes is prolonged, and when the filter plate rebounds, the collision balls can smash the dust particles in the through holes, so that the cleaning effect of the through holes is further enhanced.

Owner:方月玲

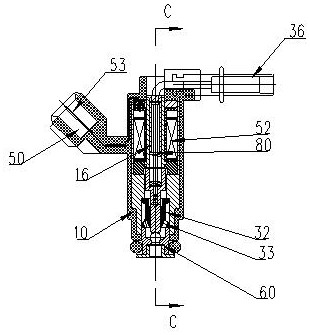

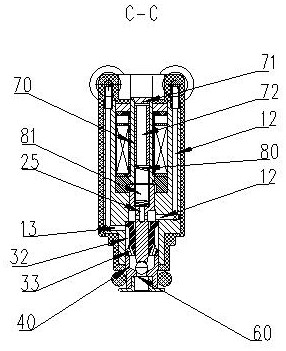

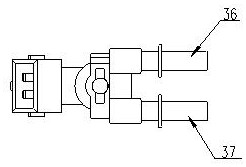

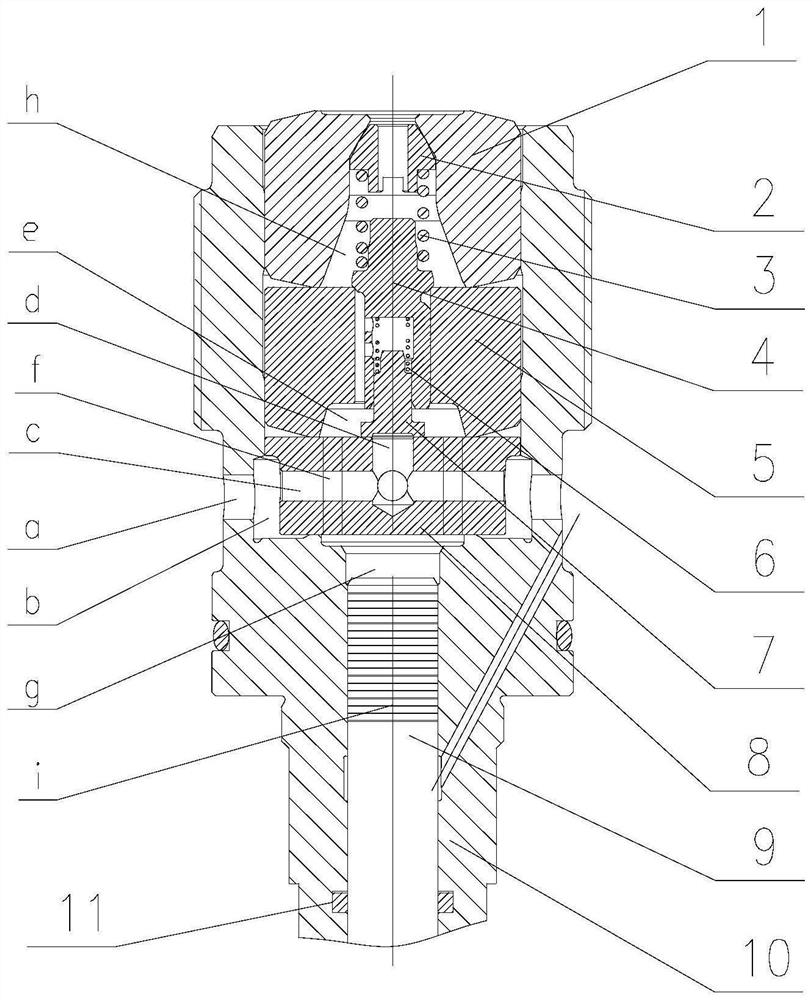

Methanol fuel injector structure

PendingCN112177825AAvoid job failureAffect normal movementFuel injection apparatusMachines/enginesMethanol fuelEngineering

The invention relates to a methanol fuel injector structure. The methanol fuel injector structure comprises a shell, a valve element, a retainer and a valve seat; a fuel flowing channel is defined bythe shell; the valve seat is arranged at the bottom end of the shell; a guide hole is formed in the middle position of the retainer; the retainer is arranged in the flowing channel; the outer side wall of the valve element is in sliding fit with the guide hole so as to divide the flow channel into a first channel and a second channel close to the valve seat; the second channel is used for introducing methanol; and the first channel is used for introducing compressed gas with the same pressure as methanol. According to the methanol fuel injector structure, through matching between the valve element and the guide hole of the retainer, the valve element moves up and down along with an excitation signal when a methanol fuel injector works, the guide hole plays an accurate guide role, methanolforms a film in a gap under the action of pressure, the air pressure in the first channel is as same as the pressure of the methanol, the methanol cannot enter the first channel, and therefore, the situation that the methanol enters the valve element to gradually form colloid to enable the valve element fails to work is avoided.

Owner:广东沛宇系统技术有限公司

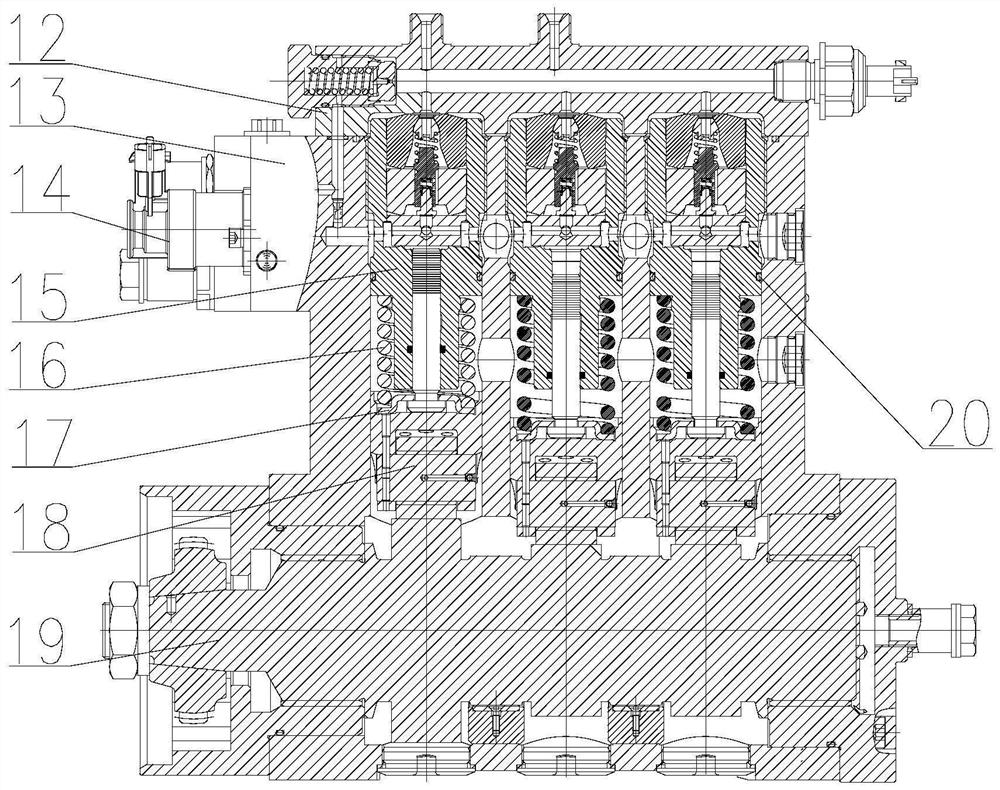

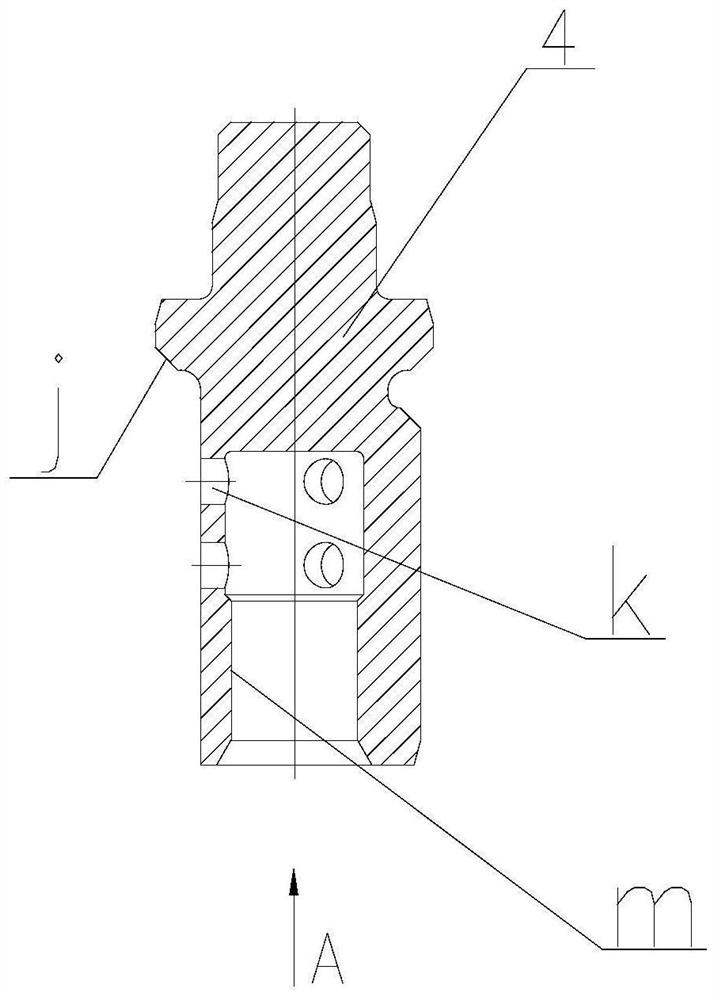

High-pressure oil supply pump oil pumping system assembly of large-flow electric control common rail system

PendingCN114278476ACompact structureImprove reliabilityMachines/enginesFuel injecting pumpsRail pressureOil supply

The invention discloses a high-pressure oil feed pump oil pumping system assembly of a large-flow electric control common rail system, which comprises a plunger and barrel assembly, an oil inlet mechanism and an oil outlet mechanism, the plunger and barrel assembly comprises a plunger and a plunger sleeve, the plunger sleeve is a main body of the whole oil pumping system assembly, the upper part of the plunger sleeve is provided with a cavity, and the lower part of the plunger sleeve is provided with a plunger sleeve cavity g; the plunger is installed in a plunger sleeve cavity g, the plunger sleeve and the plunger form a precise matching part structure and are in clearance fit, the bottom of the plunger is installed on the spring seat, the oil inlet mechanism and the oil outlet mechanism are both installed in a cavity in the upper portion of the plunger sleeve, the oil outlet mechanism is located above the oil inlet mechanism, and the oil outlet mechanism is located above the oil outlet mechanism. The plunger sleeve is connected with the top of the plunger spring, and a plurality of first oil inlet holes a are formed in the outer wall of the periphery of the upper cavity part of the plunger sleeve. The oil pumping system assembly is compact in structure, large in oil quantity and oil flow speed and high in reliability, and the requirements of a high-power diesel engine for high rail pressure and large oil quantity are met.

Owner:龙口龙泵柴油喷射高科有限公司

Carton sheet pushing device used in field of packaging

The invention belongs to the technical field of carton sheet pushing, and particularly relates to a carton sheet pushing device used in the field of packaging. The carton sheet pushing device comprises a speed reduction motor, a paper storage shell, a guide telescopic plate, a conveying mechanism, a bottom plate, a paper baffle and a paper licking roller. Compared with a traditional carton sheet pushing device, a carton sheet of the traditional carton sheet pushing device is pushed out from the lower side of the paper storage shell; in this way, each time the carton sheet is pushed out, the carton sheet is subjected to gravity applied by alignment of all carton sheets on the upper side, so that resistance of the carton sheet on the lowermost side is increased; a pushing outlet of the designed pushing device is located on the upper side of the paper storage shell; in this way, after the carton sheet is pushed each time, the pushed carton sheet is not affected by other carton sheets, andthe pushing resistance is small; according to the designed pushing device, the pressure of the paper licking roller on the carton sheet is relatively stable each time, and smaller pressure is kept; and the situation that normal movement of the carton sheet is affected since the pressure of the paper licking roller on the carton sheet is too large is avoided.

Owner:杭州富阳新堰纸制品有限公司

Dancing shoe sequin forming tool

InactiveCN107373898AAffect normal movementGuaranteed sheeting efficiencyEngine sealsShoemaking devicesEngineering

Owner:刘应华

Hydraulic Coal Bunker Arch Breaking Device

The invention discloses a hydraulic coal bunker arch breaking device, which comprises a mounting seat, the mounting seat includes a top plate and a side wall of the mounting seat connected below one side of the top plate; a spring is connected downward to the top plate, and a cover plate is connected to the lower end of the spring. There is a water spray pipe with the opening facing upward under the plate; the extension rod of the electric push rod slides through the side wall of the mounting seat and its end is connected with a power plate, and the top of the water spray pipe passes through the installation hole of the power plate; the water spray Driven by the electric push rod and power disc, the pipe has a water spray position and a storage position. When water spray is not needed, the water spray pipe can return to the bottom of the cover plate and the top of the water spray pipe is crimped with the cover plate, which is well avoided. The phenomenon that the coal in the coal bunker enters the water spray pipe in the storage state is prevented, so that the present invention can keep the water spray pipe from being blocked during long-term use, has strong arch breaking ability, and is suitable as a regular arch breaking device.

Owner:ZHENGZHOU UNIV

A dial-up pushing device for carton sheets used in the field of packaging

ActiveCN110525731BReduce push resistanceSmall pressure changeWrapping material feeding apparatusArticle feedersCardboardCarton

The invention belongs to the technical field of carton sheet pushing, and in particular relates to a carton sheet up-dial pushing device used in the packaging field, which includes a geared motor, an adjustment mechanism, a paper storage case, a paper feeding roller, a guiding telescopic plate, a transmission mechanism, a bottom plate, and a stopper. Cardboard, paper licking roller, the push outlet of the push device designed in the present invention is located on the upper side of the paper storage case, so that after each push of a carton piece, the pushed out carton piece will not be affected by other carton pieces, and the push resistance is small The carton sheet pushing device designed by the present invention adds a paper feed roller in the process of pushing the carton sheet, so that the length of the carton sheet only needs to be greater than the distance between the bottommost side of the paper feed roller and the pressure roller, In this way, the highest point that the paper licking roller can move can be relatively increased, and when the carton pieces are first placed in the paper storage case, the number of carton pieces in the paper storage case can be increased, so that the use efficiency of the device becomes high.

Owner:GUANGDONG YUEDEBAO PACKAGING TECH CO LTD

Combined frame plate for plate-and-frame filter press

InactiveCN113457233ADiversified installationExtended service lifeMembrane filtersFiltration separationSludgeProcess engineering

The invention discloses a combined frame plate for a plate-and-frame filter press, belongs to the technical field of plate-and-frame filter presses, and can combine a traditional filter pressing plate with a membrane filter plate for use, so that the filter pressing plate has the function of filtering water and also has the function of compressing a filter pressing chamber of the membrane filter plate. Therefore, the space use efficiency of the filter press can be improved, more filter pressing plates can be installed on the filter press, the overall filtering efficiency of the filter press is indirectly improved, the push plate is used for replacing traditional membrane compression, the overall service life of the membrane filter plate is prolonged, and the situation of non-uniform membrane compression is avoided when the push plate is used for compression. Through cooperative use of the push plate and a flow limiting pipe, the sludge entering the filter pressing chamber can fill the filter pressing chamber firstly and then enter other filter pressing chambers, so that the phenomenon that the filter pressing effect is influenced by empty bags when the sludge is filled into the filter pressing chamber is avoided.

Owner:梁桂庆

10KV floor metering box with moisture-proof function

PendingCN113484558AImprove adsorption capacityDischarge fullyToothed gearingsMeasurement instrument housingWater vaporEngineering

The invention discloses a 10KV floor metering box with a moisture-proof function, and the top of a first partition plate is fixedly connected with two groups of first partition plates which are used for drying and cooling the top of an electric appliance. Second drying devices used for drying and cooling the positions of the side walls of the box body are rotationally installed on the two sides of the inner wall of the box body and located on one side of the second partition plate, and the first drying devices and the second drying devices are rotationally connected through connecting devices. The first drying device can effectively adsorb water vapor on the top of the box body and discharge the water vapor out of the top of the box body through the mounting hole in the top of the box body, and the second drying device can effectively adsorb water vapor generated on the side face of the box body. The water vapor and the generated heat can be adsorbed to one side of the second partition plate, and the water vapor is conveyed upwards through the second drying device, so that the water vapor can be conveyed to the top of the first drying device, and the water vapor generated in the box body can be fully discharged through the arrangement.

Owner:安徽龙和电力集团有限公司

Carton sheet upward-pulling type pushing device used in field of packaging

ActiveCN110525731AReduce push resistanceSmall pressure changeWrapping material feeding apparatusArticle feedersCardboardCarton

The invention belongs to the technical field of carton sheet pushing, in particular to a carton sheet upward-pulling type pushing device used in the packaging field. The carton sheet pushing device comprises a gear motor, an adjusting mechanism, a paper storage shell, a paper feeding roller, a guiding telescopic plate, a conveying mechanism, a bottom plate, a paper blocking plate and a paper picking roller; the pushing outlet of the pushing device is located in the upper side of the paper storage shell, and therefore after the carton sheets are pushed every time, the pushed carton sheets are not affected by other carton sheets, and pushing resistance is small; the invention discloses the carton sheet pushing device. The paper feeding roller is added in the process of pushing the carton sheets; the length of the carton sheets only needs to be larger than the distance between the lowermost side of the paper feeding wheel and a paper pressing roller, the highest point that the paper pickup roller can move to can be relatively increased, the number of the carton sheets in the paper storage shell can be increased when the carton sheets are just placed in the paper storage shell, and theuse efficiency of the device is improved.

Owner:广东粤德堡包装科技有限公司

Tool used for pressing dance shoes sequins

InactiveCN107440241AAffect normal movementGuaranteed sheeting efficiencyEngine sealsShoemaking devicesEngineeringMechanical engineering

The invention discloses a tool used for pressing dance shoes sequins. The tool comprises a spindle, a first fixing plate, a second fixing plate, a third fixing plate, first pressing columns and second pressing columns; the first fixing plate, the second fixing plate and the third fixing plate are sequentially sleeved on the spindle from top to bottom, and elastic pieces are arranged between the first fixing plate and the third fixing plate; forming holes are structured in the second fixing plate, upper through holes are formed in the first fixing plate, the first pressing columns penetrate the upper through holes, lower through holes are formed in the third fixing plate, and the second pressing columns penetrate the lower through holes to be embedded in the forming holes; annular isolating parts are connected to positions of lower openings of the upper through holes and upper openings of the lower through holes, the first pressing columns and the second pressing columns penetrate the isolating parts, limit rings are arranged at lower ends of the first pressing columns and upper ends of the second pressing columns, and the outer annular diameter of the limits is greater than the bore diameter of the through holes. By the arrangement, normal movement of the pressing columns is unaffected in operation when dust enters gaps between the fixing plates and the pressing columns, and pressing efficiency of raw materials can be guaranteed.

Owner:郑洪均

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com