Angling cylinder with pressure maintaining function

A technology of rotary oil cylinder and function, applied in the field of rotary oil cylinder and rotary oil cylinder with pressure maintaining function, can solve the problems of falling off, affecting the machining accuracy of workpiece, and oil return.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

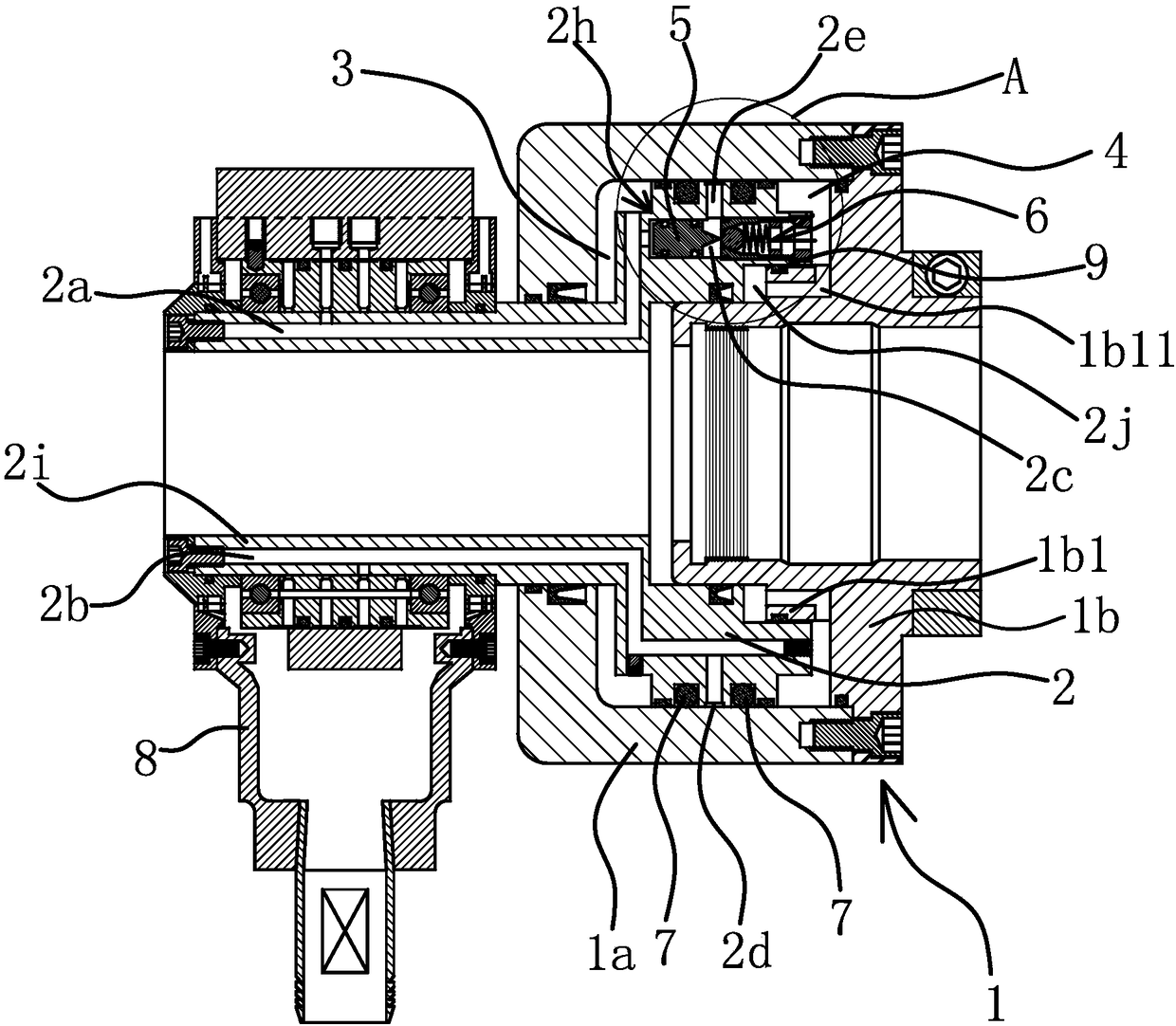

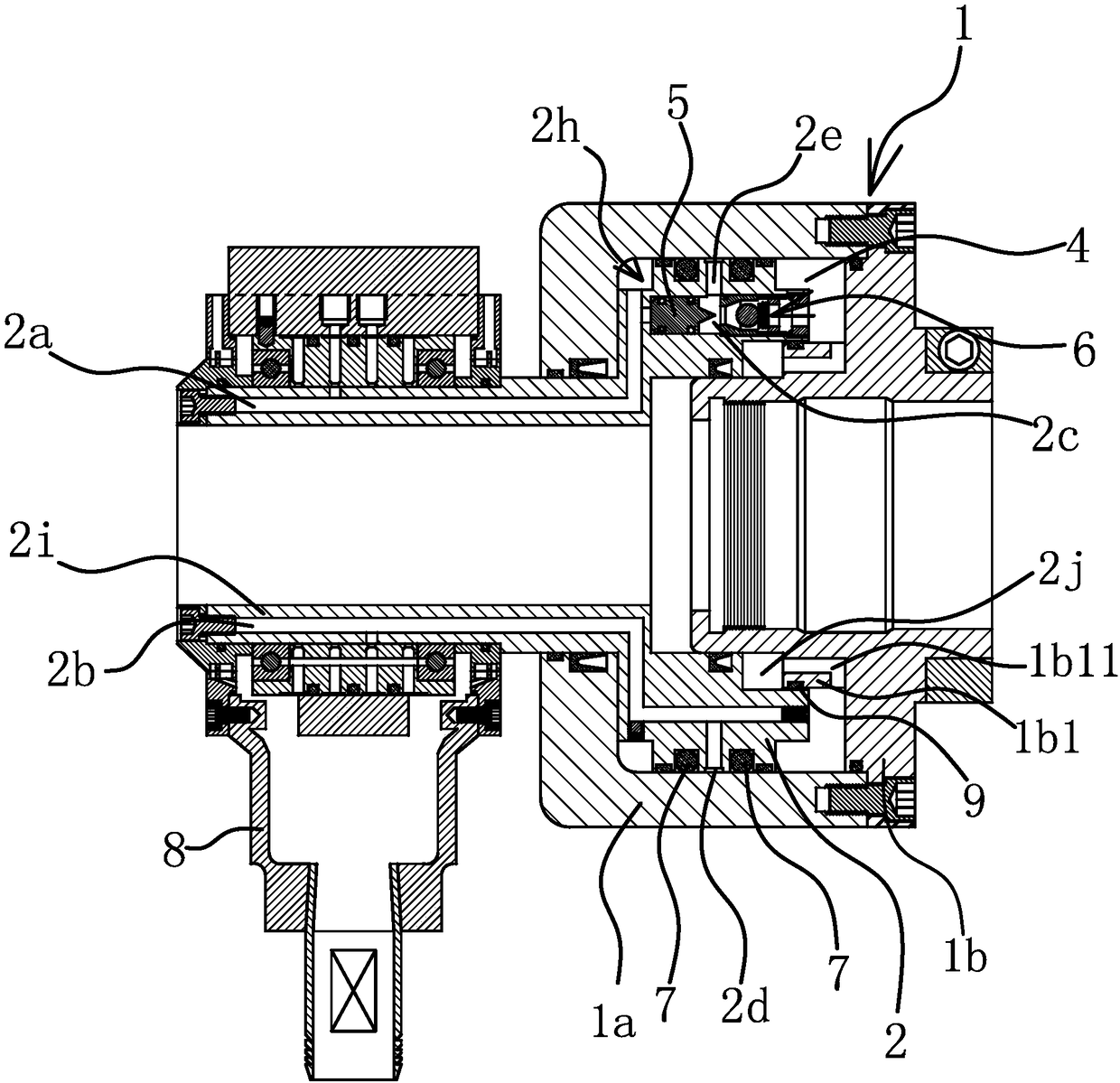

[0034] Such as figure 1 and Figure 5 As shown, a rotary oil cylinder with a pressure maintaining function includes a cylinder body 1 and a large piston 2 arranged in the cylinder body 1 and capable of moving back and forth. The rear end of the large piston 2 forms an oil chamber 3 with the inner wall of the cylinder body 1, and the piston The front end and the inner wall of the cylinder body 1 form an oil chamber 2 4 . The big piston 2 is provided with an oil passage one 2a and an oil passage two 2b, the outlet of the oil passage one 2a communicates with the oil chamber one 3, and the outlet of the oil passage two 2b communicates with the oil chamber two 4.

[0035] Such as figure 1 As shown, a protruding fitting part 2i is provided on the rear end surface of the large piston 2, and the fitting part 2i extends out of the rear end of the cylinder body 1, and the inlet of the oil passage 2a and the inlet of the oil passage 2b are both located at the ends extending to the cyli...

Embodiment 2

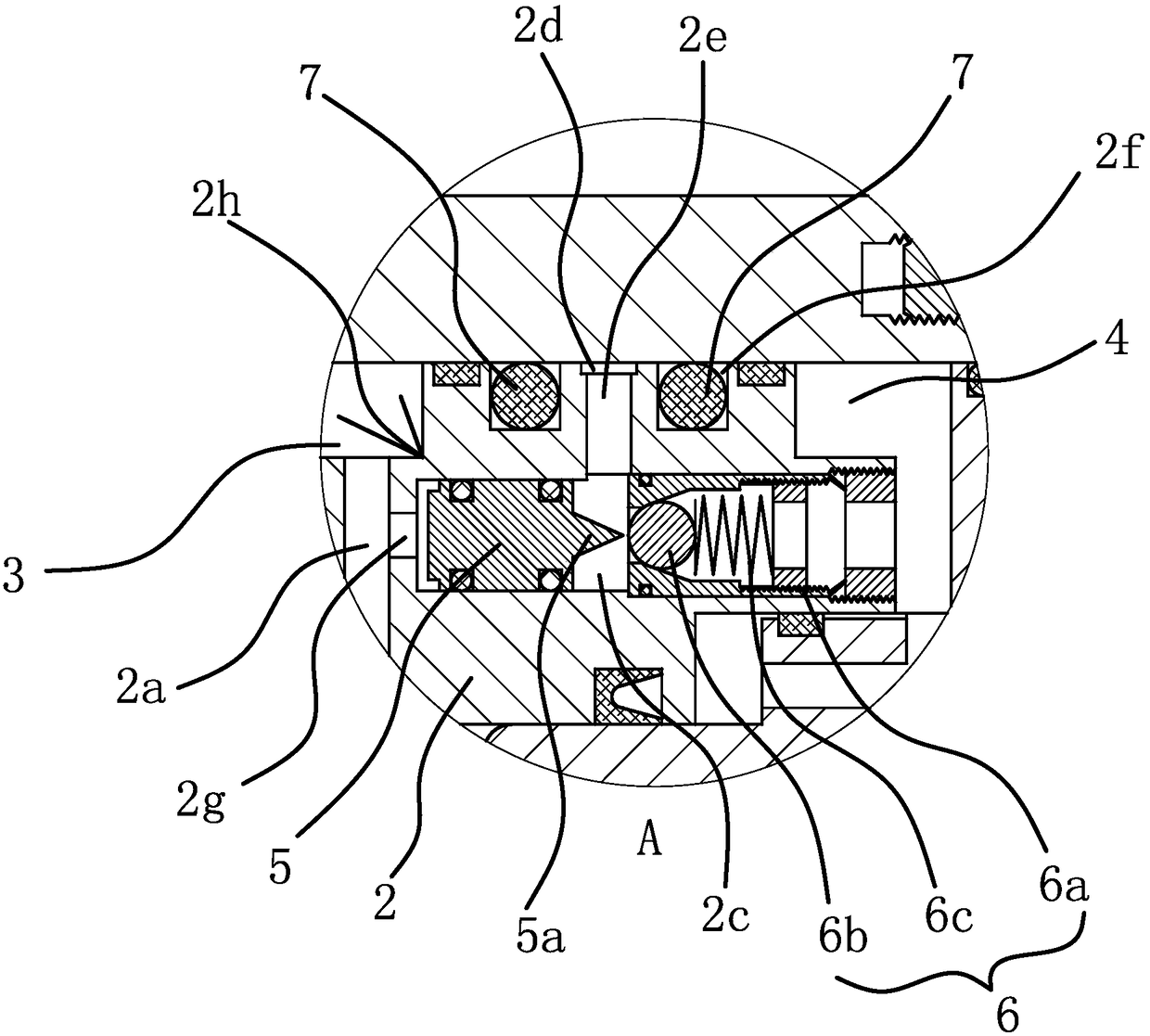

[0047] The structure and principle of this embodiment are basically the same as that of Embodiment 1, the difference is that in this embodiment, the check valve 6 includes a valve body 6a fixed in the positioning hole 2c and a sealing head arranged in the valve body 6a With the spring 6c, the valve body 6a is cylindrical with both ends open and the sealing head closes the rear port of the valve body 6a under the elastic force of the spring 6c, the small piston 5 is cylindrical, and the rear end of the sealing head is provided with a protruding Connecting rod, the end of the connecting rod extends to the outside of the rear port of the valve body 6a.

[0048]Adopt sealing head and spring 6c to form the non-return structure of check valve 6, and arrange the connecting rod extending to the outside of the rear port of valve body 6a at the rear end of sealing head, oil passage-2a when oil enters in oil passage-2a The oil inside pushes the small piston 5 to move forward, and when th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com