Work-clamping means

A fixture and main body technology, applied in the direction of clamping, clamps, manufacturing tools, etc., can solve the problems of workpiece loosening, not setting, disappearing, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

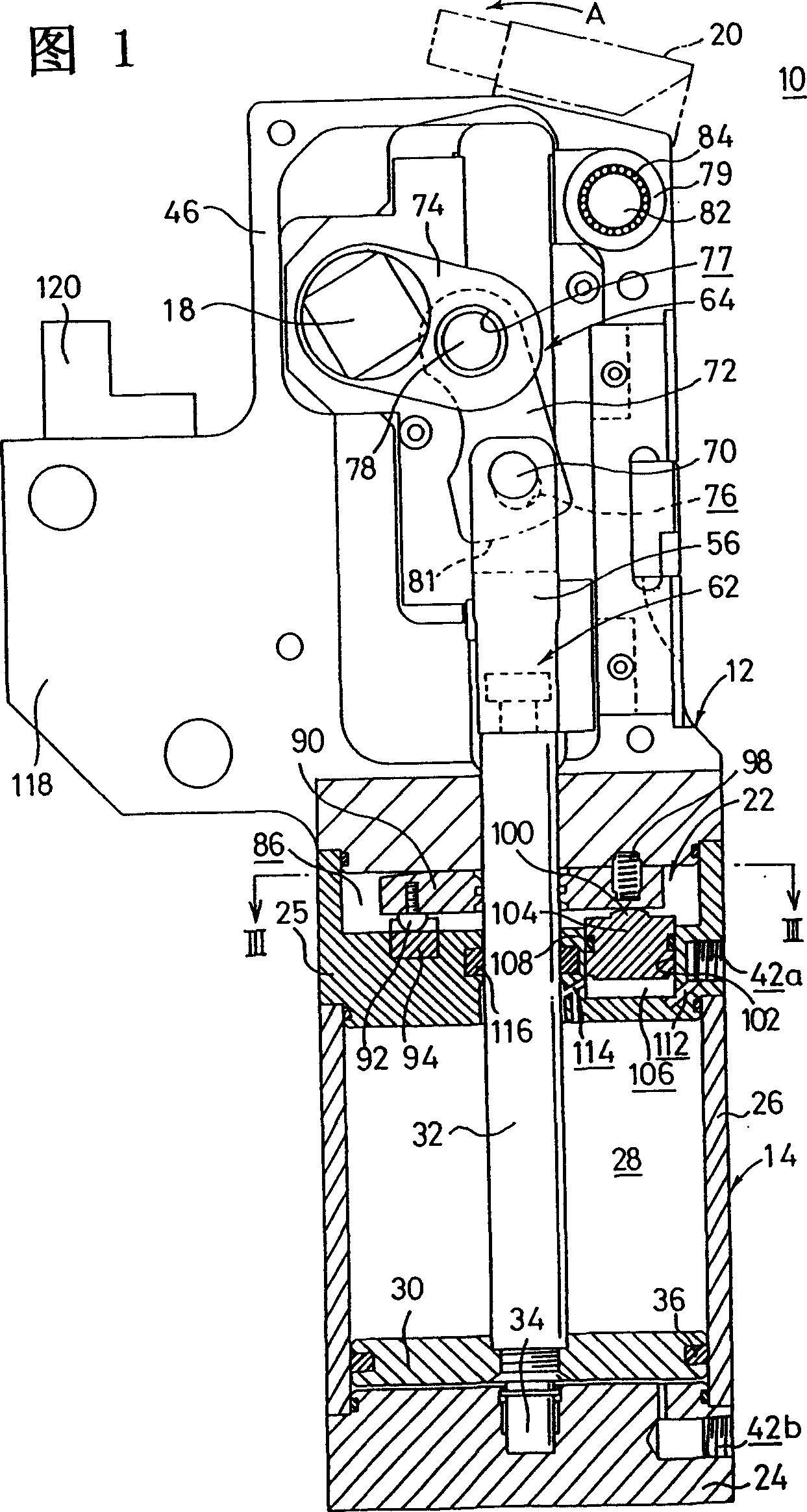

[0021] FIG. 1 shows a clamp 10 according to an embodiment of the present invention. The clamp 10 comprises: a main body 12; a cylinder part (drive mechanism) 14 connected in a sealed manner to the lower end of the main body 12; an arm 20 connected to a support part 18 having a rectangular cross-section through which protruding outside through a pair of substantially circular openings (not shown) formed through the main body 12;

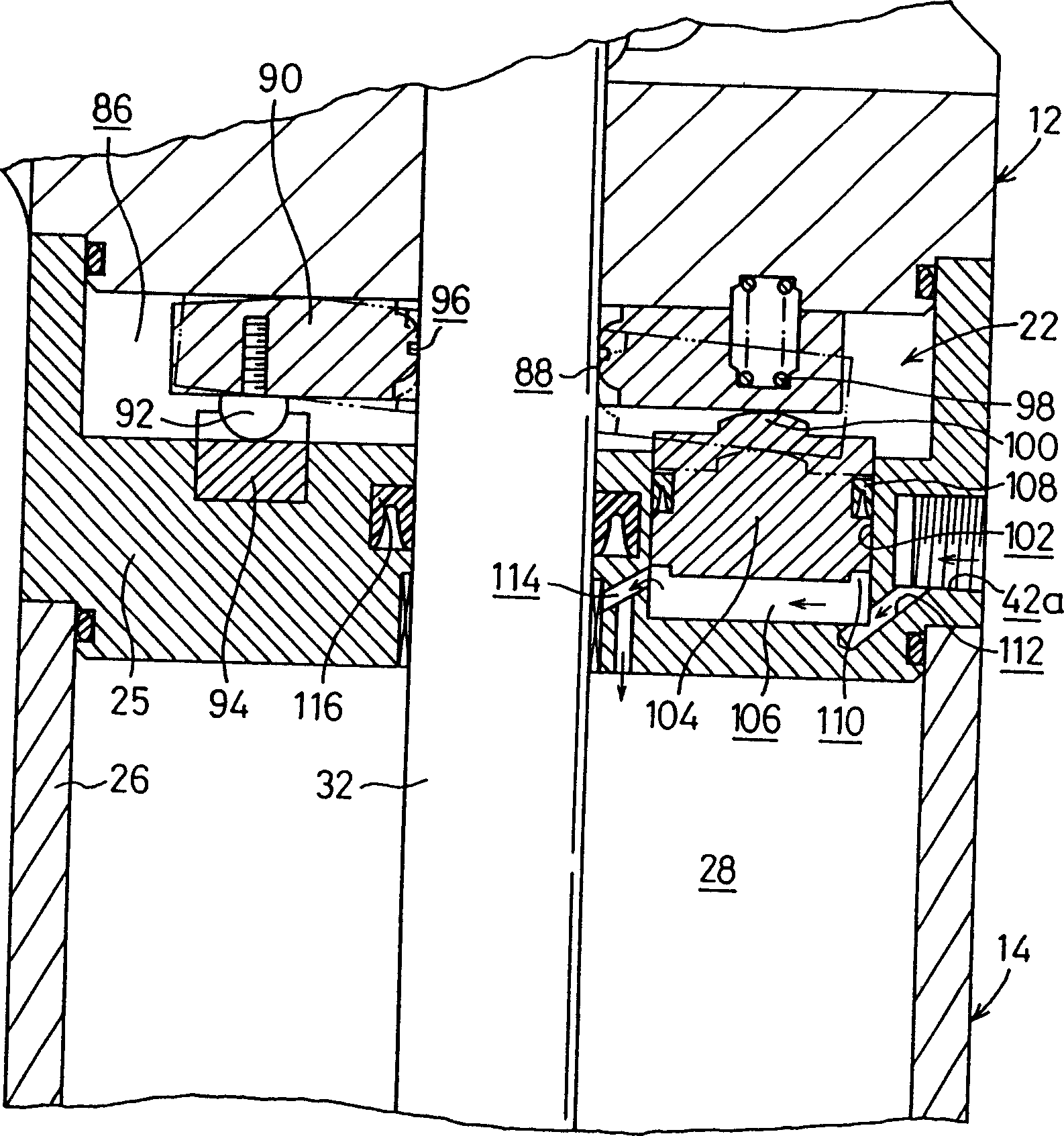

[0022] Cylinder portion 14 comprises an end block 24 and a generally cylindrical member of oval cross-section, and the cylinder portion comprises a cylinder 26, the first end of which is sealed with the recess of end block 24. connection, the second end of which is connected in a sealed manner to a block-shaped element 25 constituting the locking mechanism 22 .

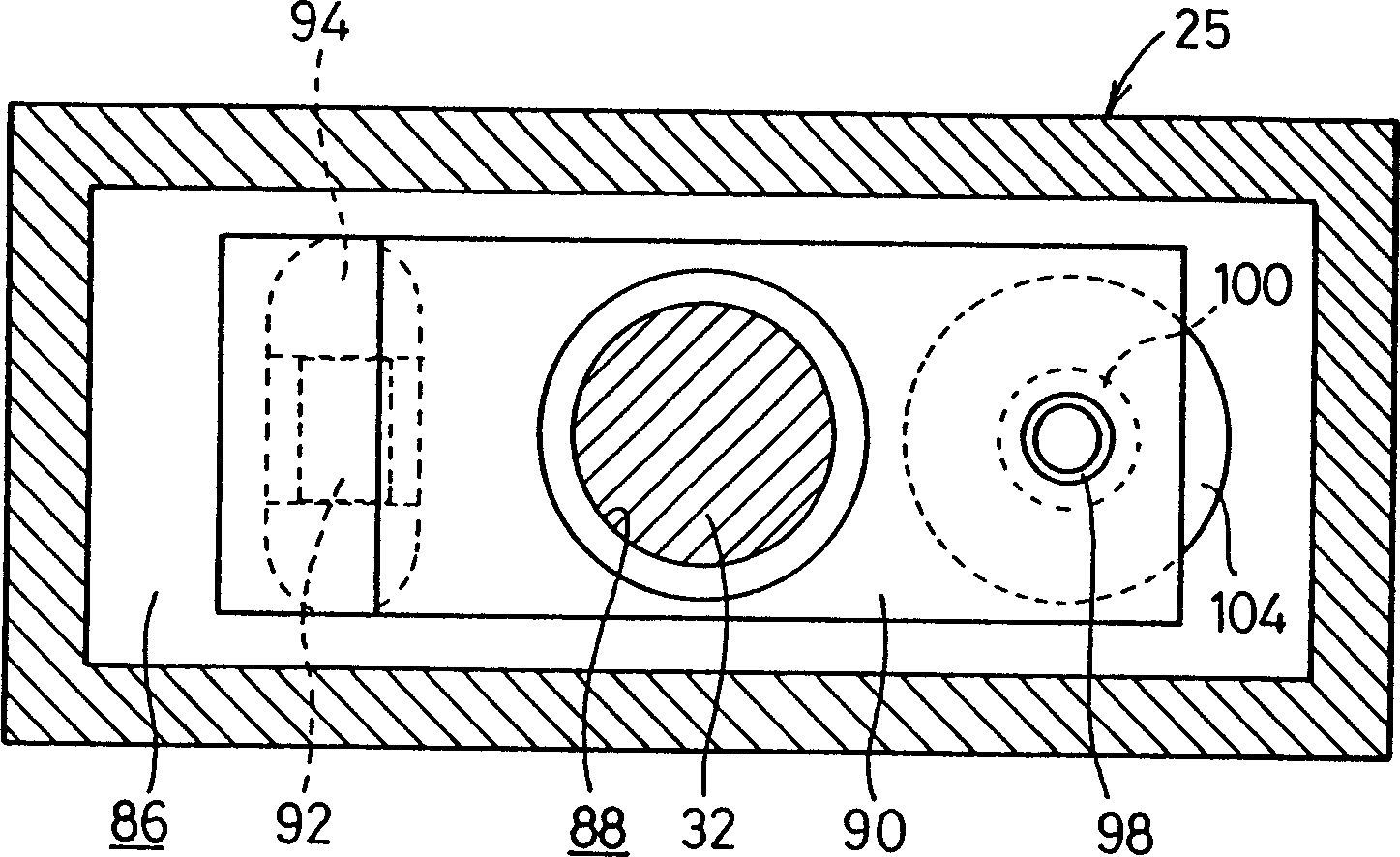

[0023] The pressure cylinder part 14 also includes: a piston 30 housed in the cylinder 26, which reciprocates along the cylinder chamber 28; move. like image 3 As shown, the cross-sectio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com