Solid reagent clamping reactor

A reactor and reagent technology, applied in the field of solid reagent clamping reactor, can solve problems such as troublesome operation, easy introduction of impurities, hidden dangers of operation safety, etc., and achieve the effect of ingenious structural design and convenient experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

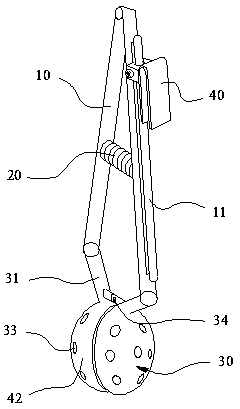

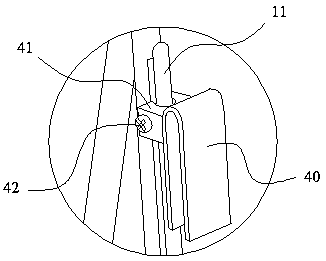

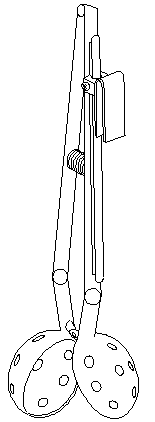

[0017] The invention provides a solid reagent clamping reactor, such as figure 1 As shown, the solid reagent holding reactor has two elongated holding arms 10 with the same length, one end of the two holding arms 10 is rotatably connected together, and the two holding arms 10 face to one side A compression spring 20 abuts against the middle part of the two clamping arms 10, and a clamping spoon 30 made of transparent potassium glass is rotatably connected to the other ends of the two clamping arms 10 respectively. Each clamping spoon 30 includes a spoon handle 31 and a spoon body 32. Several leak holes 33 are distributed on the spoon body 32. One end of the spoon handle 31 is fixedly connected to the edge of the spoon body 32, and the spoon handle 31 is far away from the end of the spoon body. The side inclined towards the concave side of the spoon body 31; the ends of the handles 31 of the two clamping spoons 30 away from the spoon body are rotatably connected to the ends of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com