Auxiliary welding clamp for mechanical design and manufacturing

An auxiliary fixture and mechanical design technology, applied in welding/cutting auxiliary equipment, manufacturing tools, auxiliary devices, etc., can solve the problems of precision workpiece damage, uncontrollable clamping force, and inability to maintain the clamping state for a long time, to achieve The control operation is simple and the effect of limiting the clamping force is good

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

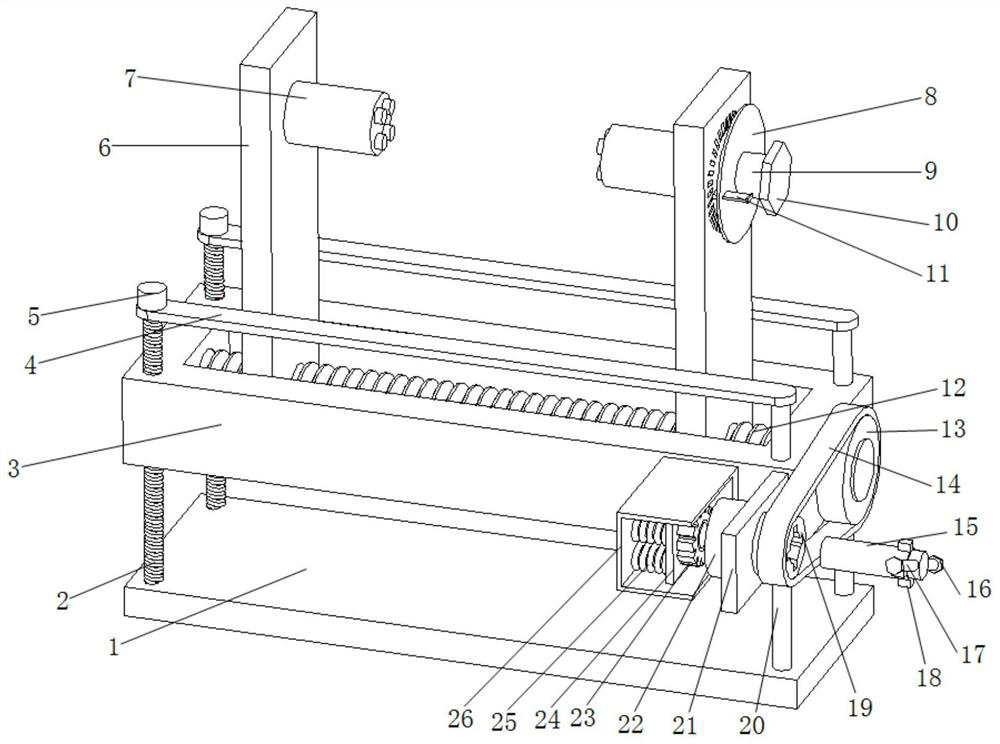

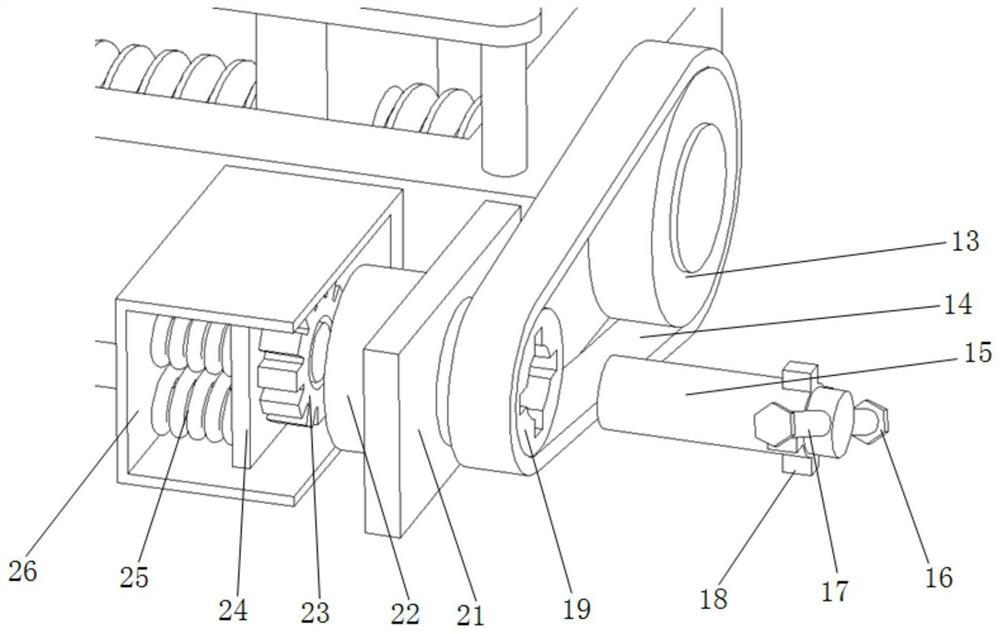

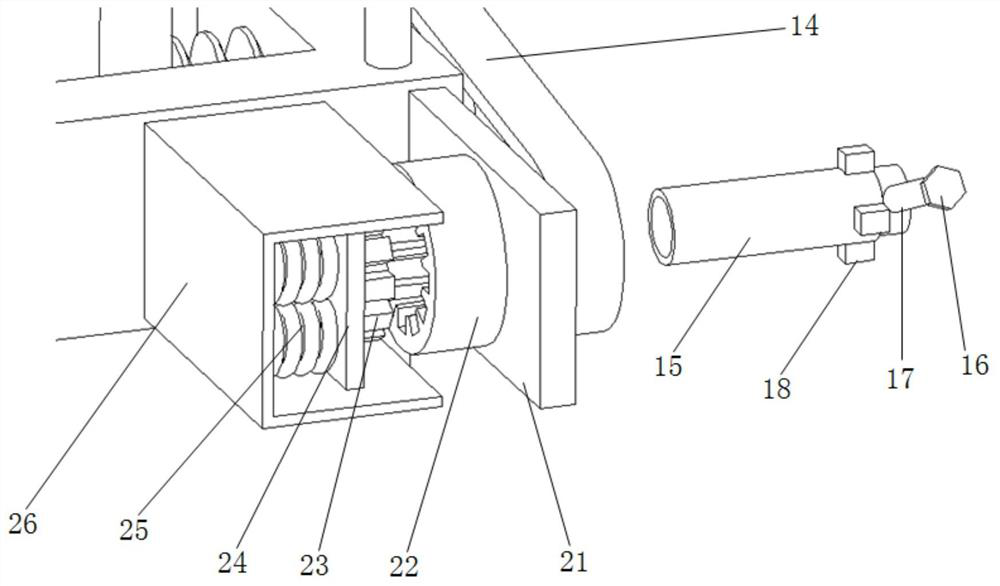

[0026] A welding auxiliary fixture for mechanical design and manufacture, such as Figure 1-4 As shown, it includes a return table 3, a double-ended screw 12, a console, a sleeve 15 and two clamping plates 6;

[0027] The two clamping plates 6 are arranged symmetrically in the 3 slots of the writing platform; further, the upper part of each clamping plate 6 is set with a clamping platform 7 through an angle adjustment device, such as Figure 4 As shown, each group of angle adjustment devices includes a limit plate 8, a rotating shaft 9 and a clip 11; one side of the upper part of the clamping plate 6 is provided with a clamping table 7 for rotation, and the other side is provided with a rotation shaft 9; The limit disk 8 is fixedly arranged on the rotating shaft 9; the other side of the upper part of the clamping plate 6 is provided with several square grooves along the circumference, and the limit disk 8 is provided with a through groove matching with the square groove; the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com