Building construction crane with anti-shaking function

A technology for building construction and cranes, which is applied in the direction of trolley cranes, cranes, cleaning methods using tools, etc., can solve problems such as abnormal noise and jamming, and achieve the effects of reducing friction, preventing shaking, and reducing potential safety hazards

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

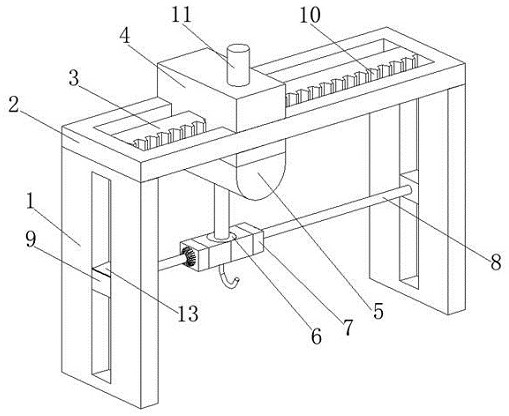

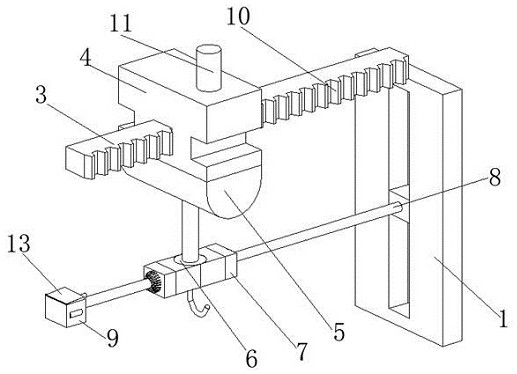

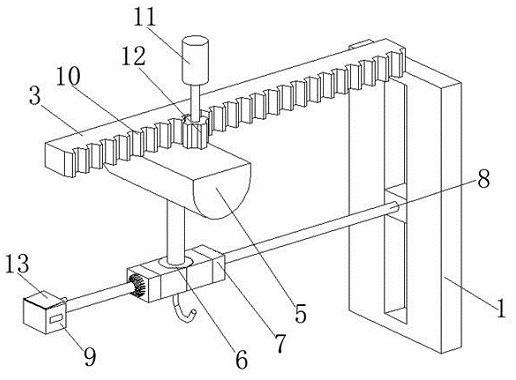

[0028] A construction crane with an anti-sway function, such as Figure 1-Figure 7 As shown, the support column 1 is included, the top of the support column 1 is fixedly connected with the support plate 2, the inner wall of the support plate 2 is fixedly connected with the support bar 3, the surface of the support bar 3 is slidably connected with the slider 4, and the bottom of the slider 4 is fixed An electric hoist 5 is connected, and the output end of the electric hoist 5 is fixedly connected with a hook 6, and the inner wall of the hook 6 is slidingly connected with a limit rod 8, and both ends of the limit rod 8 are fixedly connected with a moving block 9 and a support bar 3. The front part is fixedly connected with a number of teeth 10, the top of the slider 4 is fixedly connected with a motor 11, and the output end of the motor 11 is fixedly connected with a transmission gear 12, and the motor 11 is a servo motor, which can realize self-locking and prevent heavy objects ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com