Dancing shoe sequin forming tool

A technology of sequins and tools, applied in the field of dancing shoes, can solve the problems of affecting the efficiency of raw material sheeting, easily falling into dust, affecting the normal movement of the first pressing column and the second pressing column, etc. The effect of sheeting efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

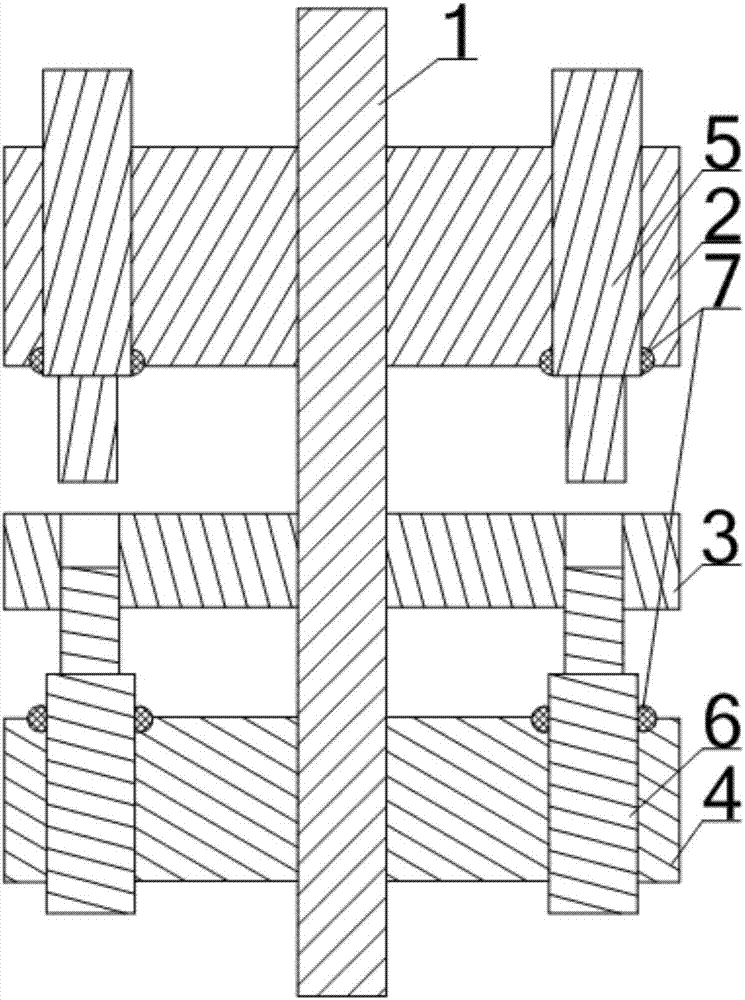

[0014] Such as figure 1 As shown, the molding tool for dancing shoe sequins includes a main shaft 1, a first fixed plate 2, a second fixed plate 3, a third fixed plate 4, a first pressure column 5 and a second pressure column 6, wherein the main shaft 1 is vertical It is provided that the first fixing plate 2 , the second fixing plate 3 and the third fixing plate 4 are sleeved on the main shaft 1 from top to bottom and form an interference fit with the main shaft 1 . The second fixing plate 3 is formed with a plurality of forming holes passing through its upper and lower end surfaces, and the plurality of forming holes are arranged at equal intervals on the same circumference. The first fixing plate 2 is provided with upper through holes corresponding in number to the forming holes, and the first pressure columns 5 pass through the upper through holes in the same number and in one-to-one correspondence. The third fixing plate 4 is provided with lower through holes correspondi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com