Clamping device of eight-station cold heading machine

A cold heading machine, eight-station technology, applied in the direction of conveyor objects, transportation and packaging, can solve the problems of billet feeding, lubricating oil splashing, polluting the working environment, etc., to solve the problem of material clamping, reduce mold loss, The effect of a high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

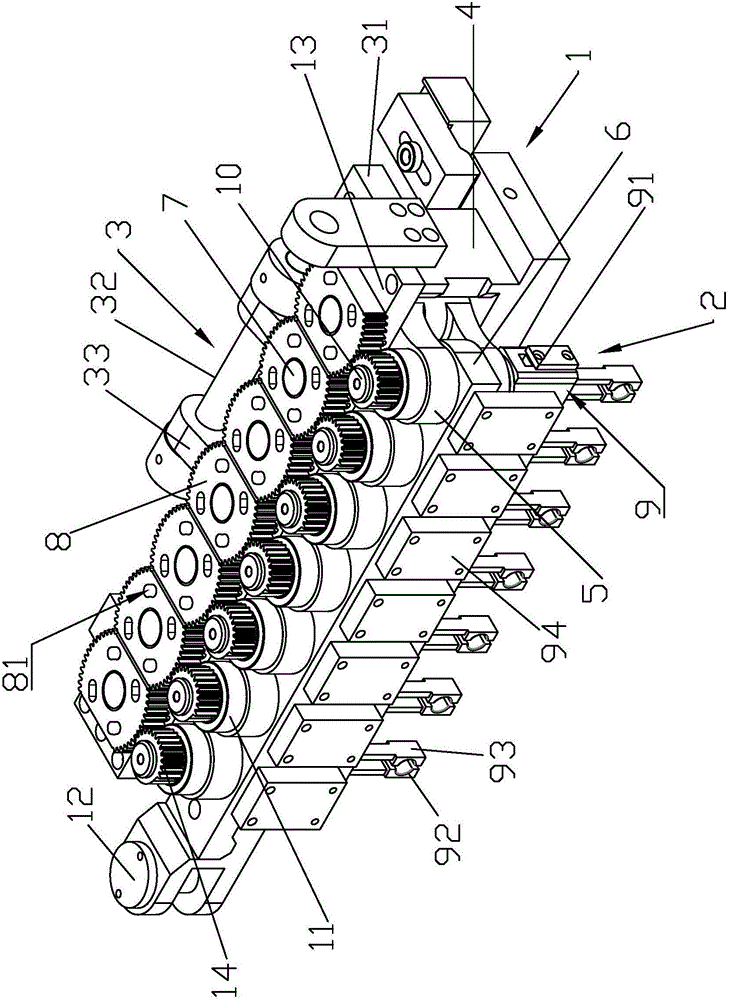

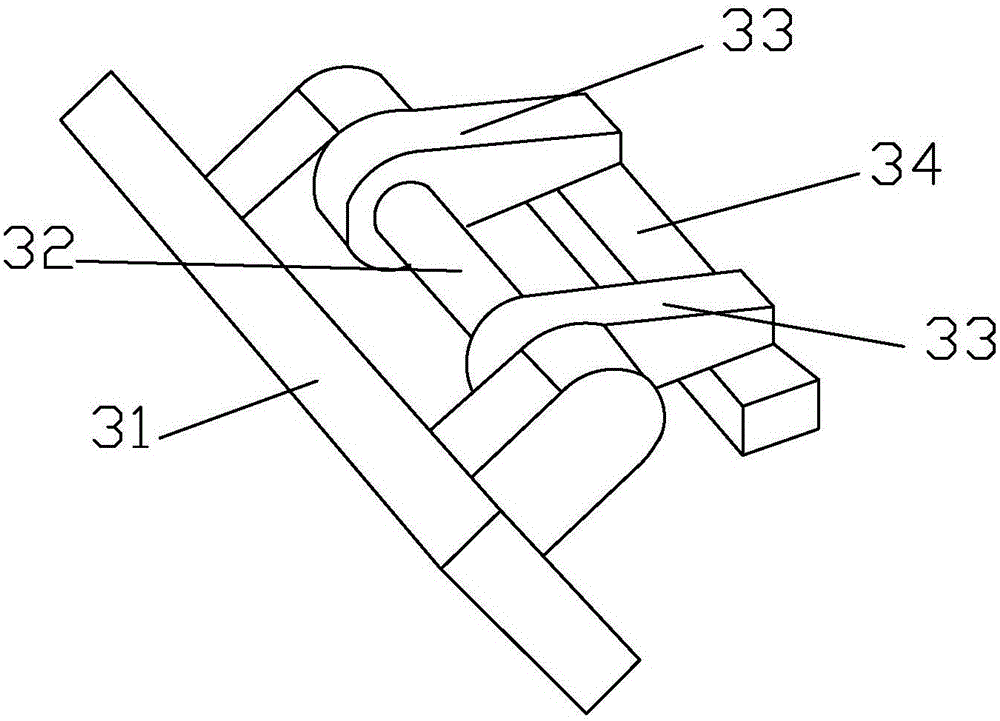

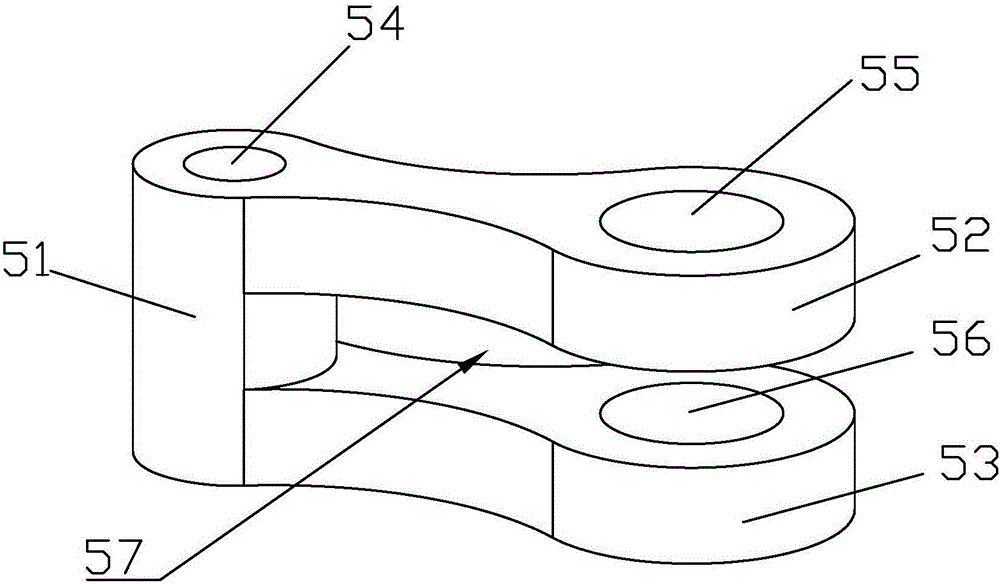

[0034] like Figure 1 to Figure 6 As shown, the clamping device of the eight-station cold heading machine includes a clamping mechanism 1 and a sandwich mechanism 2, and the clamping mechanism 1 is connected to the sandwich mechanism 2. Clamping mechanism 1 includes clamping box 4, clamping connecting rod 6 and clamping swing rod 5, clamping connecting rod 6 is connected with clamping swing rod 5, clamping swing rod 5 is installed in clamping box 4, clamping table swings The bar 5 is connected with the clamping table swinging rod shaft 7, and the clamping table swinging rod shaft 7 is provided with a guide gear 8. The clamping box 4 wraps the clamping table connecting rod 6 and the clamping table swinging rod 5 inside to prevent the external harsh working environment from affecting the normal movement of the clamping table mechanism 1. The structure is simple and compact, which reduces the exposed parts of the equipment and saves materials. The sandwich mechanism 2 includes a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com