Latch bolt assembly machine

A technology of assembling machine and oblique tongue, applied in the direction of feeding device, positioning device, storage device, etc., can solve the problems of manual assembly and inspection, and achieve the effect of increasing output, automatic and precise feeding, and reducing labor.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

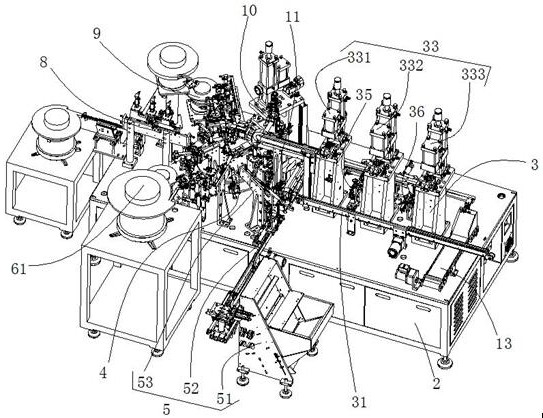

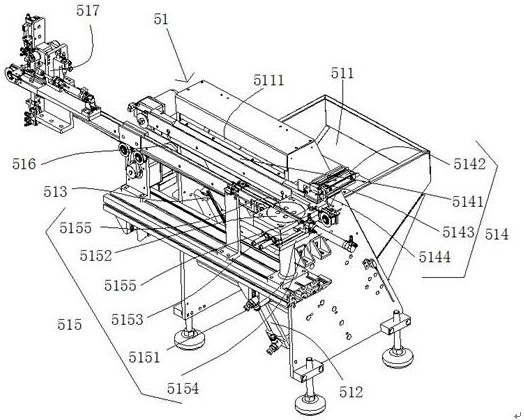

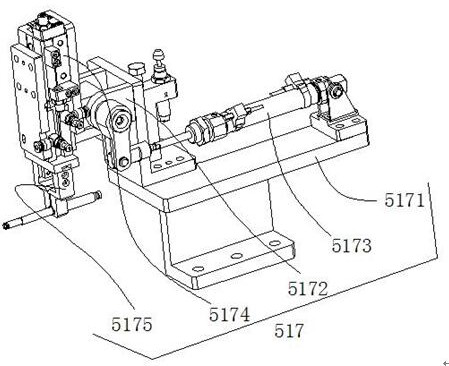

[0059] Such as Figure 1-15 Shown: a latch bolt assembly machine, including frame assembly 2, fork riveting assembly 3, turntable assembly 4, latch rod feeding assembly 5, long spring feeding assembly 6, front block feeding assembly 7, support Sheet feeding assembly 8 , rear stopper and short spring feeding assembly 9 , rod end riveting assembly 10 , transfer unloading manipulator 11 and detection assembly 12 . Wherein, the frame 2 can generally be made of metal materials such as steel and aluminum. The turntable assembly 3 is arranged on the frame assembly 2, and on the peripheral side along the rotation direction of the turntable assembly 3, there are a latch bar feeding assembly 5, a long spring feeding assembly 6, and a front flap feeding assembly in sequence. 7. Support plate feeding assembly 8, backstop and short spring feeding assembly 9, ro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com