Denitration treatment system and method for pellet roasting flue gas of grate rotary kiln

A treatment system and rotary kiln technology, applied in the field of waste gas treatment, can solve the problems of denitration efficiency decline, blockage, catalyst wear, etc., and achieve the effect of increasing the use effect and service life, enhancing the cleaning effect, and increasing the service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

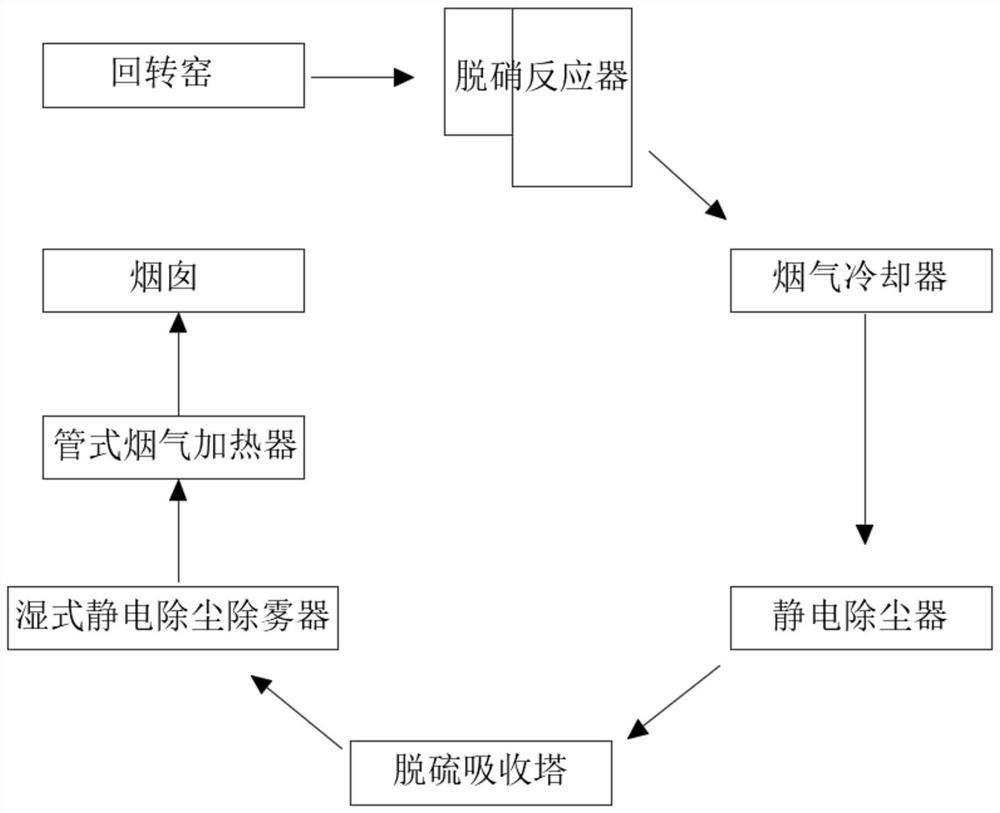

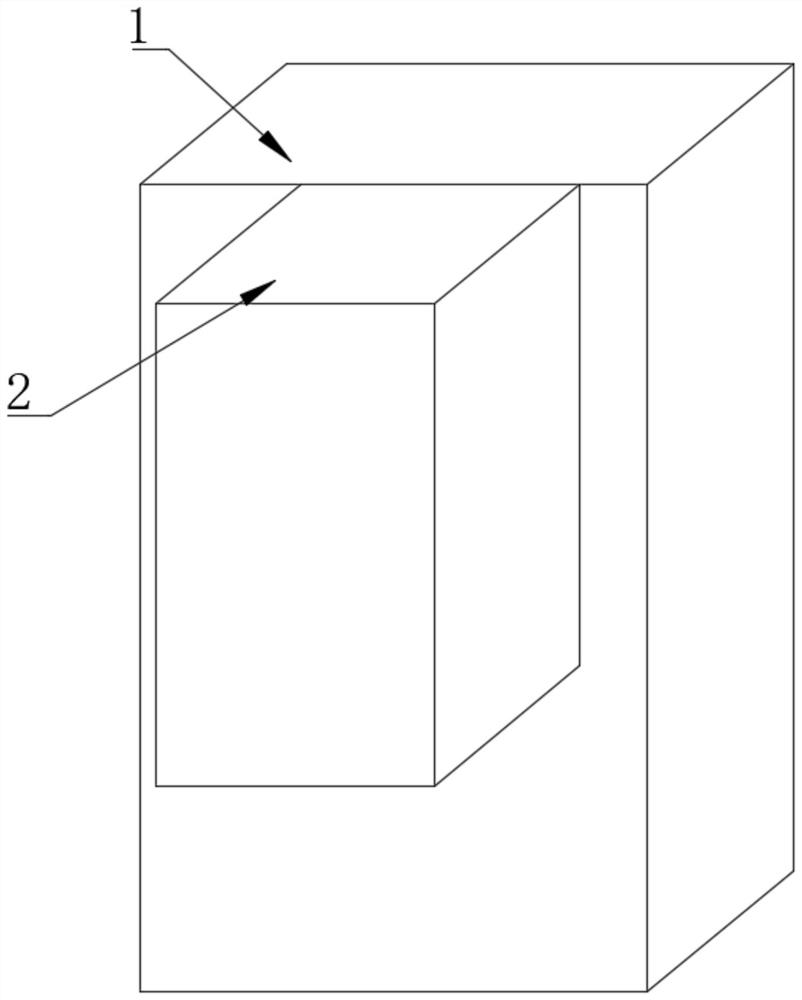

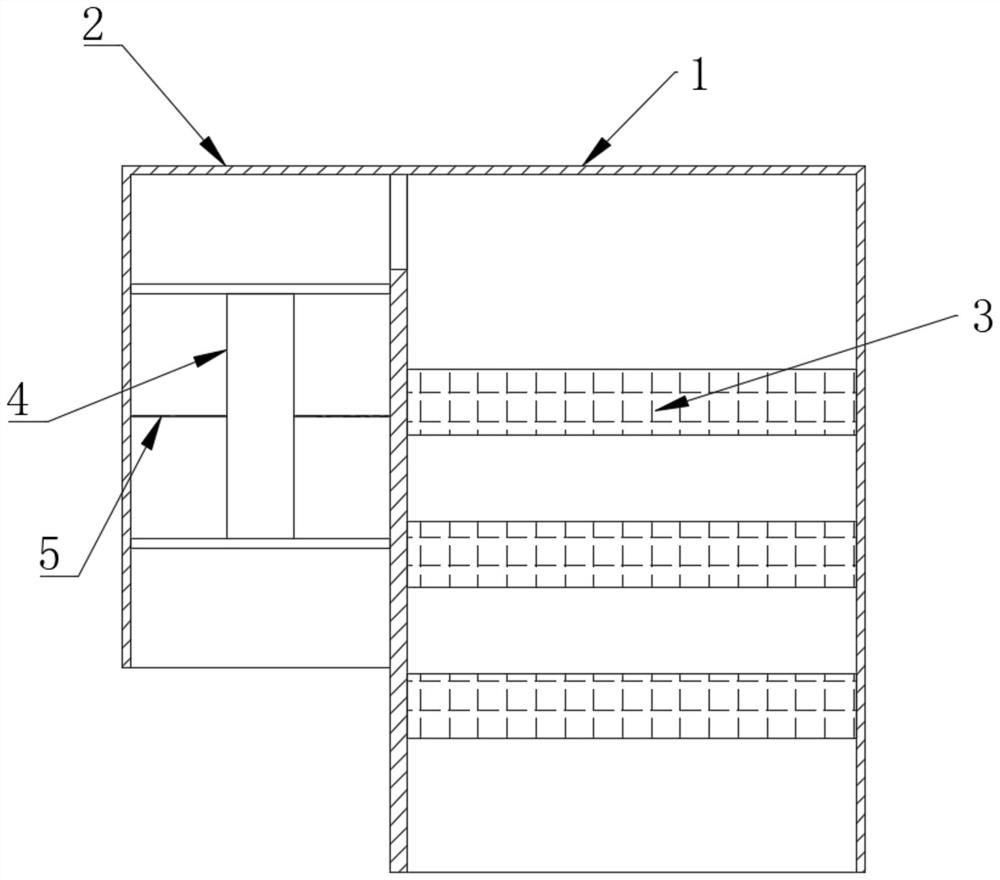

[0053] see Figure 1-5 , denitrification treatment system for flue gas from grate rotary kiln pellet roasting, including rotary kiln, denitrification reactor, flue gas cooler, electrostatic precipitator, desulfurization absorption tower, wet electrostatic precipitator, tubular flue gas heater, chimney , the denitration reactor includes a denitration box 1, the side wall of the denitration box 1 is fixedly connected with an air inlet box 2, the inside of the denitration box 1 is fixedly connected with a plurality of catalytic plates 3, and the middle part of the air inlet box 2 is fixedly connected with an energy supply pipe 4. Multiple slots 8 are opened between the inner and outer walls of the energy supply pipe 4, and a plurality of filter plates 5 corresponding to the slots 8 are fixedly connected to the inner wall of the air inlet box 2, and one end of the filter plate 5 runs through the slots 8 And extend to the inner side of the energy supply pipe 4, a plurality of evenl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com