Speed chain assembly line

An assembly line and double-speed chain technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve problems that affect the assembly of parts, easy to detach from the surface of the tooling board, and shape changes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

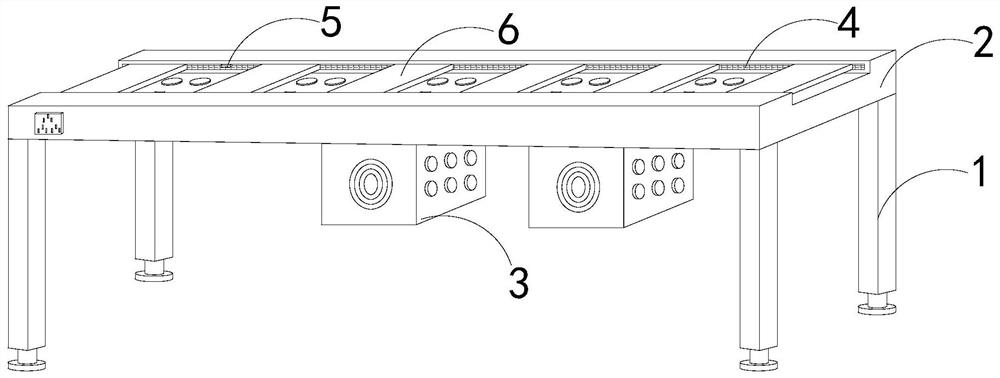

[0025] as attached figure 1 to attach Figure 5 Shown:

[0026] The invention provides a double-speed chain assembly line, the structure of which includes a support frame 1, a workbench 2, a distribution box 3, a chain 4, a blocking block 5, and a tooling plate 6. The workbench 2 is fixed on the top of the support frame 1, and the The distribution box 3 is installed at the bottom of the workbench 2, the chain 4 is installed on both sides inside the workbench 2, the blocking block 5 is fixed on the left inner wall of the workbench 2, and the tooling plate 6 is arranged on the top of the workbench 2, And cooperate with chain 4 activities.

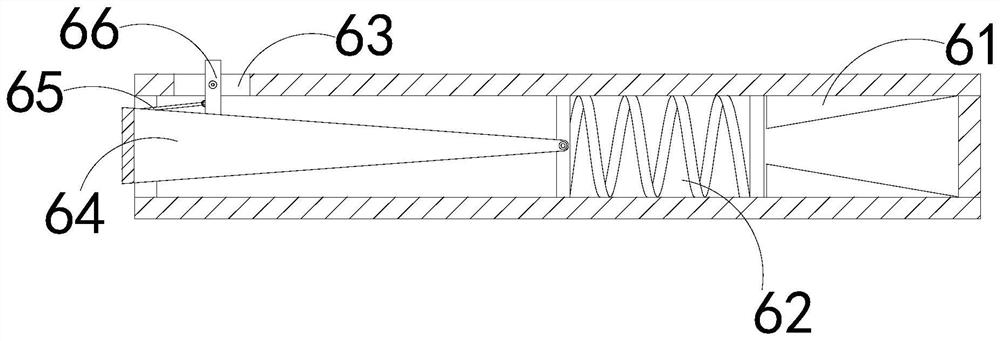

[0027] The tooling plate 6 is provided with a block 61, a spring 62, an opening 63, a push block 64, a push rod 65, and a block 66. The block 61 is fixed on the inner wall on the right side of the tooling plate 6, and the spring 62 is located on the card. On the left side of the block 61, the opening 63 runs through the top of the left end...

Embodiment 2

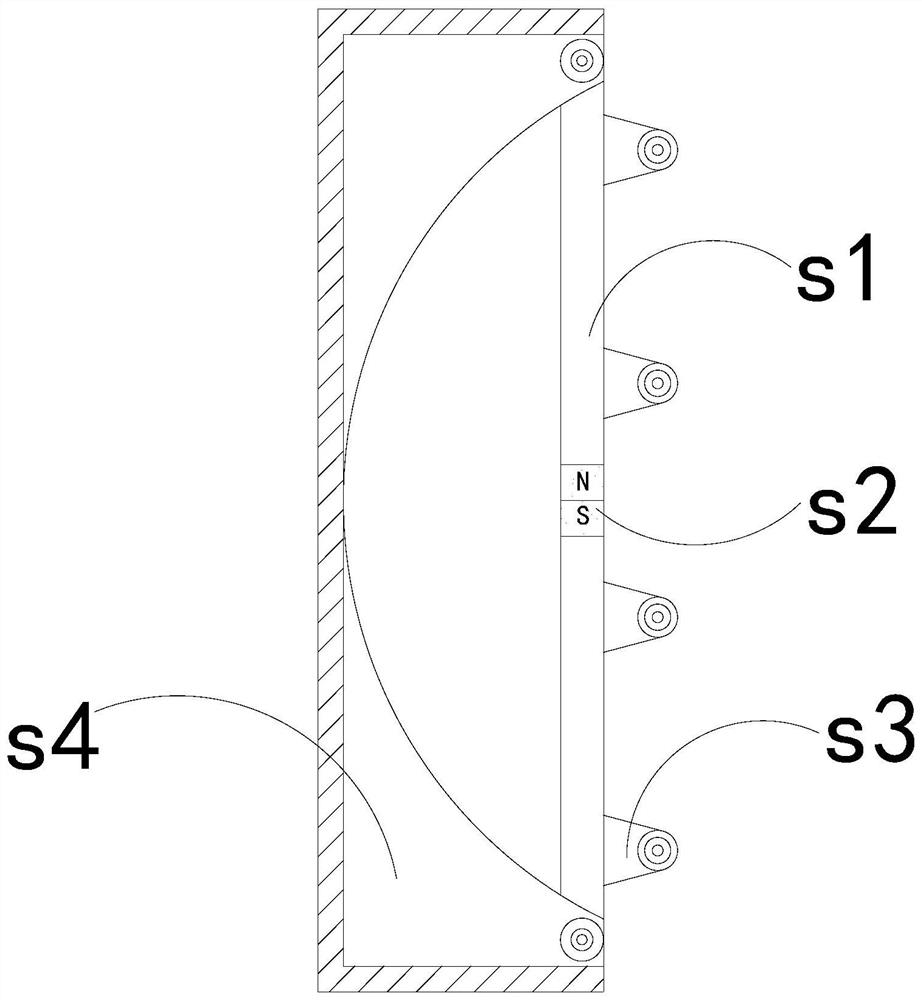

[0034] as attached Image 6 to attach Figure 7 Shown:

[0035]Wherein, the opening 63 is provided with a side block n1, clamping teeth n2, and a pull cord n3, the side block n1 is fixed in the middle of the inner side of the opening 63, the clamping teeth n2 are located on the upper and lower sides of the side block n1, and the pull cord n3 Connected between the clamping teeth n2 and the inner wall of the opening 63, the clamping teeth n2 are provided with four, and are in a triangular shape. The pressure is beneficial to limit the stopper 66.

[0036] Wherein, the side block n1 is provided with a fixed block m1, a contact plate m2, a tooth plate m3, a pressing block m4, and an elastic block m5, the fixed block m1 is fixed on the inner wall of the left end of the side block n1, and the contact plate m2 is installed on Inside the side block n1, the tooth plate m3 is arranged on the left side of the contact plate m2, the pressure block m4 is fixed on the right side of the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com