Paraffin-treatment device for a workstation on a textile machine producing cross-wound bobbins

A technology for cross-winding bobbins and textile machines, used in textiles and papermaking, transportation and packaging, thin material handling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

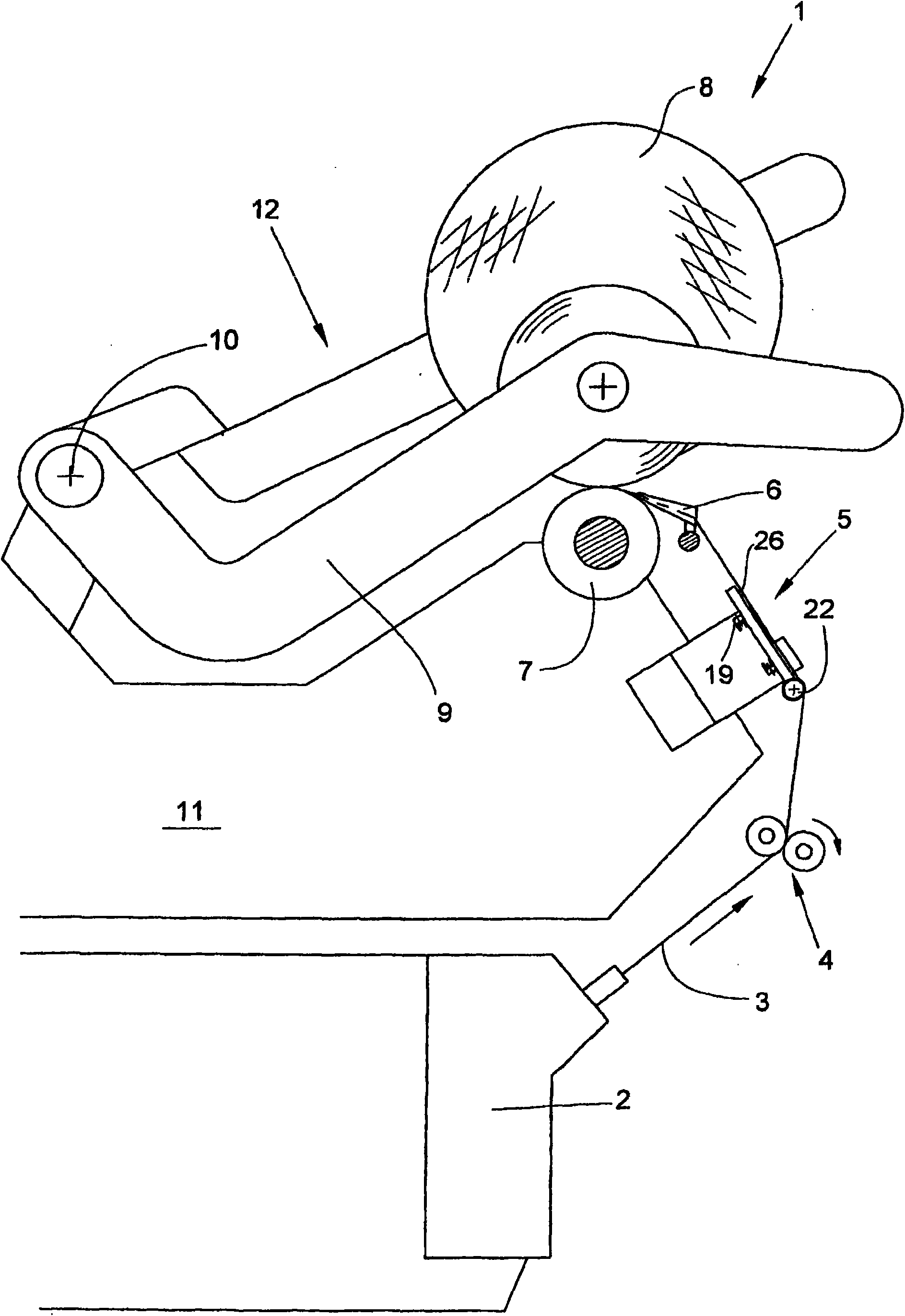

[0033] figure 1 A station 1 of an open-end rotor spinning machine is shown schematically in which a waxing device 5 is used. As is known per se, such a station 1 in each case has an open-end rotor spinning unit 2 for producing yarn 3 and a winding device 12 for producing cross-wound bobbins 8 . The yarn 3 produced here in the open-end rotor spinning group 2 is drawn off from the same by means of a yarn take-off device 4 , which can be driven by a separate motor, for example, from which the yarn 3 is on its way to the winding device 12 . The path also passes through a waxing device 5 constructed according to the invention.

[0034] As is also known, the winding device 12 has a creel 9 , a yarn traversing device 6 and a cross-winding bobbin drive roller 7 .

[0035] The present exemplary embodiment shows a conical cross-wound bobbin 8 , which is rotatably supported in a creel 9 , which itself is connected to the station housing 11 at least via a pivot axis 10 . .

[0036] At...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com