Comb retainer for Sendzimir bearing

A cage, comb-shaped technology, used in bearing components, shafts and bearings, mechanical equipment, etc., can solve problems such as bearing accuracy loss, bearing life decline, bearing raceway scratches, etc., to ensure accuracy and life, and reduce weight. , Improve the effect of lubrication

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

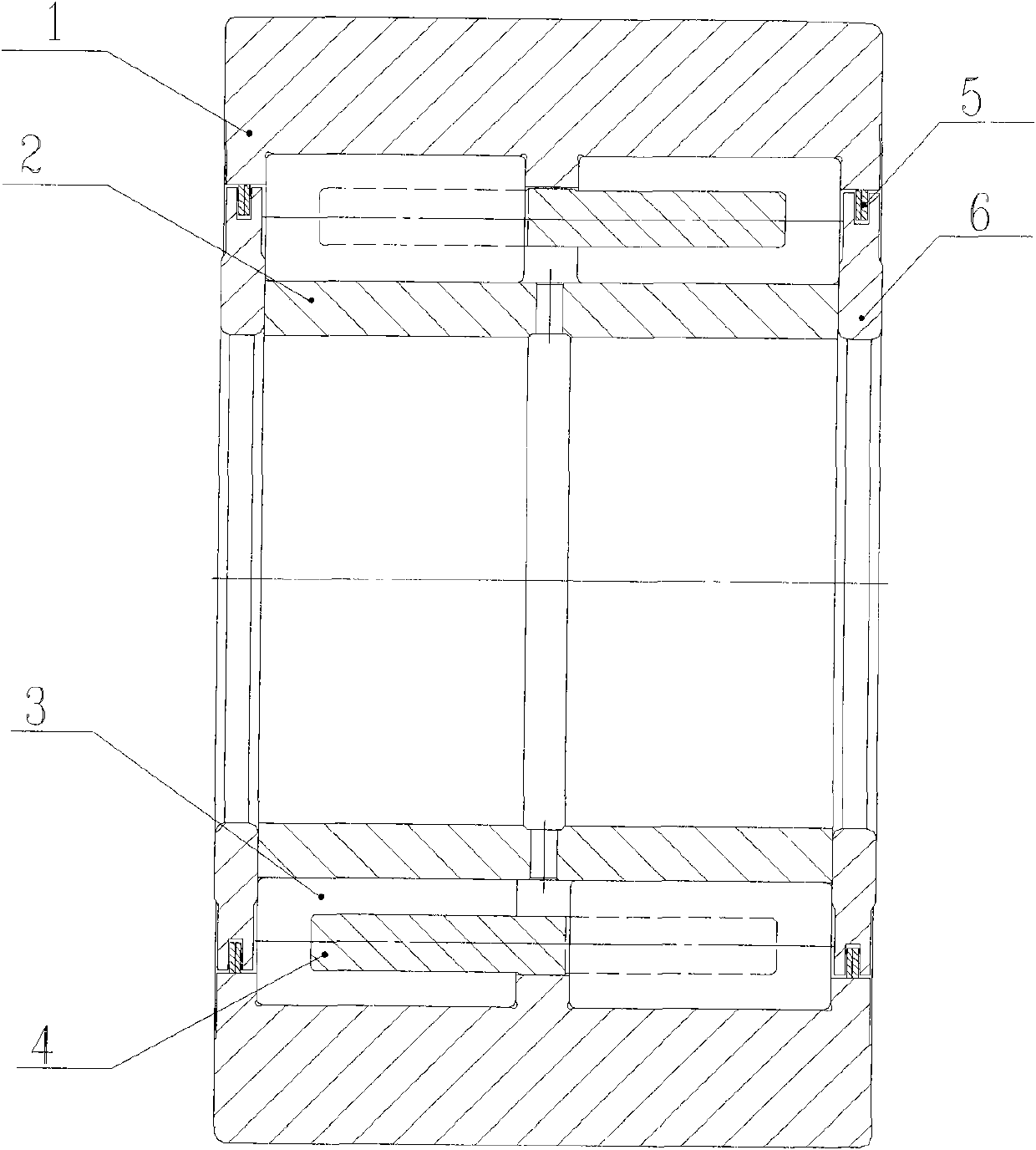

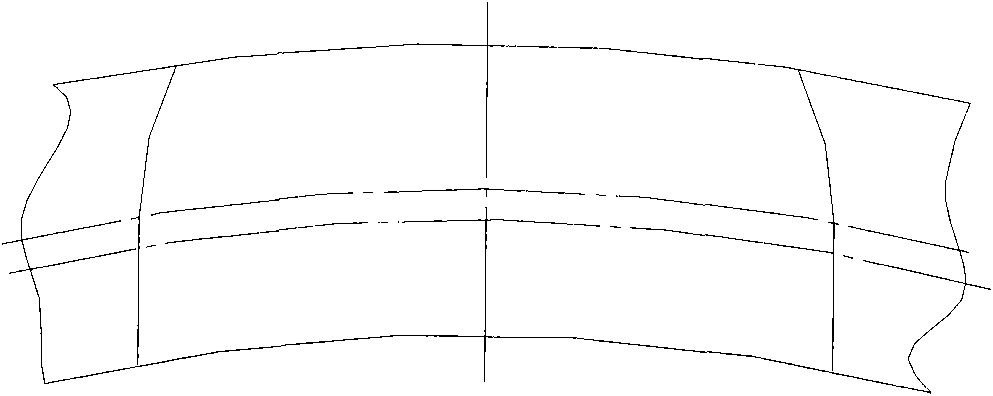

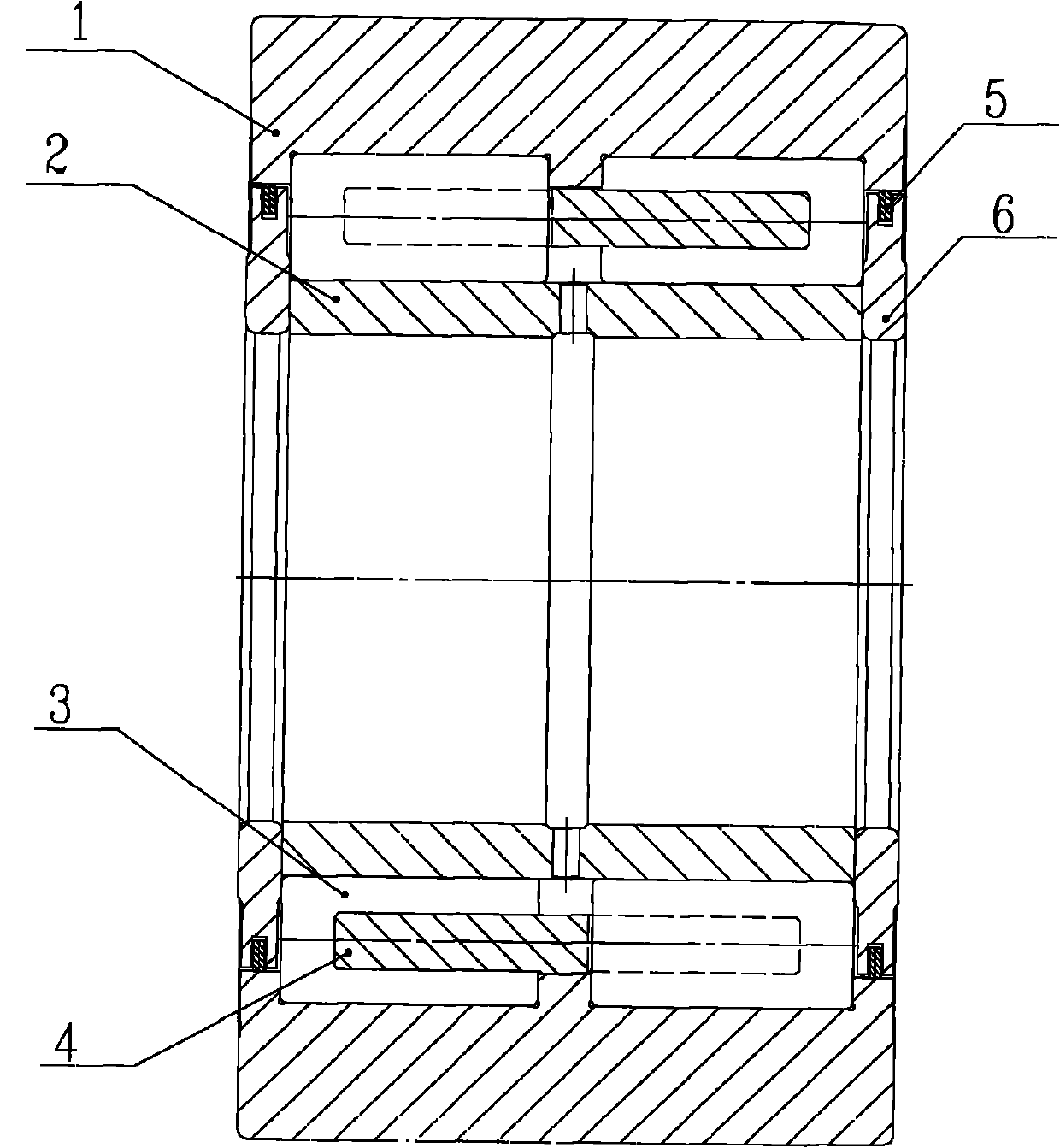

[0009] like figure 1 As shown, the Sendzimir bearing is composed of outer ring 1, inner ring 2, roller 3, cage 4, spring seal ring 5 and flat retaining ring 6, figure 2 It is the structural shape diagram of the double-segment cage pocket with arc and straight line of Sendzimir bearing. The cage 4 has the structural shape of the double-segment cage pocket with arc and straight line. The shape of the pocket is not a single arc. The pocket holes are a combination of a part of arc shape and a part of straight line shape. The depth of the pocket holes adopts a staggered arrangement of one deep and one shallow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com