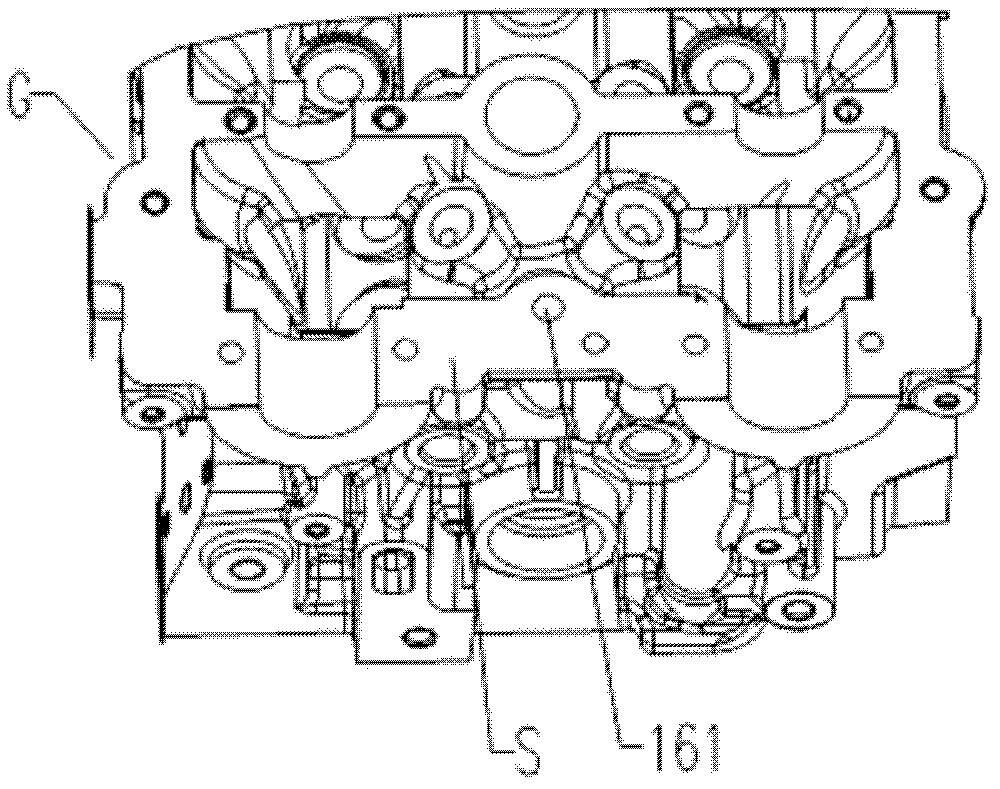

First bearing cover of engine cylinder cover

A technology of engine cylinder head and bearing cover, which is applied in the directions of engine components, machines/engines, bearing components, etc., can solve the problems of difficult processing, complicated oil circuit layout, cumbersome processing procedures, etc., and achieve the effect of reducing the difficulty of machining

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

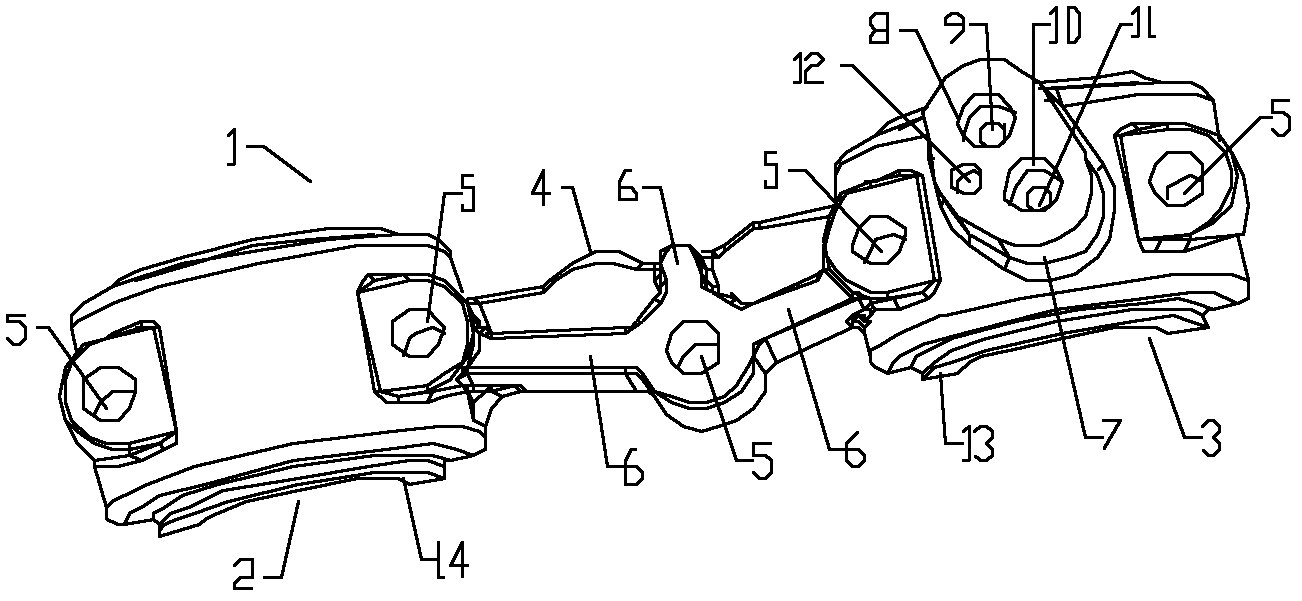

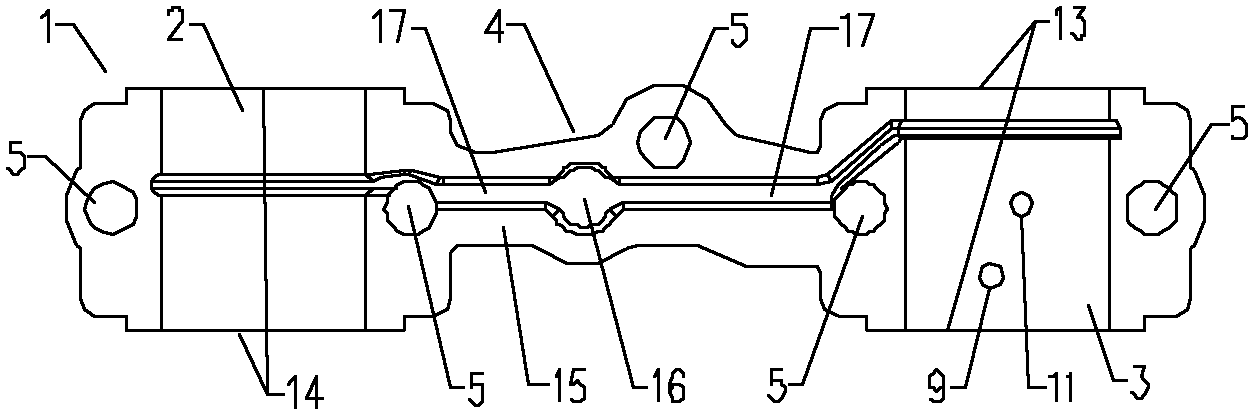

[0021] The present invention will be described in detail below according to the accompanying drawings, which is a preferred embodiment among various implementations of the present invention.

[0022] Bolts are screwed through each bolt hole to fix the first bearing cap 1 to the cylinder head G, so that the lower surface 16 of the bearing cap is closely attached to the upper surface S of the cylinder head. When the engine is running, when the lubricating oil in the main oil passage 161 of the cylinder head reaches the oil storage tank 16, the lubricating oil in the oil storage tank supplies oil to the intake and exhaust camshaft bearings respectively through the oil passage 17 arranged on the lower surface 16 of the first bearing cover. , and enter the oil passage inside the hollow camshaft through the corresponding oil hole 171 on the camshaft T, and then lubricate each camshaft bearing.

[0023] In this embodiment, an oil pipe can be installed on the installation hole 8 of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com