An Axially Translatable Conveyor

An axial translation and conveyor technology, which is used in mining equipment, tunnels, earth-moving drilling, etc., can solve the problems that the collecting ring cannot move axially and occupy the space for the axial movement of the collecting ring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate the understanding of the present invention, the following will be described in conjunction with the accompanying drawings and embodiments.

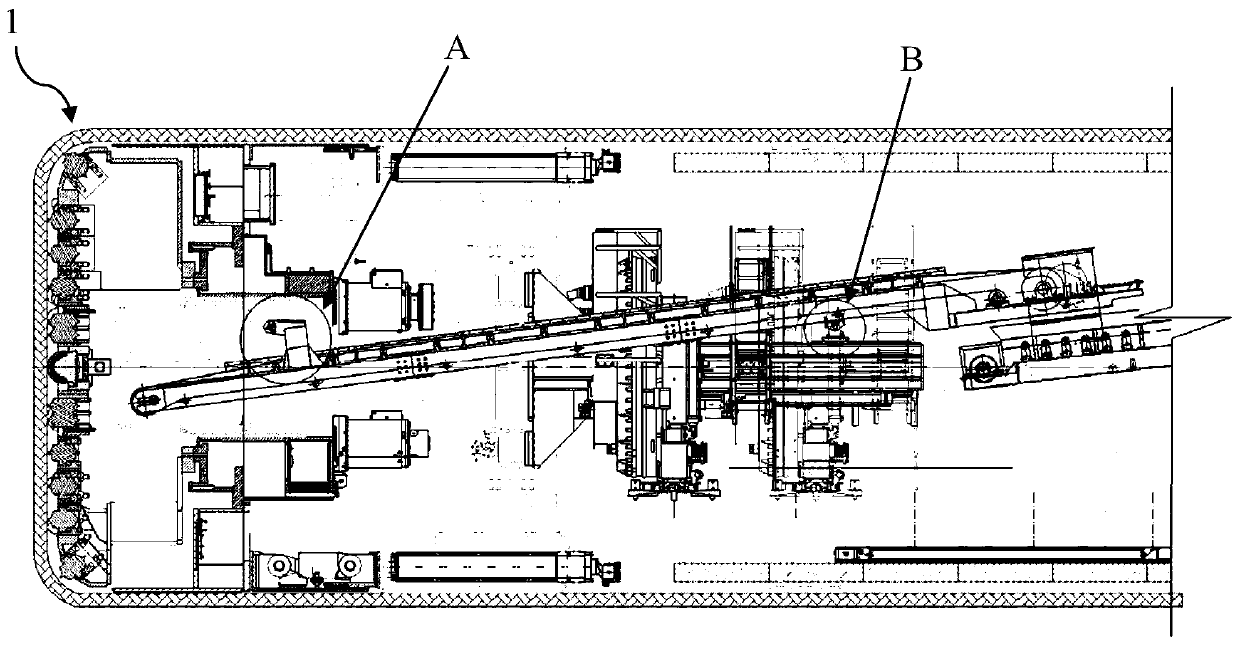

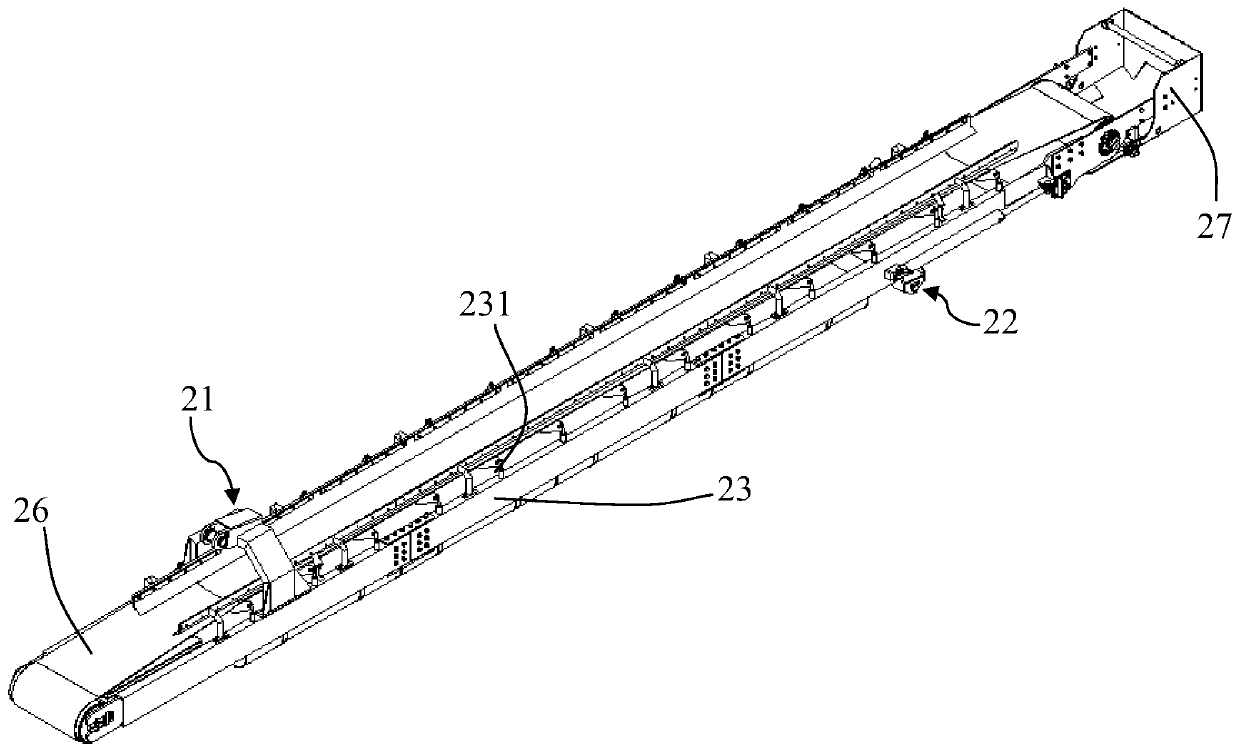

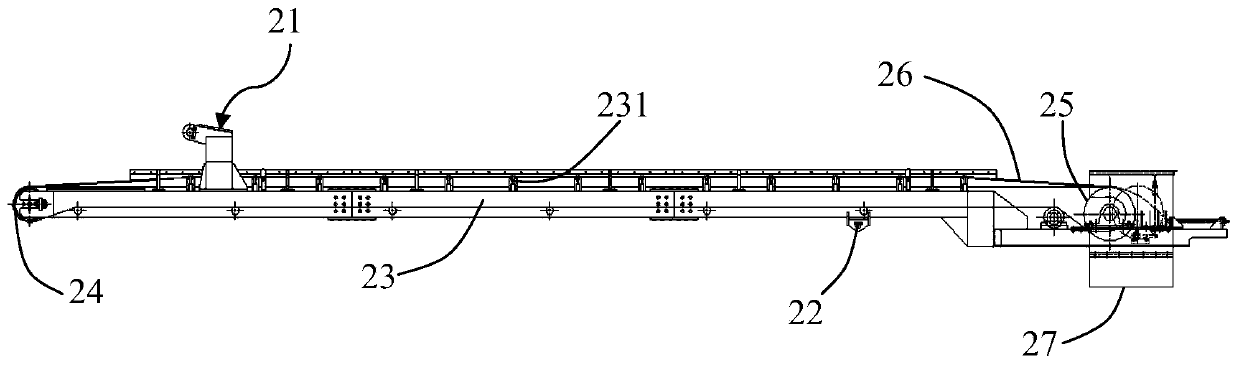

[0033] refer to Figure 1 to Figure 5 It can be seen that the present invention discloses an axially translatable conveyor, including a conveyor body, a head assembly 21 and a support 22 for connecting the soil collecting ring 11 in the shield tunneling machine 1; wherein the head assembly 21 Installed on the frame 23, the support 22 is provided with a sliding surface 2241 for supporting the frame 23 in the conveyor main body (such as Figure 6 to Figure 10 shown). In this embodiment: the connection between the axially translatable conveyor and the soil collecting ring 11 in the shield boring machine 1 is realized through the head assembly 21, and the frame 23 is supported on the sliding surface 2241 of the support 22 Above, when the soil collecting ring 11 is driven to move along its axis, the axially tran...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com