H-shaped wheel tightening device for water tank wire-drawing machine

A technology of I-shaped wheel and water tank, which is applied in the field of I-shaped wheel tightening device of water tank wire drawing machine, which can solve problems such as flying out, disappearance of I-shaped wheel’s top tightening force, and injury to operators, and achieves simple power transmission structure and long-term guarantee Time running, stable and reliable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

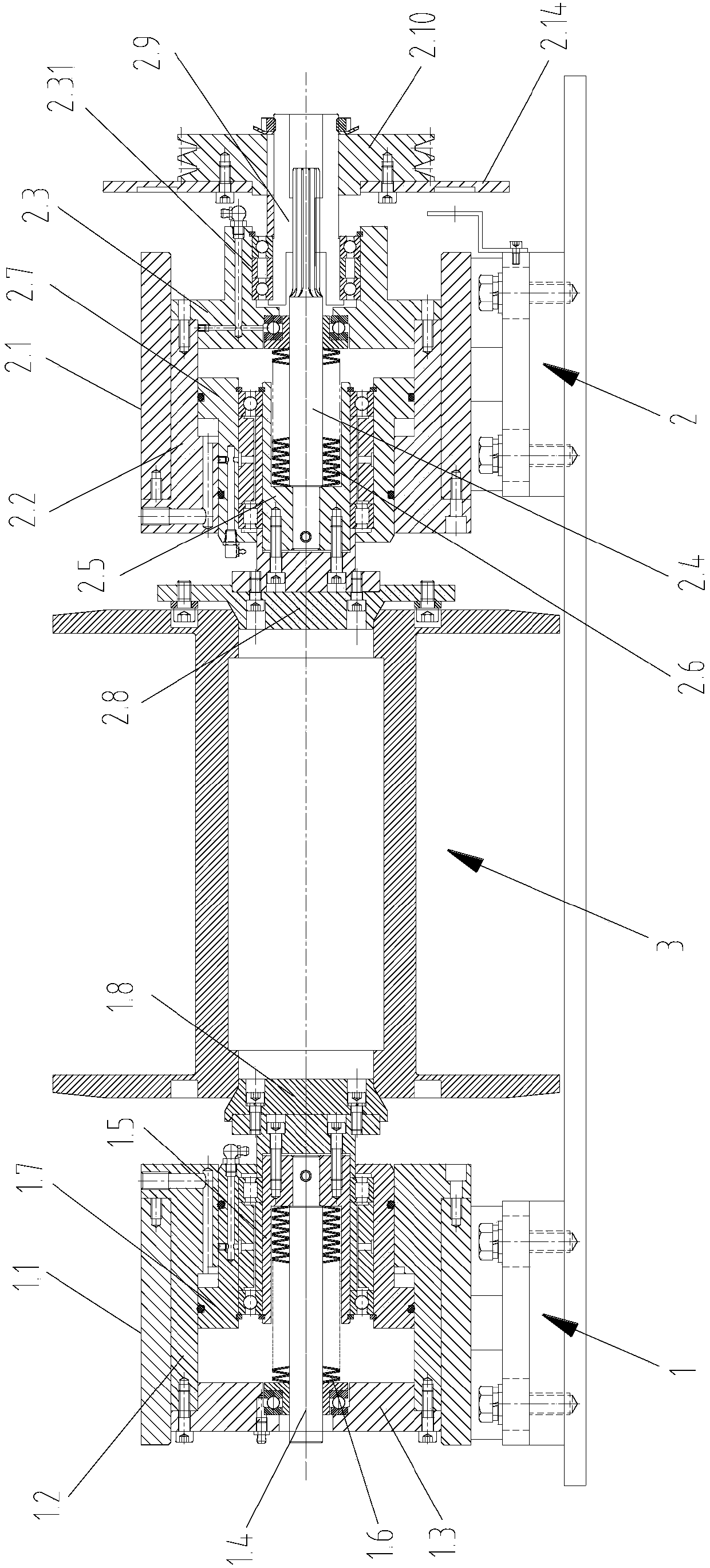

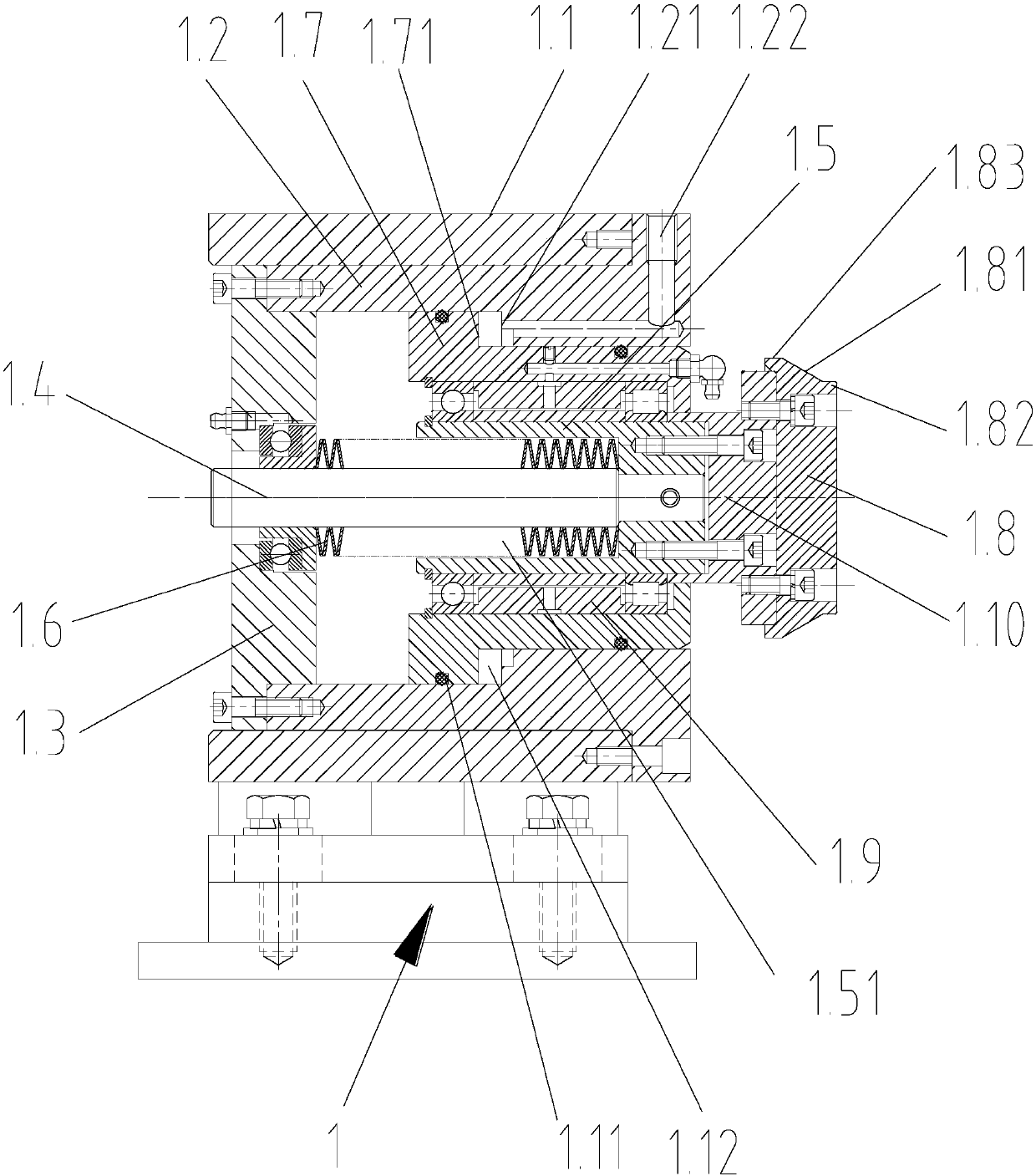

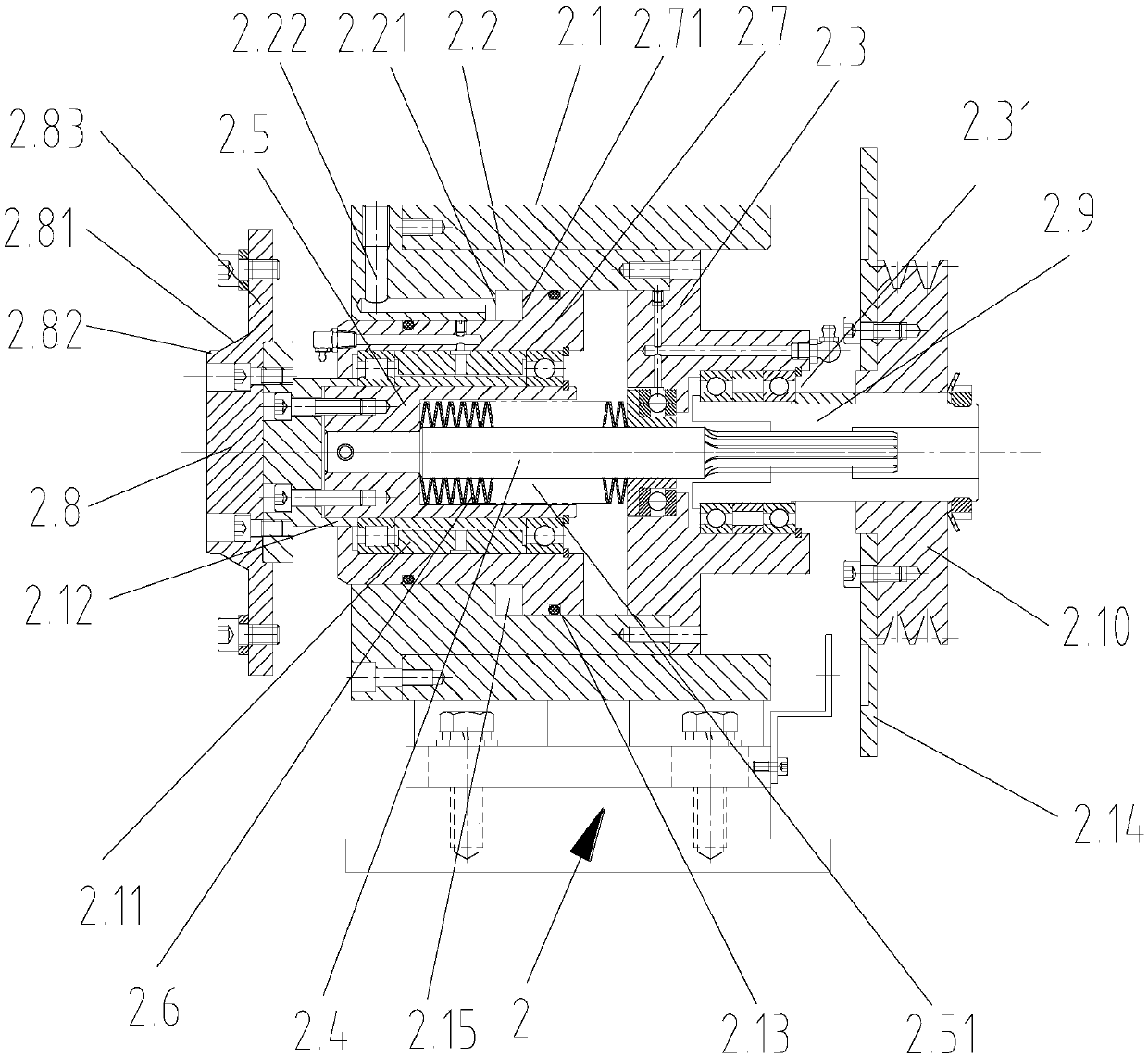

[0034] As shown in the figure, an I-wheel tightening device for a water tank wire drawing machine includes a first disc spring tightening mechanism 1 and a second disc spring tightening mechanism 2 arranged at both ends of the I-wheel 3 in the axial direction. The first disc spring tightening mechanism 1 includes a cylindrical first mounting seat 1.1, a first fixing sleeve 1.2 arranged circumferentially on the inner cavity of the first mounting seat 1.1 and its inner wall, One end of the inner cavity is fixed to the first end cover 1.3 of the first fixed sleeve 1.2 in the circumferential direction, and the first sliding shaft 1.4 axially penetrates the middle part of the inner cavity of the first mounting base 1.1; one end of the first sliding shaft 1.4 runs through the first The center hole of the end cover 1.3 is slidingly matched wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com