Patents

Literature

104results about How to "Reduce cleaning intensity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt less multi element high speed tool steel and its manufacturing method

InactiveCN1693527AReasonable range of performanceLow content of alloying elementsFurnace typesHeat treatment furnacesElectrical resistance and conductanceChemical composition

A non-Co multi-element high-speed tool steel contains proportionally C, Si, Mn, S, P, Cr, V, Mo, W, Ni, Nb, Ti, Mg, RE and Fe. Its preparing process includes such steps as smelting by MF furnace, modifying with Y-based RE alloy, centrifugal casting, and heat treating.

Owner:JIUQUAN IRON & STEEL GRP

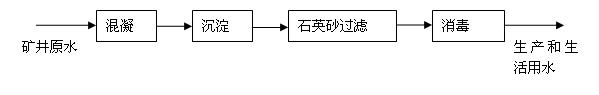

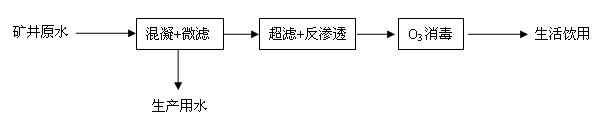

Comprehensive recycling technology for mine water with high suspended matter content and high mineralization degree

InactiveCN102491564AReduce membrane foulingRestore membrane fluxWater/sewage treatment bu osmosis/dialysisMultistage water/sewage treatmentRaw waterChemistry

The invention discloses a comprehensive recycling technology for mine water with high suspended matter content and a high mineralization degree. A coagulating agent is added into mine raw water, so that suspended colloid fine particles in water are subjected to conventional compressive double-electric-layer destabilization, and are treated with a three-membrane gradual filtering technology consisting of first-stage microfiltration membrane filtering, second-stage microfiltration membrane filtering and third-stage microfiltration membrane filtering. After the mine raw water is subjected to first-stage microfiltration membrane filtering, effluent can meet the requirement of production under a coal mine; and after the mine raw water is subjected to second-stage microfiltration membrane filtering and third-stage microfiltration membrane filtering and is disinfected with O3, effluent can meet the requirement of daily drinking. Different reverse osmosis membrane automatic back washing technologies and back washing chemical medicament formulae are adopted according to water of different mineralization degrees, so that the problem of poor running effect of a mine water reverse osmosis system with a high mineralization degree is solved, and the effluent quality and stable running of a water treatment system are enhanced.

Owner:CHINA UNIV OF MINING & TECH (BEIJING)

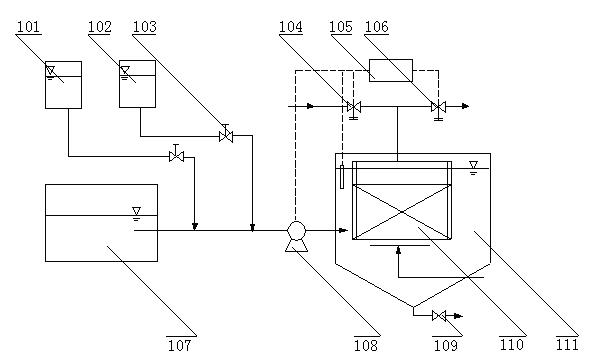

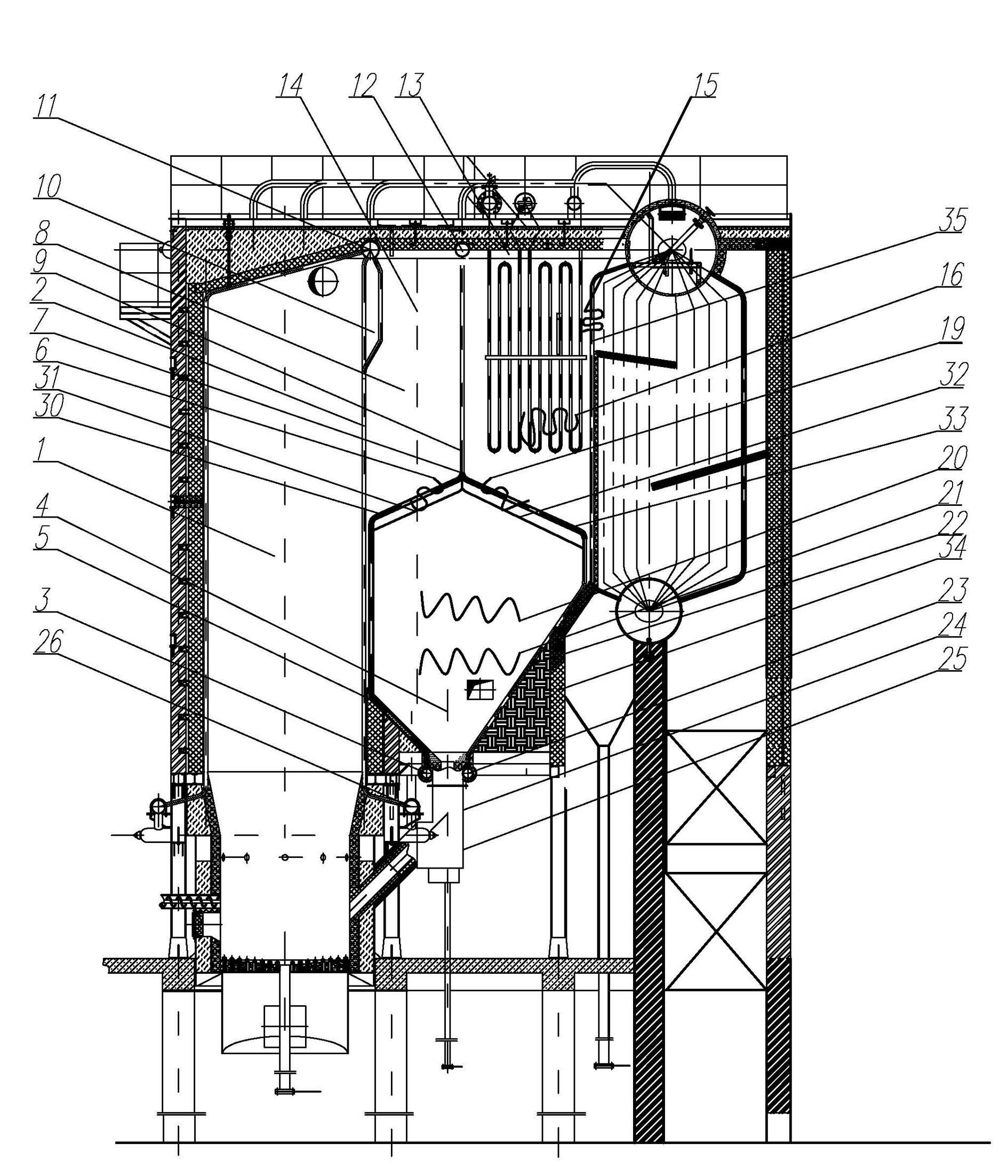

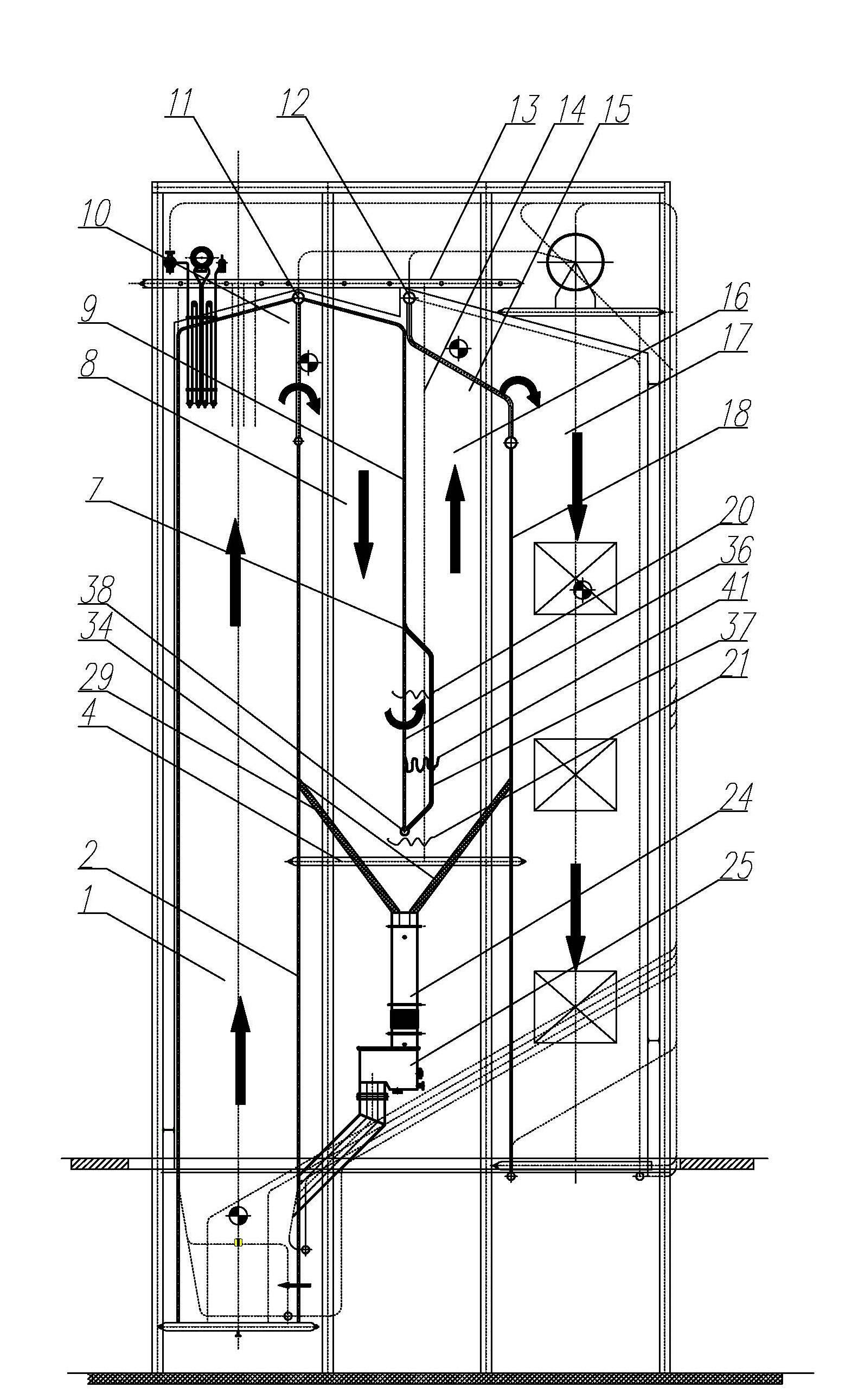

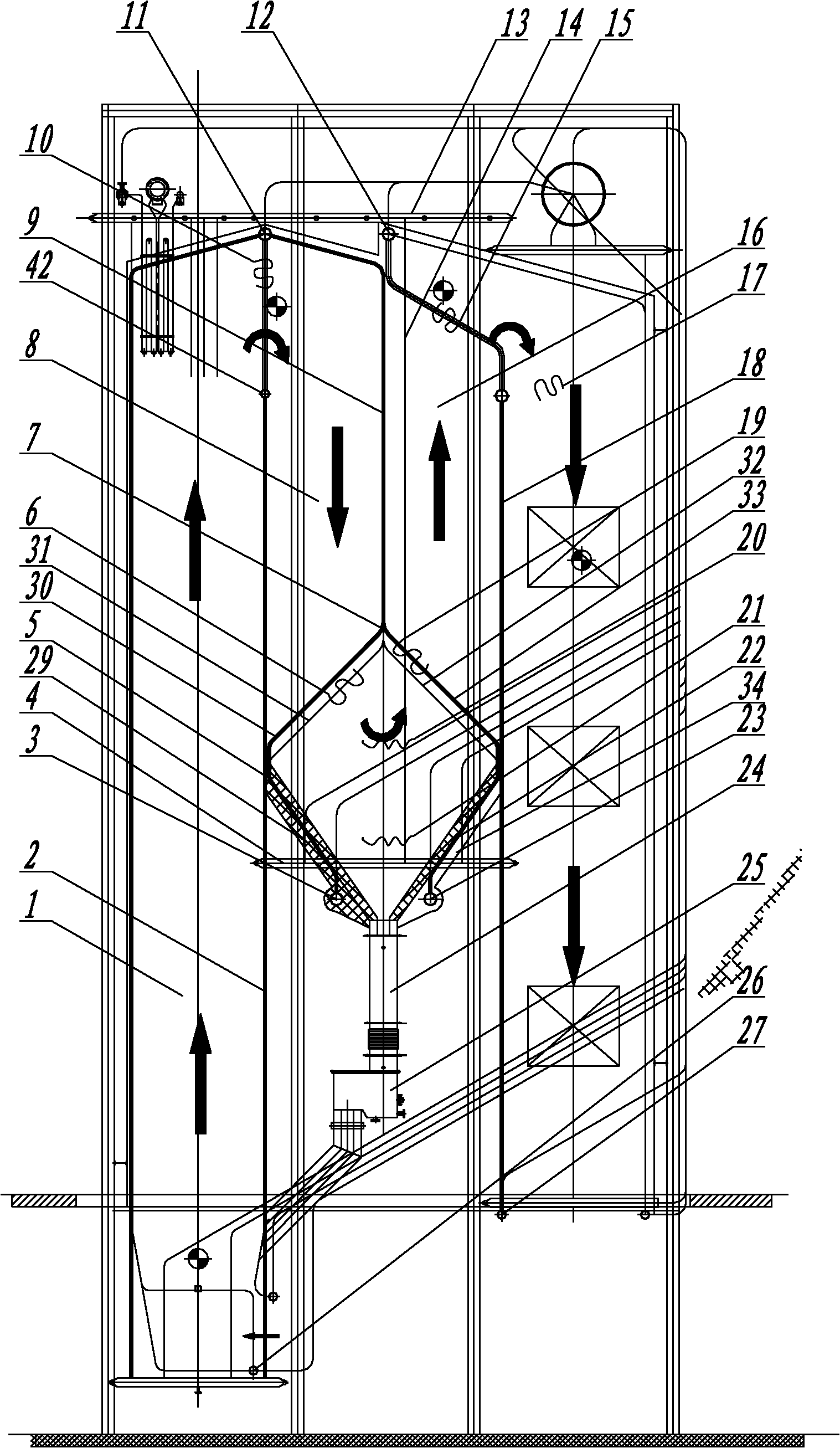

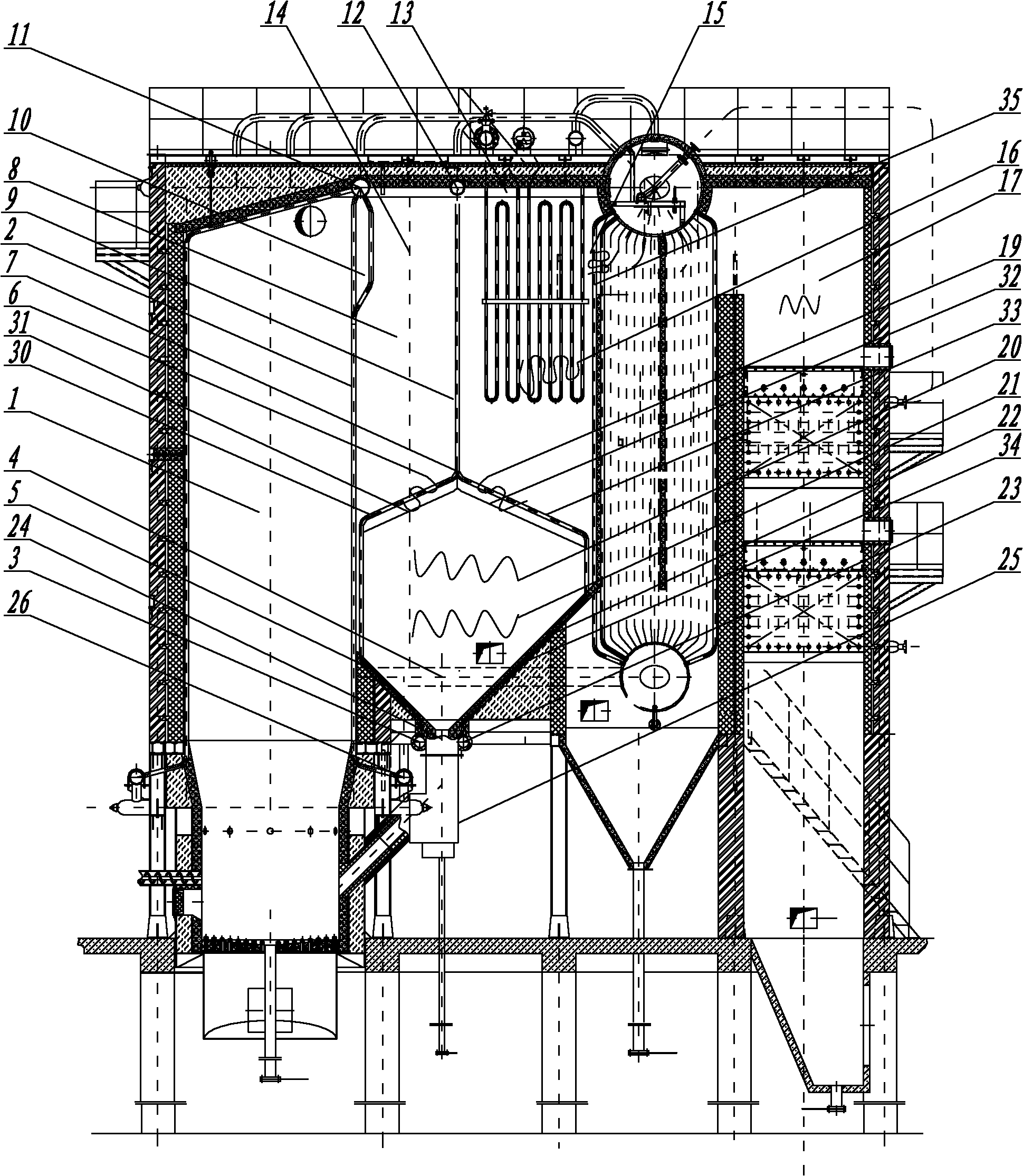

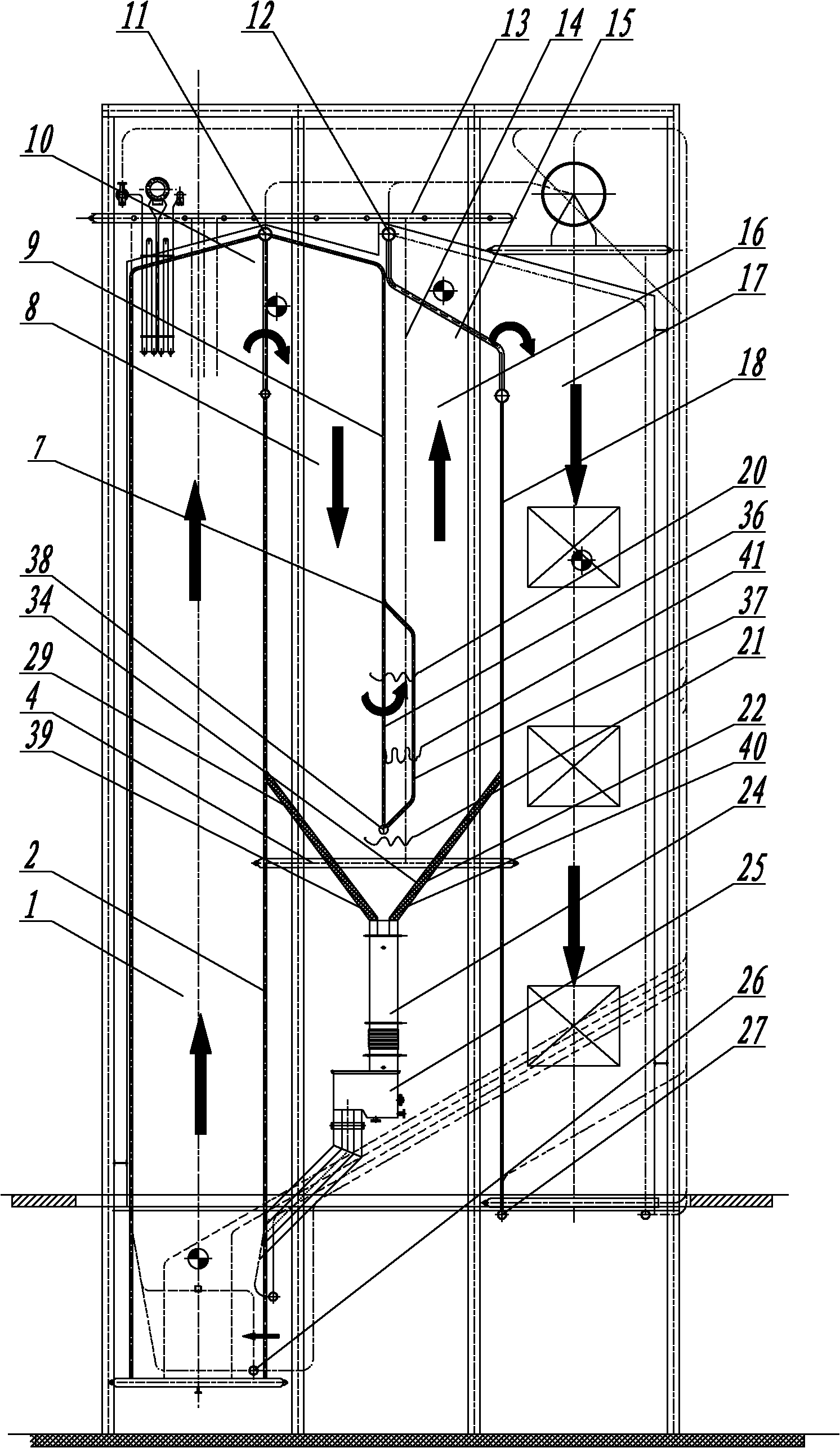

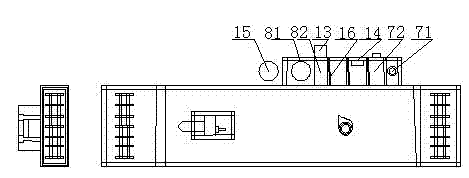

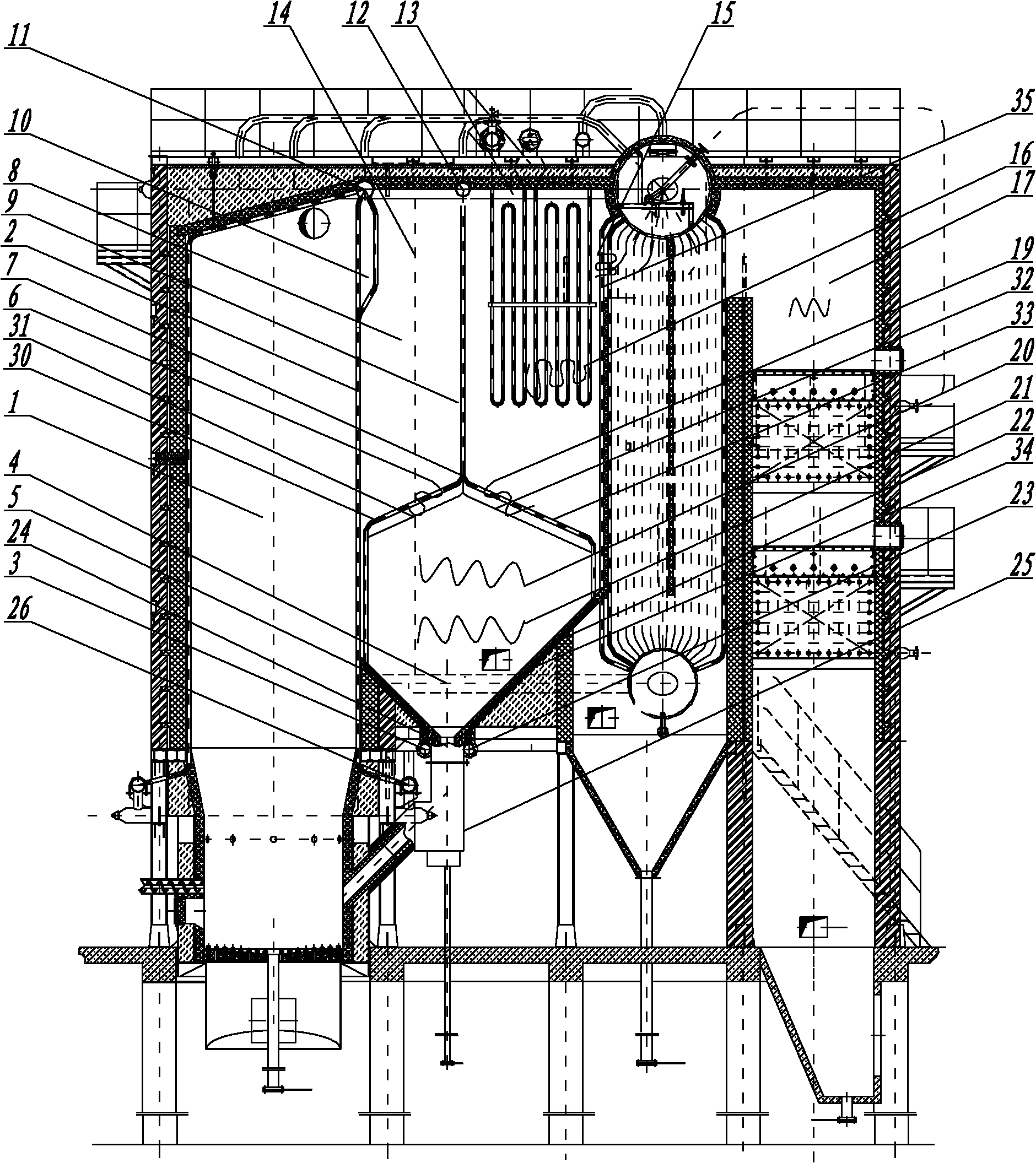

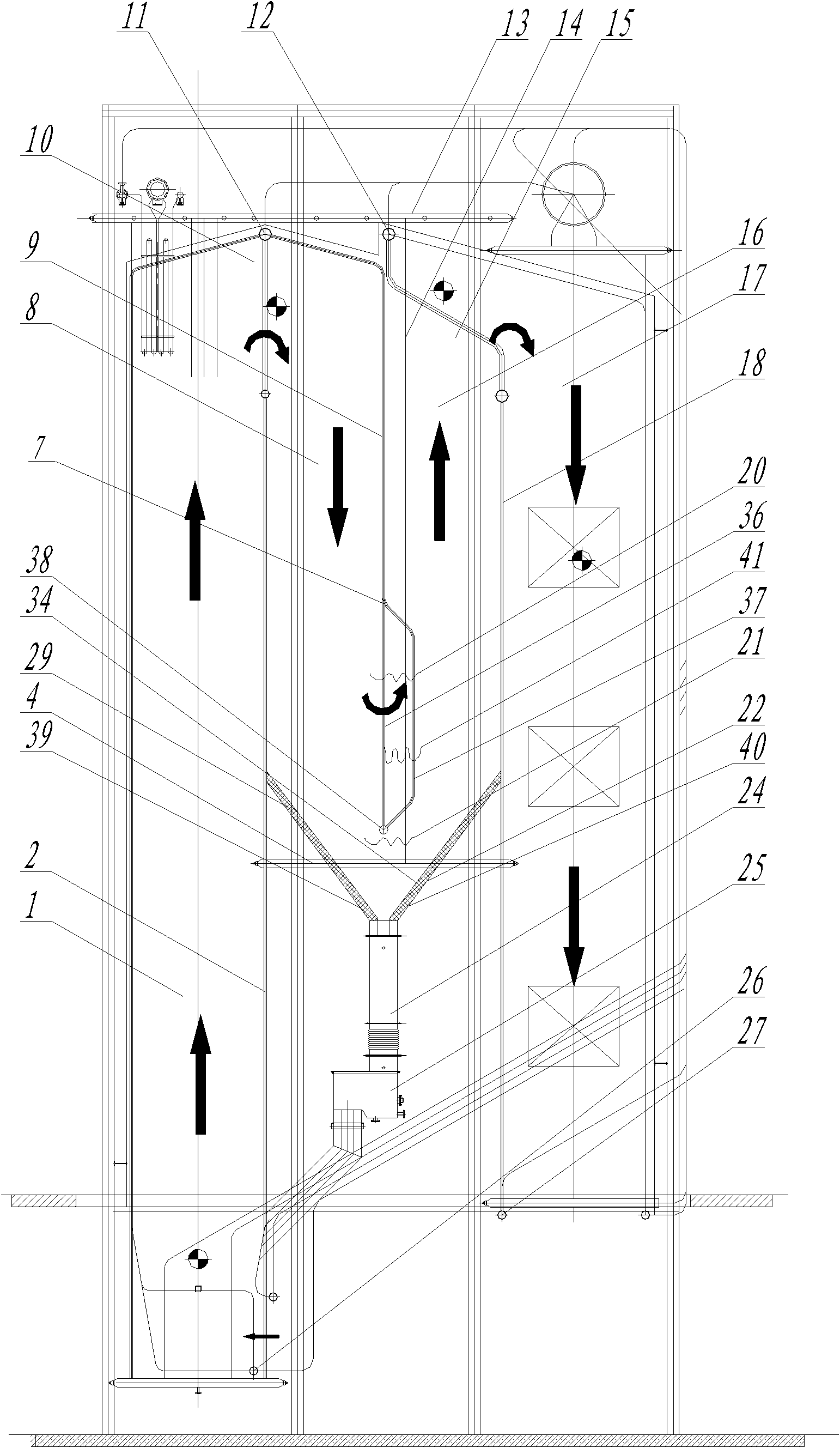

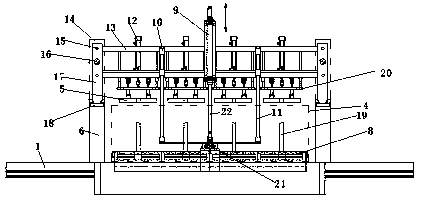

Gas-solid separator of recirculating fluidized bed boiler and boiler comprising same

ActiveCN102588959AReduce power consumptionSave long runFluidized bed combustionDispersed particle separationCycloneEngineering

A gas-solid separator of a recirculating fluidized bed boiler comprises a downward flue and an upward flue which are separated from front to back by a membrane-type guided flue gas downward and upward turning screen; the downward flue and the upward flue are communicated with each other through a swerving passageway and a feed bin which is hermetically installed below the downward flue and the upward flue; a flue gas inlet is arranged at the front upper part of the gas-solid separator and a flue gas outlet is arranged at the back upper part of the gas-solid separator; four walls of the gas-solid separator are all water cooled walls which are integrated with the boiler; the gas-solid separator further comprises a flow equalizing and separating tube bundle and an abrasion-proof communication pipe which are located on the swerving passageway; the upper end of the flow equalizing and separating tube bundle on the swerving passageway is communicated with a lower cross collecting tank of the membrane-type guided flue gas downward and upward turning screen, and the lower end of the flow equalizing and separating tube bundle on the swerving passageway is communicated with a cross collecting tank of the feed bin; and the upper end of the abrasion-proof communication pipe on the swerving passageway is communicated with the lower cross collecting tank of the membrane-type screen, and the lower end of the abrasion-proof communication pipe on the swerving passageway is communicated with a cross collecting tank of the communication pipe. In the case of circulation at low ratio, inertia gravity is used for single stage separation, and in the case of circulation at high ratio, when the speed of the smoke in the upward flue is high, low-temperature cyclone separation can be combined with inertia gravity separation for double-stage separation.

Owner:王森

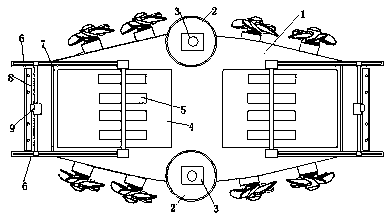

Material separator for circulating fluidized bed boiler

PendingCN101963350AExtended service lifeSave electricityFluidized bed combustionDispersed particle separationFluidized bedPulp and paper industry

The invention discloses a material separator for a circulating fluidized bed boiler. The material separator is characterized in that: the lower end of a fume guide film-type screen which can be bent over is branched into two front rows of light tube bundles and two back rows of light tube bundles, wherein the two front rows of light tube bundles and the two back rows of light tube bundles are bridged above a storage bin and form a fume inlet and a fume outlet of a turning channel respectively; and the lower ends of the two front rows of light tube bundles and the two back rows of light tube bundles are communicated with a middle transverse collecting box of the boiler. The invention also discloses another material separator for the circulating fluidized bed boiler. The other material separator is characterized in that: the lower end of the fume guide film-type screen which can be bent over is branched into a front row of tube bundles and a back row of tube bundles, wherein the front row of tube bundles and the back row of tube bundles are positioned on the turning channel. The material separator has the advantages of advanced process, simple manufacturing and installation, wide application range, energy conservation, consumption reduction and remarkable emission reduction.

Owner:王森

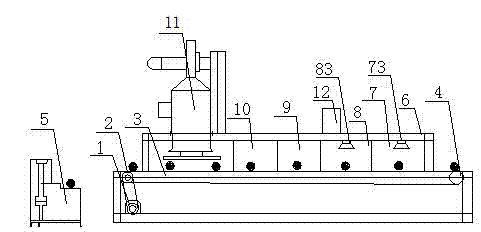

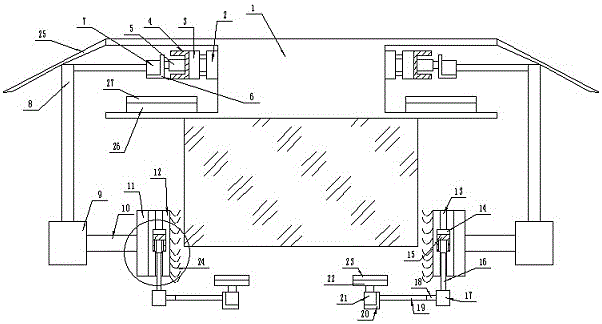

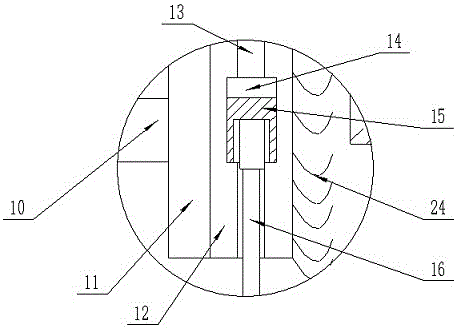

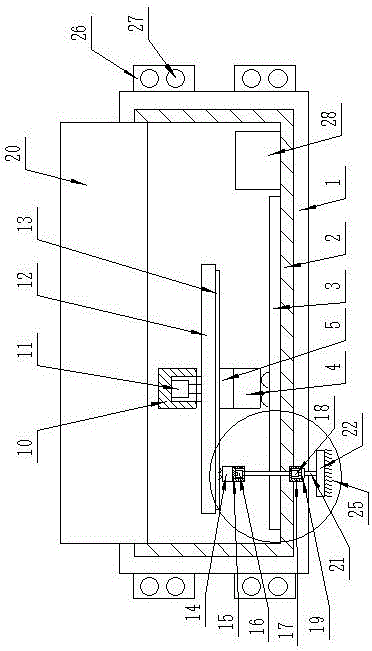

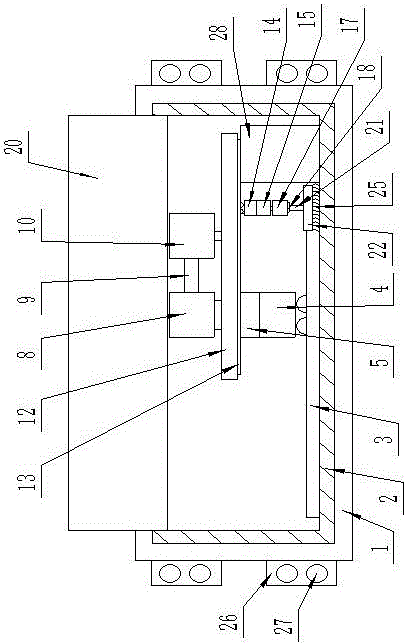

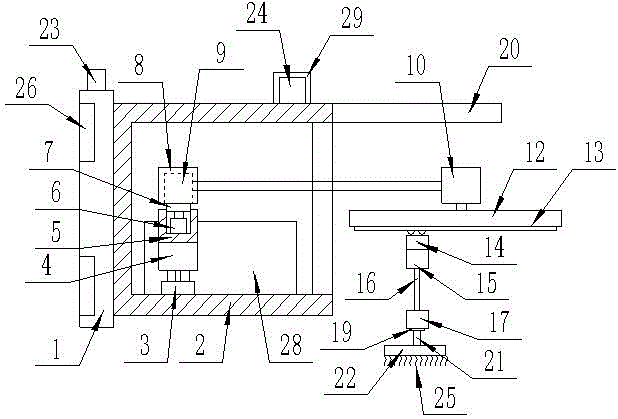

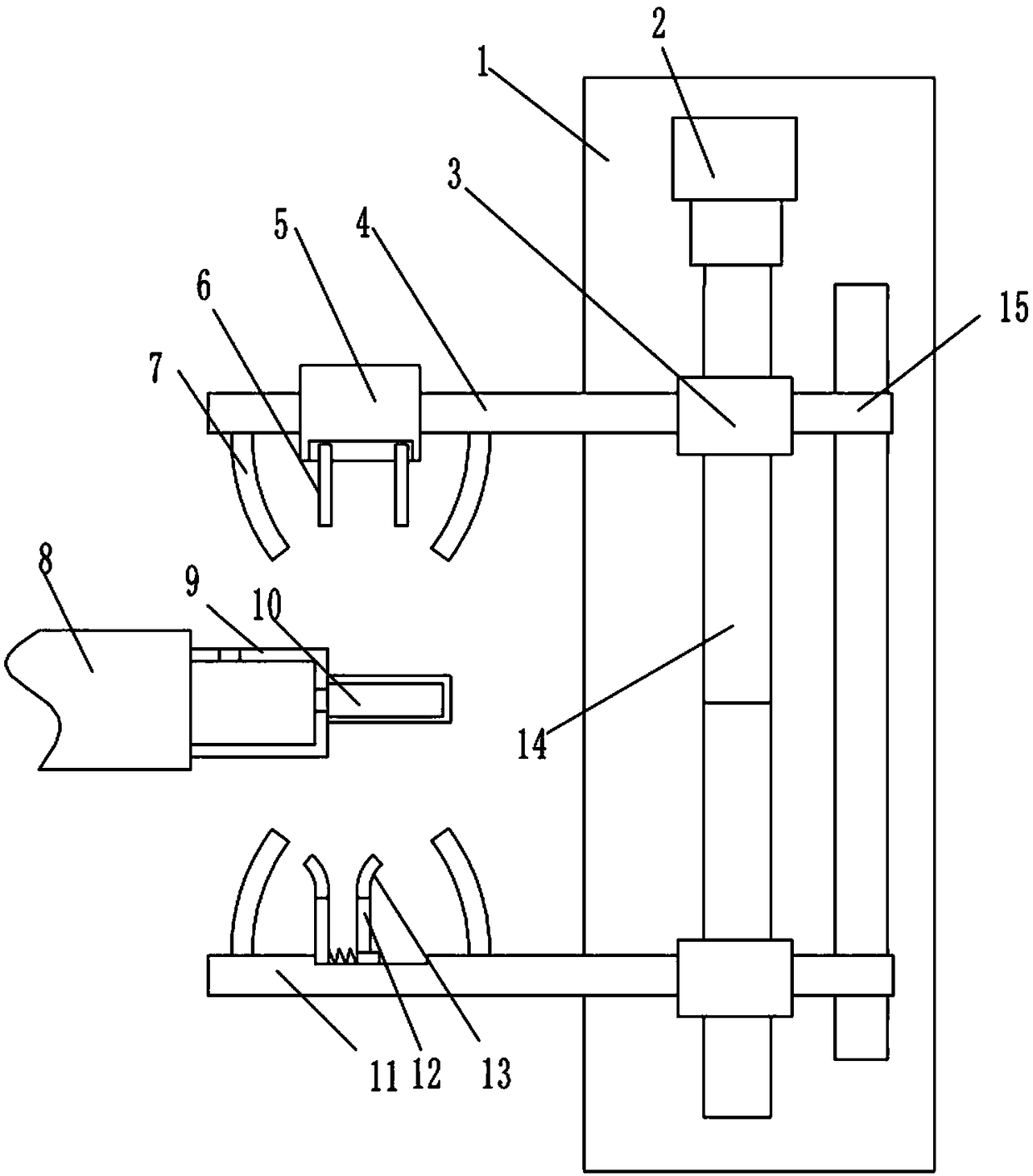

Connecting rod cleaning machine of cam shaft

The invention relates to the technical field of a cleaning device, and particularly relates to a connecting rod cleaning machine of a cam shaft. The connecting rod cleaning machine of the cam shaft comprises a conveyer speed reducer, a main drive shaft, a conveyer belt, a driven shaft, a lifting oil soak machine, an upper shield, a cleaning spraying device, a rinsing spraying device, an artificial washing oil road, an artificial blowing oil road, a hot air circulating system and a condensate oil mist device; the conveyer speed reducer is connected with the main drive shaft; the main drive shaft is connected with the driven shaft through the conveyer belt; the lifting oil soak machine is arranged at one side of the conveyer belt; the upper shield is arranged above the conveyer belt; the cleaning spraying device is arranged between the conveyer belt and the upper shield; the rinsing spraying device is arranged at one side of the cleaning spraying device; the rinsing spraying device is connected with the artificial washing oil road; the artificial washing oil road is connected with the artificial blowing oil road; the hot air circulating system is arranged at one side of the artificial blowing oil road, and the condensate oil mist device is arranged above the rinsing spraying device. The connecting rod cleaning machine of the cam shaft achieves basic automation of cleaning, therefore, the cleaning strength is reduced, and the cleaning quality is improved.

Owner:CRRC QISHUYAN CO LTD

Gas and solid separator of recirculating fluidized bed boiler and boiler containing same

InactiveCN102062395AExtended service lifeSave wear-resistant and high-temperature resistant materialsFluidized bed combustionDispersed particle separationFlue gasFluidized bed

The invention discloses a gas and solid separator of a recirculating fluidized bed boiler, which comprises a downstream flue and an upstream flue which are partitioned by a guiding flue gas up-down replicating film type screen, wherein the downstream flue and the upstream flue are communicated with storage bins hermetically installed below the downstream flue and the upstream flue through a turning channel, the front upper part of the gas and solid separator is provided with a flue gas inlet, the back upper part of the gas and solid separator is provided with a flue gas outlet, and four walls of the gas and solid separator are all heated water-cooling walls integrated with the boiler; and the gas and solid separator also comprises a uniform flow separating pipe bundle positioned on the turning channel, the upper end of the uniform flow separating pipe bundle on the turning channel is communicated with the guiding flue gas up-down replicating film type screen, and the lower end of the uniform flow separating pipe bundle on the turning channel is communicated with a lower transverse container. The invention also discloses a recirculating fluidized bed boiler containing two sets of gas and solid separators. The recirculating fluidized bed boiler has the advantages of wide application range, advanced process, simple manufacturing and installation, energy saving, consumption reduction and obvious emission reduction.

Owner:王森

Air detection bearing device

InactiveCN106770968ALiberate manpowerReduce cleaning intensityCleaning using toolsGas analyser construction detailsEngineeringLight-emitting diode

The invention discloses an air detection bearing device. The air detection bearing device comprises a mounting plate, wherein a mounting box is arranged on the front surface of the mounting plate; a rotary cleaning mechanism is arranged in the mounting box; a rectangular opening matched with the rectangular mounting plate is machined on the front surface of the mounting box. The air detection bearing device has the beneficial effects that the air detection bearing device can be used for automatically cleaning; when the air detection bearing device is used, a detection part stretches out; when the air detection bearing device is not used, the detection part is retracted back; when indoor formaldehyde and nitric oxide reach certain extent, an LED (Light Emitting Diode) warning lamp is turned on and is used for warning.

Owner:CHENGDU PUJIANG KEXIAN TECH

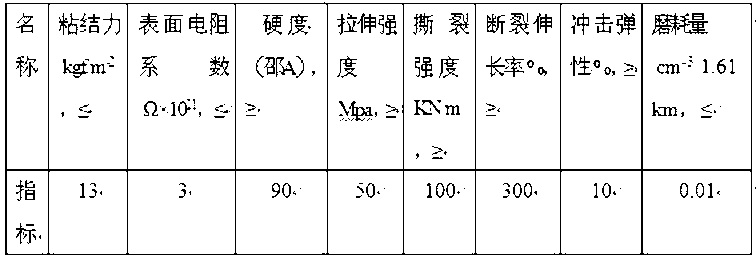

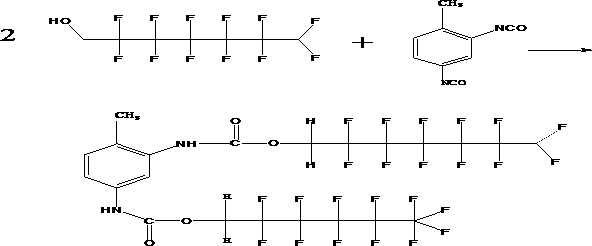

Making method of anti-sticking polyurethane elastomer lining plate

A making method of an anti-sticking polyurethane elastomer lining plate comprises the following steps: putting polyester polyol in a sand mill, adding molybdenum disulfide micropowder and colloidal graphite micropowder, dispersing, placing the obtained mixture in a reaction kettle, heating, carrying out vacuum pumping stirring dehydration, cooling, adding toluene diisocyanate and methyl diphenylene diisocyanate, heating, carrying out a polymerization reaction, and defoaming to prepare a polyurethane prepolymer; adding 1H,1H,7H-dodecafluoro-1-heptanol, a TDI-100 compound, triethyl silane and polytrifluoropropylmethylsiloxane, stirring, and carrying out heating reacting and defoaming to obtain a polyurethane prepolymer mixture containing fluorine and silicon; and heating 3,3'-dichloro-4,4'-diaminodibenzyl methane for melting, mixing with the polyurethane prepolymer mixture containing fluorine and silicon, carrying out cast molding by a casting machine, and carrying out release vulcanizing to make the anti-sticking polyurethane elastomer lining plate. The lining plate has the advantages of seismic resistance, low noise, sticking resistance, wear resistance and the like, and can satisfy the requirements of the lining plate in the material transportation process of all industries.

Owner:太原英可奥笔墨科技有限公司

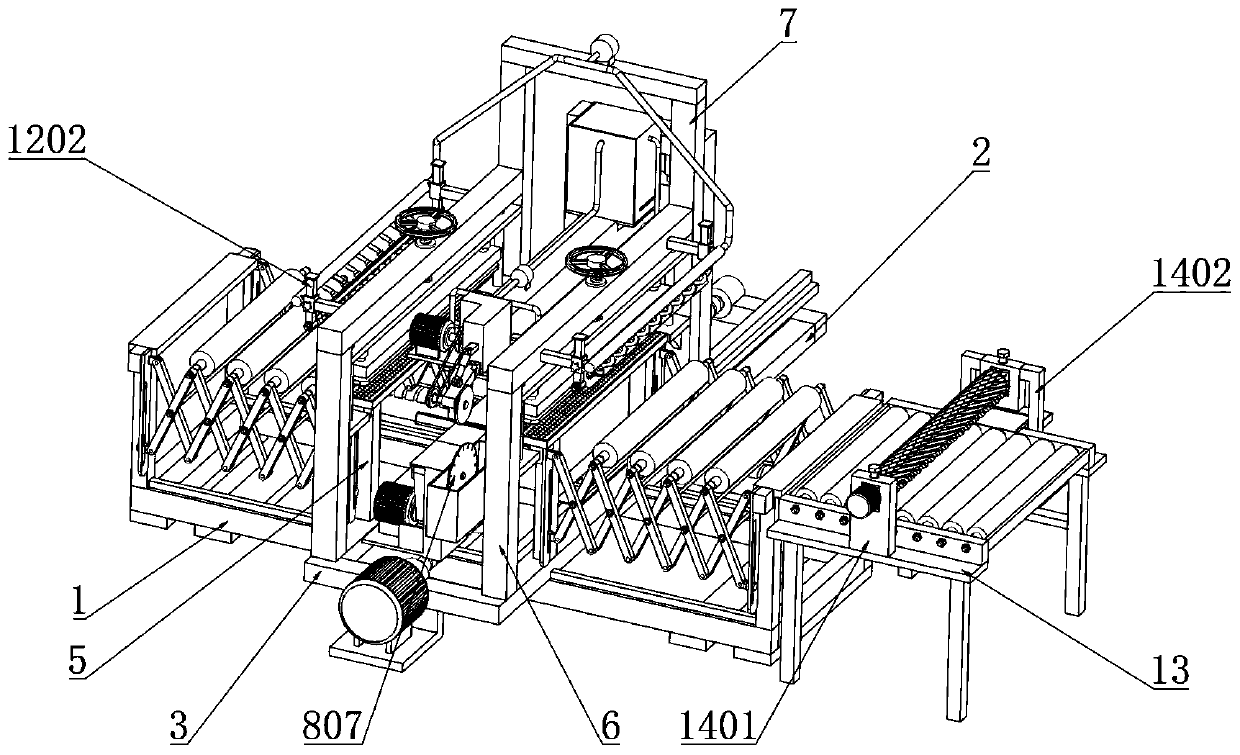

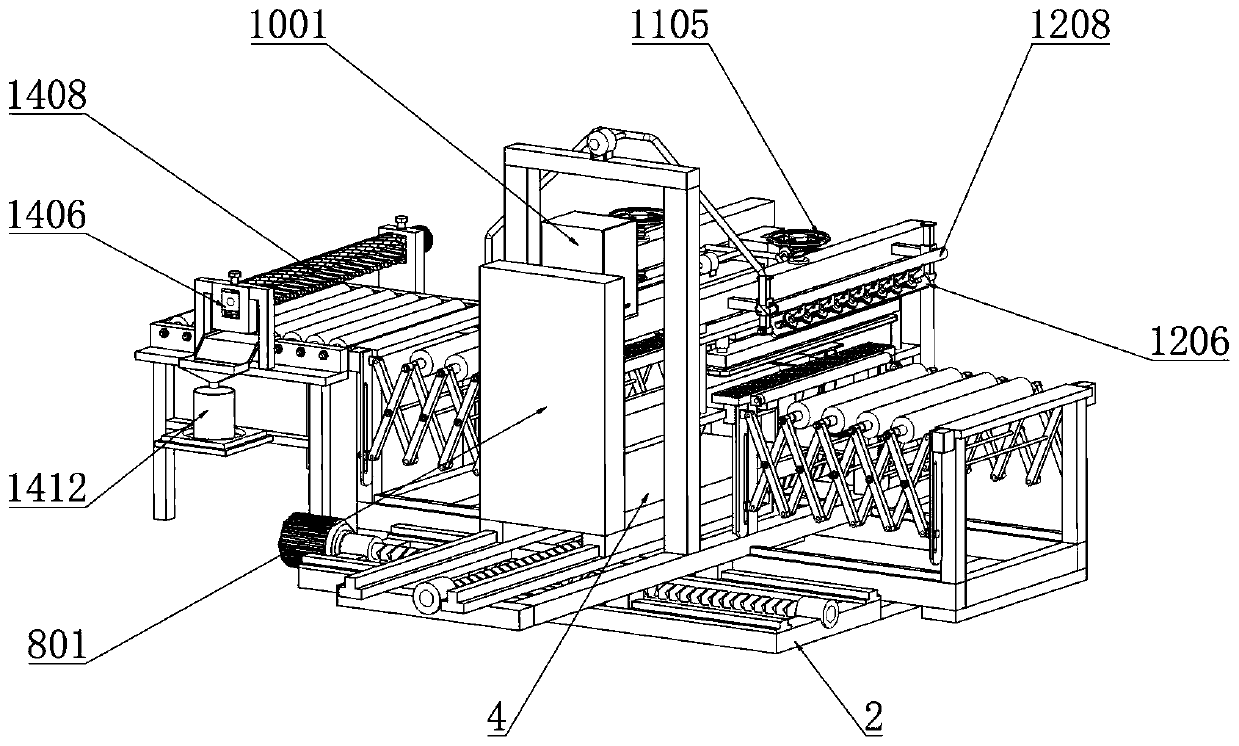

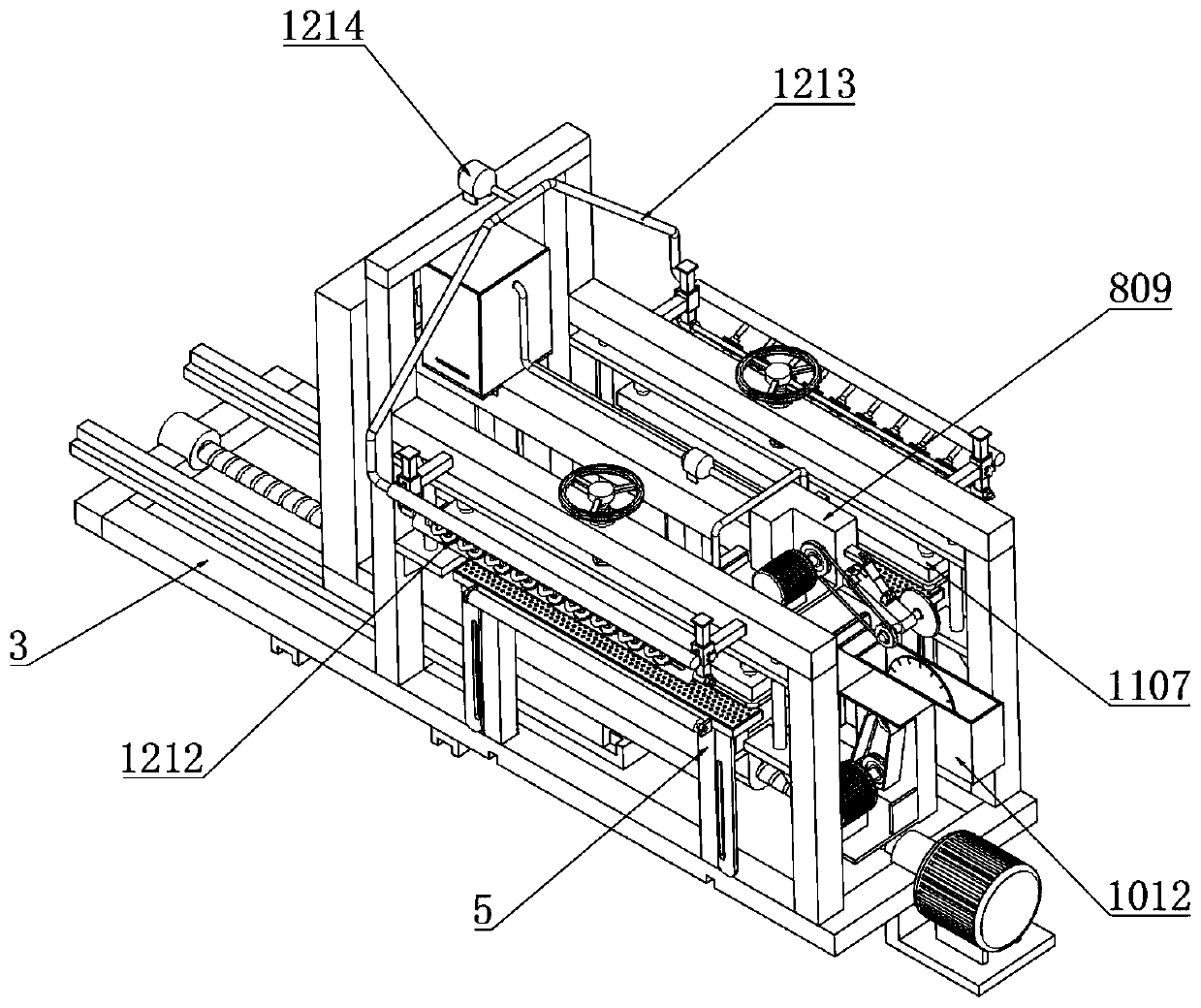

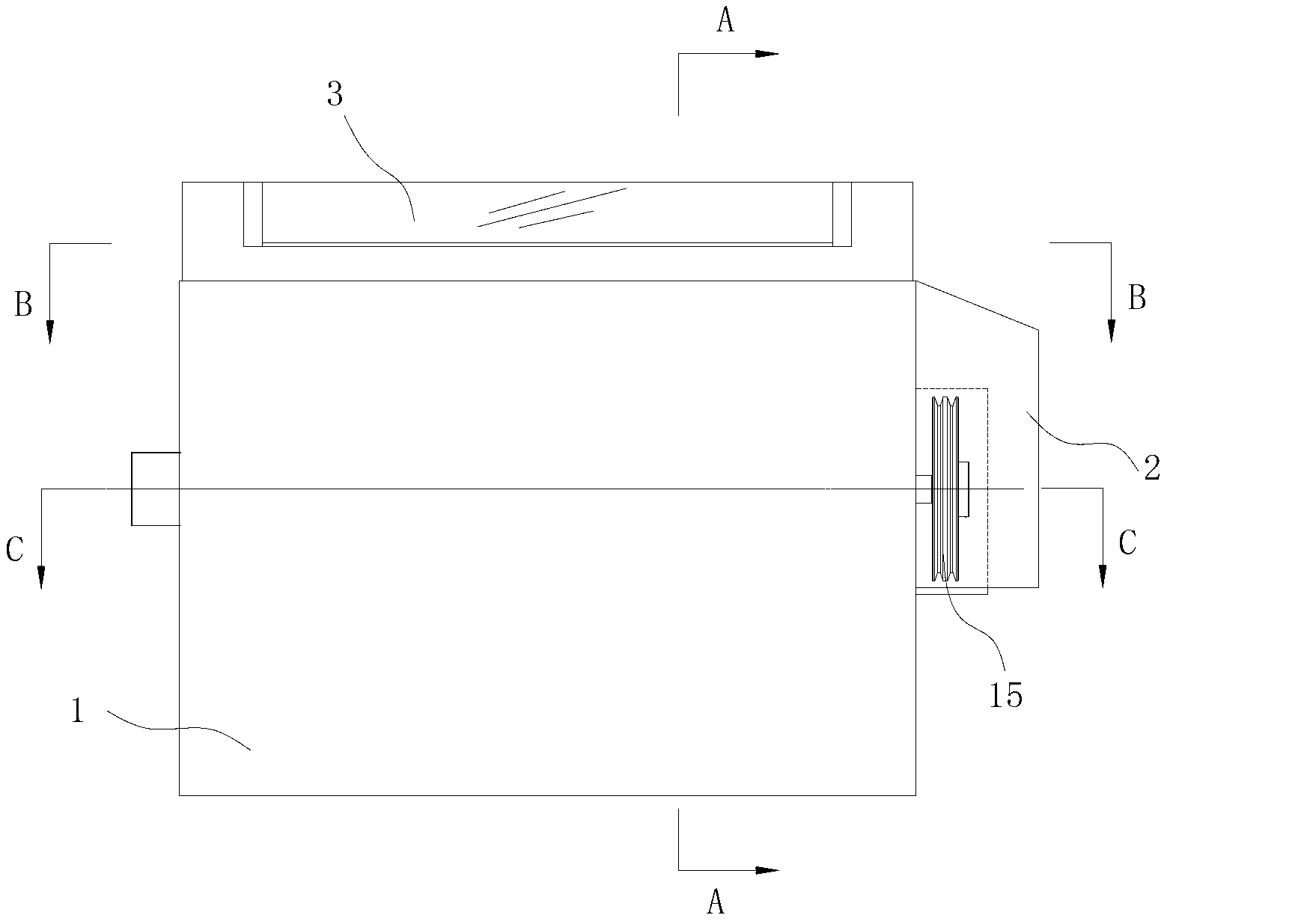

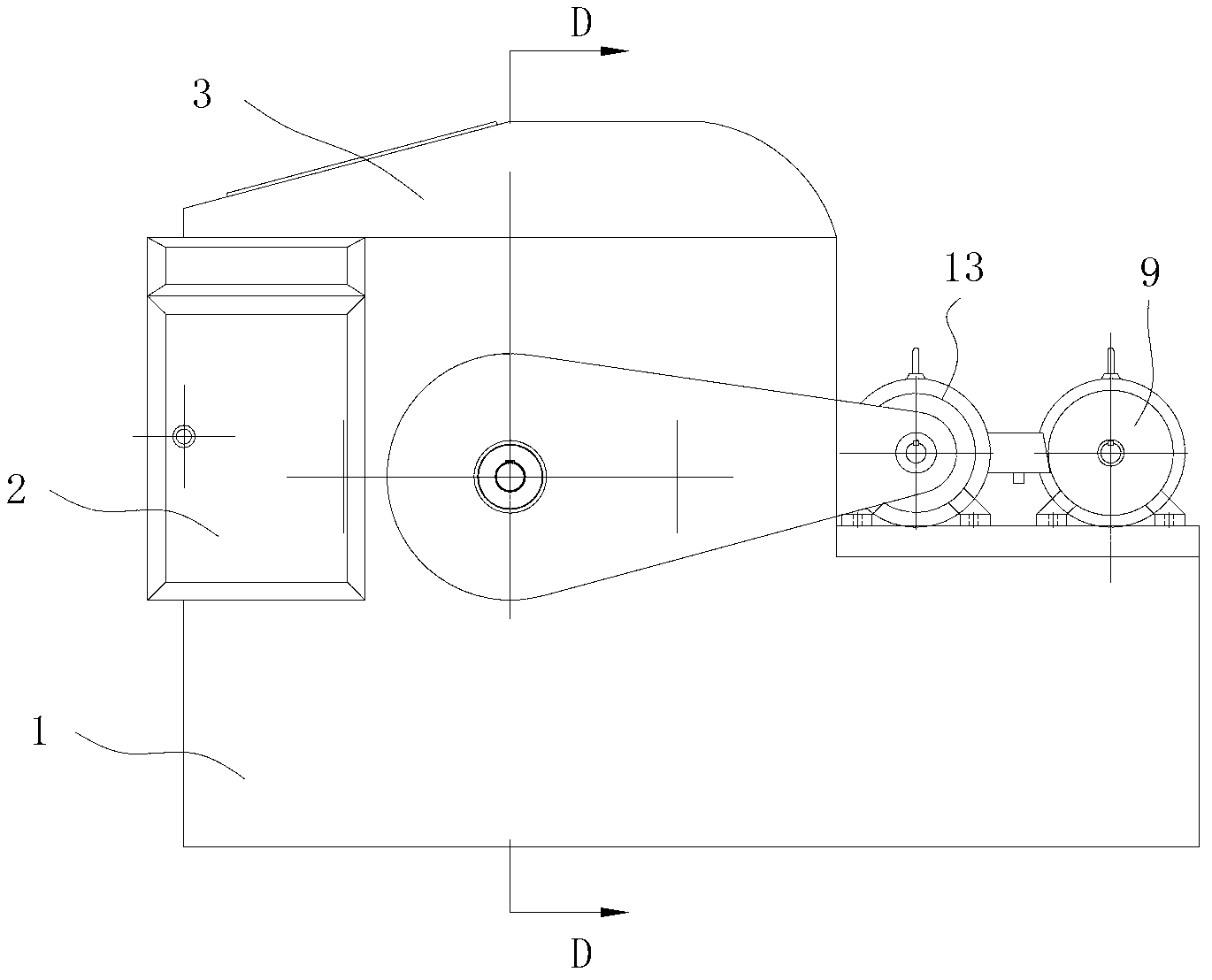

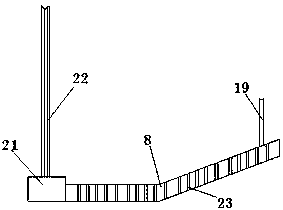

Manufacturing equipment of light-weight, waterproof and environment-friendly composite board

ActiveCN111496543AScientific and reasonable structureEasy to useGrinding machine componentsOther manufacturing equipments/toolsComposite plateIndustrial engineering

The invention discloses manufacturing equipment of a light-weight, waterproof and environment-friendly composite board. The equipment comprises a lower supporting frame. One side of the lower supporting frame is fixedly connected with a side supporting frame. The middle of the top end of the lower supporting frame is movably connected with a middle slide support. The middle of the top end of the middle slide support is movably connected with an upper slide support. Internal supporting frames are fixedly connected to the positions, corresponding to the two sides of the upper slide support, of the top end of the middle slide support correspondingly. One end of the top of the upper slide support is fixedly connected with a cutting and grinding mechanism. According to the manufacturing equipment provided by the invention, a grinding disc is lifted down while the upper slide support moves backwards so that one end surface of the composite board can be ground and chamfered, sharp burrs formed on the side portions of a metal plate on the upper layers of the end surfaces of the composite board are effectively removed, hidden safety hazards in the transporting and using process of the composite board are eliminated, the using safety of the composite board is improved, the two steps of cutting and grinding are completed in the two-way process of the upper slide support, and the production process of the composition board is optimized.

Owner:SHENZHEN LANDUN WATERPROOF ENG

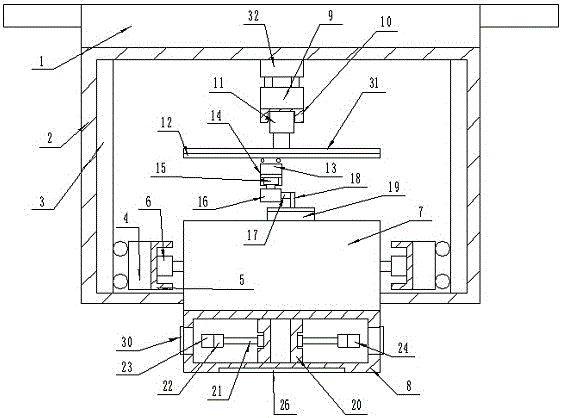

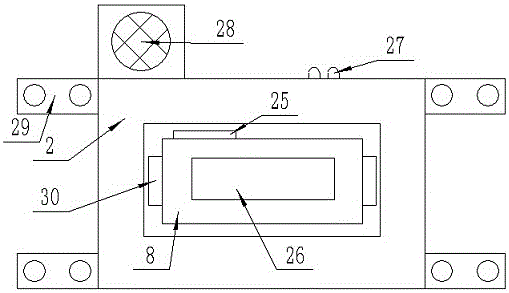

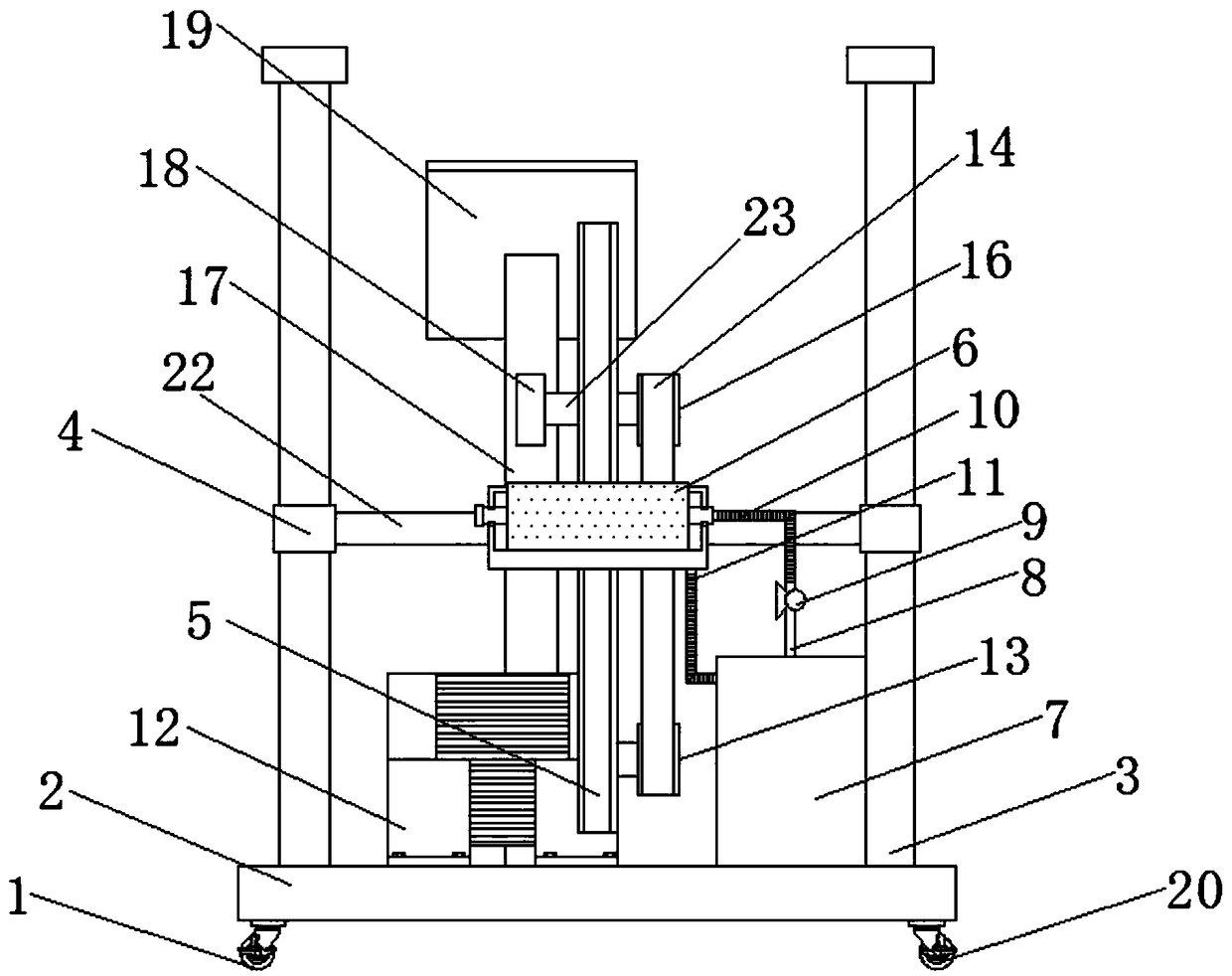

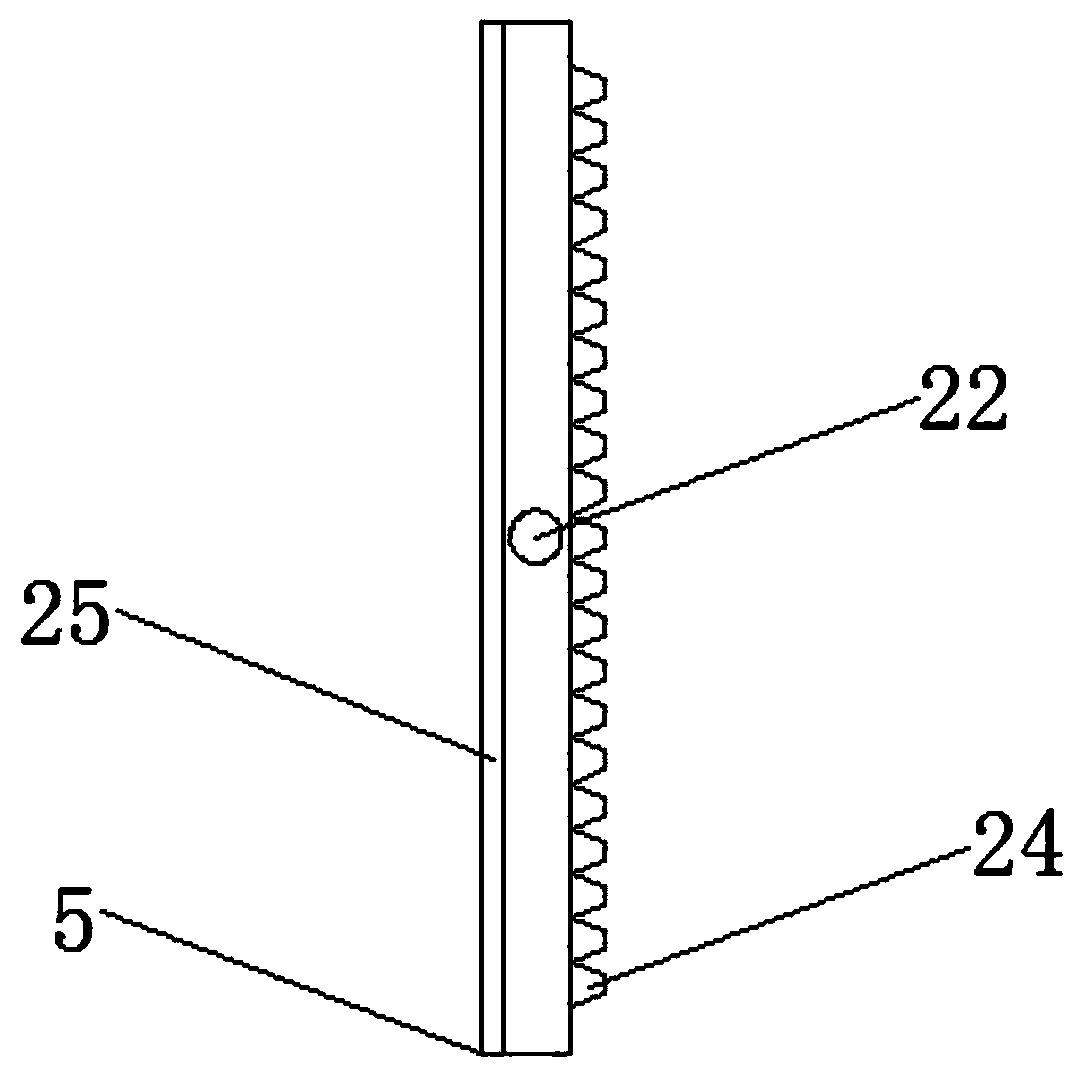

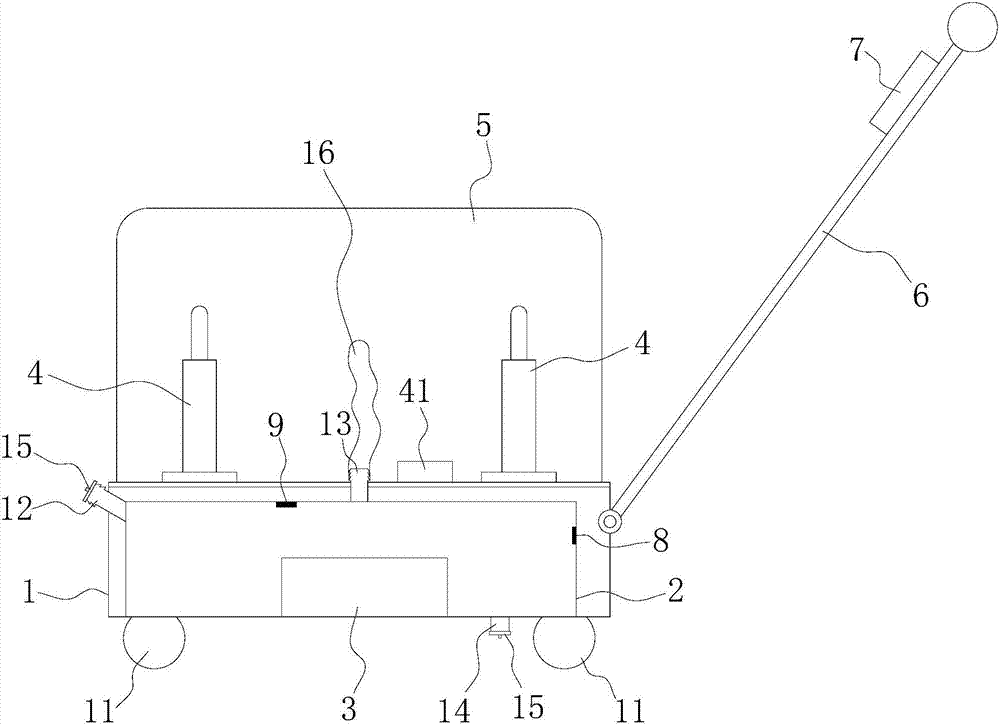

Roller type pressure cleaning device

InactiveCN103157617AImprove cleanlinessRealize cleaning automationCleaning using liquidsEngineeringLow speed

The invention discloses a roller type pressure cleaning device which comprises a machine body. A support assembly used for supporting a to-be-cleaned workpiece and enabling the to-be-cleaned workpiece to maintain the state of rotation, a cleaning assembly used for cleaning the workpiece and a controller used for controlling the support assembly and the cleaning assembly to be in motion are arranged on the machine body. The workpiece is placed on the support assembly, the rotation of the workpiece is realized through the support assembly, the workpiece is rotated continuously during the cleaning process, thus the workpiece is fully cleaned, and cleanliness is improved. Meanwhile, the support assembly and the cleaning assembly are both connected with the controller, the automation of cleaning is realized, and the labor intensity of cleaning workers is reduced. The support assembly adopts the structure of a driving shaft matching with a double-speed motor, and the double-speed motor is connected with the controller so that the rotation speed of the driving shaft can be changed according to actual needs, cleaning and spin-dry of the workpiece can be achieved step by step, namely, the workpiece is cleaned at low speed and is spin-dried at high speed, cleaning strength is reduced, and drying speed is increased.

Owner:佛山市鑫昕宇五金配件有限公司

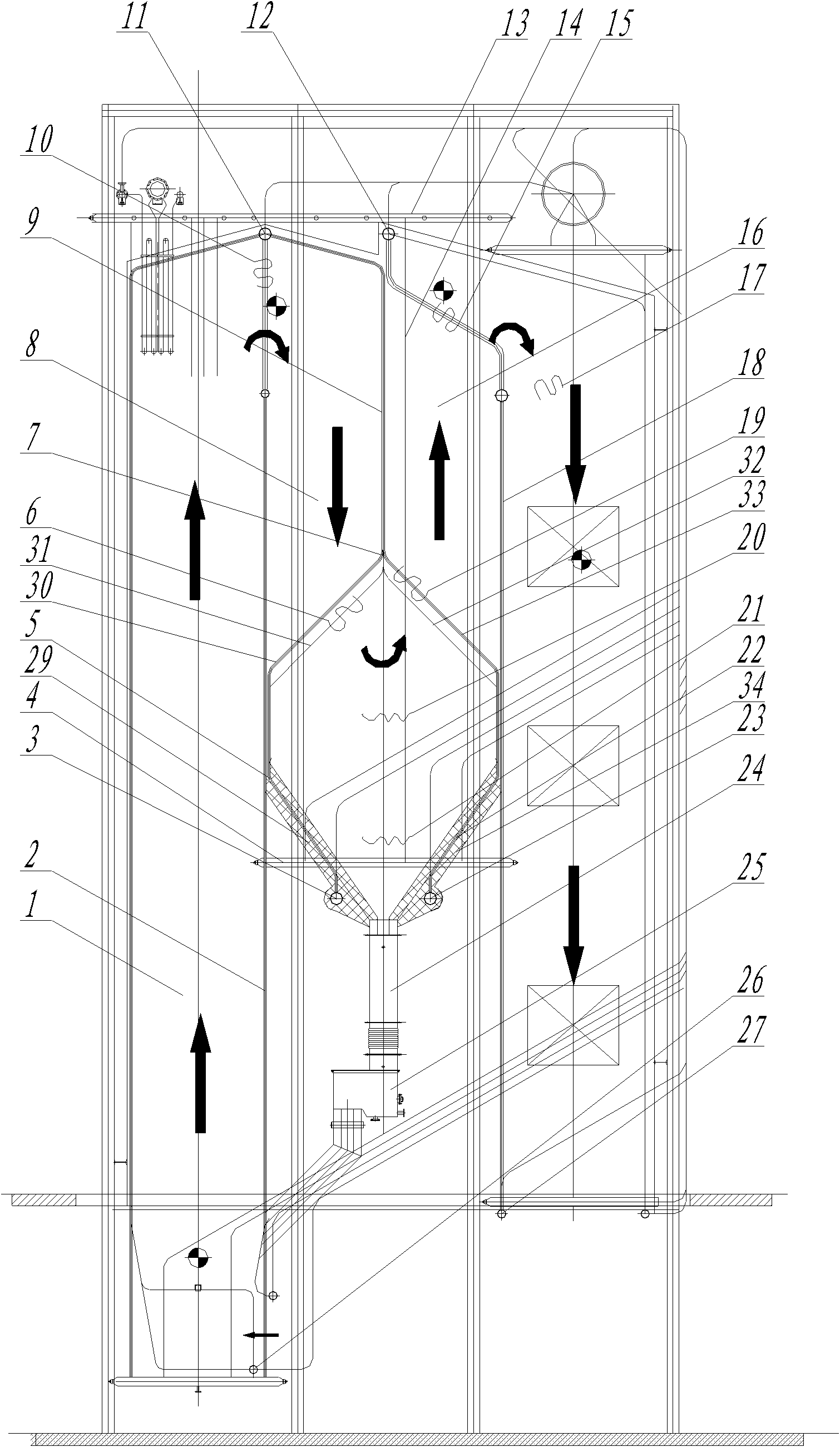

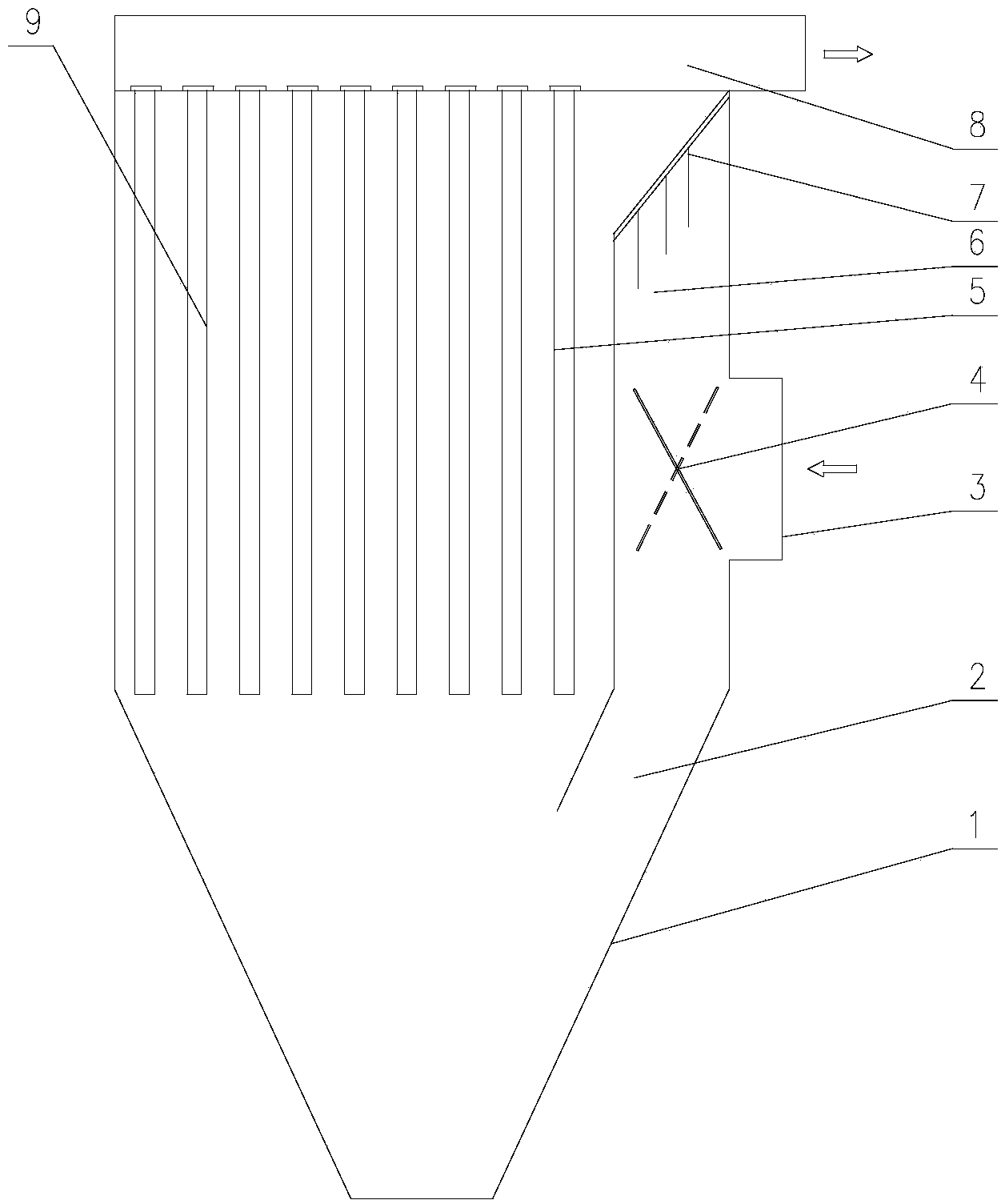

Bag chamber air inlet device of bag type dust collector

InactiveCN103721488AReduce resistanceSlow ascentDispersed particle filtrationFiltrationPulp and paper industry

The invention discloses a bag chamber air inlet device of a bag type dust collector. The bag chamber air inlet device comprises a bag chamber, a filter bag, an ash hopper, a wind shield, an air inlet and a lower air inlet duct, wherein the lower air inlet duct is communicated with the bottom of the bag chamber through the ash hopper; an upper air inlet duct (6) communicated with the air inlet (3) is arranged on the upper part of the bag chamber (9). As the upper air inlet duct communicated with the air inlet is additionally arranged on the upper part of the bag chamber, a dusty air flow entering the air inlet is shunted and the resistance of the air inlet is reduced; the ascending speed of the dusty air flow entering the bottom of the filter bag in the bag chamber through the lower air inlet duct is greatly reduced, the motion direction of the dusty air flow entering the upper part of the filter bag in the bag chamber through the upper air inlet duct is consistent with the dust precipitation direction, thus the resistance of dust precipitation is reduced, the dust precipitation is accelerated, the adsorption quantity and the filtration resistance of the filter bag are reduced, the ash removal intensity is alleviated, the ash removal frequency is decreased, the service life of the filter bag is prolonged and the work efficiency of the dust collector is greatly improved.

Owner:合肥中亚环保科技有限公司

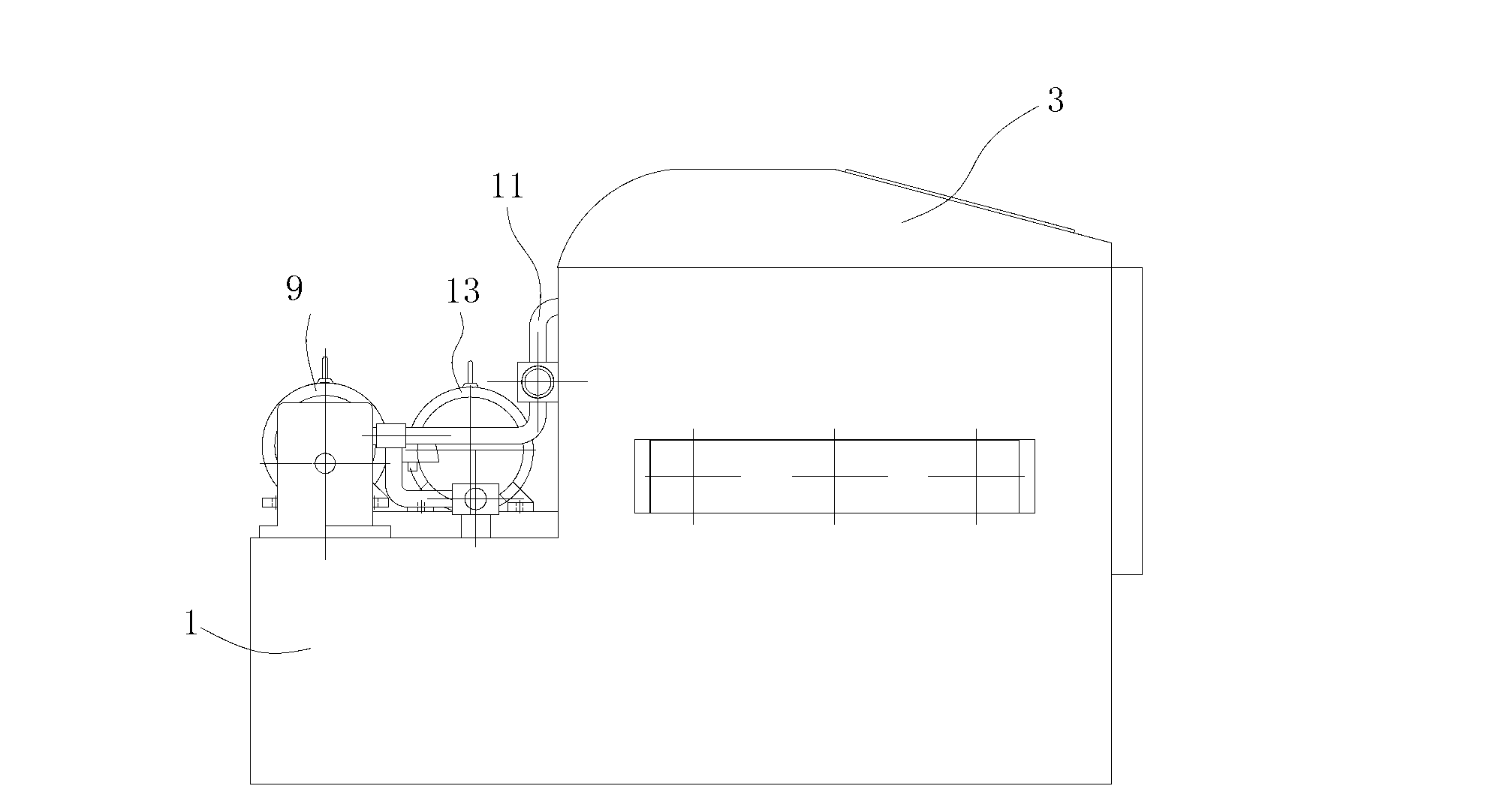

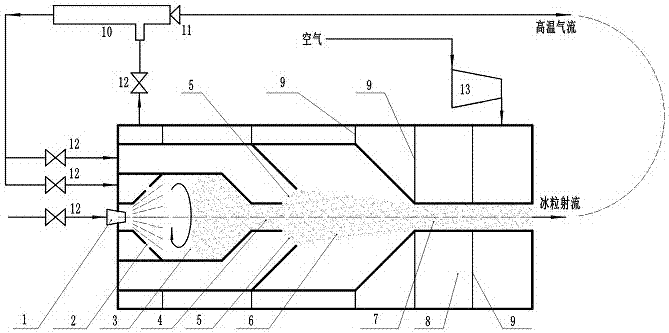

Continuous ice particle jet flow washing device based on vortex tube

InactiveCN107270767AGuaranteed generation speedGuaranteed setting strengthFood processingIce productionEngineeringCooling capacity

The invention provides a continuous ice particle jet flow washing device based on a vortex tube. The continuous ice particle jet flow washing device based on a vortex tube mainly comprises an atomizing nozzle, a swirl nozzle, an ice making chamber, a hollow tube, a hollow circulation nozzle, a mixing chamber, an ice particle jet flow nozzle, a pre-cooling cavity, the vortex tube and the like. The continuous ice particle jet flow washing device carries out refrigeration through the vortex tube and is simple in structure, small in volume, low in weight and convenient to use. Ice particle jet flow and high-temperature airflow alternately spray a heat dissipation surface, and online washing is completed. Water is atomized through the atomizing nozzle to form water drops, the swirl nozzle carries out swirl mixing in the ice making chamber to form ice particles in a freezing manner, through the jetting, entrainment and mixing effects of the hollow circulation nozzle, the ice particles are further frozen and shaped in the mixing chamber, the strength of the ice particles is high, and the ice particle jet flow is sprayed through the ice particle jet flow nozzle. The pre-cooling chamber carries out pre-cooling to reduce the temperature, recovers the cooling capacity and reduces and eliminates low-temperature air flow heat loss, and energy sources are saved. The system can be applied to various surface washing and treating occasions, especially to finned radiators.

Owner:QINGDAO UNIV

Environment-friendly painting device

InactiveCN108756155APlay a guiding roleEasy to recycleBuilding constructionsEngineeringMaterial storage

The invention discloses an environment-friendly painting device. A base is arranged at the bottom of a device body. Sliding rods are mounted at the two ends of one side of the top of the base. Slidingsleeves are mounted on the outer sides of the sliding rods. The inner sides of the sliding sleeves are fixedly connected with a connecting rod. A tooth plate is mounted at one end of the connecting rod. A protruding arris is arranged on the obverse side of the tooth plate. A painting head is mounted on the front side of the protruding arris. A baffle is mounted on the reverse side of the paintinghead. A roller is mounted on the inner side of the baffle. A rotating shaft is mounted in the middle of the roller. One end of the rotating shaft is fixedly connected with a material conveying pipe.A material pump is mounted at one end of the material conveying pipe. One end of the material pump is fixedly connected with a material pumping pipe. A material storage box is mounted at one end of the material pumping pipe. A backflow pipe is mounted at one end of the bottom face of the baffle. Trundles are mounted at the bottom of the base. According to the environment-friendly painting device,the material storage box and the baffle are connected through the backflow pipe, paint leaked in the painting process of the device body conveniently flows back into the material storage box to be reused through the backflow pipe, the environment-friendly painting device is simple and practical, and the painting cost is also lowered while resource waste is avoided.

Owner:WENZHOU QIBANG ENVIRONMENTAL PROTECTION TECH

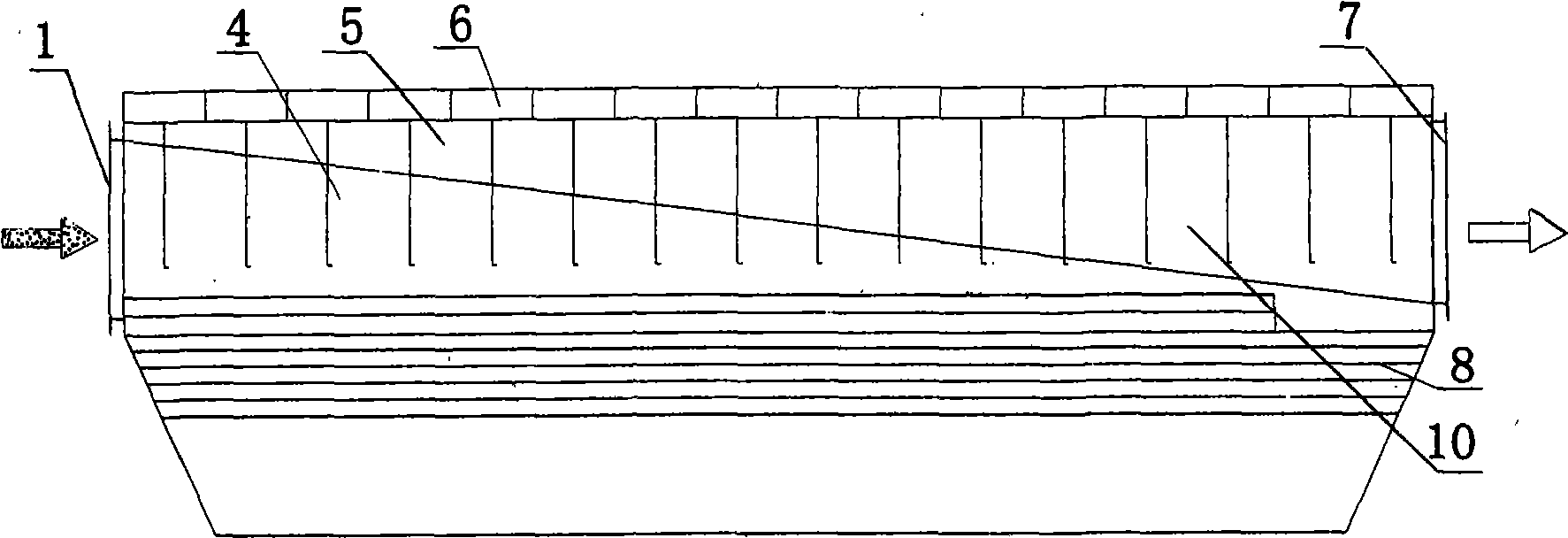

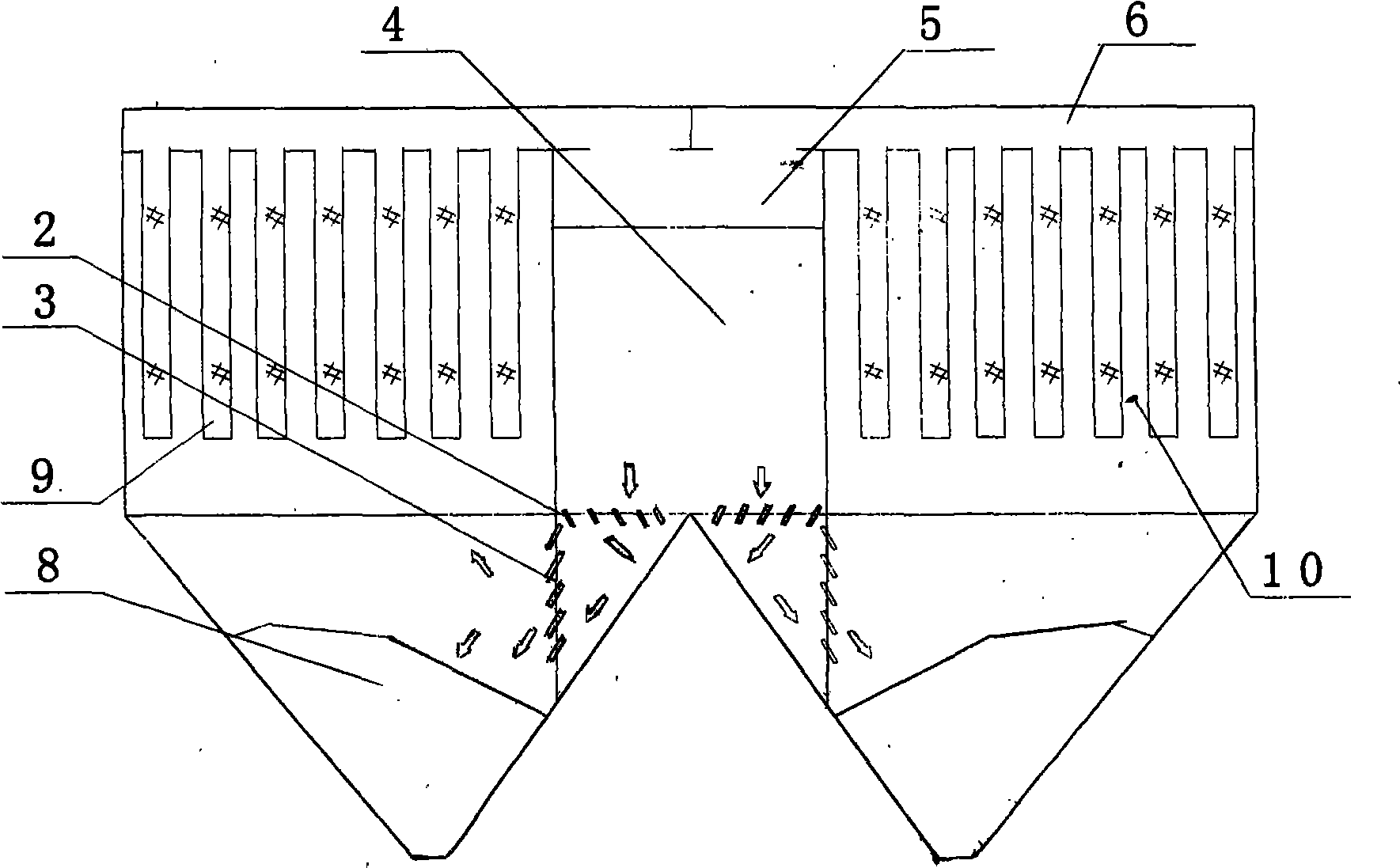

Inertial dust precollecting air flow uniform distribution device

ActiveCN101518703AReduce adsorptionImprove work efficiencyDispersed particle filtrationChemical industryFiltration

An inertial dust precollecting air flow uniform distribution device belongs to the technical field of bag-type dust collectors and aims to provide an inertial dust precollecting air flow uniform distribution device capable of lowering the resistance of the bag-type dust collectors and prolonging the service life of filtering bags. The inertial dust precollecting air flow uniform distribution device is technically characterized in that a horizontal louver-shaped guide plate (2) and a vertical louver-shaped guide plate (3) are arranged between a fresh flue (4) in a flue and a dust hopper (8). The horizontal louver-shaped guide plate and the vertical louver-shaped guide plate are arranged between the fresh flue in the flue and the dust hopper, therefore, the invention has very good air uniform distribution effect and dust settlement effect; the subpressure of each bag chamber, which is operated and measured actually, is basically equal to the filter pressure difference, the dust settlement quantity reaches 40-60 percent, therefore, the inertial dust precollecting air flow uniform distribution device has more remarkable effect to dust with the density larger than 2500kg / m<3> and the grain diameter larger than 40 microns. The invention greatly improves the working efficiency of the dust collector, lowers the dust absorption quantity and the filtration resistance of the filtering bags and the dust-clearing intensity, reduces the dust-clearing times, and can be widely used for treating the dust pollution in industries such as building materials, metallurgy, chemical industry, and the like.

Owner:合肥中亚环保科技有限公司

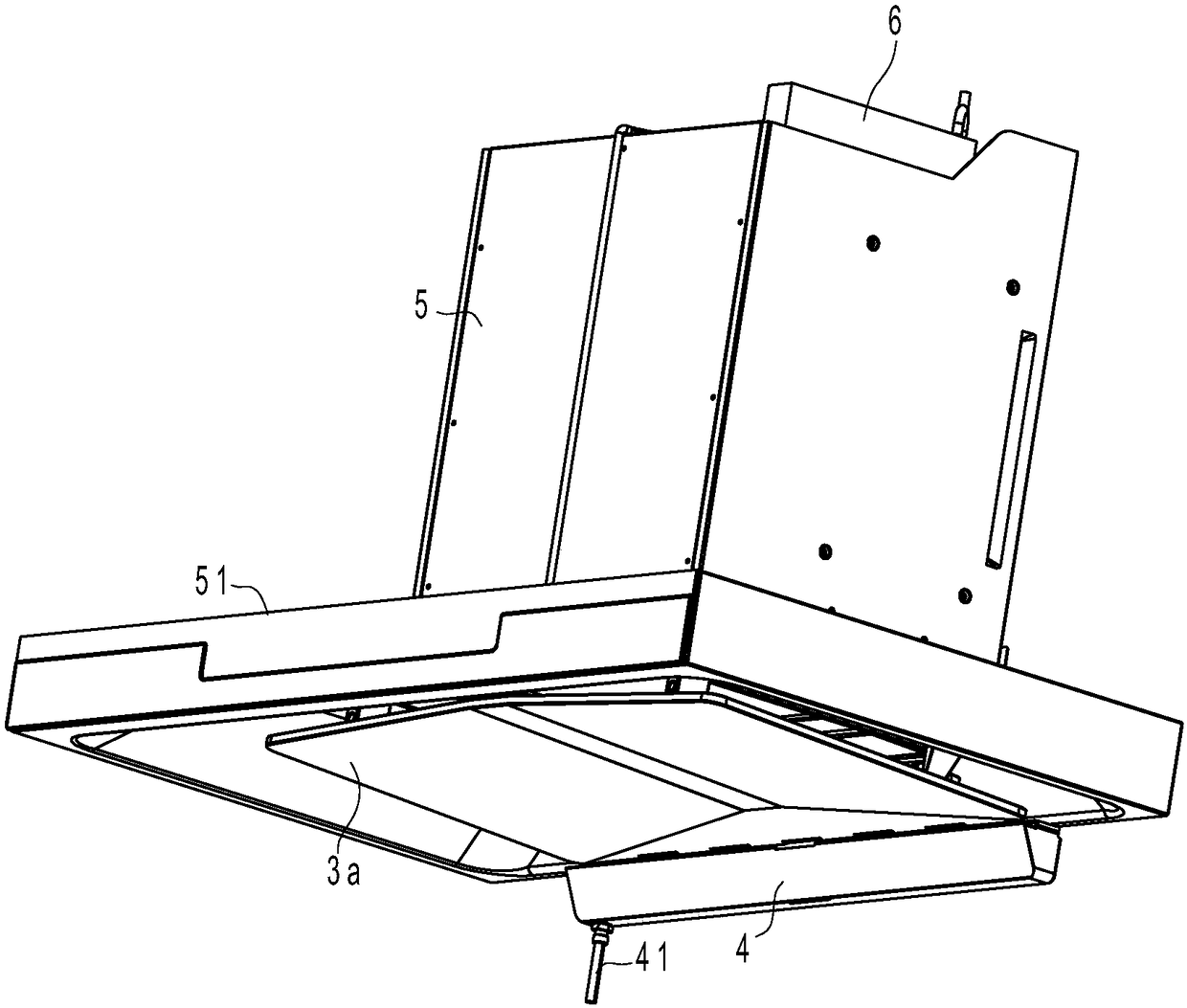

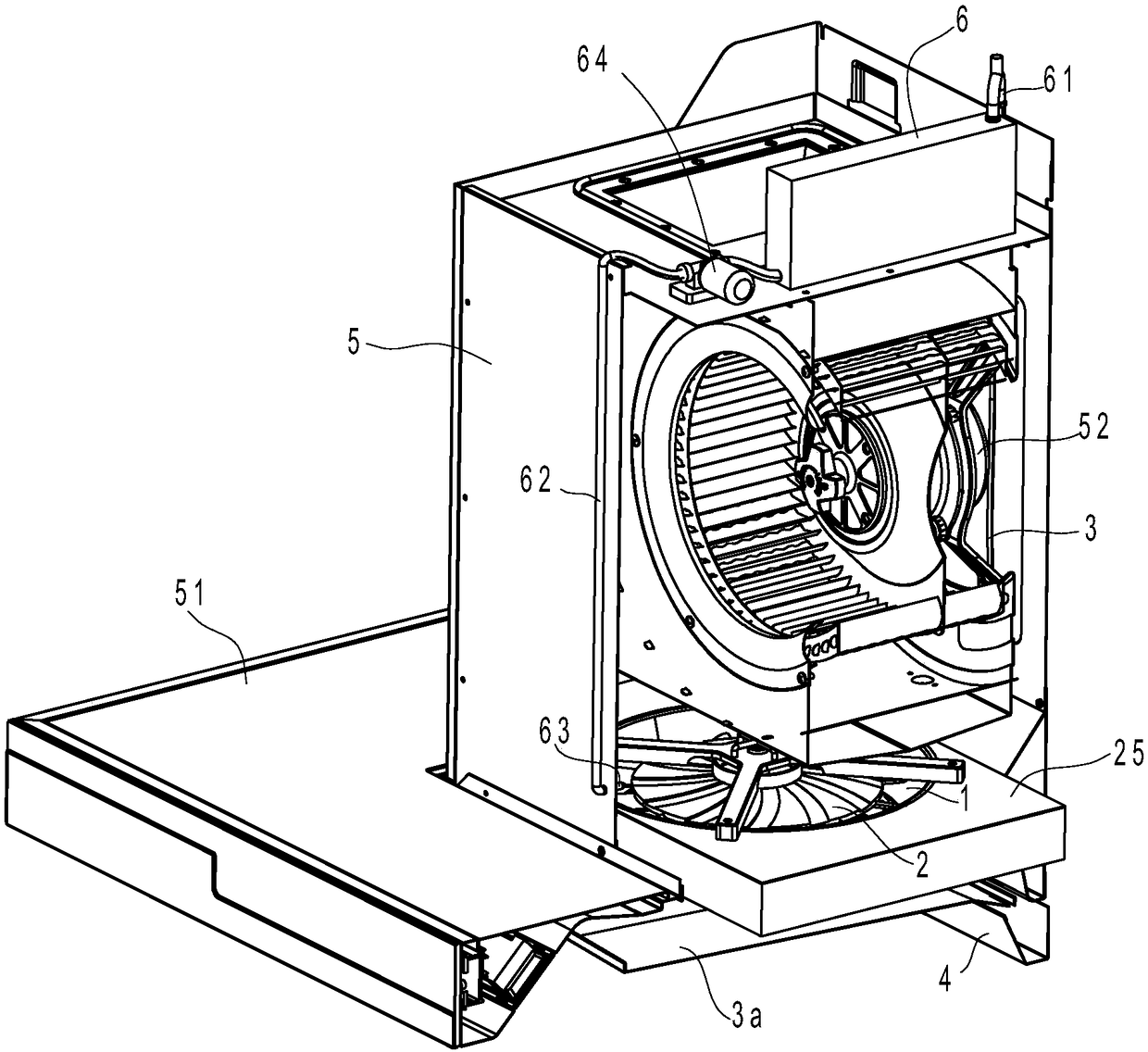

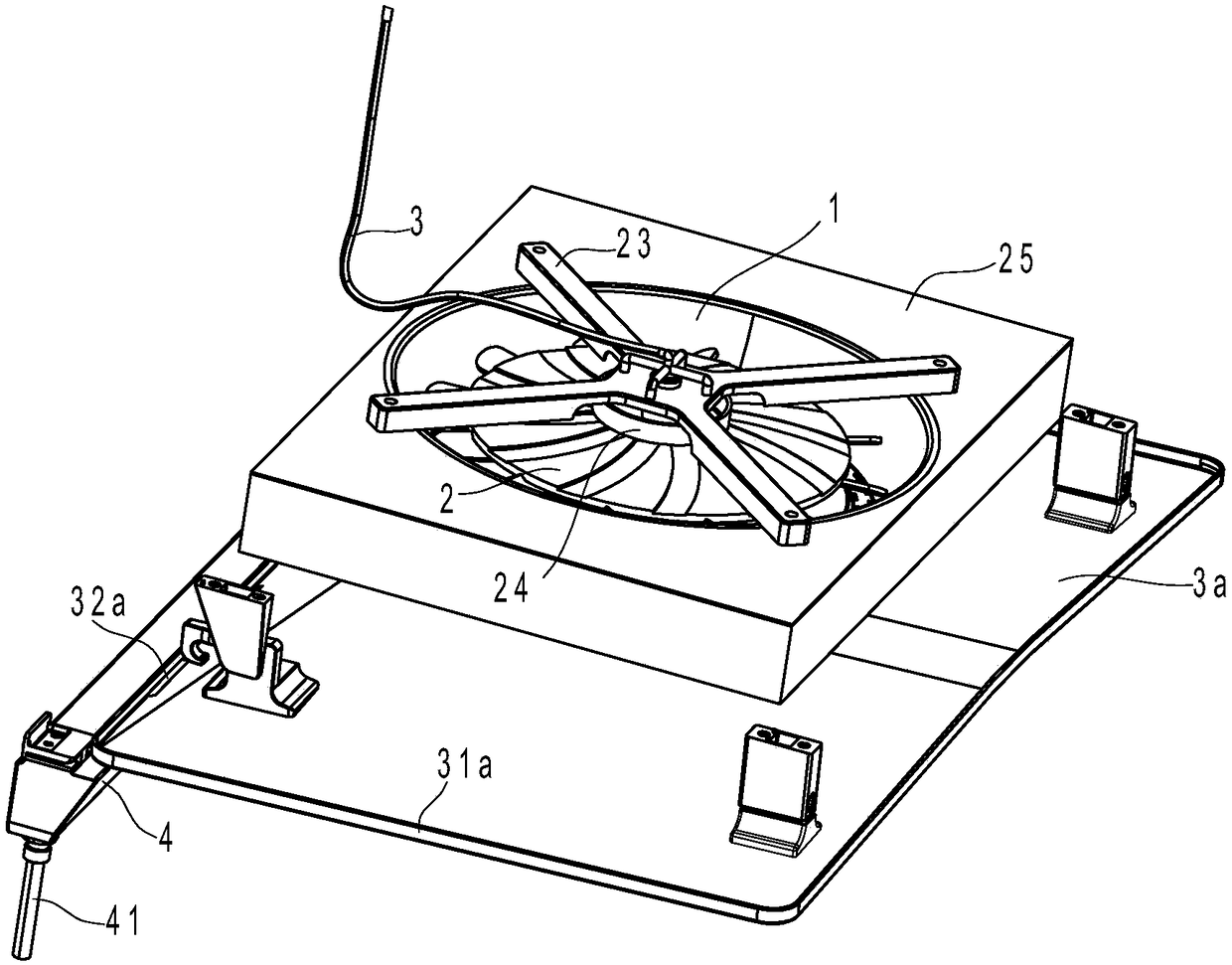

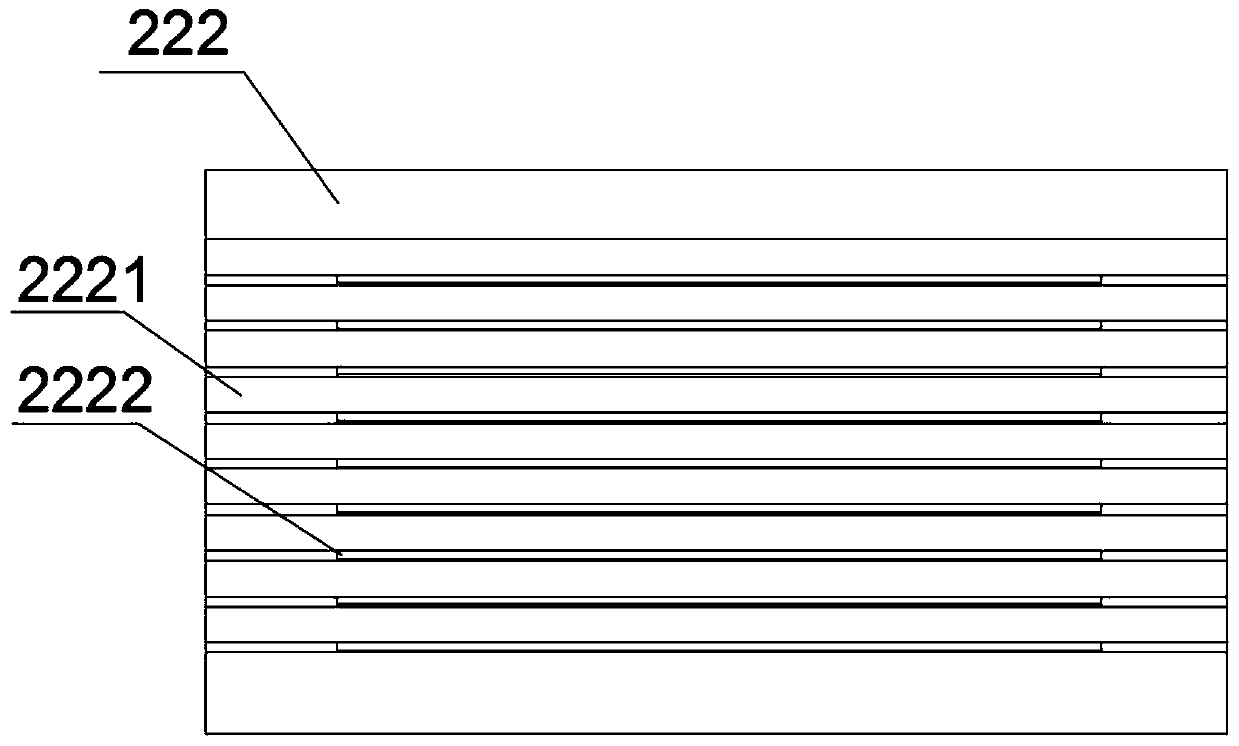

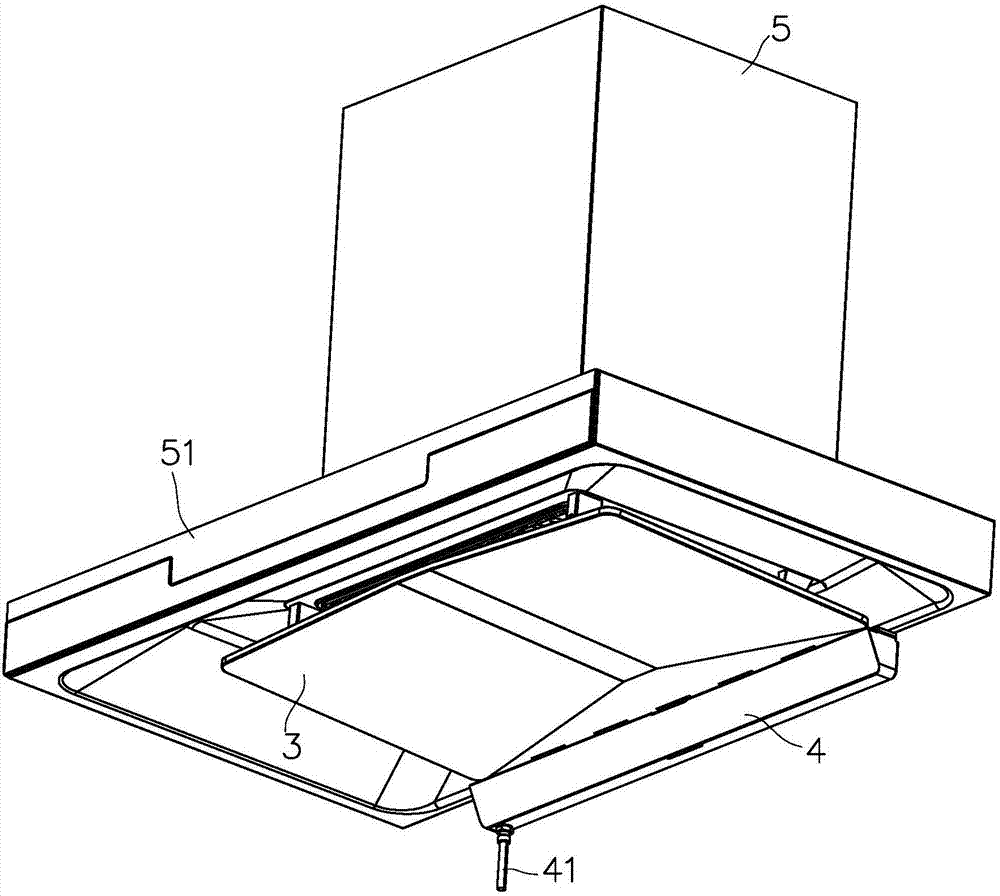

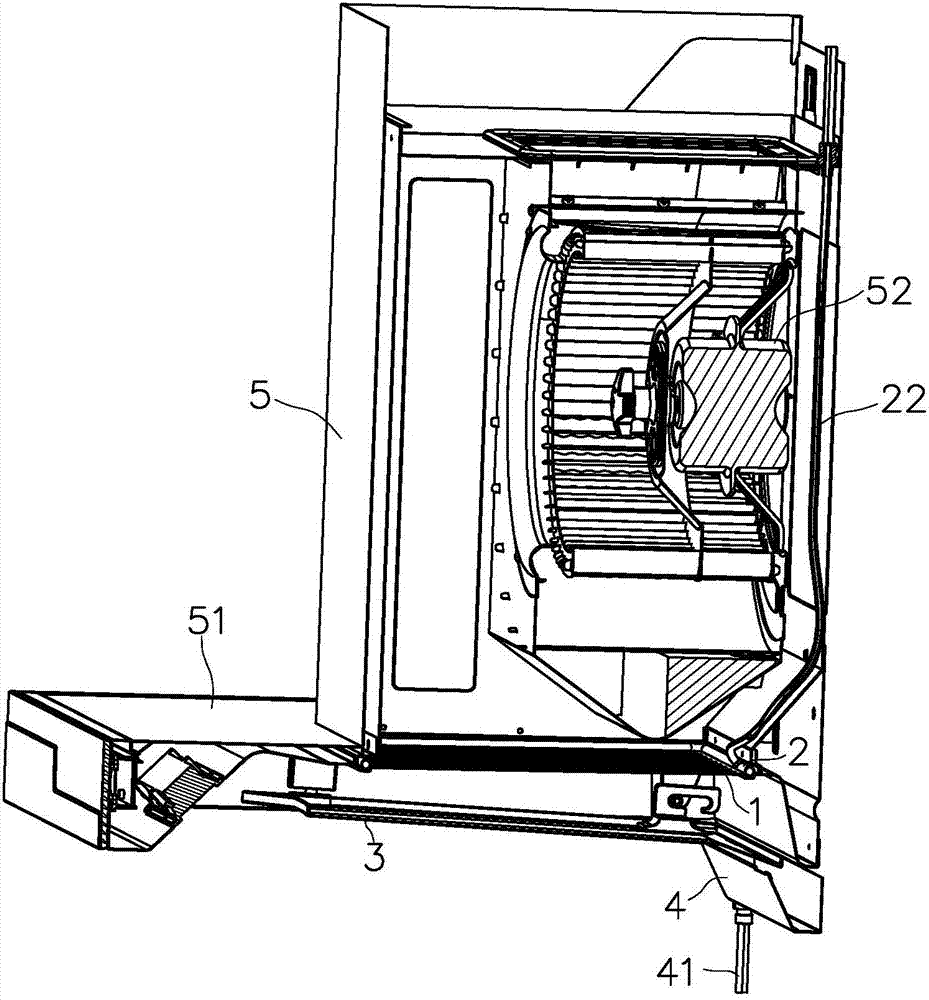

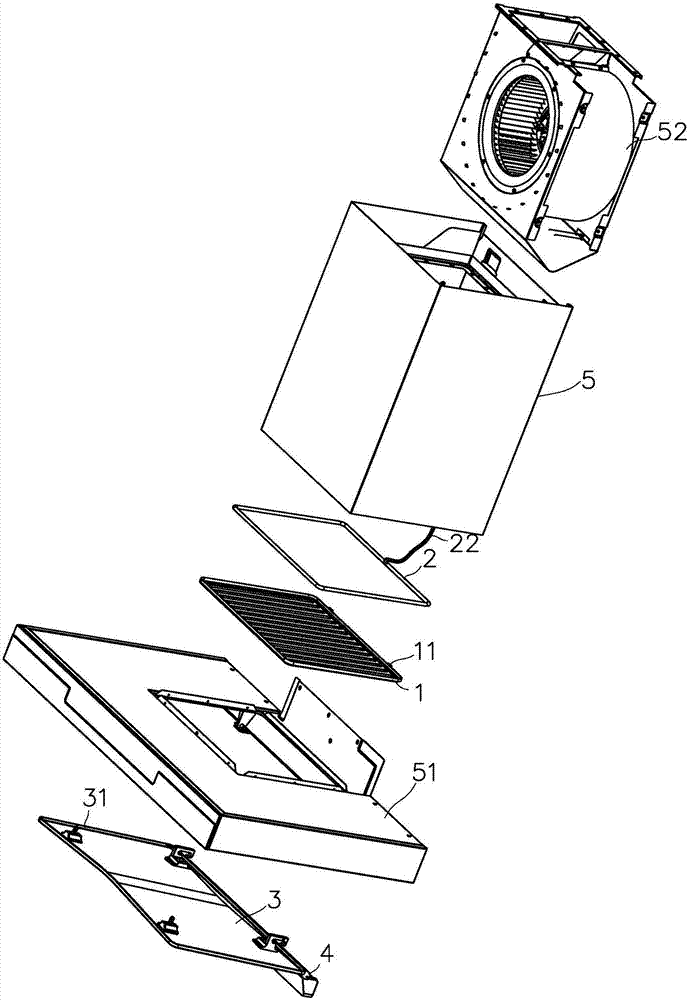

Double-water curtain rotating curtain and atomization filtration range hood

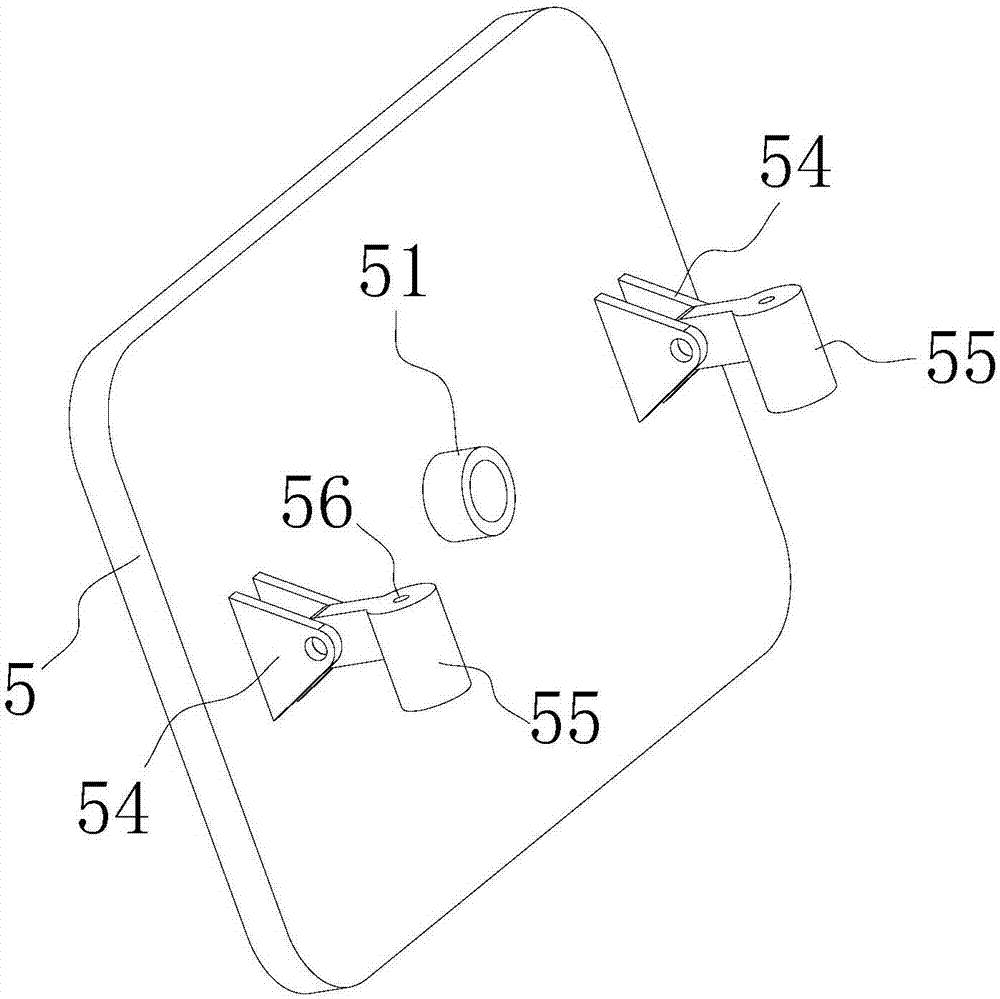

PendingCN109404996APromote environmental protectionImprove purification effectDomestic stoves or rangesLighting and heating apparatusFiltrationLiquid storage tank

A double-water curtain rotating curtain and atomization filtration range hood comprises a housing (5), a fan (52), a smoke-collecting hood (51), a smoke-guiding plate (3a) and an oil-collecting cup (4), and is characterized by further comprising a liquid storage tank, a water pump, a liquid dripping disc (1), a bracket (23), a water dispersing disc (2) and a water conveying pipe (3), wherein a primary water curtain area is formed between the water dispersing disc (2) and the upper end surface of the inner ring of the liquid dripping disc (1); a secondary water curtain area is formed between the lower end surface of the inner ring of the liquid dripping disc (1) and the upper end surface of the smoke-guiding plate (3a); the smoke-guiding plate (3a) can receive cleaning water or cleaning liquid flowing out from water dripping holes (13) and guide the cleaning water or the cleaning liquid into the oil-collecting cup (4). Oil in smoke gas filtered by a secondary water curtain is collected,so that improvement on the environment friendliness of exhausted soot is facilitated; the primary water curtain area forms a dynamic rotating water curtain, and in combination with atomization treatment, the purification and the oil absorbing treatment of the soot are further facilitated.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

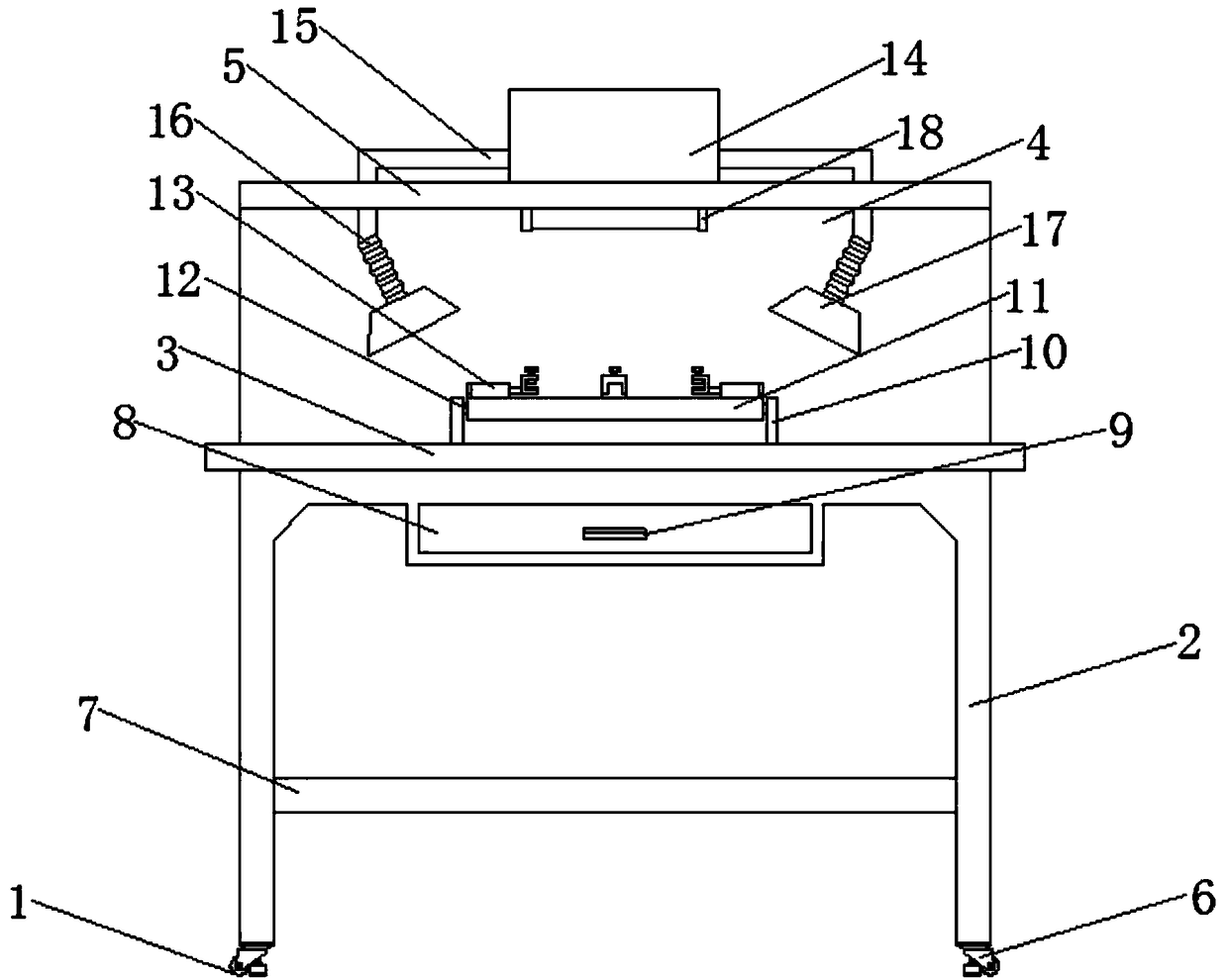

Welding workbench for electronic product machining

InactiveCN108608087AHigh strengthImprove practicalityDirt cleaningSoldering auxillary devicesEngineeringWorkbench

The invention discloses a welding workbench for electronic product machining. A table frame is arranged at the bottom of a workbench body; a table surface is installed at the top of the table frame; agroove is formed in the middle part of the table surface; a bottom plate is arranged at the bottom end of the groove; support plates are installed at the two ends of each of the two sides of the topof the bottom plate; a rotary shaft is installed at the top end of each support plate; a welding plate is installed at one end of each rotary shaft; a fixer is installed around the top of each weldingplate; a tin collection drawer is installed at the bottom of the bottom plate; a vertical plate is installed on the back surface of the table surface; a top plate is installed at the top of the vertical plate; a smoke extraction box is installed at the top of the top plate; a smoke extraction machine is installed at the top end in the smoke extraction box; smoke extraction pipes are installed atthe bottom ends of the two sides of the smoke extraction box; a universal telescopic pipe is fixedly connected to the bottom end of each smoke extraction pipe; a smoke absorption cover is installed atthe bottom of each universal telescopic pipe; an illumination lamp is installed on the bottom surface of the top plate; and castors are installed at the bottom of the table frame. According to the welding workbench for electronic product machining, a filter screen is installed at the bottom of the smoke extraction machine, so that filtering for the smoke generated due to welding is facilitated; and the welding workbench for electronic product machining is simple and practical, and secondary pollution is avoided.

Owner:芜湖通全电子电器科技创业有限公司

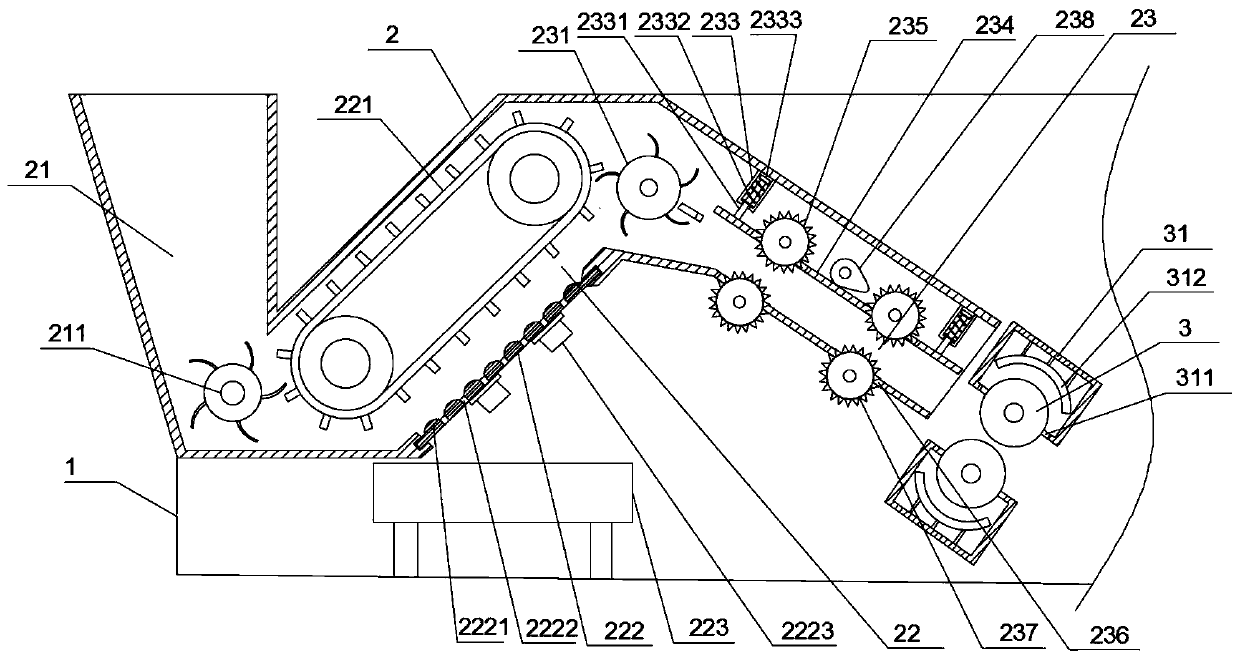

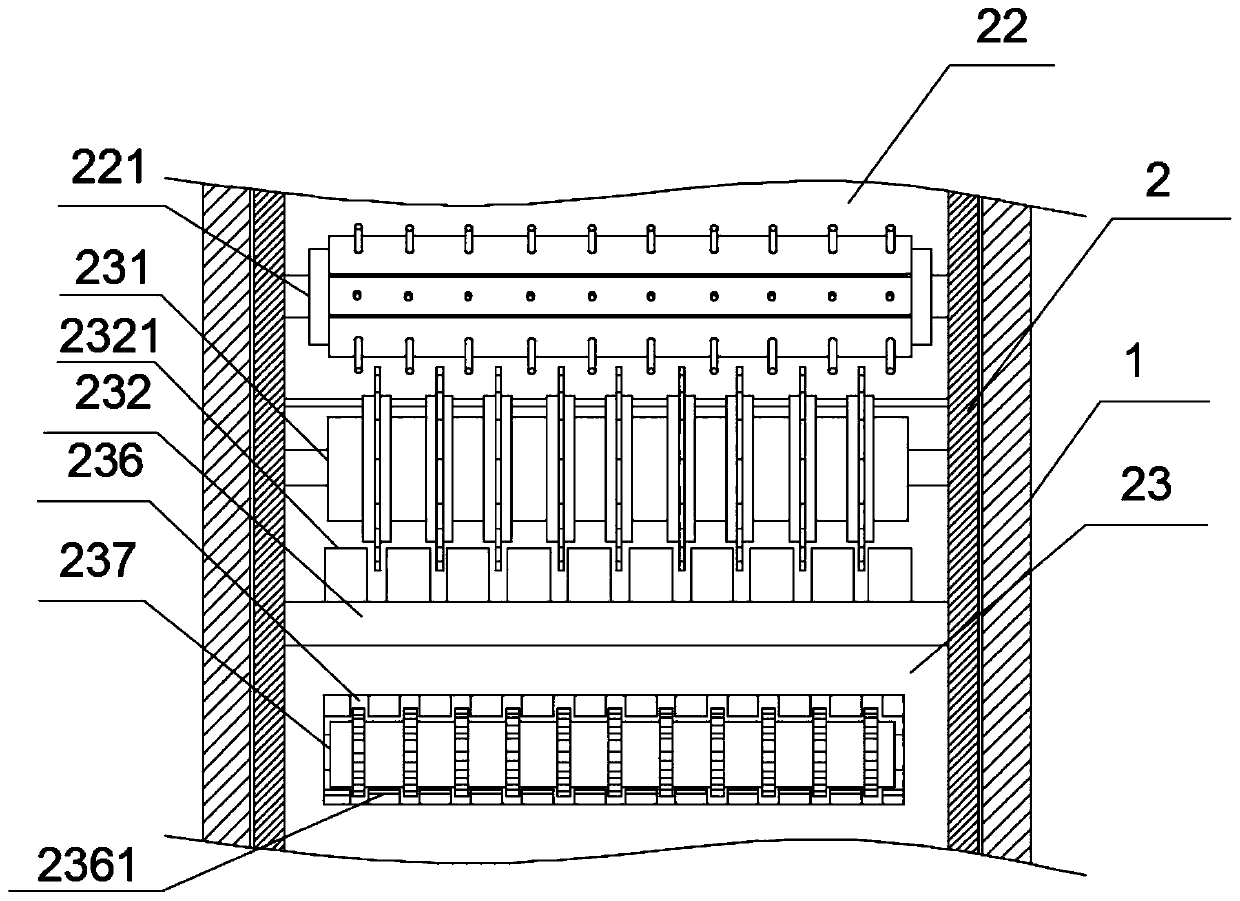

Special cotton carding machine feeding mechanism for functional blended yarn

The invention relates to a special cotton carding machine feeding mechanism for functional blended yarn. A rack is included and provided with a conveying machine shell and cotton feeding guide rollers. The conveying machine shell sequentially comprises a cotton feeding bin, a cotton conveying bin and a cotton pressing bin from left to right. The two cotton feeding guide rollers are arranged and located at one end of an outlet of the cotton pressing bin. Collecting covers are arranged on the outer sides of the two cotton feeding guide rollers. The two collecting covers are arranged in an up-down symmetry manner, through ports are formed in the opposite sides of the two collecting covers, the cotton feeding guide rollers are arranged at the positions of the through ports, static plates are arranged in the collecting covers and are close to the sides, away from the through ports, of the cotton feeding guide rollers, the static plates are electrically connected with an outside static generator through wires, the static plates can adsorb fiber, impurities and short fluff left on the surfaces of the cotton feeding guide rollers, cleanliness of the cotton feeding guide rollers is effectively guaranteed, and accordingly the cotton feeding quality is guaranteed.

Owner:丹阳市永泰纺织有限公司

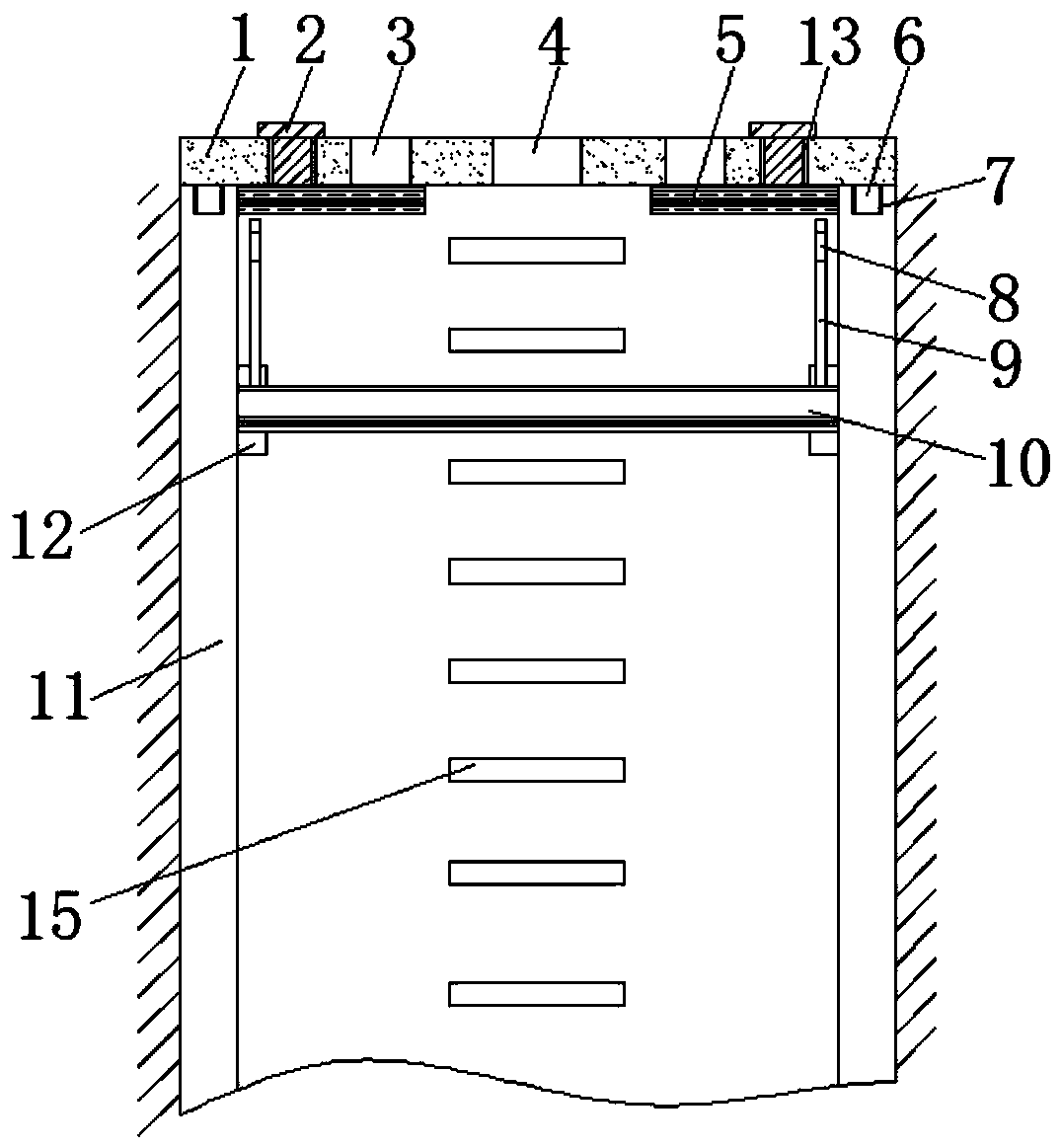

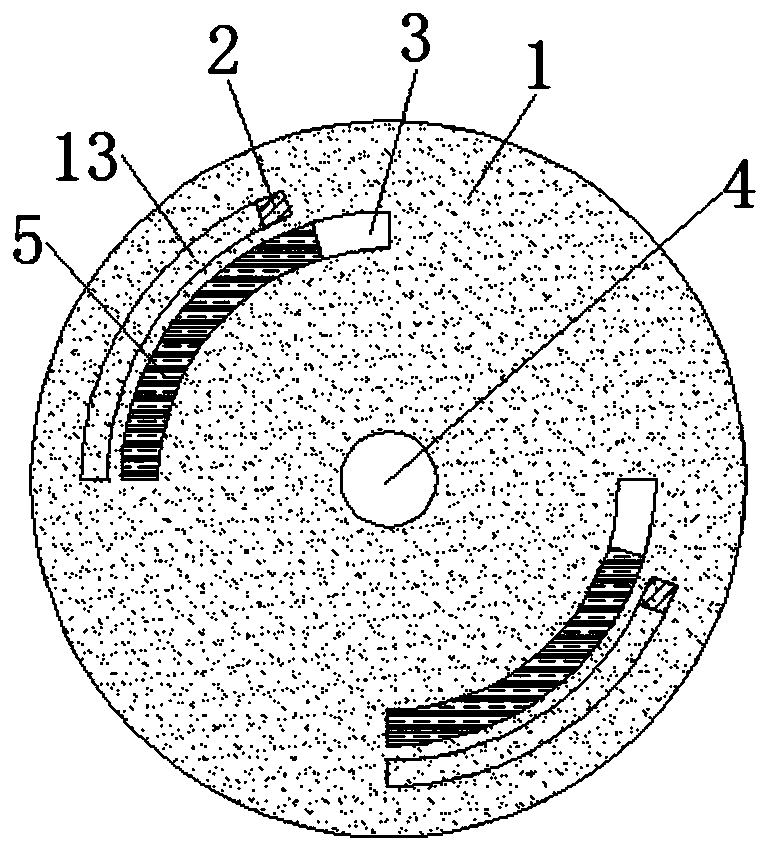

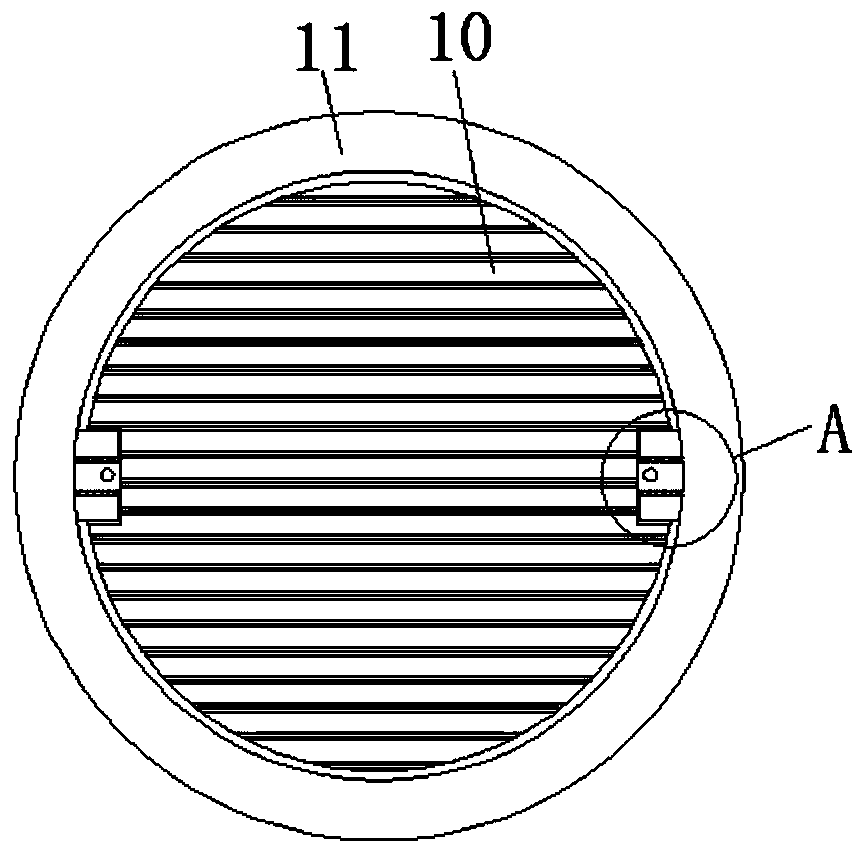

Municipal rain sewage inspection well and using method thereof

InactiveCN110747967AAvoid displacementEntry does not affectFatty/oily/floating substances removal devicesSewerage structuresStream flowSewage

The invention belongs to the technical field of rain sewage inspection wells, in particular to a municipal rain sewage inspection well and a using method thereof. The municipal rainwater sewage inspection well comprises a wellhore, wherein a fixing groove is formed in the top of the wellhore, a fixing block is arranged in the fixing groove, a well lid is fixedly connected to the top of the fixingblock, and a sliding groove is formed in the well lid. According to the municipal rain sewage inspection well and the using method thereof, the fixing block and the fixing groove are arranged, so thatthe well lid and the wellhore can be fixed together, the well lid is prevented from being displaced from the wellhore, the occurrence of potential safety hazards is reduced, under the combined actionof the sliding groove, the sliding block, a water inlet and a baffle, the baffle cannot shield the water inlet by sliding the sliding block under the condition of encountering heavy rain or rainstorm, the flow of rain sewage entering the wellhore is increased, ponding water is reduced, when in sunny days, the baffle can shield a part of the water inlet, garbage is prevented from entering the wellhore from the water inlet, when the baffle is covered, the water inlet cannot be completely shielded, and the entering of daily sewage is not affected.

Owner:吕福学

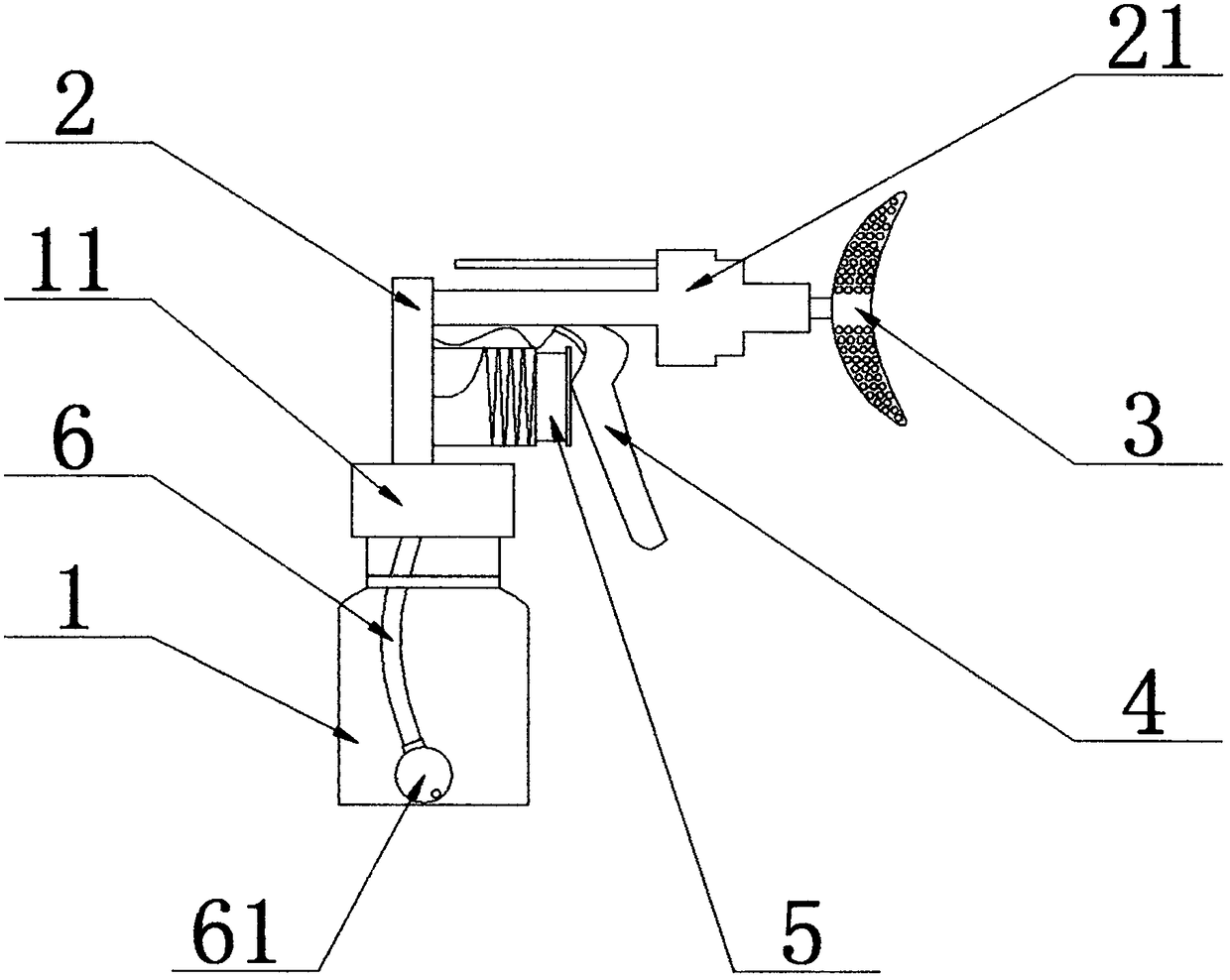

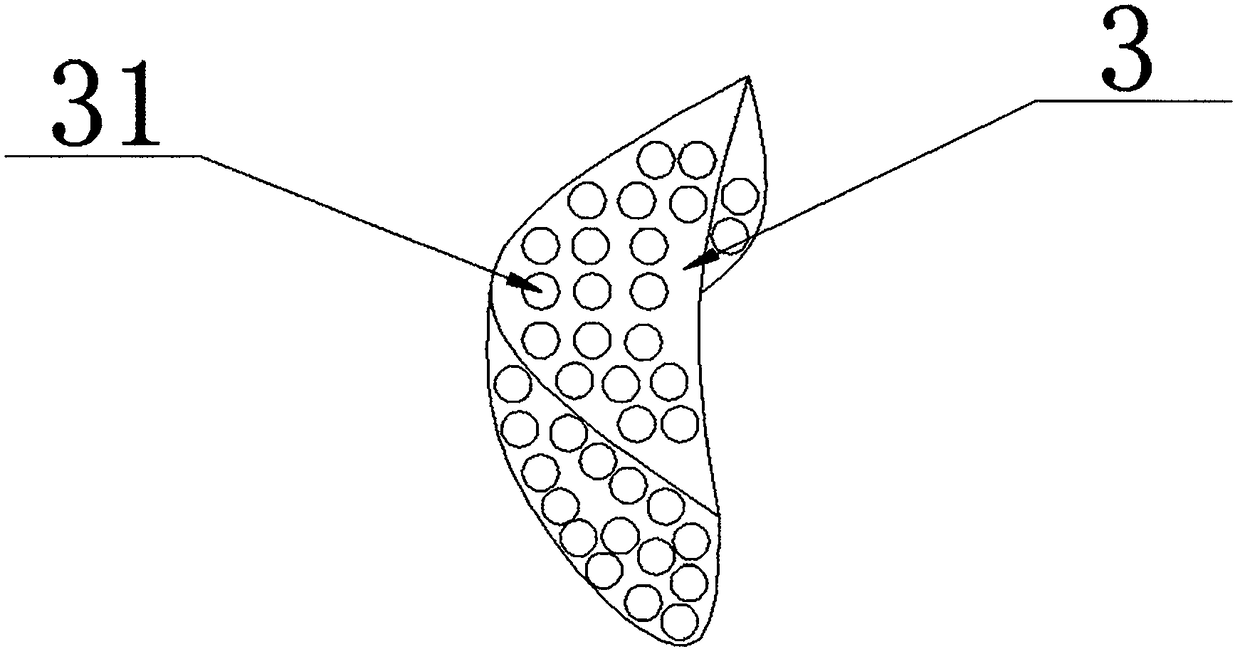

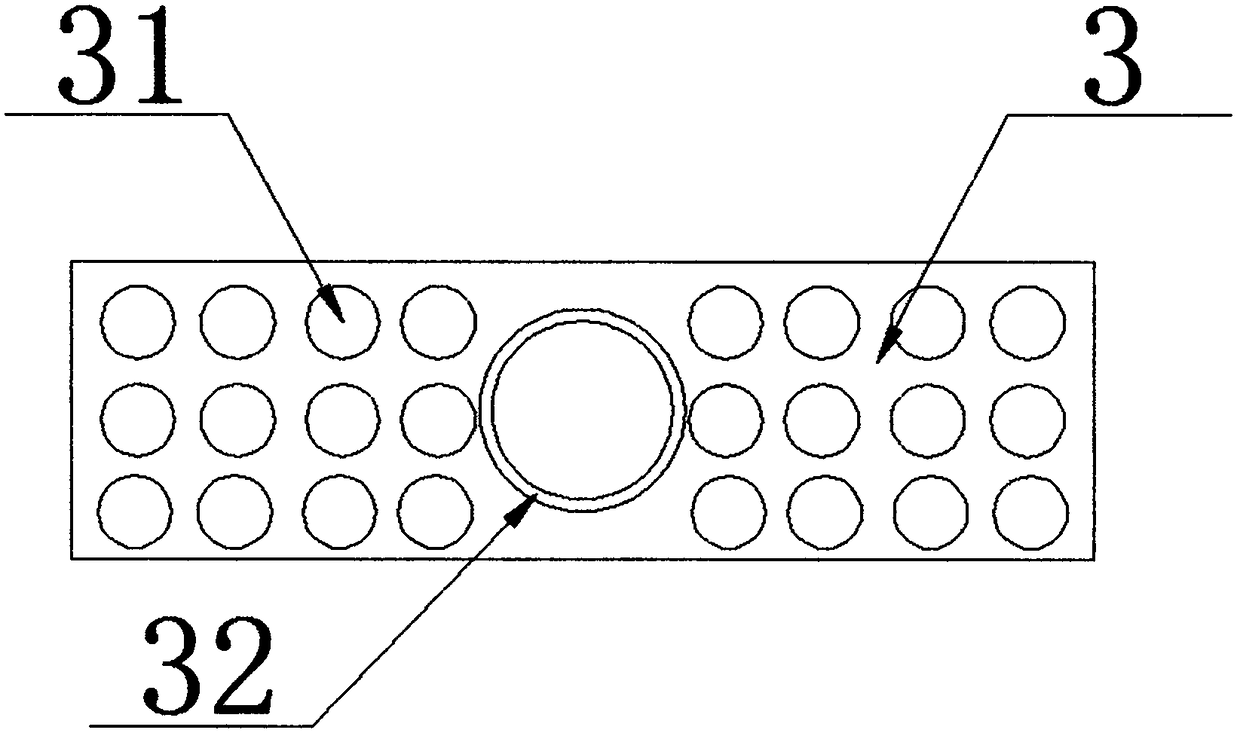

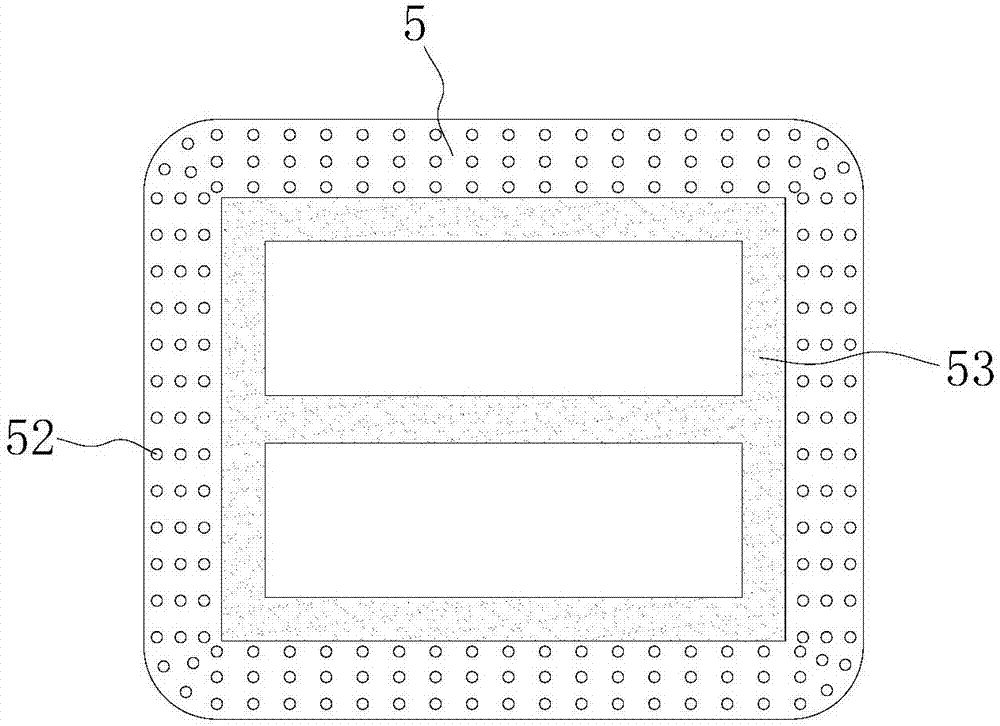

Oral cavity drug delivery device for periodontal mucosa

InactiveCN109364354AEnsure hygiene and safetyReduce cleaning intensityDentistryMedical devicesAir compressionBuccal use

The invention belongs to the technical field of small medical machinery, in particular to an oral cavity drug delivery device for the periodontal mucosa. The device comprises a drug bottle, wherein the upper end of the drug bottle is in threaded connection with a bottle cover, the bottle cover is in sealed connection with a catheter, one end of the catheter is connected with a connecting tube, theend, away from the catheter, of the connecting tube is connected with liquid release cotton, the side, close to the inner side of the connecting tube, of the catheter is fixedly connected with an aircompression device, the inner side, close to one side of the air compression device, of the connecting tube is rotationally connected with a pressing handrail, the inner portion of the drug bottle isin sealed connection with a liquid extracting tube, the liquid release cotton can adapt to the structural particularity in the oral cavity and can fit the wounded part, so that drug delivery is moreuniform and sufficient, since more bacteria exist in the oral cavity, the used liquid release cotton is not suitable for being used again, and the disposable product not only ensures the sanitary safety but also reduces the cleaning strength of medical workers.

Owner:马丽丽

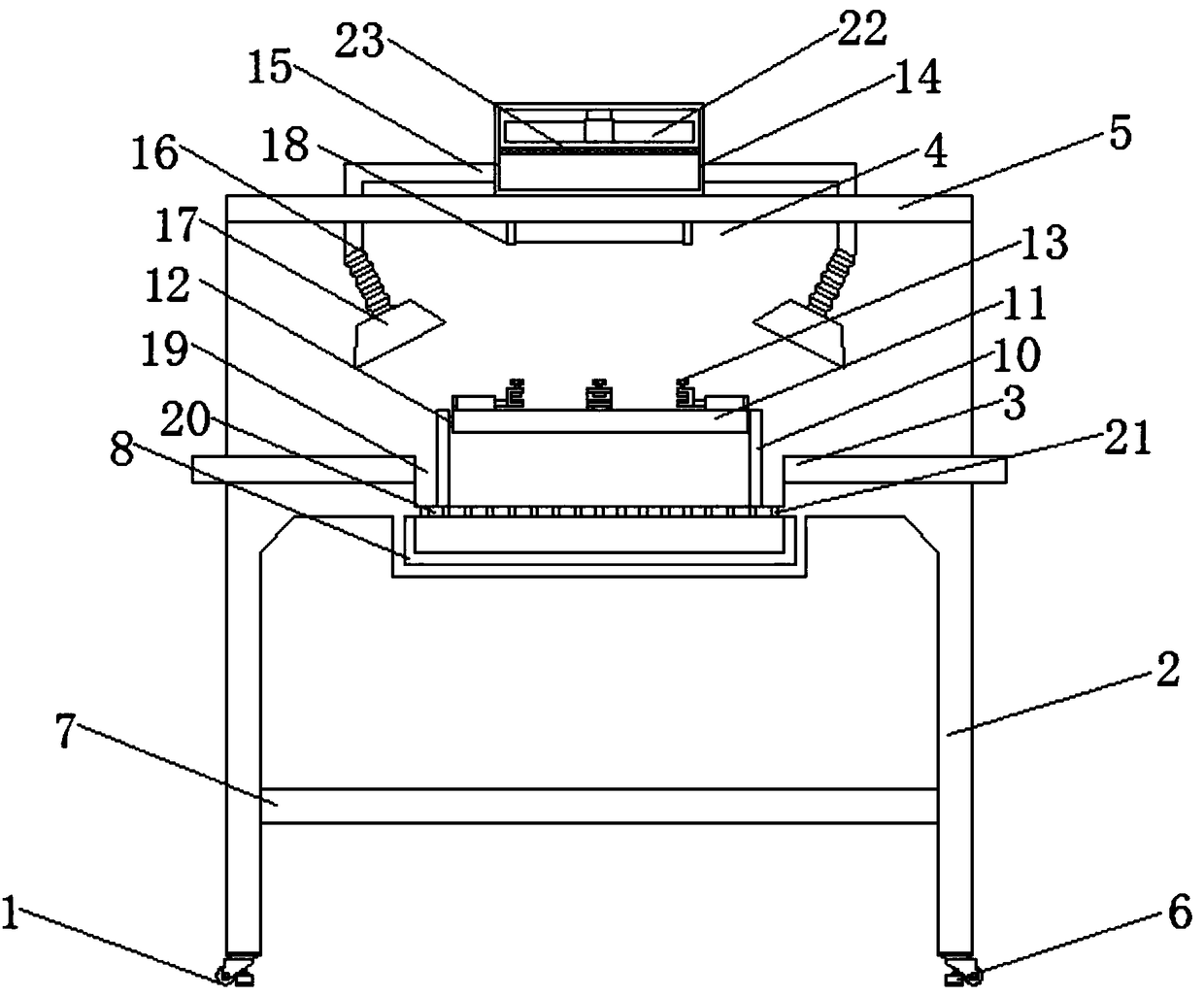

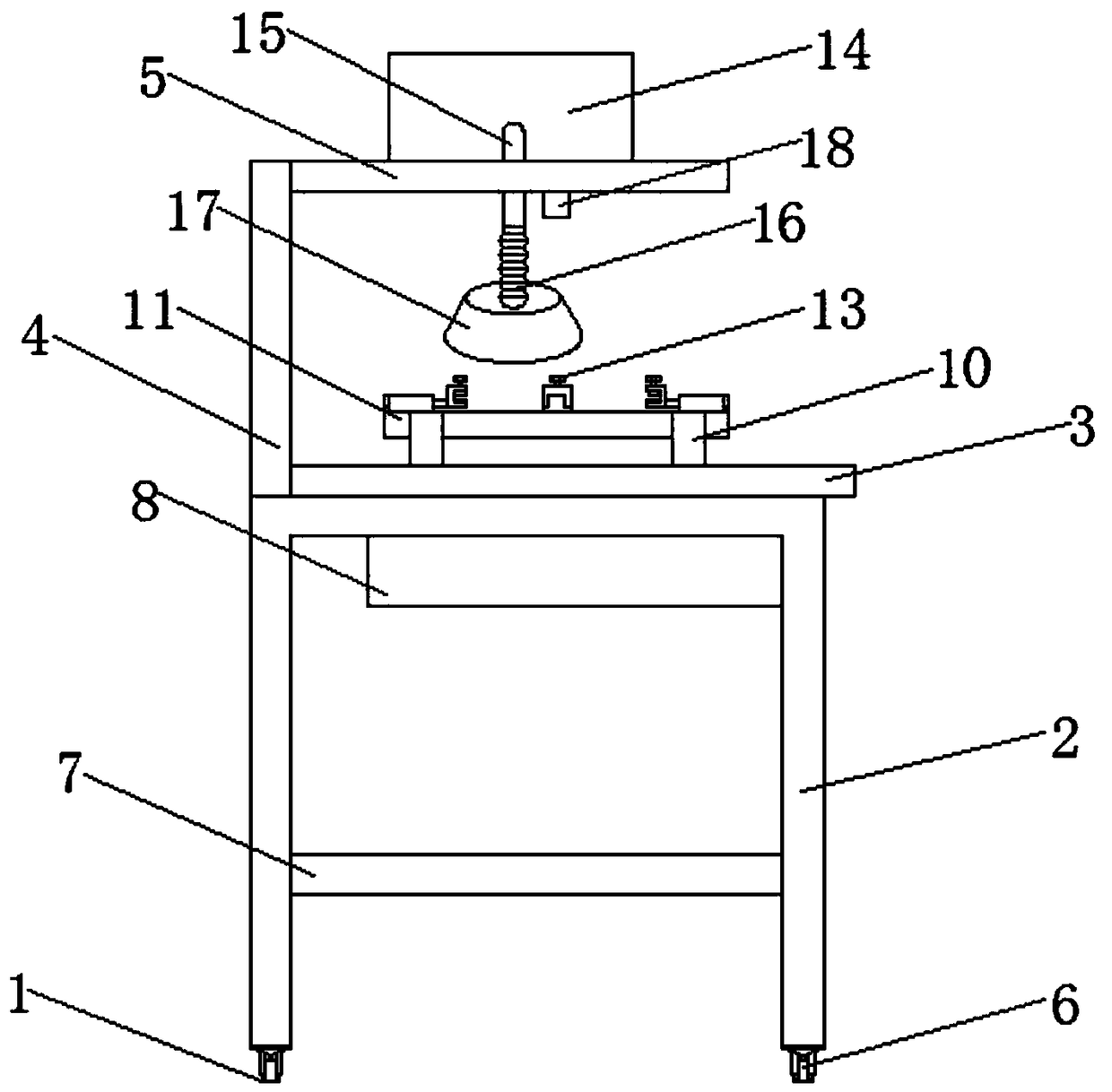

Lampshade cleaning device

ActiveCN106725243AThere will be no damage to the lampshadeControllable cleaning powerHousehold cleanersEngineeringUltimate tensile strength

The invention discloses a lampshade cleaning device comprising a mounting base, wherein a lampshade cleaning mechanism is arranged on the side surface of the mounting base. The lampshade cleaning device has the beneficial effects that the device can automatically clean a lampshade when in use, is controllable in cleaning strength, and does not damage the lampshade when in use, so that the device is well librated in manpower, reduced in potential safety hazard, decreased in cleaning strength, and convenient to use.

Owner:重庆驰硕电子科技股份有限公司

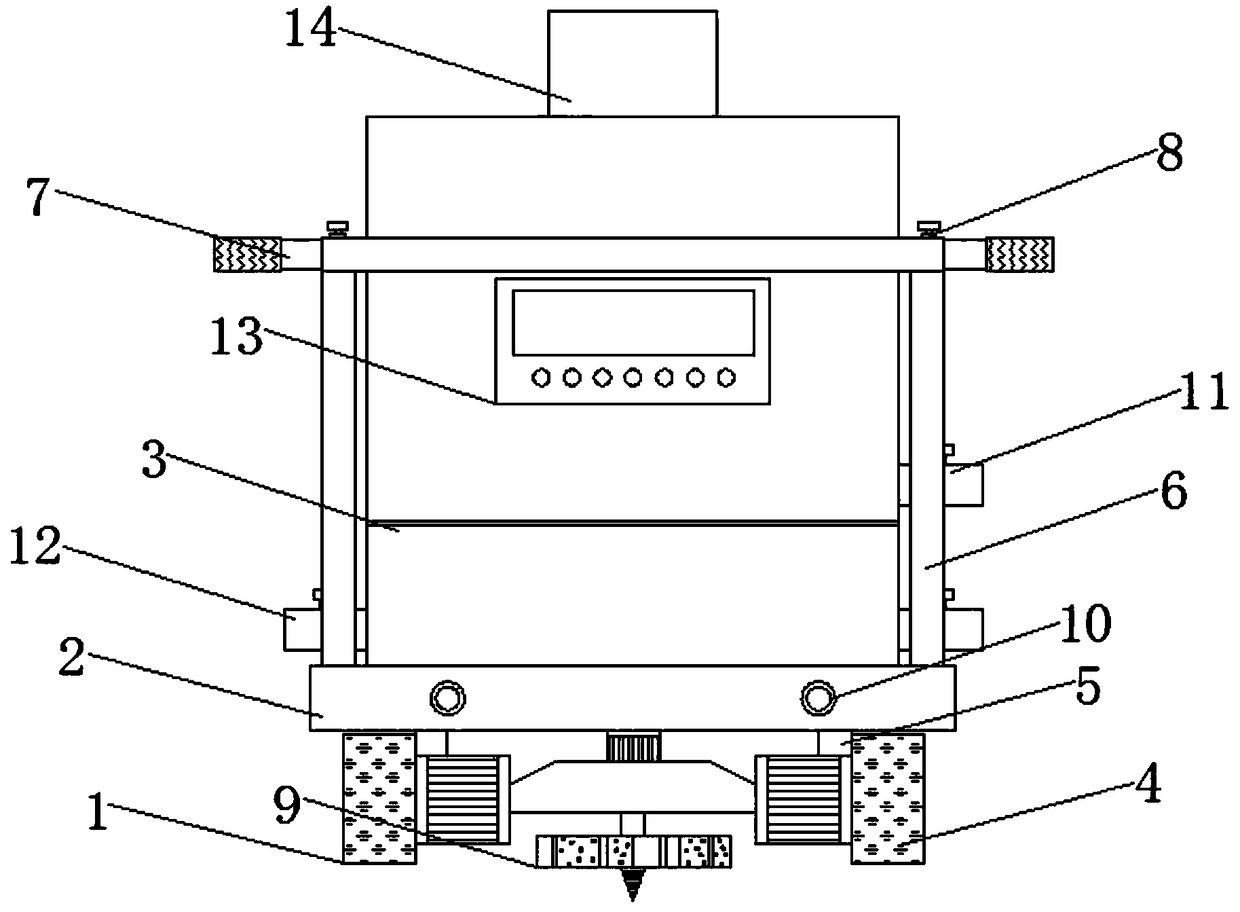

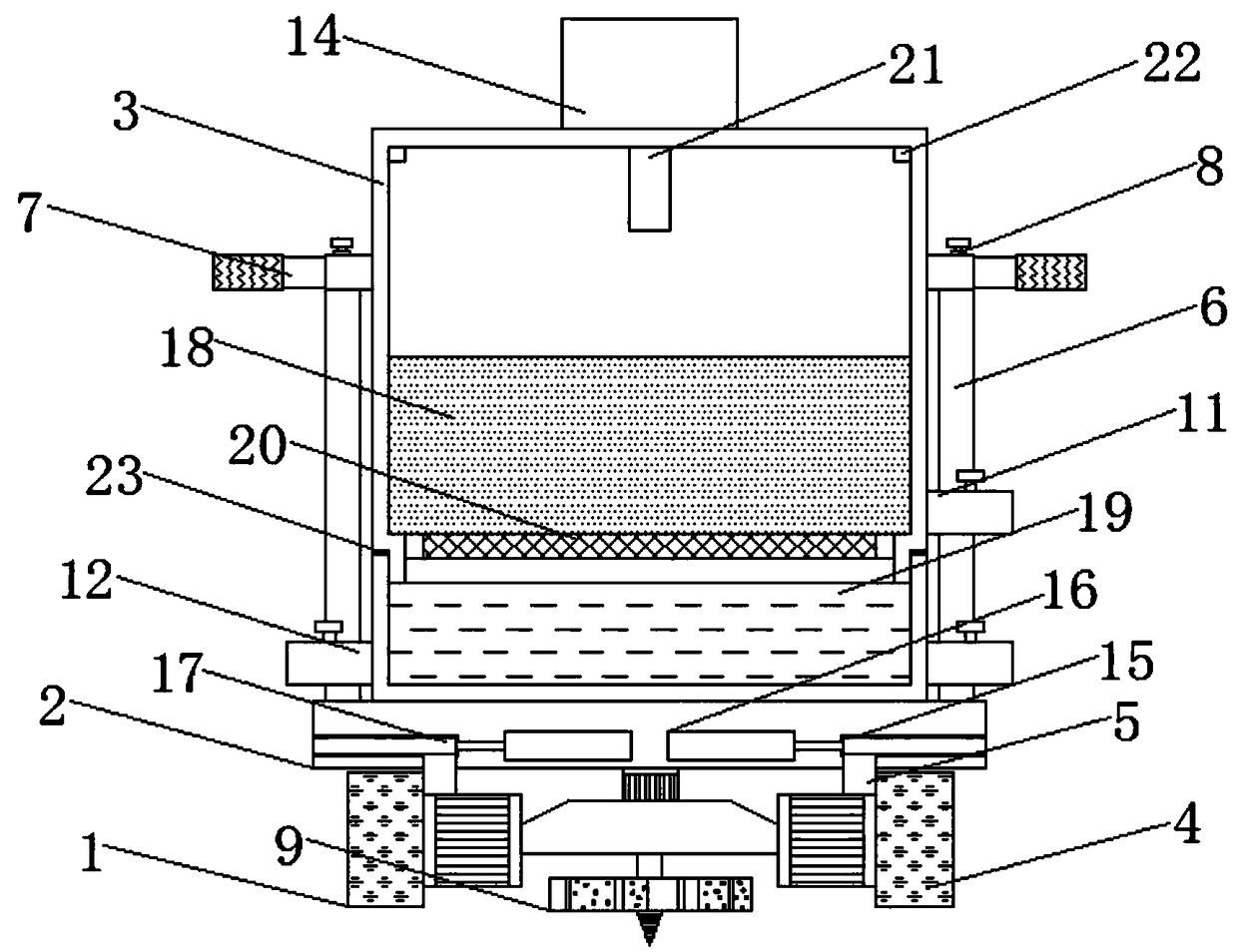

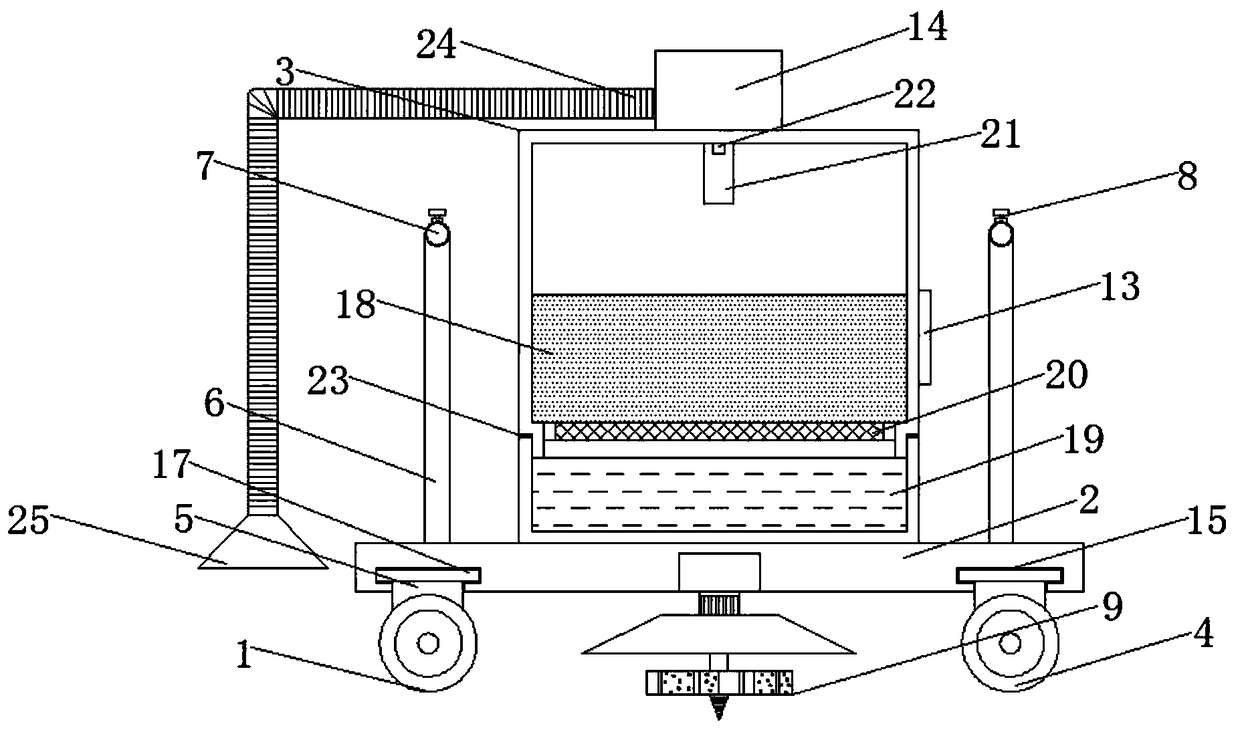

Hospital floor cleaning device

InactiveCN106618389AEasy to operateReduce maintenance costsCarpet cleanersFloor cleanersHydraulic cylinderElectricity

The invention discloses a hospital floor cleaning device. The device comprises a bearing plate. The front surface of the bearing plate is provided with a cleaning mechanism. The upper surface of the bearing plate is provided with an electric supply interface. The upper surface of the rectangular installation box is provided with a controller. A power connection terminal of the controller is connected with the electric interface through conductors. The output terminals of the controller are connected with a number 1 electric trolley, a number 1 rotation motor, an electric push rod, a number 2 rotation motor, a number 2 electric trolley, a micro-hydraulic cylinder and a number 3 rotation motor through conductors. The hospital floor cleaning device has the advantages of having the function of semi-automatic cleaning and processing, having a large cleaning area, liberating labor forces, enhancing cleaning efficiency, increasing medical therapy period, reducing the cleaning work intensity of both the doctors and the patients, being convenient to use and strong in novelty.

Owner:LISHUI PEOPLES HOSPITAL

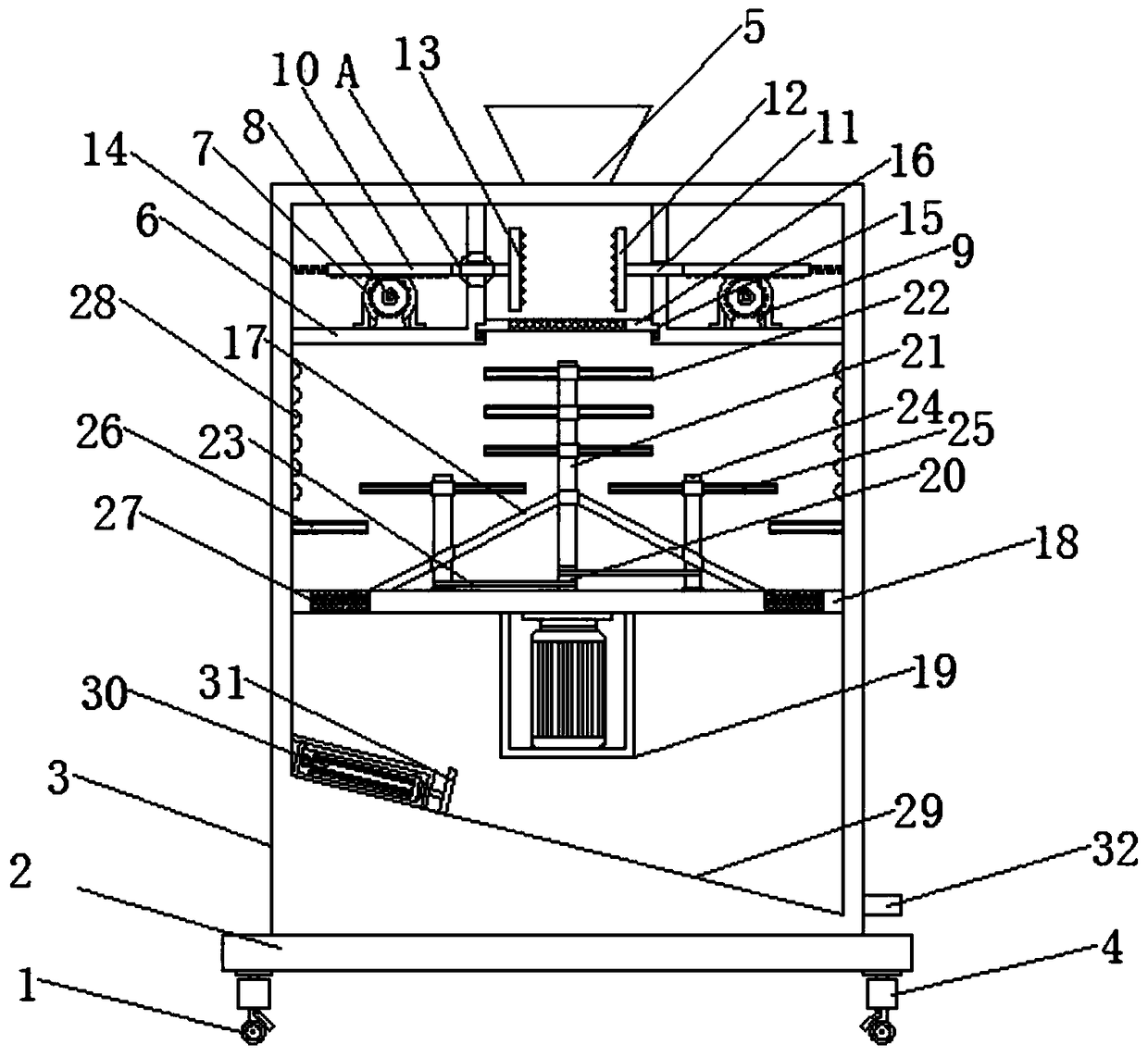

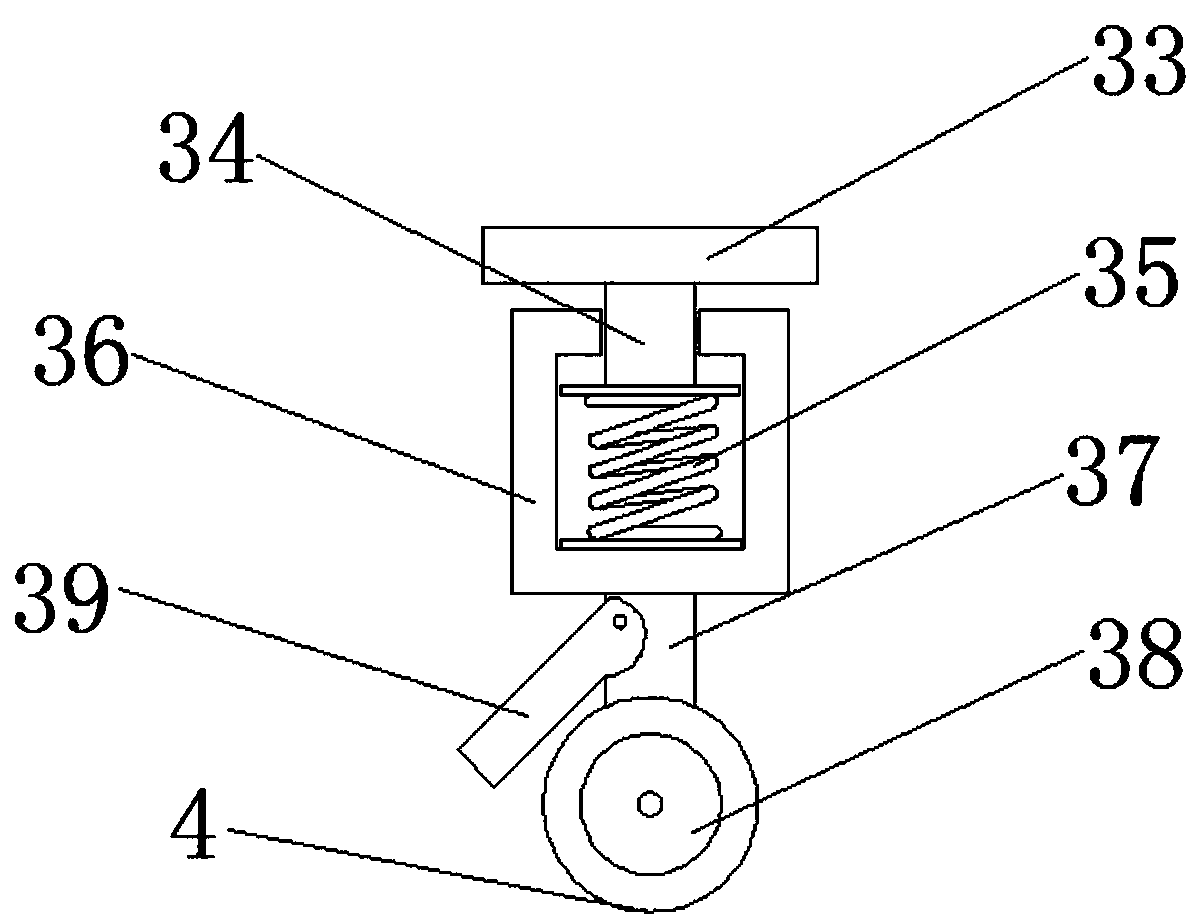

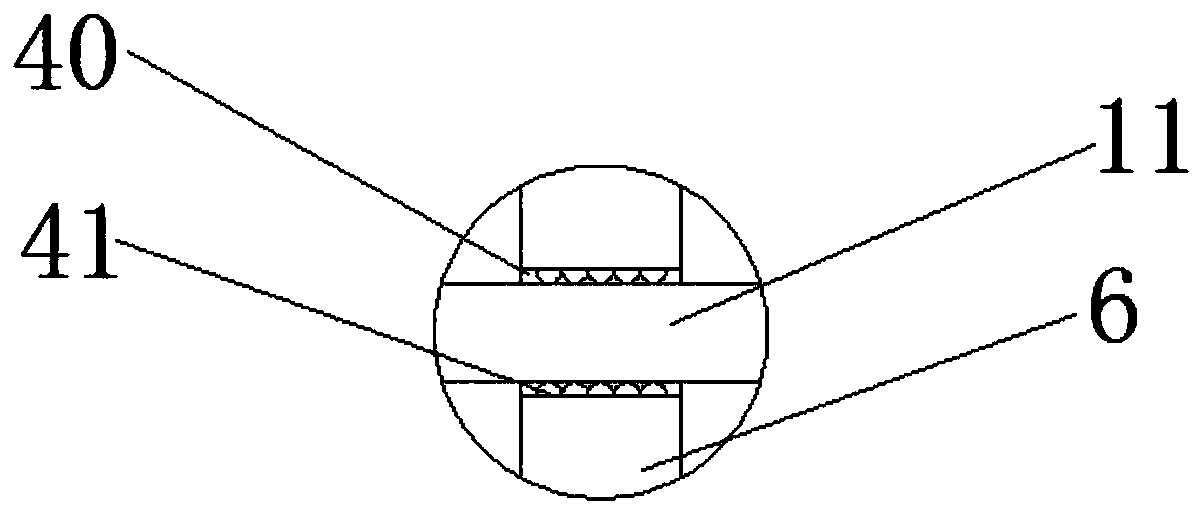

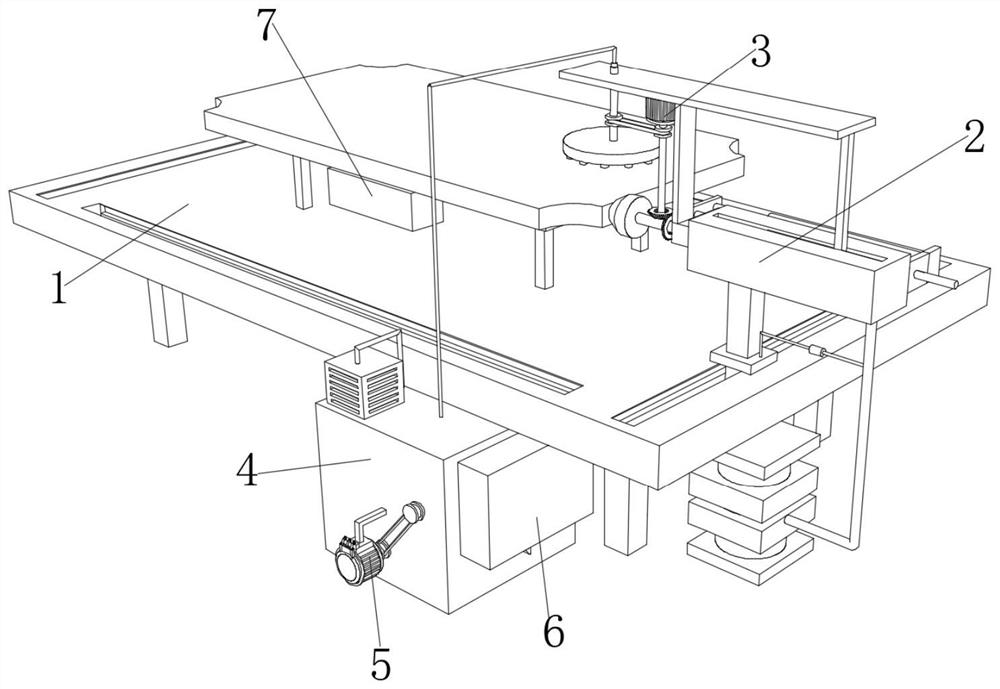

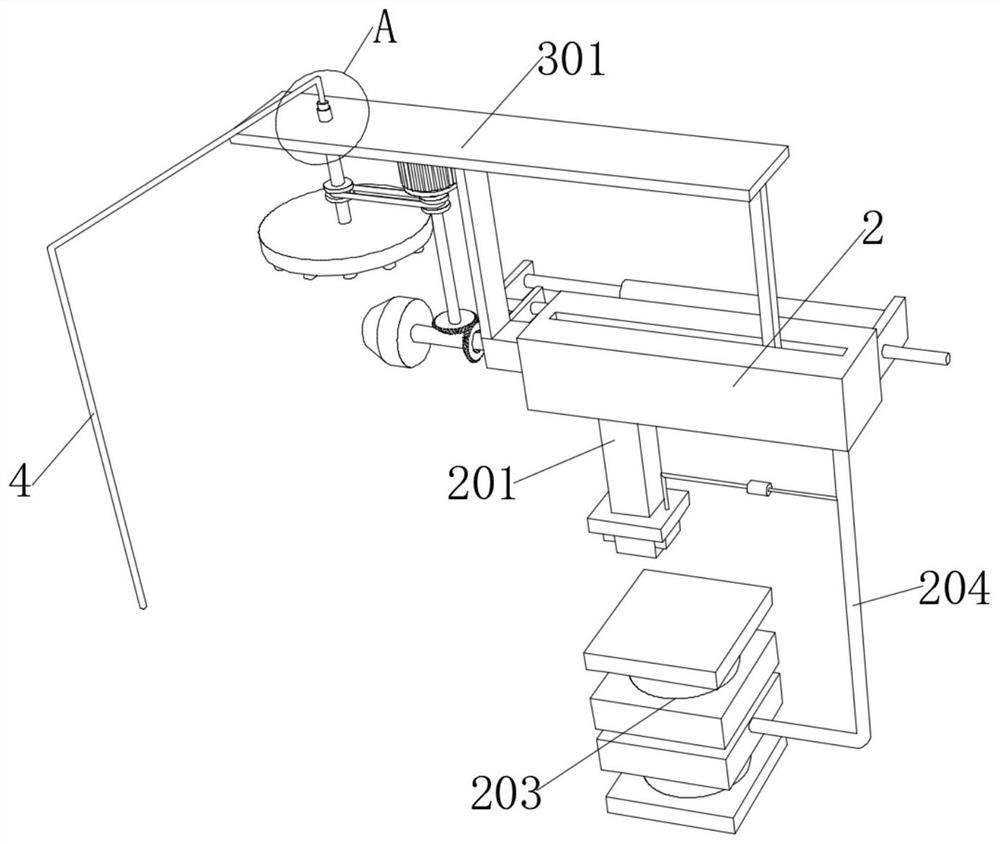

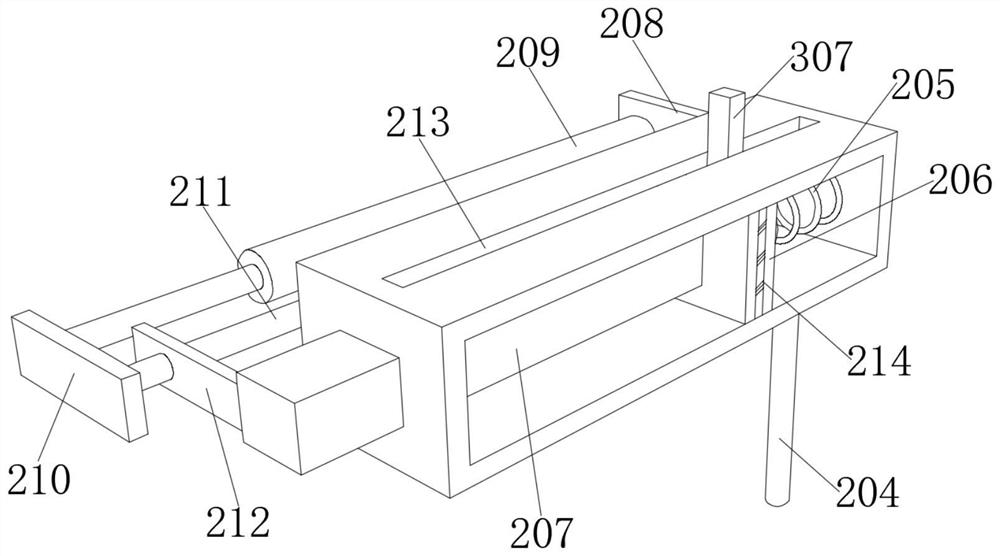

Smashing device for food detection

PendingCN108844795AEasy to achieve primary crushingAchieve primary crushingPreparing sample for investigationTesting foodDrive shaftEngineering

Owner:冒志华

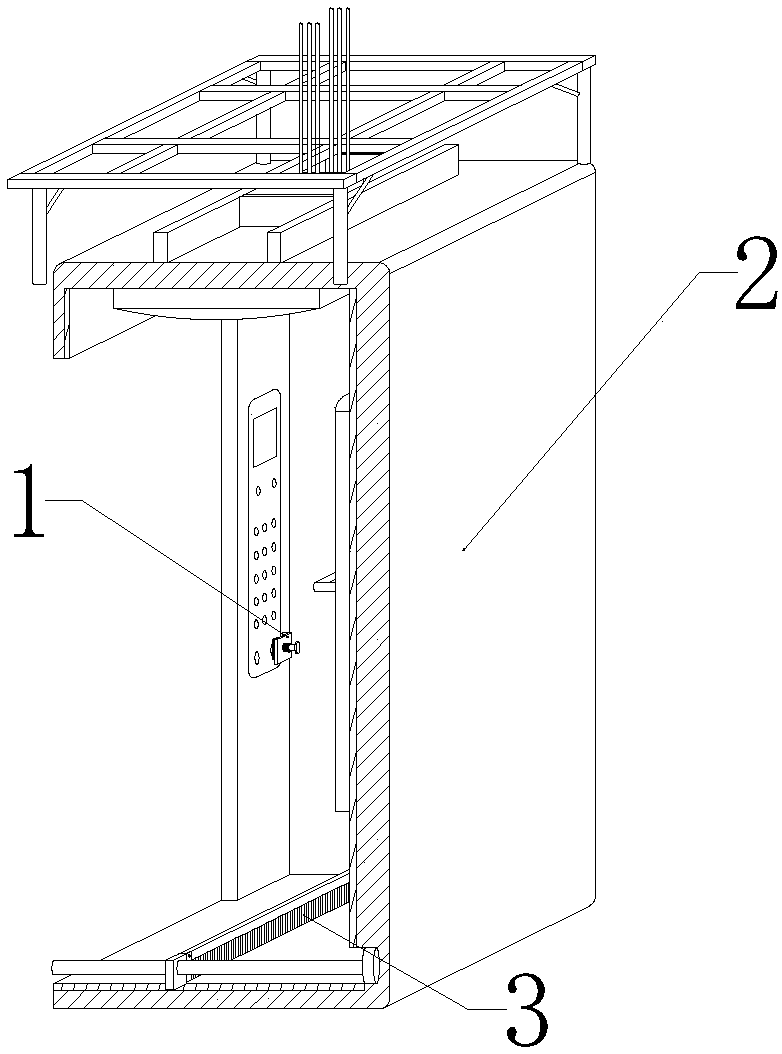

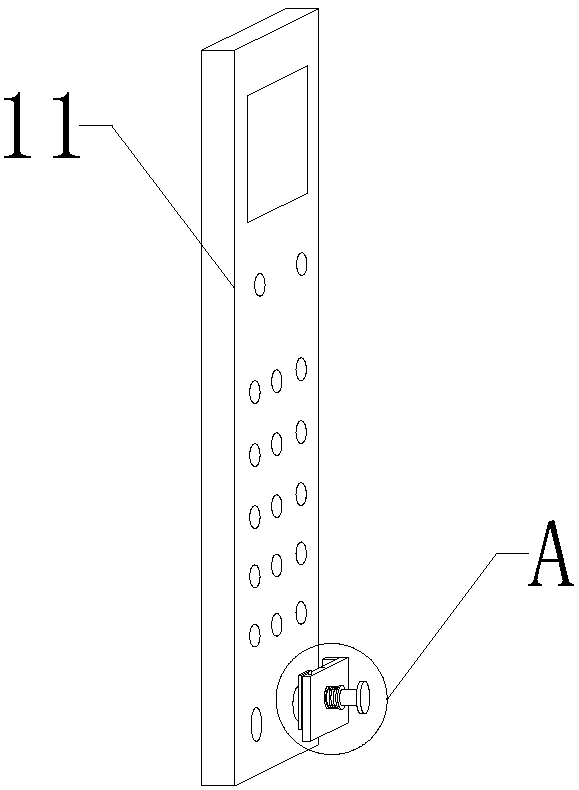

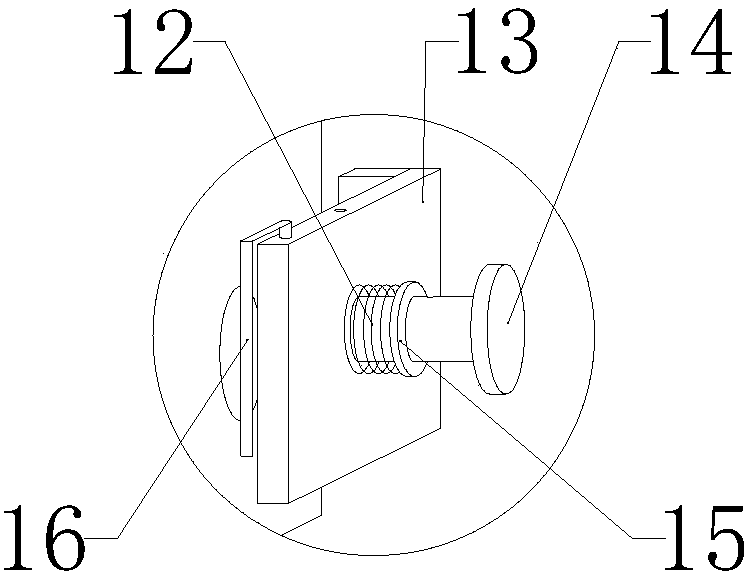

Multi-layer building lifting elevator car device

InactiveCN108190669AEasy to carryImprove the safety of useCleaning using toolsElevatorsEngineeringSurface plate

The invention provides a multi-layer building lifting elevator car device. The multi-layer building lifting elevator car device comprises an operation panel, a spring, a stabilizing plate, a moving rod, a limiting ring, an inserting rod, a car main body, a cleaning brush, a bearing seat, a screw rod and a motor. The left side of the operation panel is provided with the stabilizing plate. The moving rod and the spring are mounted at the right end of the stabilizing plate. The spring is mounted on the moving rod. The right end of the spring is provided with the limiting ring. The limiting ring is mounted on the moving rod. The inserting rod is assembled at the upper end of the stabilizing plate. The design achieves the function that an elevator door is maintained to be open for a long time.The screw rod is mounted at the left end of the motor. The bearing seat is assembled on the screw rod. The cleaning brush is arranged at the inner end of the bearing seat. The motor is mounted on theleft wall of the interior of the car main body. The cleaning brush is mounted at the bottom end of the interior of the car main body. The design achieves the function of mechanical cleaning. The laborintensity of a user is reduced. The multi-layer building lifting elevator car device improves safety, the cleaning intensity is reduced, and the using effect is improved.

Owner:杭州蔓漫文化创意有限公司

Water curtain type filtering range hood

ActiveCN107191986APromote environmental protectionReduce cleaning difficulty and intensityDomestic stoves or rangesLighting and heating apparatusLiquid storage tankCirculating pump

The invention provides a water curtain type filtering range hood. The water curtain type filtering range hood comprises a fan housing, a fume collection hood, a fume guiding plate, an oil collection cup and a water curtain filtering mechanism. The water curtain filtering mechanism comprises a liquid storage tank, an air inlet net cover, a water outlet cavity and a circulating pump, wherein the liquid storage tank is connected with a liquid outlet pipeline, the water outlet cavity is formed in the edge of the air inlet net cover in a ring shape or in a surrounding mode, and a plurality of water outlets are formed in the lower end face of the water outlet cavity at intervals. The fume guiding plate is located below the air inlet net cover and can receive cleaning water or cleaning liquid flowing out of the water outlets and guide the cleaning water or the cleaning liquid to the oil collection cup. A return pipe is arranged between the oil collection cup and the liquid storage tank. Compared with the prior art, the water curtain type filtering range hood has the advantages that the water curtain filtering mechanism can wash and filter cooking fume entering the water curtain filtering mechanism, and meanwhile, the cleaning water or the cleaning liquid obtained after washing can automatically clean the back side of the fume guiding plate and the inner wall of the oil collection cup.

Owner:NINGBO FOTILE KITCHEN WARE CO LTD

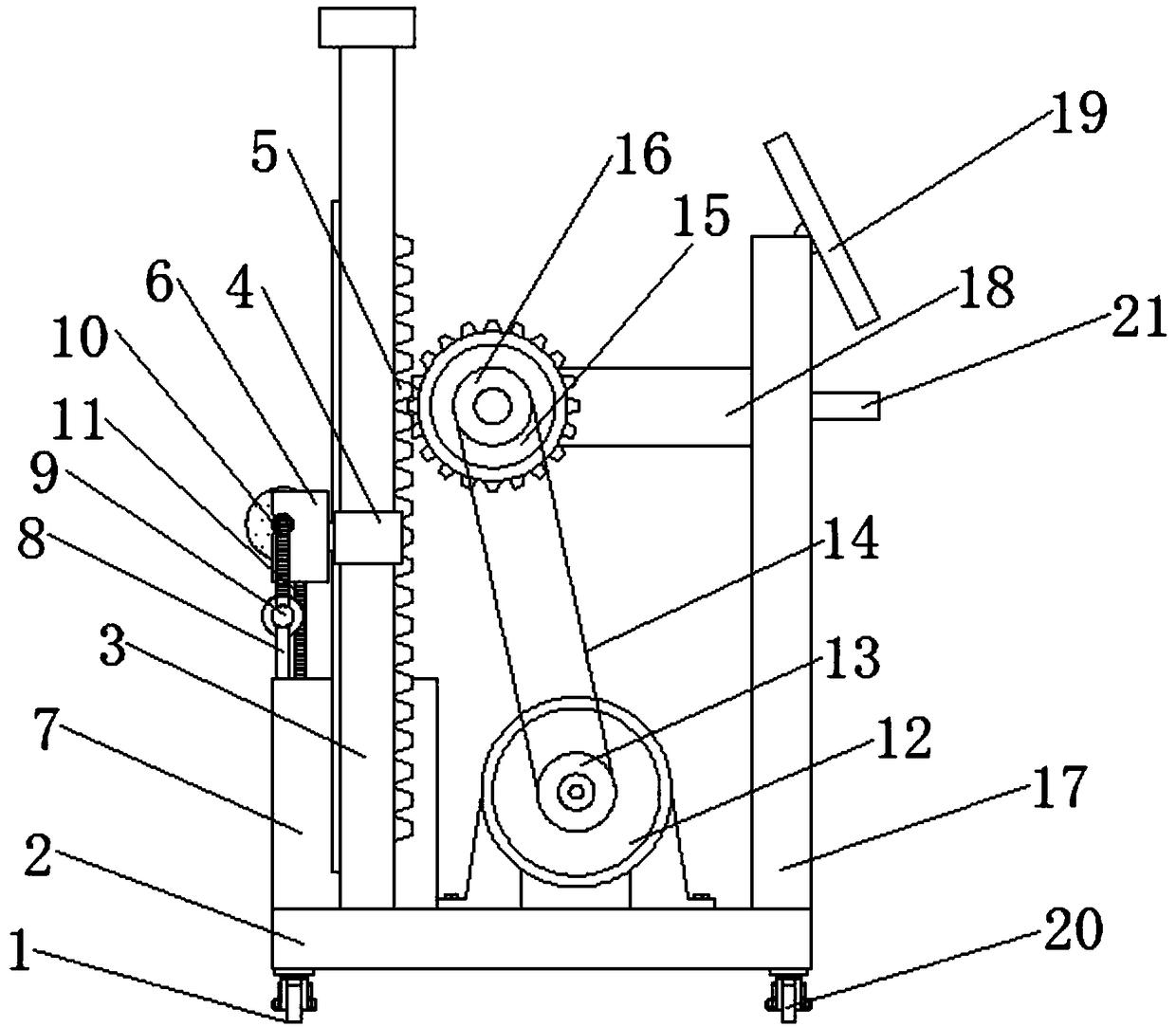

Gear chamfering and deburring composite device

InactiveCN108213606AQuick fixRealize automatic separationMaintainance and safety accessoriesGear teethEngineeringDrive motor

The invention belongs to the technical field of gear machining equipment, and particularly discloses a gear chamfering and deburring composite device. The gear chamfering and deburring composite device comprises a rack and a workbench. The rack is provided with a drive motor. The drive motor is connected with a fixing shaft for gear fixing and an air expansion shaft. The workbench is provided witha servo motor. The servo motor is connected with a both-way lead screw provided with two nut supports. The two nut supports are connected with a first movable rod and a second movable rod correspondingly. The first movable rod is provided with two burr cutters, and the second movable rod is provided with two burr cutters. A spring is connected between the two burr cutters. The right burr cutter is in sliding connection to the second movable rod. Arc sheets are arranged at the end portions of the burr cutters, and the end portions of the arc sheets are bent towards the outer side. Protection covers are arranged on the two sides of the two chamfering cutters and the two sides of the two burr cutters and are bent towards the close side, and a scrap collection box is arranged at the lower endof each protection cover. According to the scheme, gear end face deburring treatment can be finished while gear chamfering treatment is achieved.

Owner:CHONGQING SHUNHUAI MACHINERY MFG CO LTD

Furniture machinery cleaning pedestal

ActiveCN106943083AWipe clean easilyReasonable structureCarpet cleanersFloor cleanersSolenoid valveAgricultural engineering

The invention discloses a furniture machinery cleaning pedestal comprising a pedestal, a water tank, a heater, telescopic cylinders, a cleaning board, a push rod and a controller; the water tank is arranged in the pedestal; the pedestal is provided with a water inlet joint, a steam output joint and a water drainage joint respectively connected with the water tank inner side; the heater is arranged in the water tank; the pedestal top end cover plate is fixedly provided with a solenoid valve and a plurality of telescopic cylinders respectively connected with the solenoid valve; telescopic rod head ends of the plurality of telescopic cylinders are respectively movably hinged to the backside of the cleaning board; the push rod is movably hinged to one side of the pedestal; the controller is arranged on the push rod upper portion, and faces upwards; the heater and the solenoid valve are respectively connected with the controller. The furniture machinery cleaning pedestal is provided; the pedestal can be pushed while standing so as to fast clean the furniture bottom, thus greatly reducing cleaning intensity.

Owner:浙江麦知网络科技有限公司

Billiard table stone plate corner polishing device with automatic adjustment function

PendingCN114536143AReduce risk of damageImprove sanding effectEdge grinding machinesGrinding drivesPolishingBilliard ball

The invention relates to the technical field of billiard accessory machining equipment, in particular to a billiard table stone plate corner grinding device with an automatic adjustment function. The self-adaptive assembly is slidably arranged at the top end of the workbench; the polishing assembly used for polishing the corners of the stone plate is arranged on one side below the self-adaptive assembly; the dust treatment assembly is used for eliminating dust generated in the grinding process and is arranged on the grinding assembly; according to the device, the self-adaption assembly can limit the final grinding position, meanwhile, when the stone plate corners are irregular and the grinding angle is large, the grinding assembly can automatically contract, a certain protection effect is achieved on the grinding assembly, the risk of damage to the grinding assembly is reduced, meanwhile, the stone plate corners can be ground step by step, and the grinding efficiency is improved. Therefore, the polishing effect is improved, and the situation that the corners of the stone plate are broken is avoided.

Owner:JIUJIANG JINYING TECH

Automatic cleaning device for port pollutant

InactiveCN108909959AImprove automationGuarantee the environmentWater cleaningWaterborne vesselsRunning timeAutomation

The invention discloses an automatic cleaning device for port pollutant. By adopting the automatic cleaning device, automatic scanning and recognition of waste in water of a port can be improved greatly, automatic salvage can be performed, the salvaged waste is automatically transported to a cleaning storage box and is compacted with a compacting device, so that the waste storage amount can be improved effectively, the waste cleaning capacity is improved, and the waste cleaning automation at the port is improved and the cleaning strength is lowered. The automatic cleaning device can be controlled automatically and remotely, and the running time of the cleaning device can be controlled easily and conveniently according to the waste amount at the port, so that the port environment is guaranteed effectively, and the natural decomposing stress is lowered.

Owner:ZHEJIANG SCI RES INST OF TRANSPORT

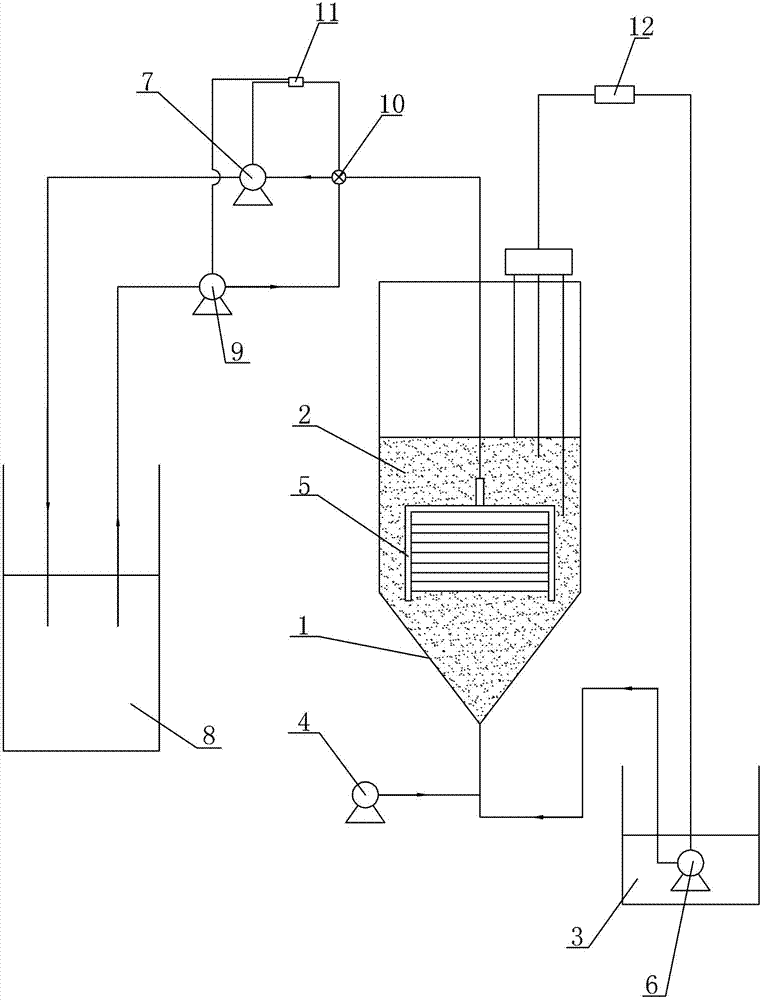

Combined membrane biological reaction device for micro-polluted source water treatment

InactiveCN102897907AUniform particle sizeImprove cohesionSustainable biological treatmentBiological water/sewage treatmentChemistryBiological reactor

The invention provides a combined membrane biological reaction device for micro-polluted source water treatment, relates to the combined membrane biological reaction device, and particularly relates to the combined membrane biological reaction device for the micro-polluted source water treatment. With the adoption of the combined membrane biological reaction device provided by the invention, the problems that the conventional membrane biological reactor has poor de-pollution effect on micro-polluted water, serious membrane pollution and short service life of a membrane assembly can be solved. According to the combined membrane biological reaction device provided by the invention, mixed liquor of attapulgite and activated sludge are filled in a reaction container; a water inlet pump is connected with a water distribution box through a pipeline; the water inlet pump is further connected with a reaction container through the pipeline; the output end of the air pump is communicated with the pipeline between the water inlet pump and the reaction container; a membrane component is mounted inside the reaction container; the membrane component is soaked inside the mixed liquor of the attapulgite and the activated sludge; the output end of the membrane component is connected with the input end of a water outlet pump through the pipeline; and the output end of the water outlet pump is connected with a clean water box through the pipeline. The combined membrane biological reaction device provided by the invention is used for treating sewage.

Owner:GRANDBLUE ENVIRONMENT CO LTD

Farmland water channel sludge cleaning device

InactiveCN108978757AGuaranteed cleanlinessReduce cleaning intensityMechanical machines/dredgersEngineeringSlide plate

The invention discloses a farmland water channel sludge cleaning device. A base is arranged at the bottom of a device body, a sludge loosening device is mounted in the middle of the bottom end of thebase, the sliding grooves are formed in two ends of the two sides of two sides of the bottom end of the base, sliding plates are arranged in the sliding grooves, a first electric pushing rod is mounted at one end of each sliding plate, supporting plates are arranged at the bottom ends of the sliding plates, electric traveling wheels are mounted at the bottoms of the supporting plates, a cleaning box is mounted in the middle of the top of the base, a sludge box is arranged at the top of the cleaning box, a sludge pump is mounted at the top of the sludge box, one end of the sludge pumping pipe is fixedly connected with a sludge pump, a sludge collection cover is mounted at the bottom end of the sludge pumping pipe, and a water purification box is mounted at the bottom of the sludge box. According to the device, the sliding groove is matched with the sliding plates, the sliding plates can move in the sliding grooves under the action of first electric push rod back and forth, the distancebetween the adjacent electric traveling wheels is flexibly and rapidly adjusted, the requirements of small water channels with different widths ca be met, the application range of the device body is widened, and the use value of the device is improved.

Owner:王奇龙

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com