Gear chamfering and deburring composite device

A composite device and deburring technology, applied in the direction of belts/chains/gears, gear teeth, components with teeth, etc., can solve the problem of affecting the axial size and end surface roughness of parts, the end surface burrs of parts cannot be completely removed, and the increase of equipment , management and labor costs, etc., to achieve the effect of high cost performance, simple structure, and reduced cleaning intensity

Inactive Publication Date: 2018-06-29

CHONGQING SHUNHUAI MACHINERY MFG CO LTD

View PDF8 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The use of this chamfering machine for chamfering of gear parts has the following disadvantages: firstly, chamfering adopts a separate process, which increases the cost of equipment, management and labor; The end surface burr cannot be completely removed, which affects the axial dimension and end surface roughness of the part, and requires subsequent finishing

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0013] The present invention will be described in further detail below by means of specific embodiments:

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

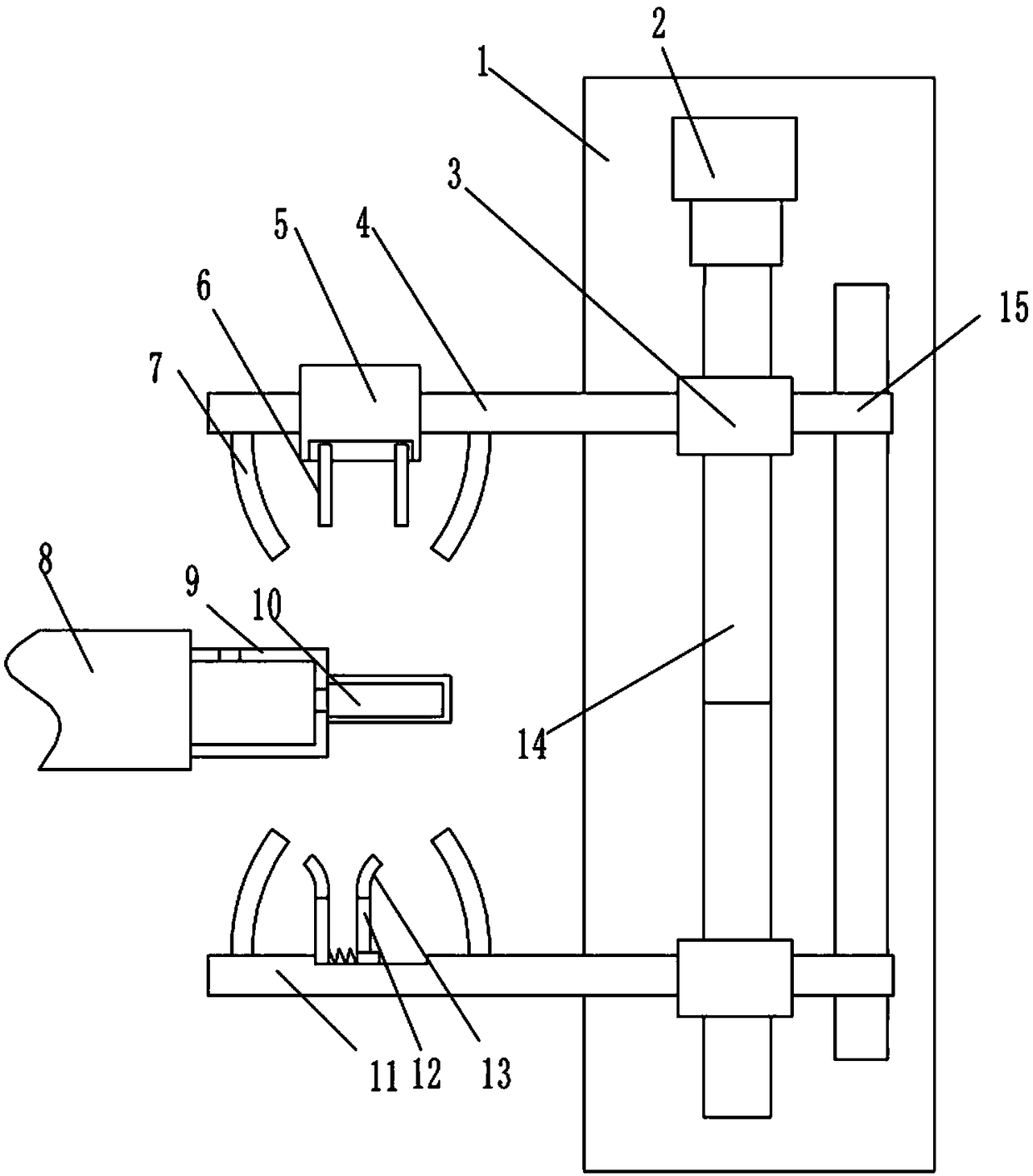

The invention belongs to the technical field of gear machining equipment, and particularly discloses a gear chamfering and deburring composite device. The gear chamfering and deburring composite device comprises a rack and a workbench. The rack is provided with a drive motor. The drive motor is connected with a fixing shaft for gear fixing and an air expansion shaft. The workbench is provided witha servo motor. The servo motor is connected with a both-way lead screw provided with two nut supports. The two nut supports are connected with a first movable rod and a second movable rod correspondingly. The first movable rod is provided with two burr cutters, and the second movable rod is provided with two burr cutters. A spring is connected between the two burr cutters. The right burr cutter is in sliding connection to the second movable rod. Arc sheets are arranged at the end portions of the burr cutters, and the end portions of the arc sheets are bent towards the outer side. Protection covers are arranged on the two sides of the two chamfering cutters and the two sides of the two burr cutters and are bent towards the close side, and a scrap collection box is arranged at the lower endof each protection cover. According to the scheme, gear end face deburring treatment can be finished while gear chamfering treatment is achieved.

Description

technical field [0001] The invention belongs to the technical field of gear processing equipment, and in particular relates to a gear chamfering and deburring compound device. Background technique [0002] The gear hobbing process generally includes multiple processes such as rough rolling → chamfering → deburring → fine rolling. Since the existing gear hobbing machines cannot complete the chamfering and deburring processes, the existing gear hobbing production line needs to include at least two gear hobbing machines and one chamfering machine. The chamfering machine is located between the two gear hobbing machines, and one of the gear hobbing machines One is used for rough hobbing of gear workpieces and another gear hobbing machine is used for finish hobbing of gear workpieces. After the rough rolling and fine rolling, the gear needs to be chamfered by a chamfering machine. After the chamfering is completed, it is deburred manually or mechanically. [0003] At present, fo...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): B23F19/00B23F19/10B23Q11/00B23Q11/08

CPCB23F19/104B23F19/00B23Q11/0042B23Q11/08

Inventor 刘险峰

Owner CHONGQING SHUNHUAI MACHINERY MFG CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com