Patents

Literature

31results about How to "Achieving Diffuse Distribution" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Cobalt less multi element high speed tool steel and its manufacturing method

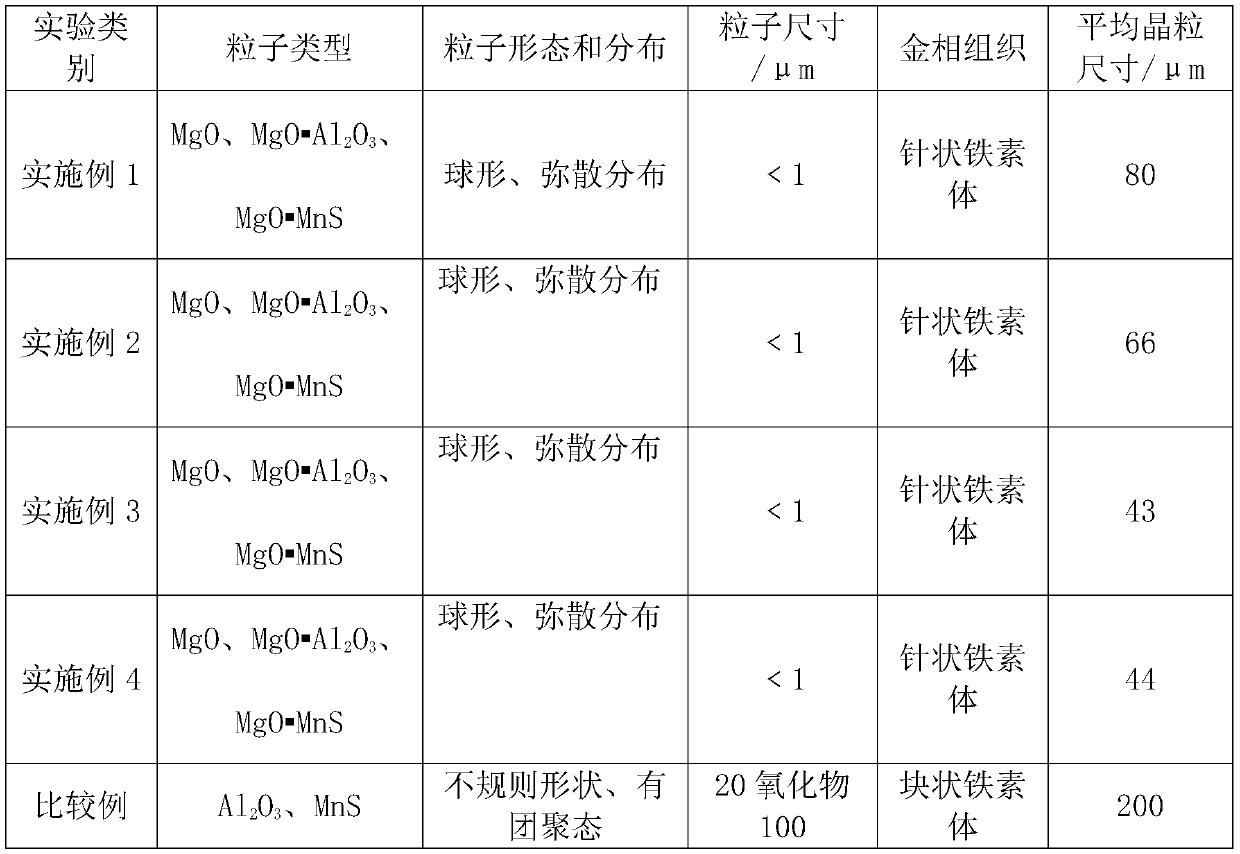

InactiveCN1693527AReasonable range of performanceLow content of alloying elementsFurnace typesHeat treatment furnacesElectrical resistance and conductanceChemical composition

A non-Co multi-element high-speed tool steel contains proportionally C, Si, Mn, S, P, Cr, V, Mo, W, Ni, Nb, Ti, Mg, RE and Fe. Its preparing process includes such steps as smelting by MF furnace, modifying with Y-based RE alloy, centrifugal casting, and heat treating.

Owner:JIUQUAN IRON & STEEL GRP

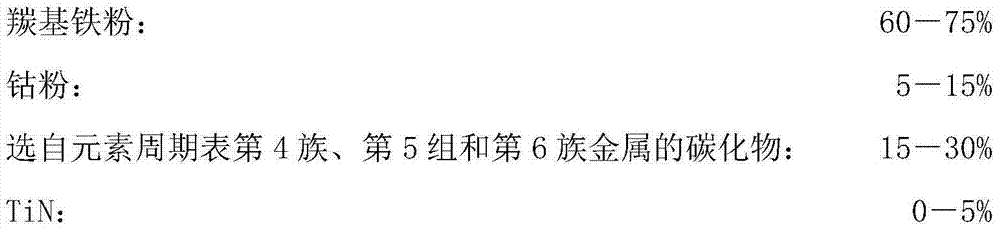

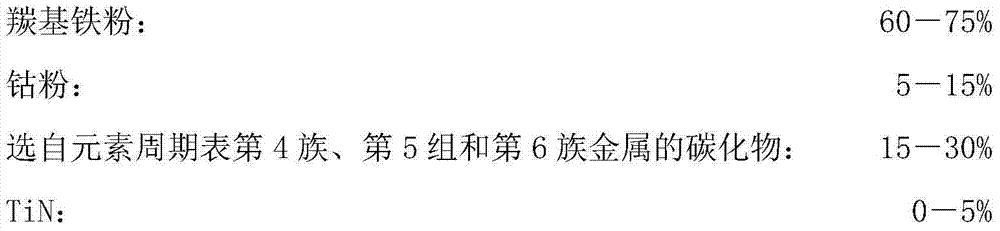

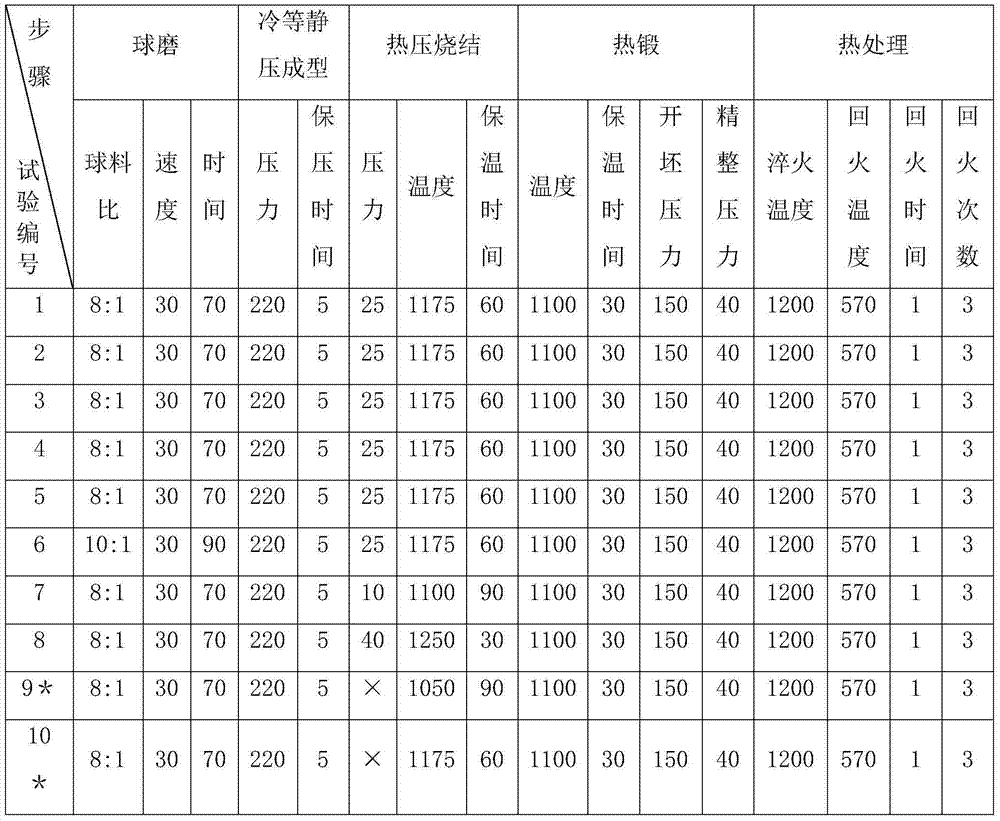

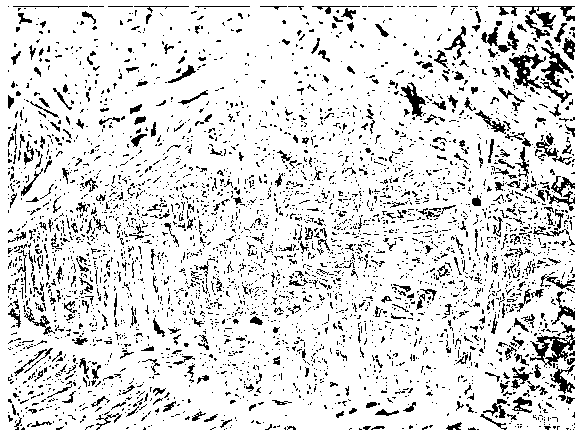

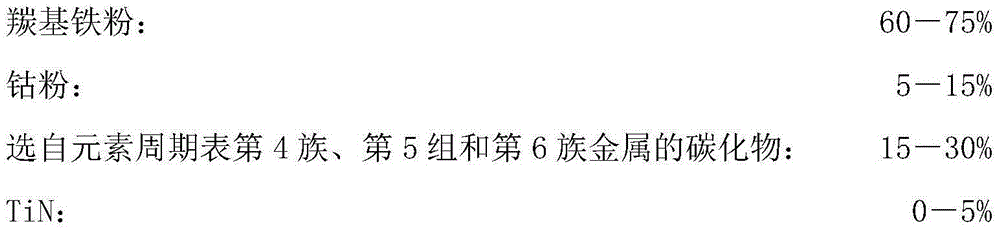

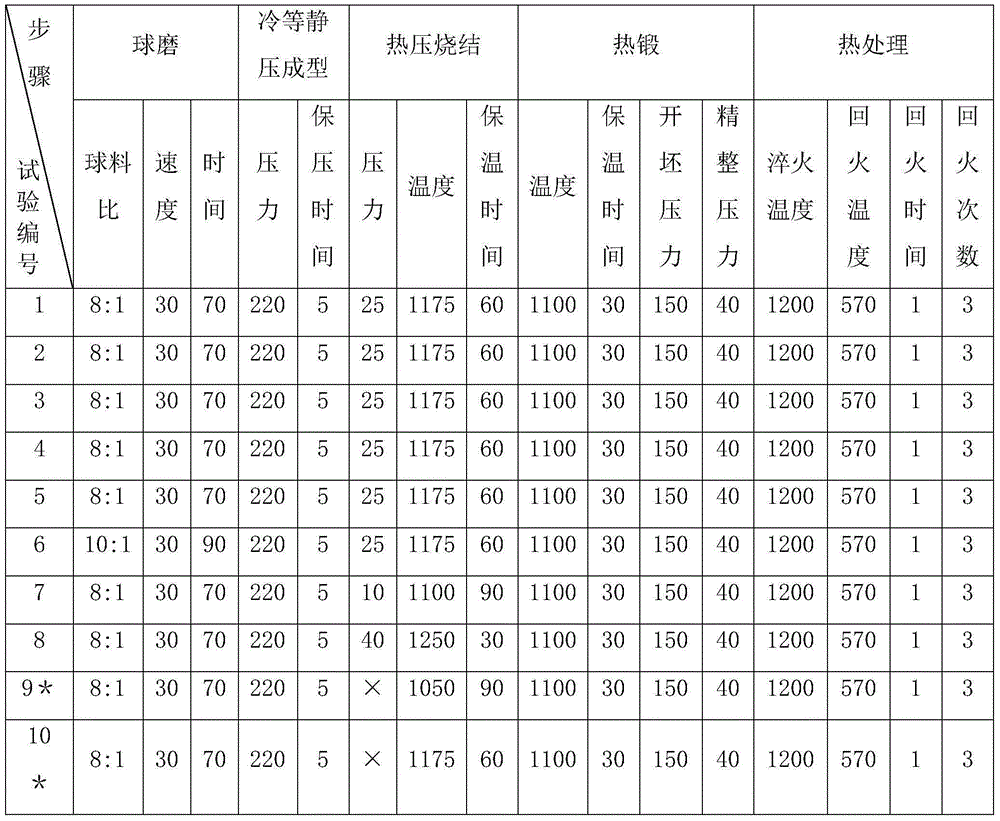

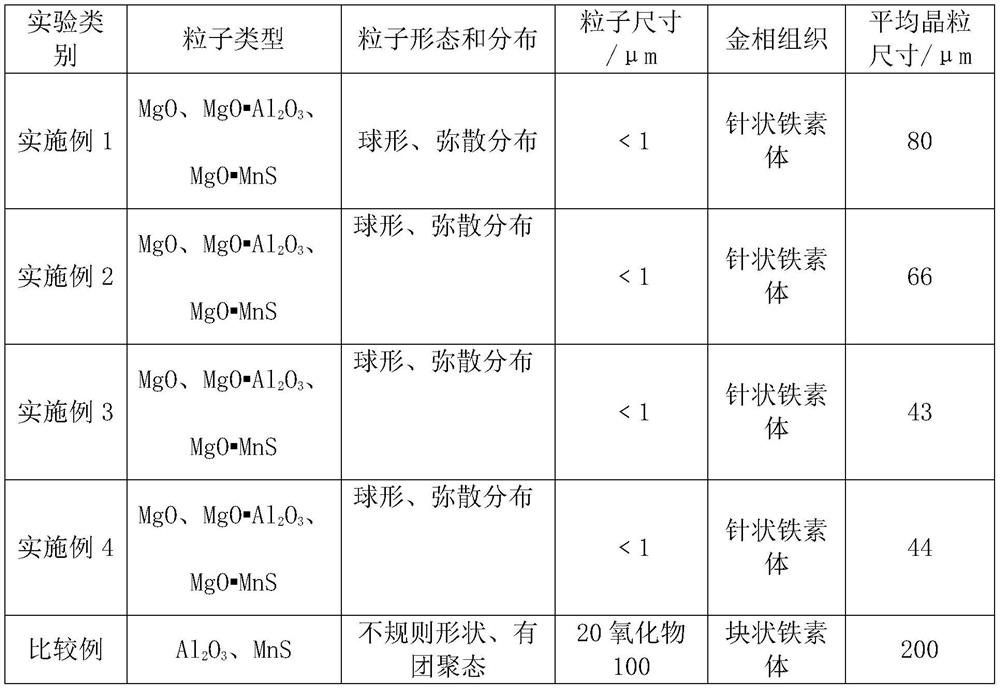

Powder metallurgy high-speed steel and preparation method thereof

The invention discloses powder metallurgy high-speed steel and a preparation method thereof. The method is simpler than the existing powder metallurgy high-speed steel preparation method, steps of high-speed steel mother alloy smelting, atomization for making powder and hot isostatic pressing are omitted, great equipment investment is not needed and the production cost of powder metallurgy high-speed steel is reduced. The impurity content of the powder metallurgy high-speed steel prepared by adopting the method provided by the invention is low and the using performance is excellent. The powder metallurgy high-speed steel provided by the invention is prepared through the steps of 1) preparing powder mixture: weighing raw materials according to set components and proportioning ratio, and mixing and ball-milling the raw materials in a roller-type ball mill to obtain the powder mixture; 2) molding: molding the powder mixture into pressed blanks through cold isostatic pressing; 3) sintering: sintering the pressed blanks in a vacuum or inert gas atmosphere by adopting a hot-pressing sintering technology, heating the pressed blanks to 1100-1250 DEG C during sintering, preserving heat for 30-90 minutes and keeping sintering pressure to be 10-40Mpa; 4) hot forging; 5) heat treatment.

Owner:长沙市萨普新材料有限公司

Method for optimizing steel structure by adding nano particles into steel liquid

The invention discloses a method for optimizing a steel structure by adding nano particles into steel liquid, which belongs to the field of ferrous metallurgy. The method comprises the following steps of: mixing and dispersing nano-powder and pure iron powder, wherein the mass percentage of the nano-powder is 1-40 percent, the mass percentage of the pure iron powder is 60-99 percent, and the average particle size of the nano-powder is 10-5,000 nm; under inert gas, sintering the mixture into a nano-powder stick by a hot-pressing technology, wherein a core material of the nano-powder stick is a steel stick, the outer layer of the nano-powder stick is provided with the mixture, the hot-pressing sintering pressure is 5-40 MPa, the sintering temperature is 1,000-1,400 DEG C, and the heat preservation time is 5-15 minutes; and inserting the nano-powder stick into the steel liquid of a steel ladle or a tundish, wherein the insertion depth of the nano-powder stick is 1 / 2-2 / 3 of the total depth of the steel liquid, and the nano-powder stick is driven by a mechanical hydraulic device to vibrate up and down or left and right. By the method, the nano particles can be effectively and uniformly dispersed and distributed in the steel liquid.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

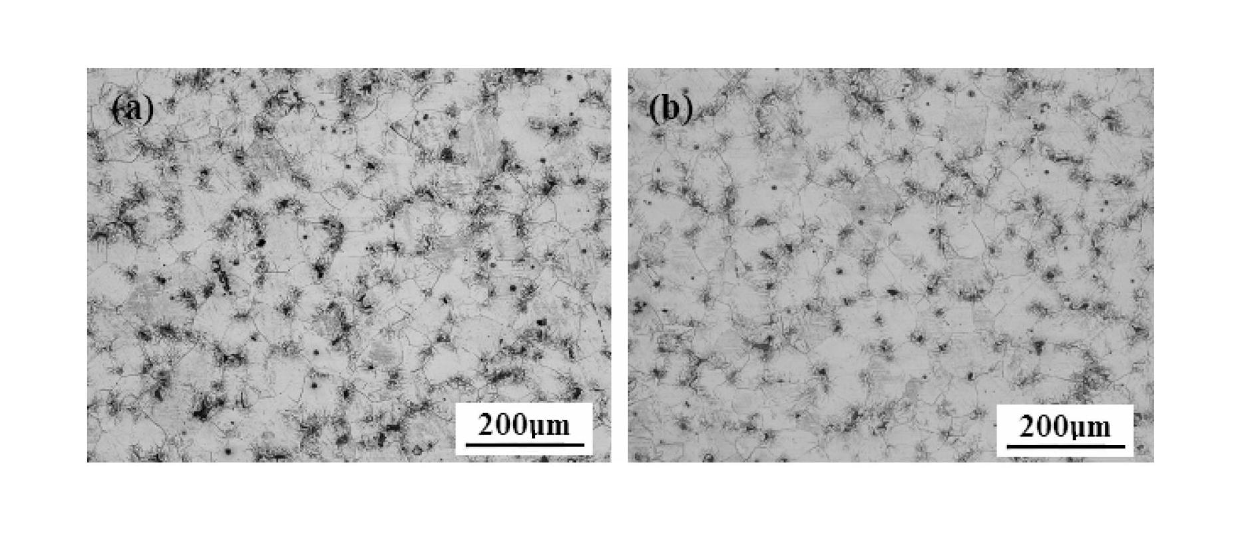

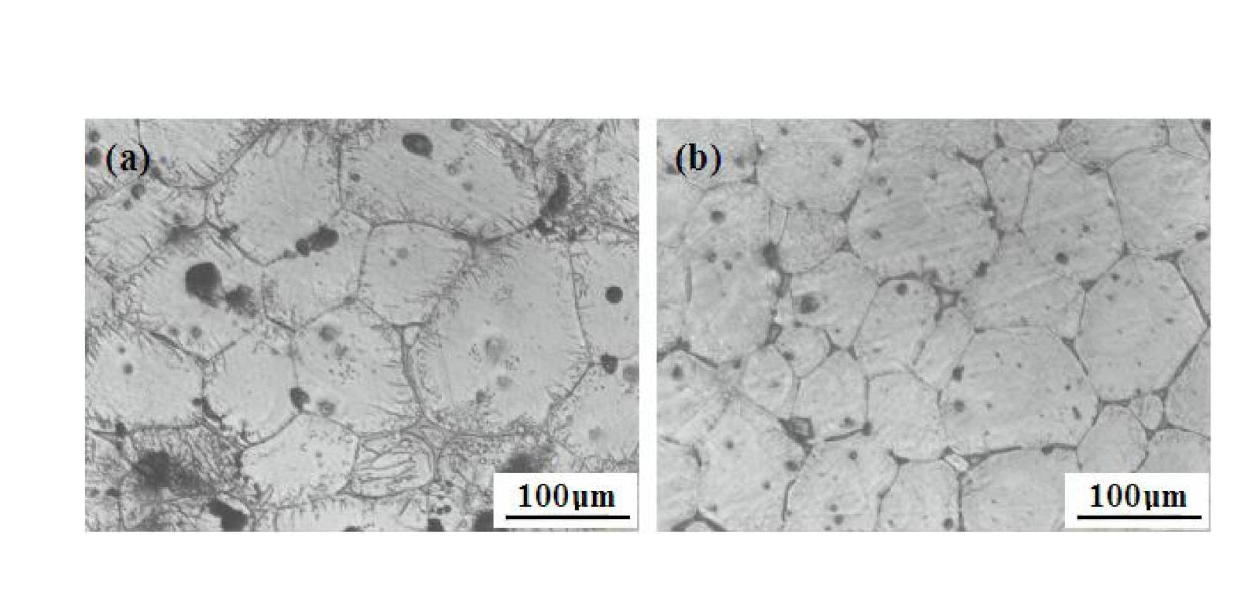

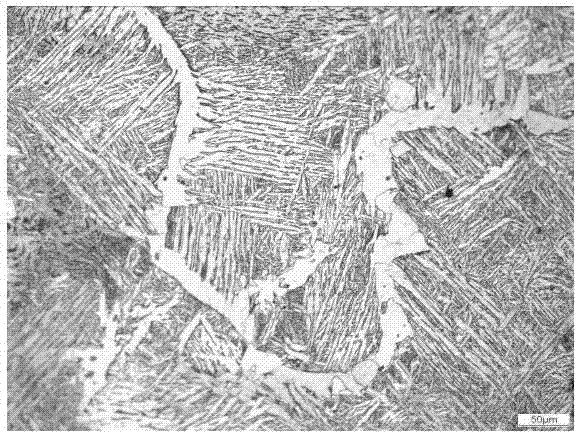

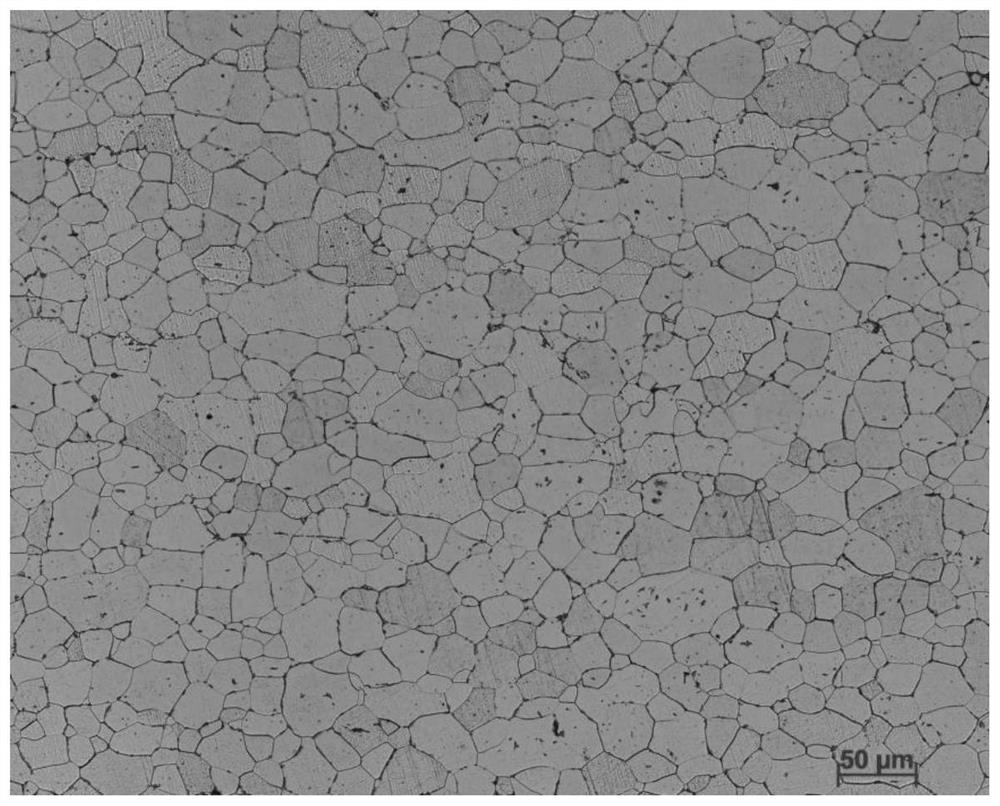

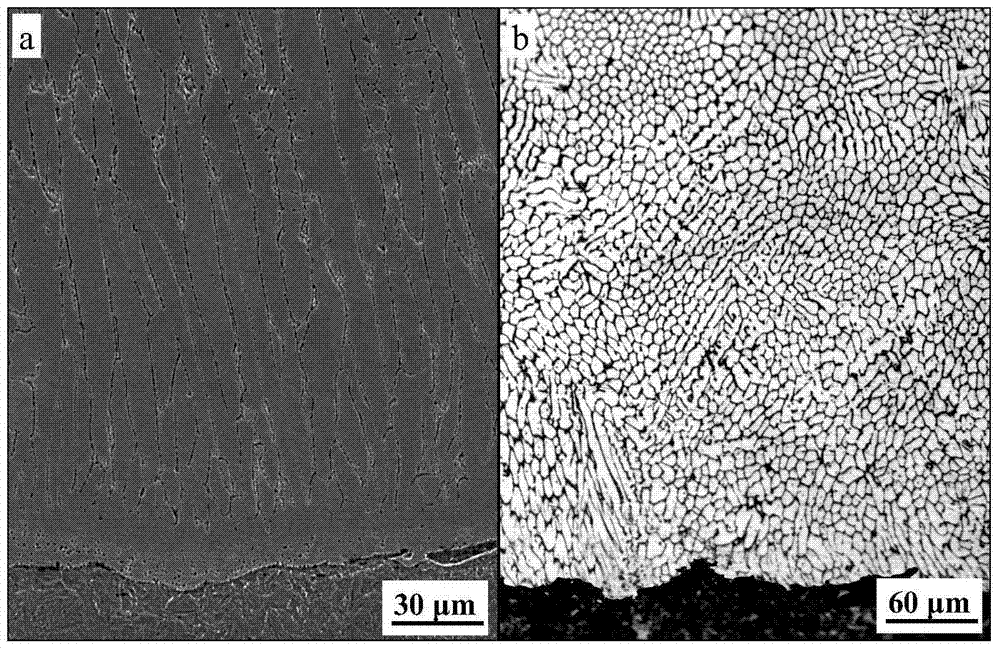

Method for compositely refining solidification structure of magnesium alloy by combination of current and Zr

The invention relates to a method for compositely refining a solidification structure of a magnesium alloy by combination of current and Zr. A Zr refiner is added in a smelting process of the magnesium alloy and current is introduced in a solidification process of the magnesium alloy till the magnesium alloy is solidified completely. The method provided by the invention comprises the specific steps of: (1) placing an electrode in a cast, and connecting the electrode with a power supply and pre-adjusting current parameters; (2) smelting the magnesium alloy by regular smelting, refining, drossing and peeling steps; (3) adding the Zr refiner till temperature of a mother solution of the magnesium alloy is adjusted to a predetermined temperature, and agitating and standing; and (4) pouring the mother solution of the magnesium alloy to the cast and turning on a power supply switch to introduce current from the beginning of pouring to complete solidication of the cast so as to obtain the refined solidification structure of the magnesium alloy. The method provided by the invention adopts a composite method which combines physical refining with chemical refining, is able to obtain the structure of the magnesium alloy with more smaller grains, more uniform structure and remarkably reduced deficiency, improves the mechanical property of the magnesium alloy, and is suitable for solidification and refining of the magnesium alloy.

Owner:SHANGHAI JIAO TONG UNIV

Method for adding nano particles into steel, refining structure and strengthening and toughening steel

The invention relates to a method for adding nano particles into steel, refining a structure and strengthening and toughening steel. The method comprises the following steps that firstly, the nano particles are pre-dispersed, oxide nano particles and pure metal nano powder are weighed and are mixed, and a mixture is subjected to pre-dispersing in a planetary ball grinder under the vacuum and liquid nitrogen cooling condition to obtain mixed nano powder; secondly, an aluminum-based intermediate is prepared, a medium-frequency induction furnace is adopted for heating and melting metal aluminum,the mixed nano powder is added, and under the joint effect of a spiral electromagnetic field and ultrasonic waves, the mixed nano powder is dispersed in the molten aluminum to obtain the aluminum-based intermediate; and thirdly, the nano particles are added, in the deoxidized alloying process in the RH refining later period, silicon, manganese, aluminum or alloy of silicon, manganese and aluminumis adopted for deoxidizing the molten steel, the aluminum-based intermediate is added, and in the continuous casting production process, a continuous casting blank with the nano particles evenly distributed is prepared. Aluminum alloying is achieved, and after aluminum dissolving, the nano particles are released to be dispersed in the molten steel.

Owner:ANGANG STEEL CO LTD

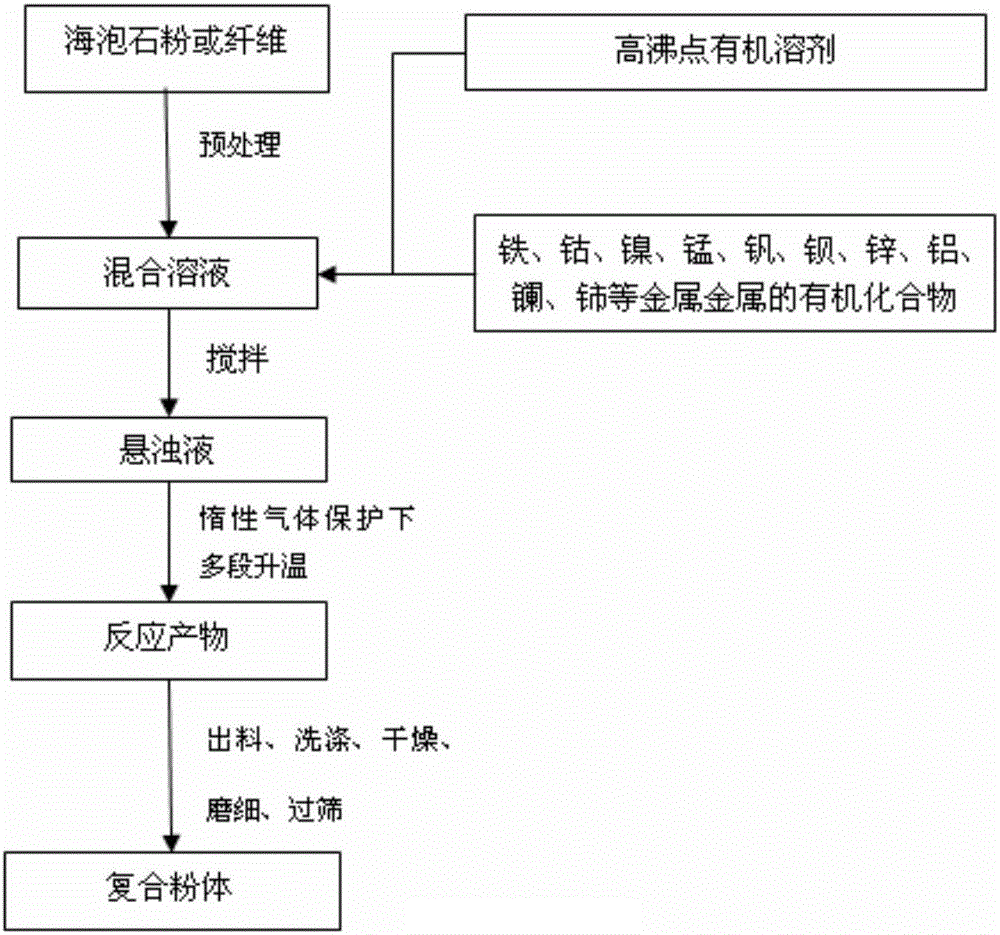

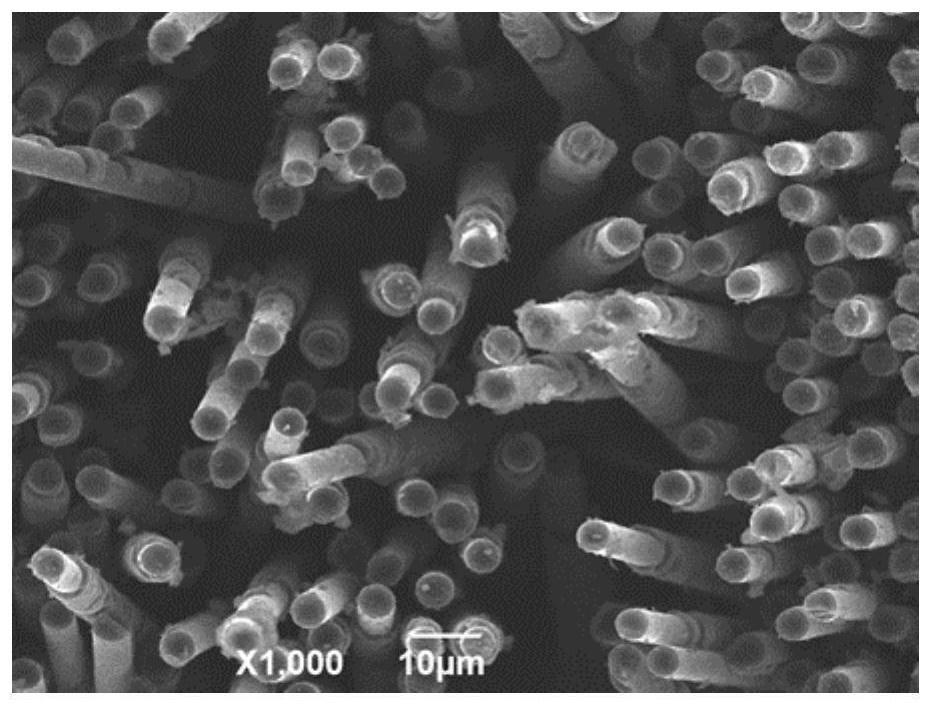

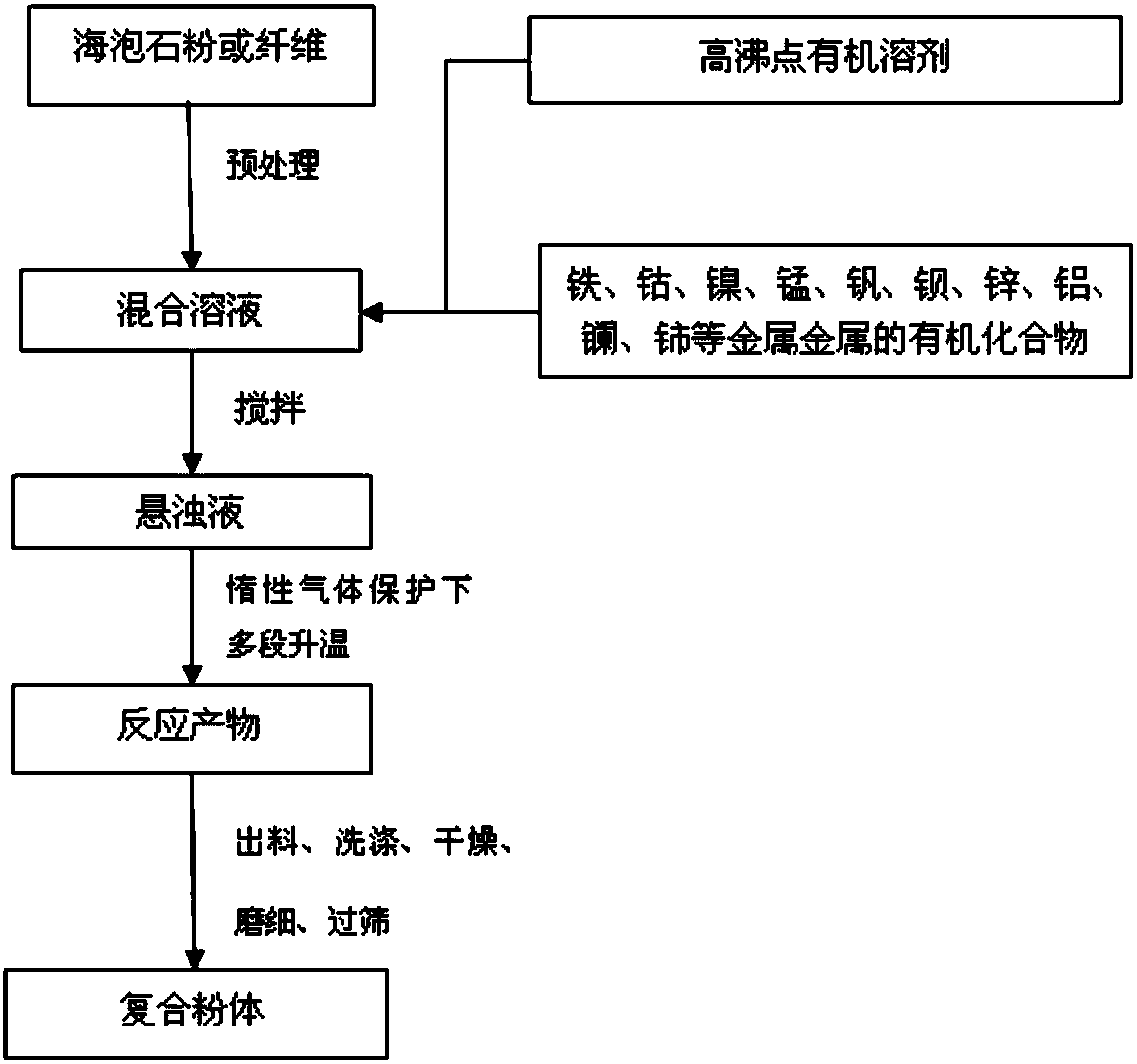

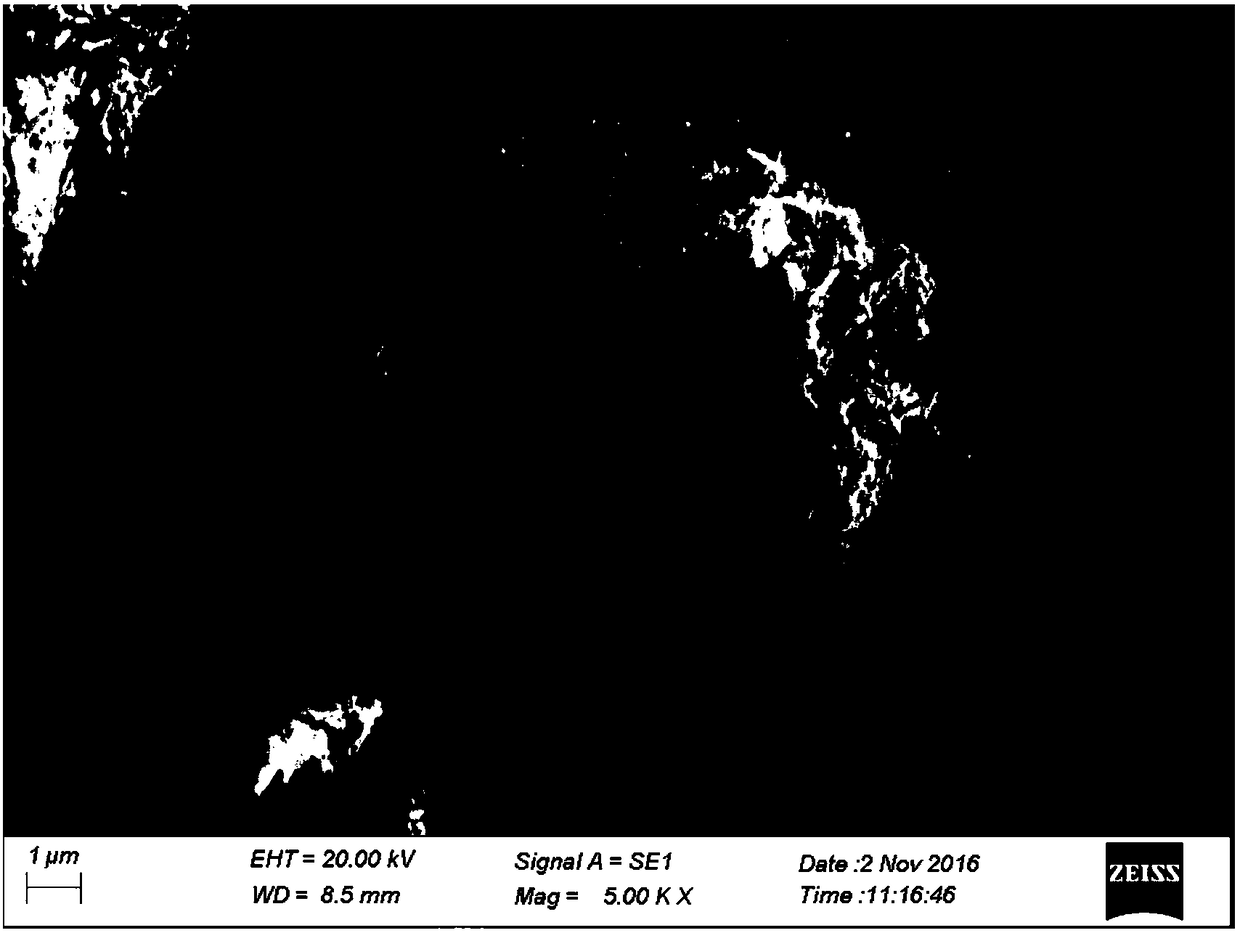

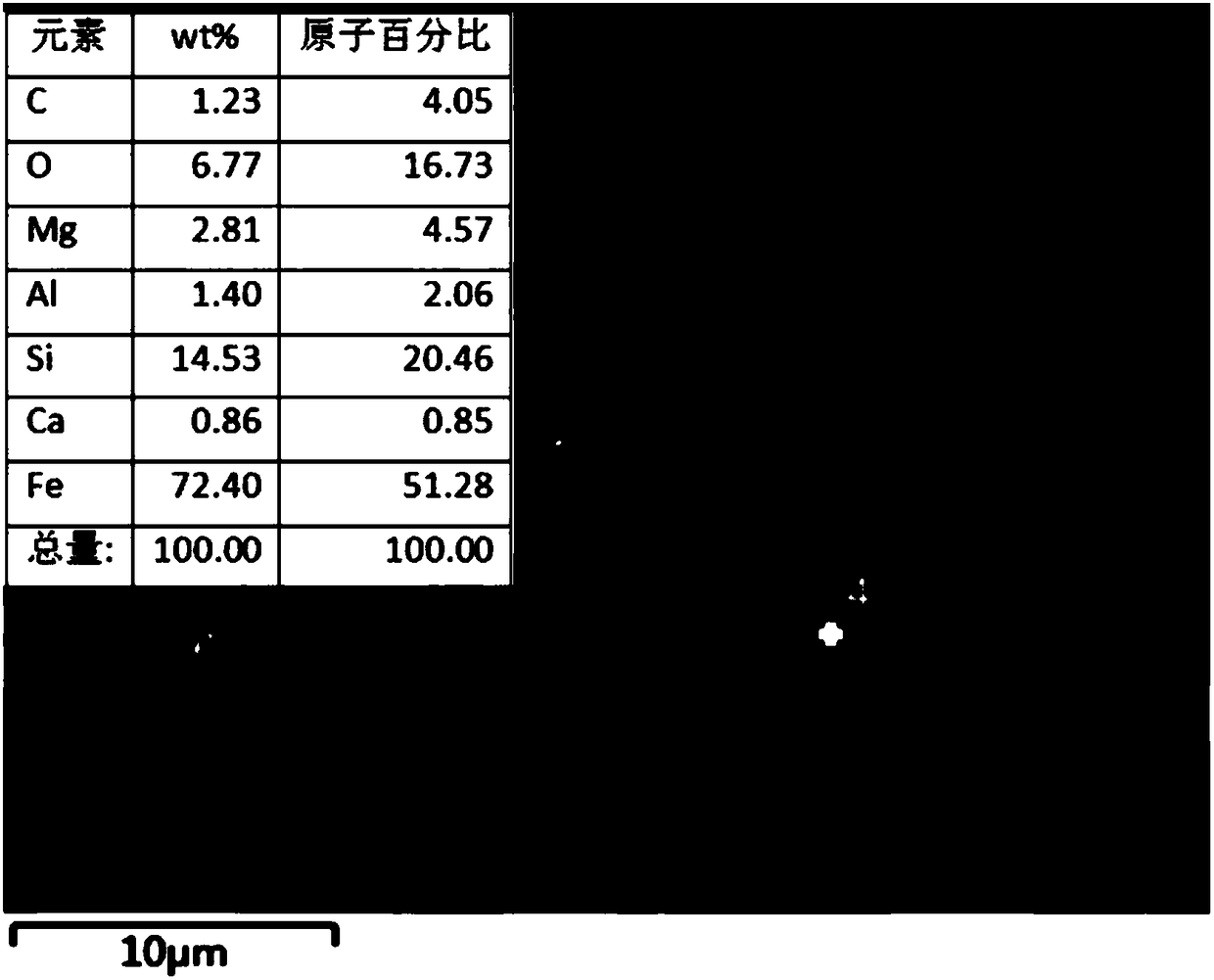

Preparing method for load magnetic metal sepiolite composite powder or fiber

ActiveCN106583752AGood adsorptionIncrease loadTransportation and packagingMetal-working apparatusSilane couplingSepiolite

The invention discloses a preparing method for load magnetic metal sepiolite composite powder or fiber. The method includes the steps that sepiolite powder or sepiolite fiber is fired or placed in a silane coupling agent to be soaked, and pretreated sepiolite powder or sepiolite fiber is obtained; and the pretreated sepiolite powder or sepiolite fiber is mixed with a magnetic metal organic matter solution, then the mixture is sealed in a reaction kettle to be subjected to a pyrolytic reaction, and the load magnetic metal sepiolite composite powder or fiber is obtained. Magnetic metal in the prepared composite material is evenly distributed in the surface or pores of sepiolite, the magnetic metal load is high, and the electromagnetic matching performance of the material can be adjusted according to the load and the metal ratio. The preparing method is simple in technology and low in cost, and large-scale production is facilitated.

Owner:CENT SOUTH UNIV

Method for performing thermal treatment on zirconium alloy

InactiveCN102586709AIncreased nucleation rate and growth rateGreat driving forceZirconium alloyCrystallite

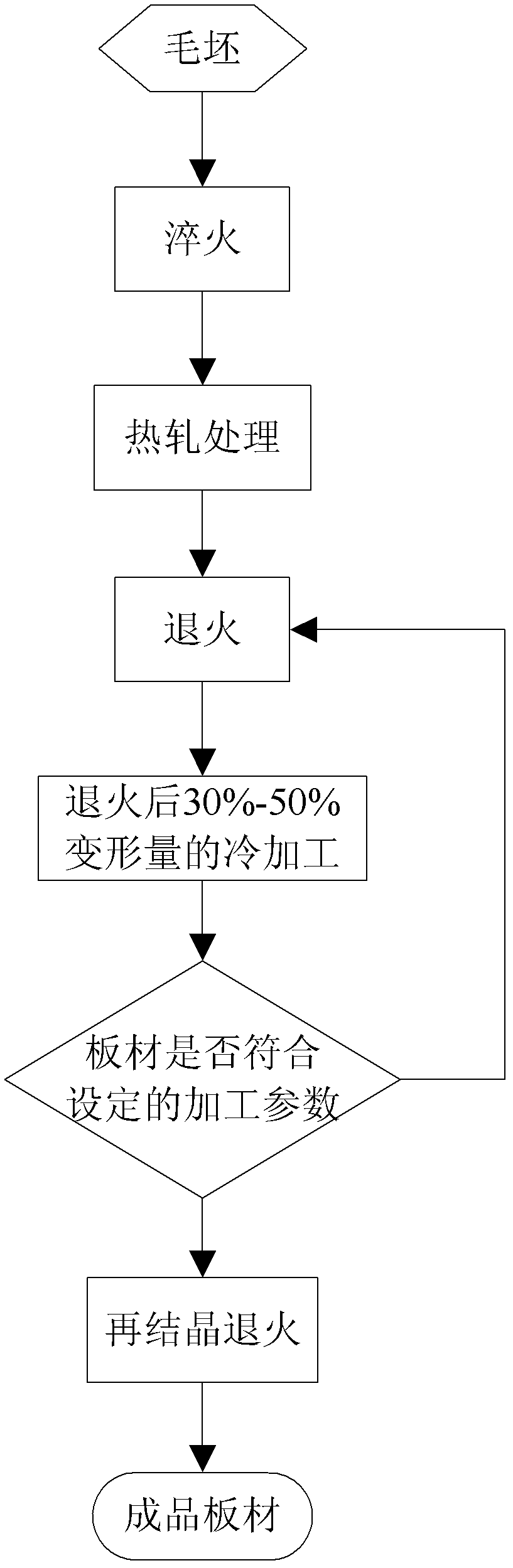

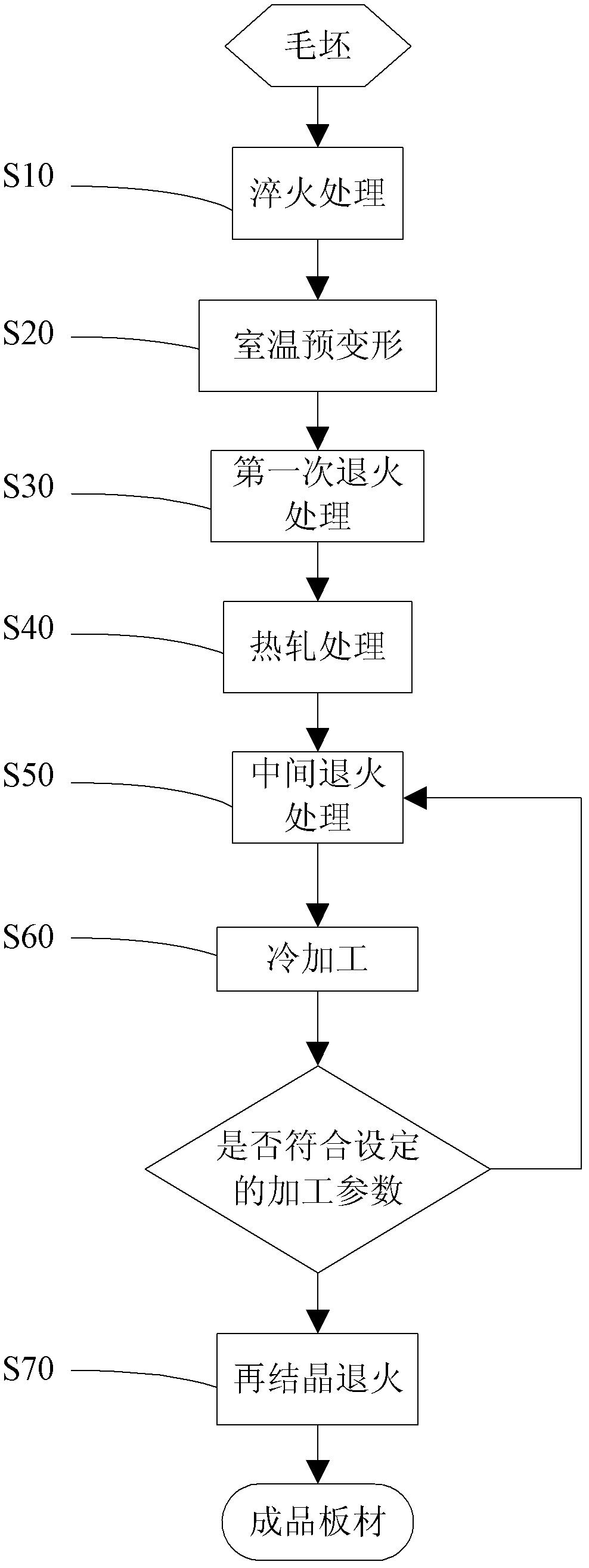

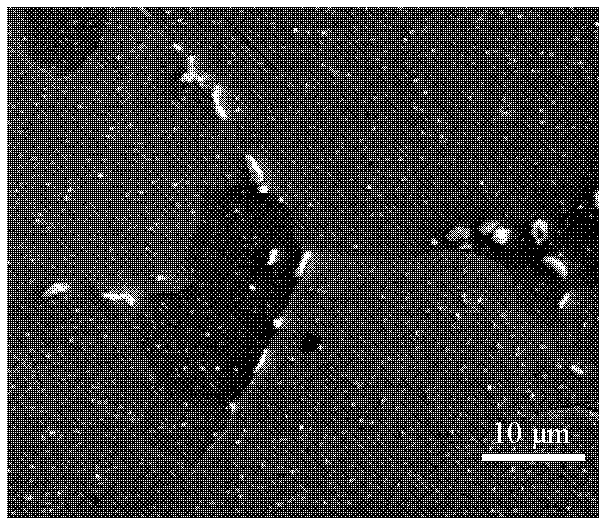

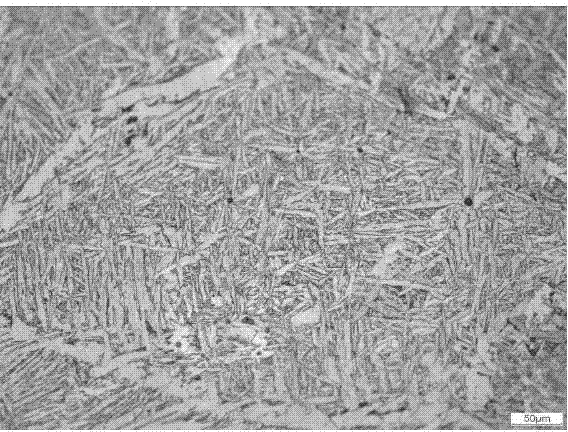

The invention discloses a method for performing thermal treatment on zirconium alloy. The method comprises the following steps of: firstly, quenching a zirconium alloy blank to obtain a quenched blank; secondly, cooling the quenched blank to room temperature, and deforming the quenched blank until the deformation degree is 5 to 30 percent, namely pre-deforming the quenched blank at room temperature to obtain a pre-deformed blank; heating the pre-deformed blank to 350 to 700 DEG C, and annealing for 0.2 to 30 hours for the first time; thirdly, performing hot-rolling on the pre-deformed blank; fourthly, annealing repeatedly, and performing cold machining to obtain a plate; and finally, re-crystallizing and annealing the plate to obtain the finished product plate. Compared with the traditional method for performing thermal treatment on the zirconium alloy, the method for performing thermal zirconium alloy fulfils the aim of distributing second phase particles of the zirconium alloy in a dispersing way and improving the size uniformity of crystal particles of the zirconium alloy.

Owner:CHONGQING UNIV

Modified high-efficiency crystalline silicon solar cell and preparation method thereof

InactiveCN108695009AImprove conversion efficiencyReduced series resistanceFinal product manufactureConductive materialSolar lightSilicon solar cell

The invention discloses a modified high-efficiency crystalline silicon solar cell comprising a crystalline silicon substrate. The front side and back side of the crystalline silicon substrate are respectively printed with an environment-friendly conductive silver paste and a high-performance crystalline silicon solar back-field aluminum slurry by means of silk-screen printing; and then drying andsintering are carried out to form a silver grid line electrode and an aluminum back field. Compared with the prior art, the modified high-efficiency crystalline silicon solar cell has the following beneficial effects: the environment-friendly conductive silver paste uses ultra-fine silver oxide and micron silver powder for compounding, so that the resistivity is reduced; the micron silver powder has the large tap density and high sintering activity; for the high-performance back-field aluminum slurry, several kinds of aluminum powder and metal magnesium powder with different average grain sizes are used for compounding, so that the contact between the aluminum paste and the suede-like silicon wafer is improved; the wettability and interface bonding force with the aluminum liquid are enhanced by using the improved carbon nano tube; the short-circuit current and open-circuit voltage are increased; the laminated passivation film is deposited on the back side of the silicon wafer based onthe traditional process, so that the good passivation effect is realized; and the suede and the anti-reflection film are prepared on the front side of the silicon wafer, so that the solar light absorption is prompted.

Owner:江苏昊科汽车空调有限公司

Method for optimizing steel structure by adding nano particles into steel liquid

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

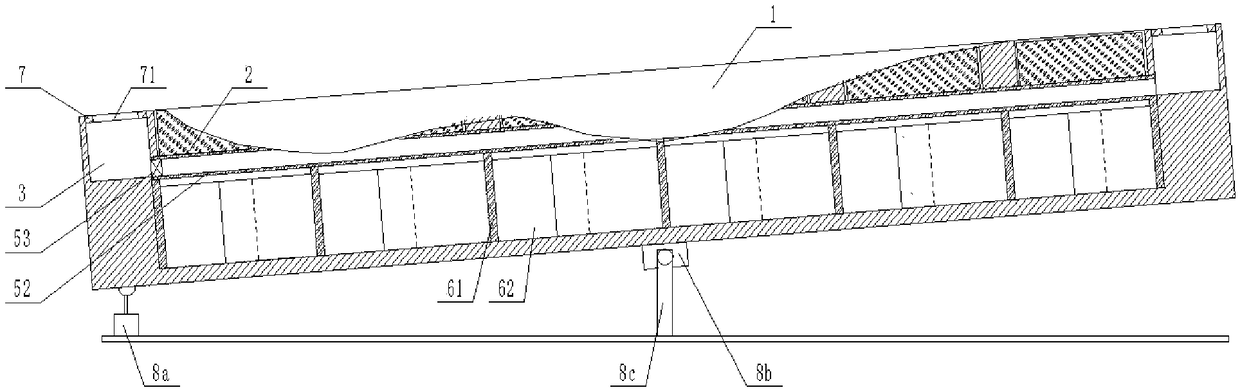

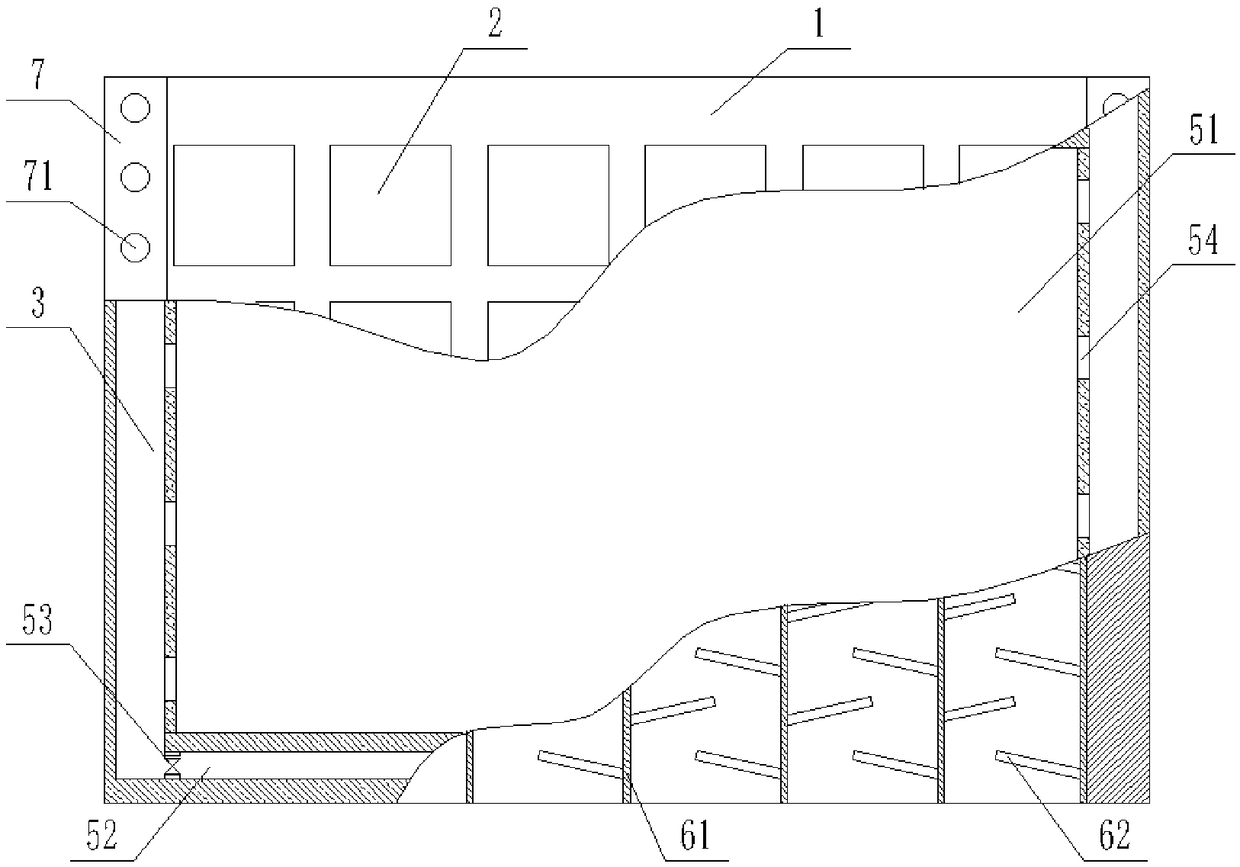

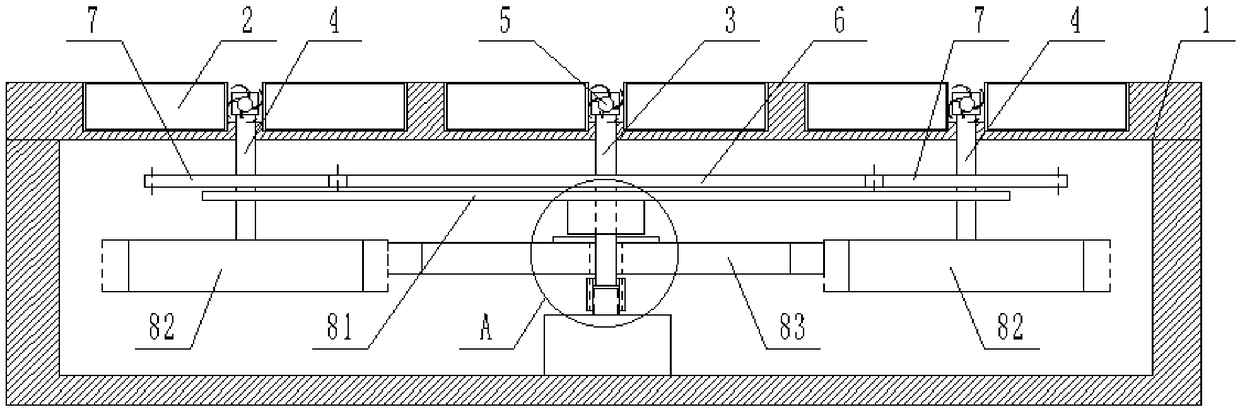

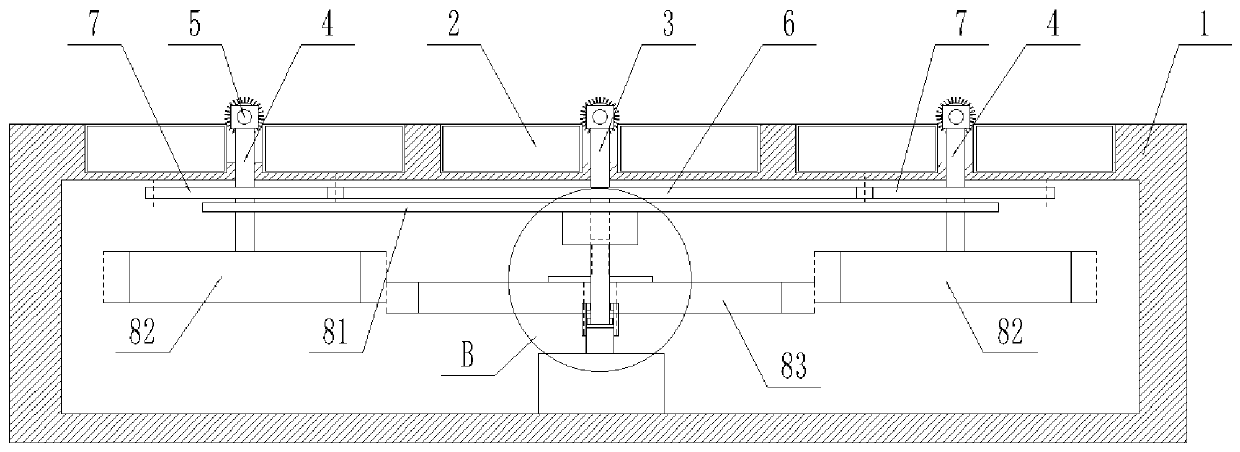

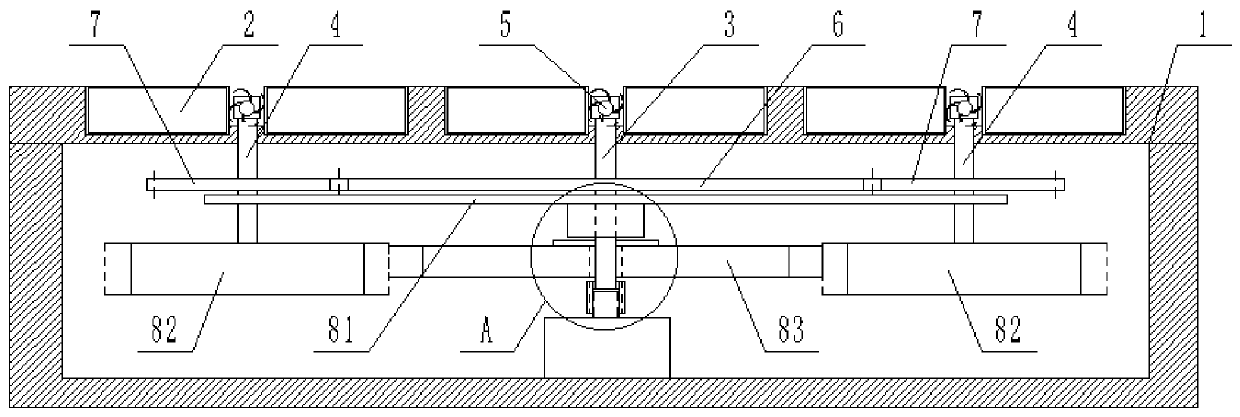

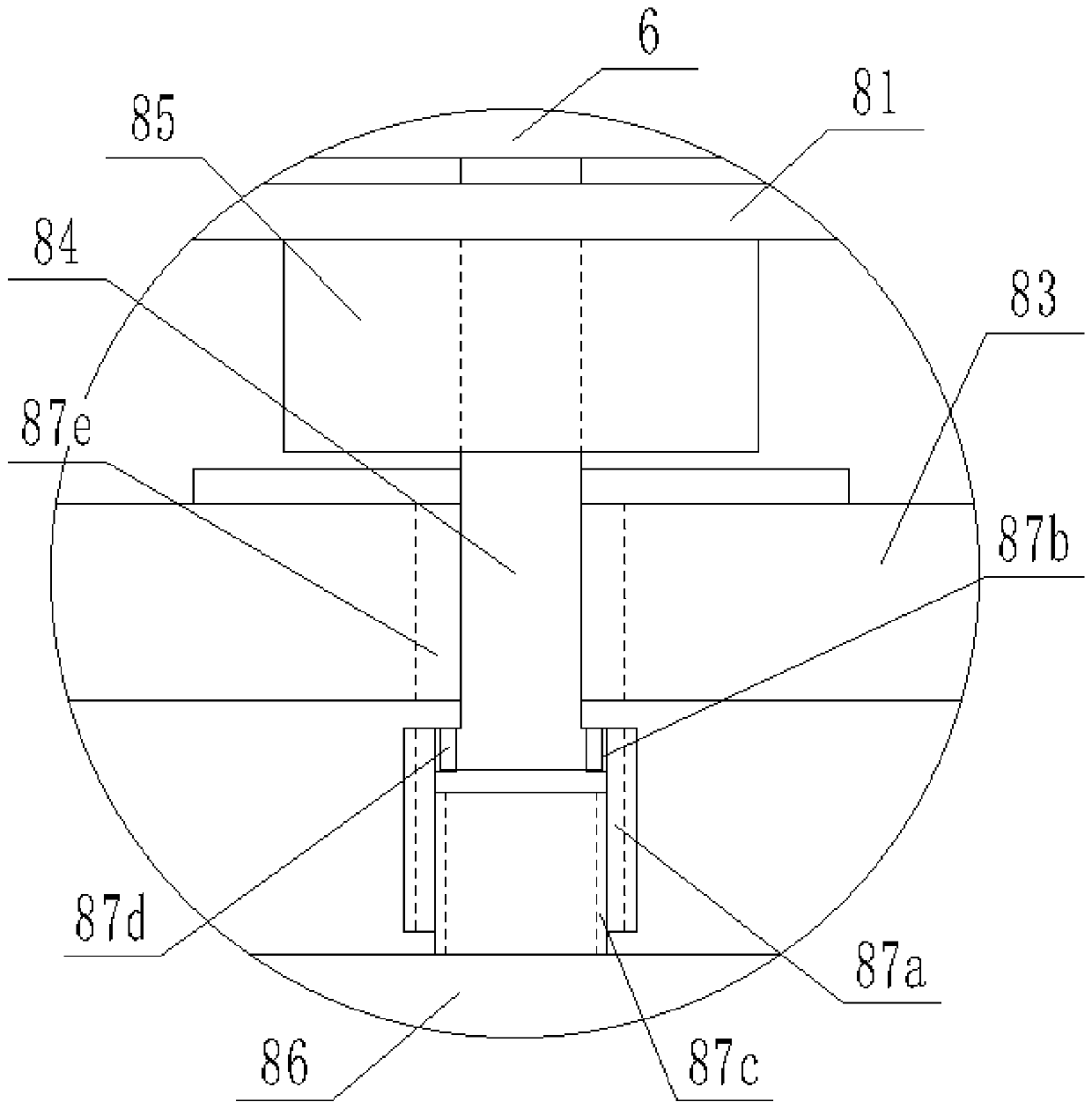

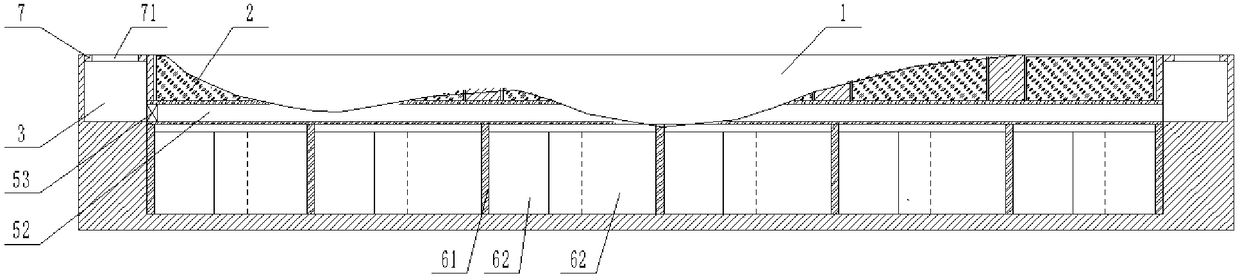

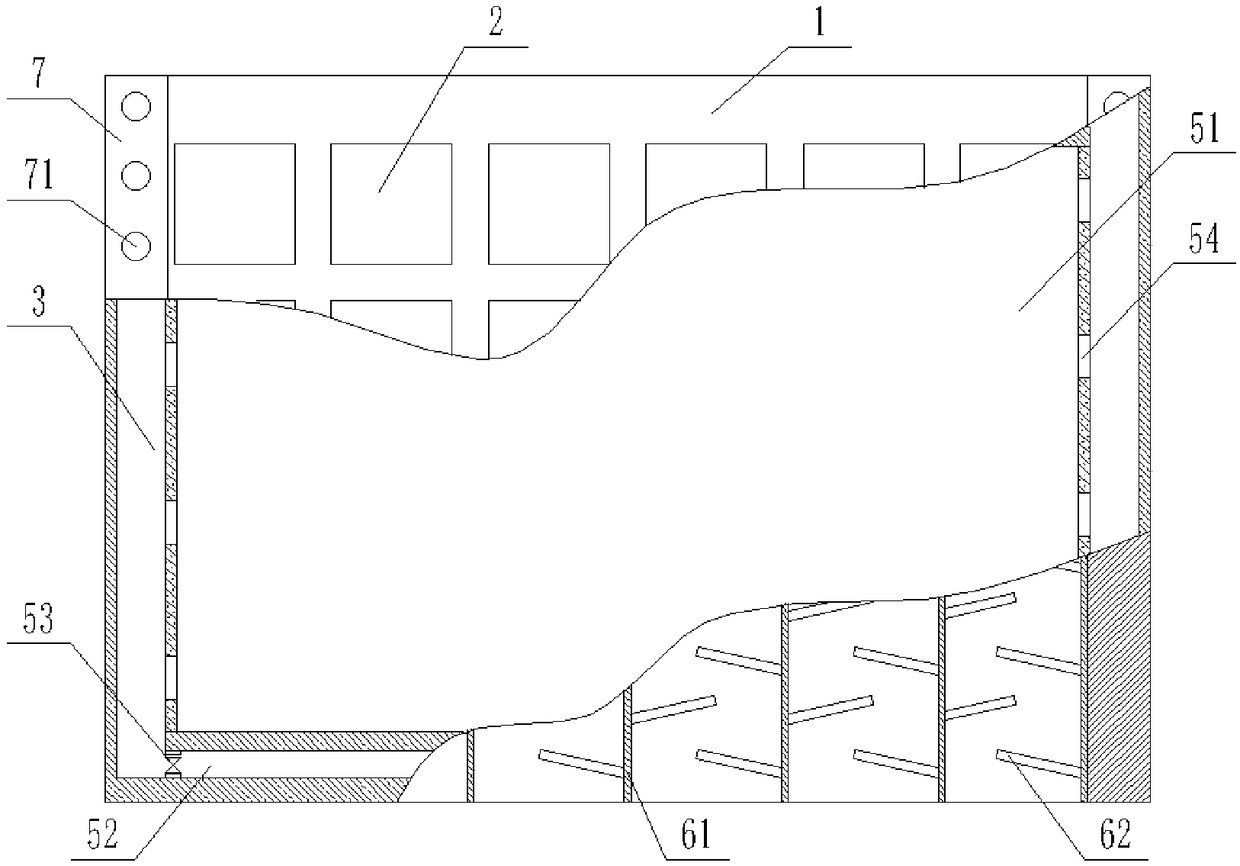

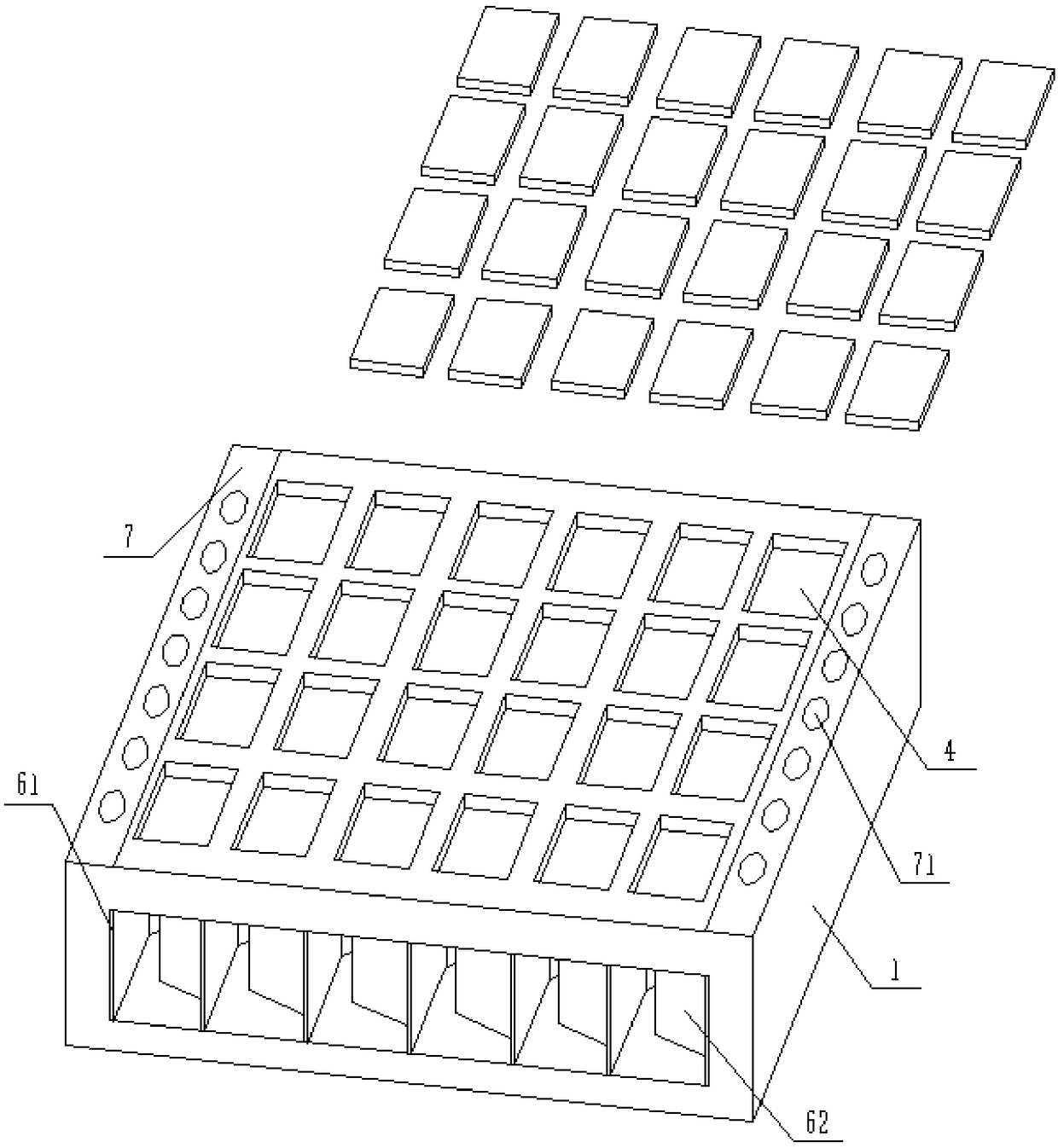

Photovoltaic panel with dual circulation cooling function

InactiveCN108667423AReduce the temperatureEfficient and long-life workCarbon compoundsPhotovoltaicsEngineeringGas cooling

The invention discloses a photovoltaic panel with a dual circulation cooling function. The photovoltaic panel comprises a mounting base and a plurality of solar cell pieces, and strip-shaped water collecting grooves are vertically formed in the mounting base oppositely; a liquid cooling unit and a gas cooling unit are arranged in the mounting base; the solar cell pieces, the liquid cooling unit and the gas cooling unit are sequentially connected from top to bottom, and the two strip-shaped water collecting grooves are communicated with the liquid cooling unit separately; the flow direction ofa medium in the liquid cooling unit and the flowing direction of a medium in the gas cooling unit are perpendicular to each other, and a turnover assembly is arranged below the mounting base. Comparedwith the prior art, the photovoltaic panel is compact in structure, rainwater circulation cooling and the cool air circulation cooling are efficiently combined, the temperature of a solar cell backboard is effectively reduced, and the cooling efficiency is integrally improved, so that the power generation efficiency of a solar cell panel is improved, and the service life of the solar cell panel is prolonged; the resistance of series connection cells of the solar cell pieces is low, the photoelectric conversion efficiency is high, the surface is flat and smooth, the adhesive force is good, thewarping curvature is low, and application prospects are wide.

Owner:江苏昊科汽车空调有限公司

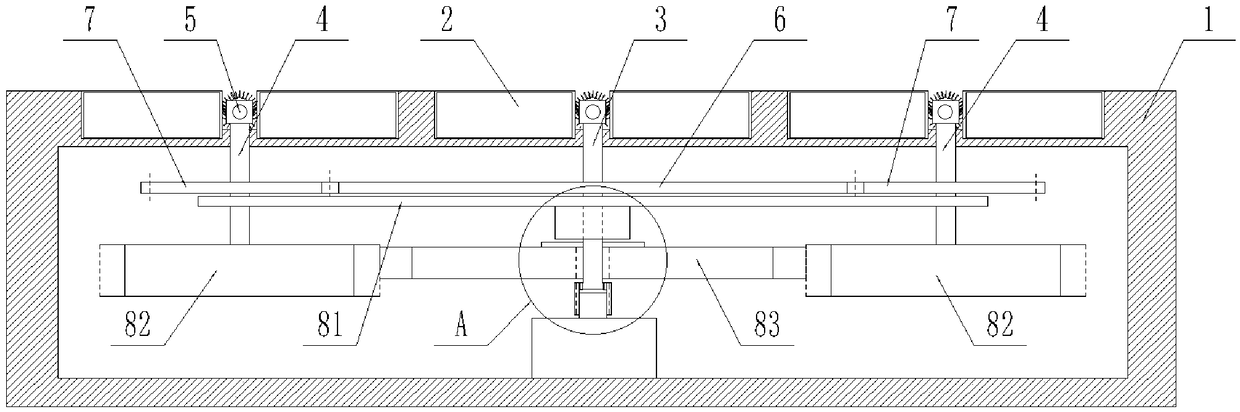

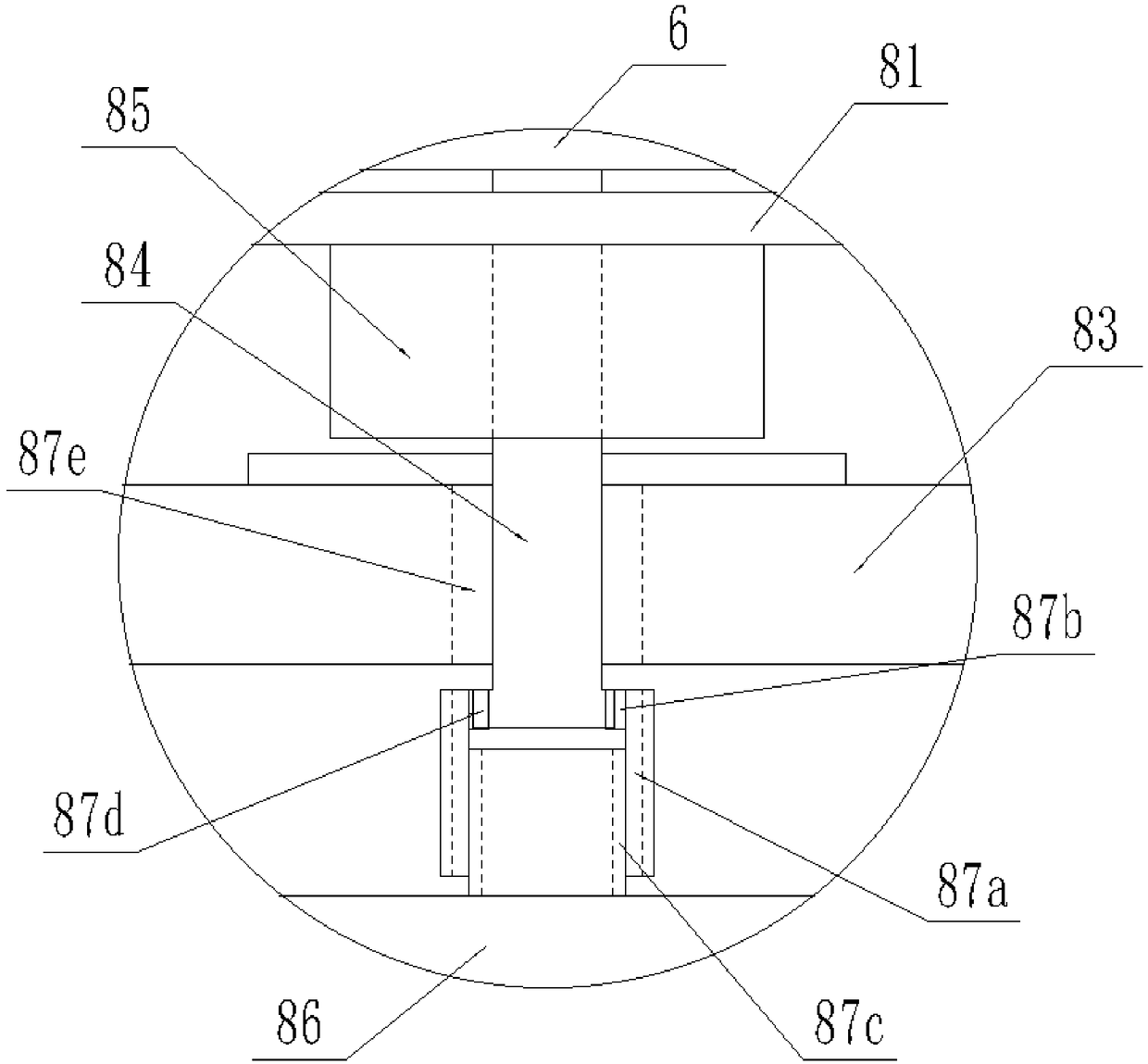

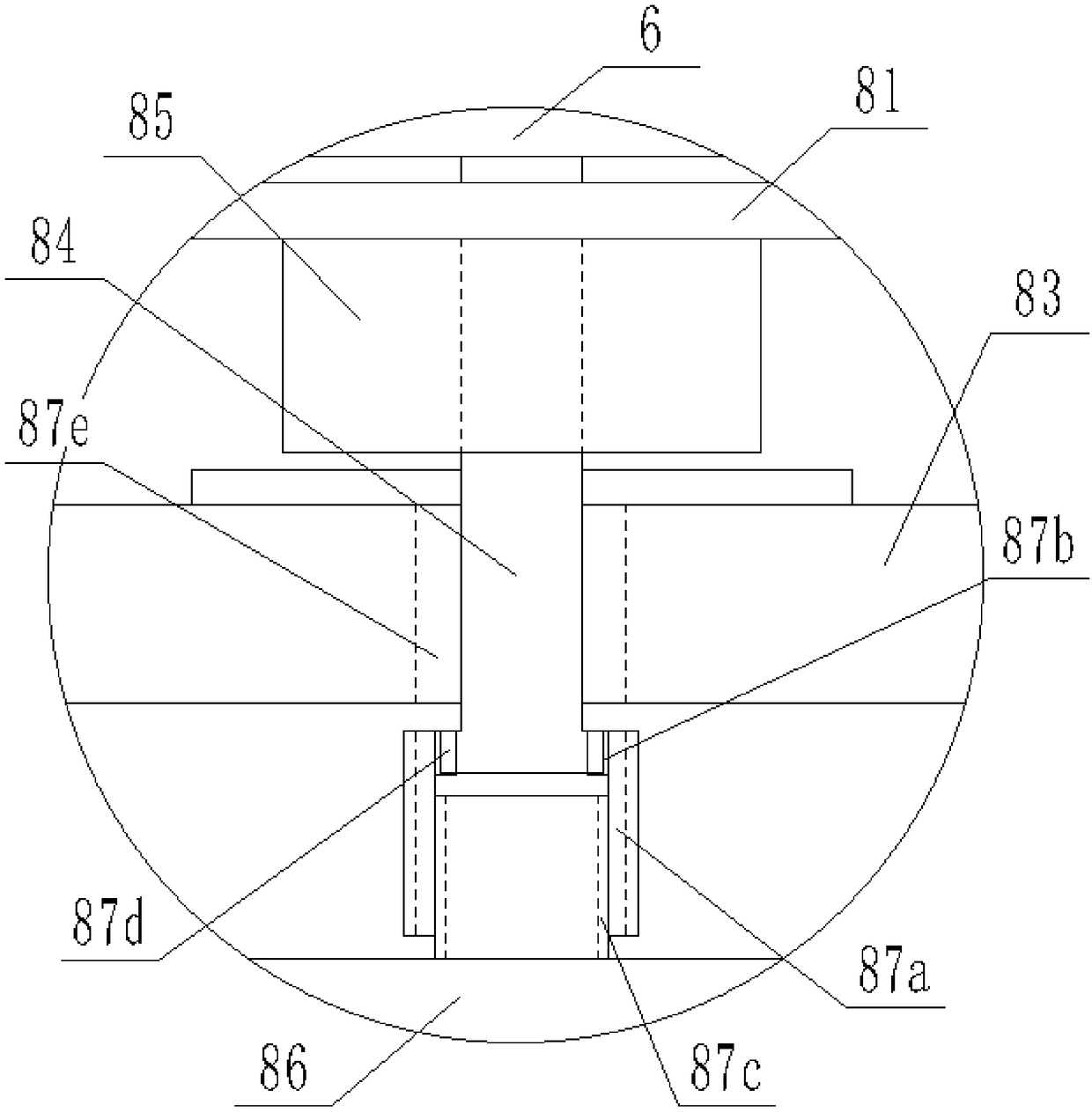

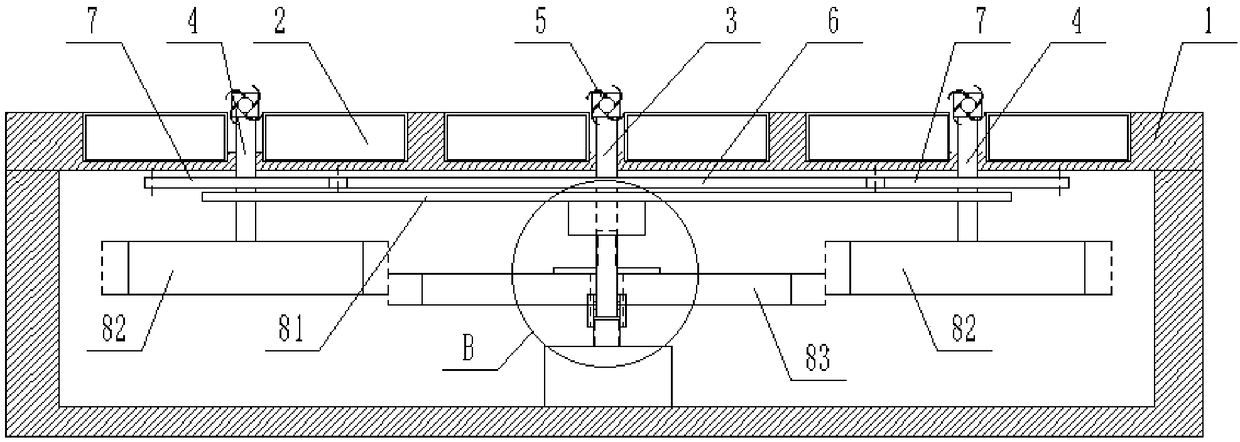

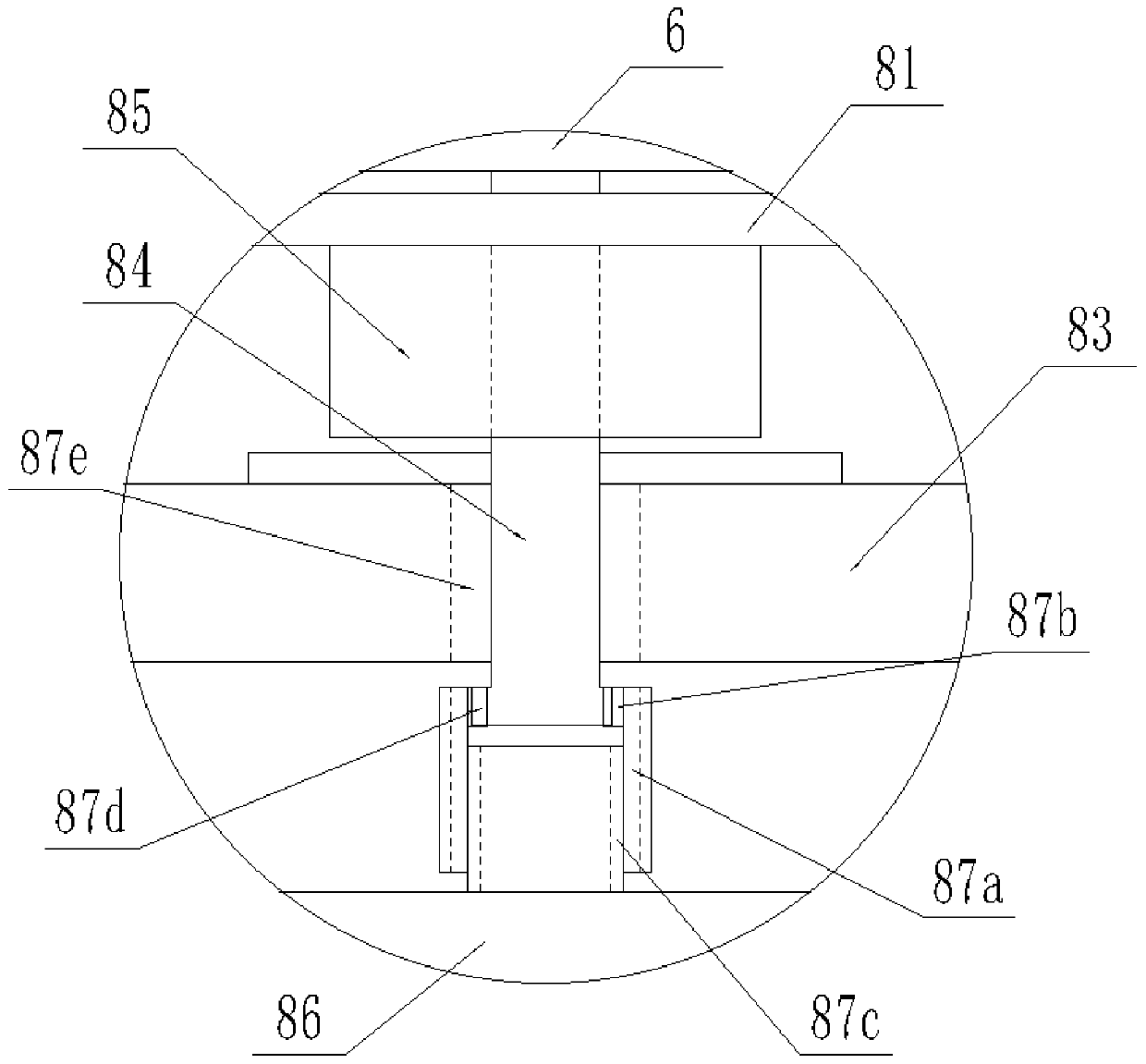

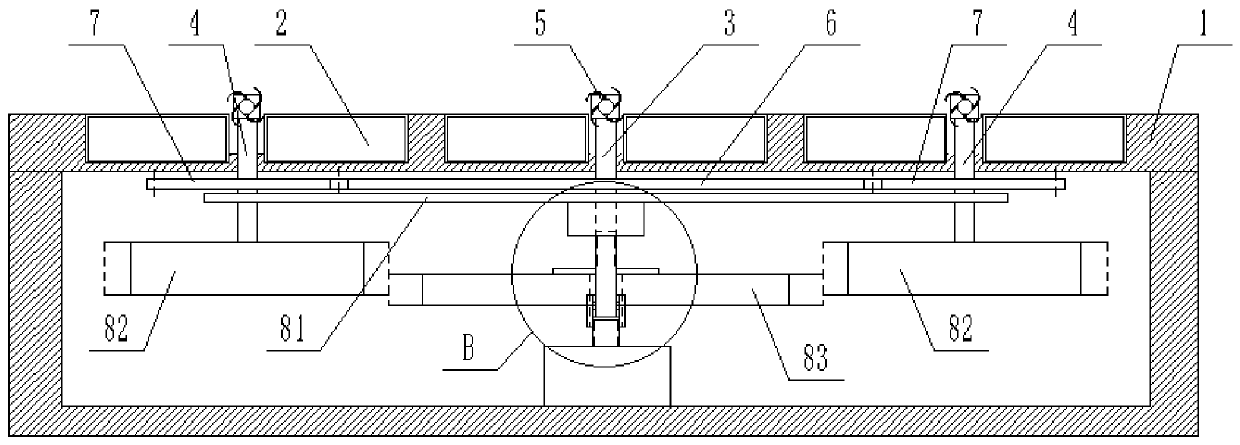

Intelligently cleaned solar energy acquisition device

ActiveCN108900155AAvoid warpingImprove efficiencyPhotovoltaicsCleaning using toolsElectrical resistance and conductanceEnergy conversion efficiency

The invention discloses an intelligently cleaned solar energy acquisition device. The device comprises an installation seat. Multiple solar energy cell sheets are installed on the installation seat. Amain rotation shaft and at least one auxiliary rotation shaft are vertically arranged in the installation seat in a penetrating manner. Upper ends of the main rotation shaft and the auxiliary rotation shafts stretch out of the installation seat and are horizontally connected with cleaning strip brushes and lower parts stretch into the installation seat and are fixedly sleeved in first active gears and first driven gears. The first active gears are engaged to the first driven gears. Lower ends of the main rotation shaft and the auxiliary rotation shafts are connected with elevating rotation adjustment assemblies. Compared with the prior art, the device is simple in structure; by highly efficiently combining elevating driving and rotation driving, all-directional cleaning of the surface ofa solar cell plate and storage of cleaning tools can be stably and reliably achieved; complexity of the device is reduced; cost is reduced; energy conversion efficiency is improved; serial connectionresistance of cells of solar cell sheets is low; photoelectric conversion efficiency is high; the surface is flat and smooth; adhesion performance is high; bending rate is low; and the device has profound application prospects.

Owner:赫冉新能源科技扬州有限公司

Preparation method of magnesium/L-polylactic acid composite bone scaffold

ActiveCN108721702AImprove bindingPromote proliferationTissue regenerationProsthesisSelective laser sinteringBiological property

The invention discloses a preparation method of a magnesium / L-polylactic acid composite bone scaffold. The preparation method comprises the following steps: mixing L-polylactic acid powder, magnesiumpowder and amphiphilic phospholipid powder are mixed through liquid phase mixing, then performing solid-liquid separation, and drying and grinding a solid to obtain composite powder; preparing the composite bone scaffold from the composite powder through a selective laser sintering technology. By the preparation method, due to relatively good binding ability between amphiphilic molecular phospholipid and metal magnesium and between the amphiphilic molecular phospholipid and L-polylactic acid, interfacial performance between the metal magnesium and a polymer L-polylactic acid is improved, and the biological properties and the mechanical properties of the magnesium / L-polylactic acid composite bone scaffold are improved.

Owner:西安勃奥生物科技有限公司

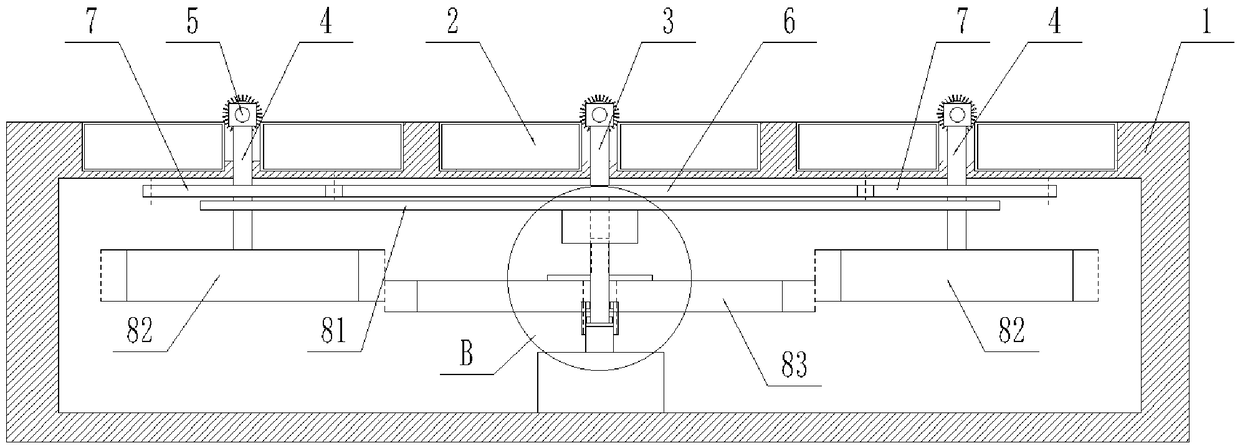

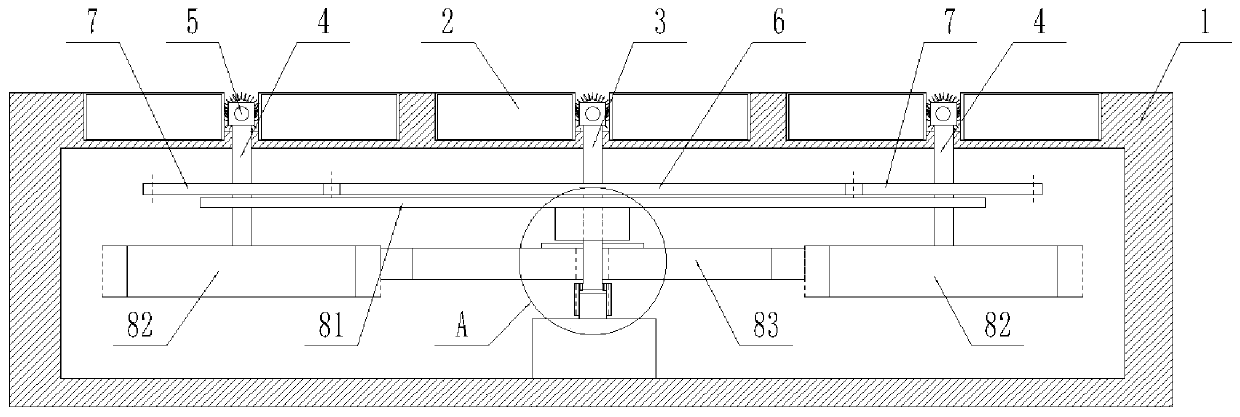

Rotatablely cleaned photovoltaic power generation device

ActiveCN108900156ASimple structureTo achieve the purpose of cleaningPhotovoltaicsCleaning using toolsElectrical resistance and conductanceSlurry

The invention discloses a rotatablely cleaned photovoltaic power generation device. The device comprises an installation seat. Multiple solar cell sheets are installed on the installation seat. Each solar cell sheet comprises a silicon sheet printed with back field aluminum slurry. A main rotary shaft and at least one auxiliary rotary shaft are vertically arranged in the installation seat in a penetrating manner. The upper ends of the main rotary shaft and the auxiliary rotation shafts stretch out of the installation seat and are horizontally connected with a cleaning strip brush. The lower ends of the main rotary shaft and the auxiliary rotation shafts are connected with an elevating rotation adjustment assembly. Compared with the prior art, the device is compact in structure; by highly efficiently combining the elevating driving and the rotary driving, all-directional cleaning of the surface of a solar cell plate and storage of cleaning tools can be stably and reliably achieved; complexity of the device is reduced; and a flexible scraping sheet on the cleaning strip brush rotates along with the shaft, so a cleaning process is automatically finished. Thus, cost is reduced; energyconversion efficiency is improved; the serial connection resistance of cells of the solar cell sheets is low; the photoelectric conversion efficiency is high; the surface is flat and smooth; the adhesive force is good; the bending rate is low; and the device has excellent application prospects.

Owner:赫冉新能源科技扬州有限公司

High-performance crystalline silicon solar back field aluminum paste and preparation method thereof, and crystalline silicon solar cell prepared from high-performance crystalline silicon solar back field aluminum paste

InactiveCN108877988AImprove efficiencyIncrease contactNon-conductive material with dispersed conductive materialPhotovoltaic energy generationModified carbonSilicon solar cell

The invention discloses high-performance crystalline silicon solar back field aluminum paste and a preparation method thereof, and a crystalline silicon solar cell prepared from the high-performance crystalline silicon solar back field aluminum paste. The high-performance crystalline silicon solar back field aluminum paste is prepared from compound aluminum powder, a modified carbon nanotube, glass frit and an organic binder, wherein the compound aluminum powder is prepared by mixing spherical aluminum powder with the mean grain sizes of 2 microns, 5 microns and 8 microns and magnesium powderwith the mean grain size of 4 microns at the mass ratio of 1:(1-5):(7.2-8.0):(1-2.5). Compared with the prior art, the high-performance crystalline silicon solar back field aluminum paste has the advantages that the aluminum powder with different mean grain sizes is compounded with the metal magnesium powder and contact between the aluminum paste and a textured silicon wafer is improved, so that reaction infiltration between aluminum liquid and the carbon nanotube is strengthened, a continuous compact coating is obtained from the carbon tube surface of the modified carbon nanotube, the wettability and the interface bonding force between the carbon nanotube and the aluminum liquid are improved and the high-performance crystalline silicon solar back field aluminum paste has high photoelectric conversion efficiency, good adhesive force, boiling resistance and low warp rate and has a broad application prospect.

Owner:YANGZHOU XINJING PHOTOVOLTAIC TECH

Smart and Clean Solar Harvesting Devices

ActiveCN108900155BAvoid warpingImprove efficiencyPhotovoltaicsCleaning using toolsRotational axisGear wheel

The invention discloses an intelligent and clean solar energy collection device, which includes a mounting base on which a plurality of solar cells are installed. A main rotation axis and at least one auxiliary rotation axis are vertically penetrated in the mounting base. The main rotation axis and The upper end of the auxiliary rotating shaft extends out of the mounting base and is connected horizontally with a cleaning strip brush respectively. The lower part extends into the mounting base and is respectively fixed with a first driving gear and a first driven gear. The first driving gear and the first driven gear are respectively fixed. Engagement, the lower ends of the main rotation shaft and the auxiliary rotation shaft are connected with lifting rotation adjustment components. Compared with the existing technology, the present invention has a compact structure, efficiently combines the lifting drive and the rotation drive, and can stably and reliably realize all-round cleaning of the surface of the solar panel and the storage of cleaning tools, reduce the complexity of the equipment, and save costs. Improve energy conversion efficiency, solar cells have low series resistance, high photoelectric conversion efficiency, flat and smooth surface, good adhesion, low warpage, and have broad application prospects.

Owner:赫冉新能源科技扬州有限公司

Photovoltaic power generation device that can be rotated and cleaned

ActiveCN108900156BSimple structureTo achieve the purpose of cleaningPhotovoltaicsCleaning using toolsSilicon chipMechanical engineering

The invention discloses a rotatable and clean photovoltaic power generation device, which includes a mounting base. A plurality of solar cells are installed on the mounting base. The solar cells include silicon wafers printed with back field aluminum slurry. The mounting base is vertically penetrated. There is a main rotating shaft and at least one auxiliary rotating shaft. The upper ends of the main rotating shaft and the auxiliary rotating shaft extend out of the mounting base and are respectively connected horizontally with cleaning strip brushes. The lower ends of the main rotating shaft and the auxiliary rotating shaft are connected with a lifting and rotating adjustment assembly. Compared with the existing technology, the present invention has a compact structure and efficiently combines the lifting drive and the rotation drive. It can stably and reliably realize all-round cleaning of the surface of the solar panel and the storage of cleaning tools, reduce the complexity of the equipment, and clean the strip brush. The flexible scraper on the machine automatically completes the cleaning process as the shaft rotates, saving costs and improving energy conversion efficiency. The series resistance of the solar cells is low, the photoelectric conversion efficiency is high, the surface is flat and smooth, the adhesion is good, the warpage rate is low, and it has a wide range of applications. application prospects.

Owner:赫冉新能源科技扬州有限公司

Cold-rolled enamelled steel for deep-drawing liner and manufacturing method thereof

ActiveCN113684413BExcellent anti-scale explosion performanceGood formabilityChemical compositionChemical element

The invention discloses a cold-rolled enamel steel for deep-drawing liner, which contains the following chemical elements in mass percentages: C: 0.02-0.06%, 0<Si≤0.08%, Mn: 0.1-0.7%, P≤ 0.055%, S≤0.03%, Al: 0.01‑0.07%, N: 0.002‑0.010%, B: 0.002‑0.009%, Ti: 0.002‑0.015%, Nb: 0.002‑0.012%, Cr: 0.01‑0.08%, And at least one of Cu, Ni and Mo, wherein Cu+Ni+Mo≤0.40%. In addition, the invention also discloses a manufacturing method of cold-rolled enamel steel for deep-drawing liner, which includes the steps: (1) smelting, refining and continuous casting (2) slab heating (3) hot rolling and coiling (4) ) Pickling (5) Cold rolling: Control the cold rolling reduction rate to 60-70% (6) Continuous annealing: Soaking temperature is 800-830°C, soaking time is 100-150s, and over-aging temperature is 350-450 ℃, the over-aging time is 250‑350s(7). The cold-rolled enamel steel for deep-drawing liner of the present invention adopts reasonable chemical composition and process design, and has good formability, high strength after high-temperature enameling, excellent welding performance and excellent scale explosion resistance.

Owner:BAOSHAN IRON & STEEL CO LTD

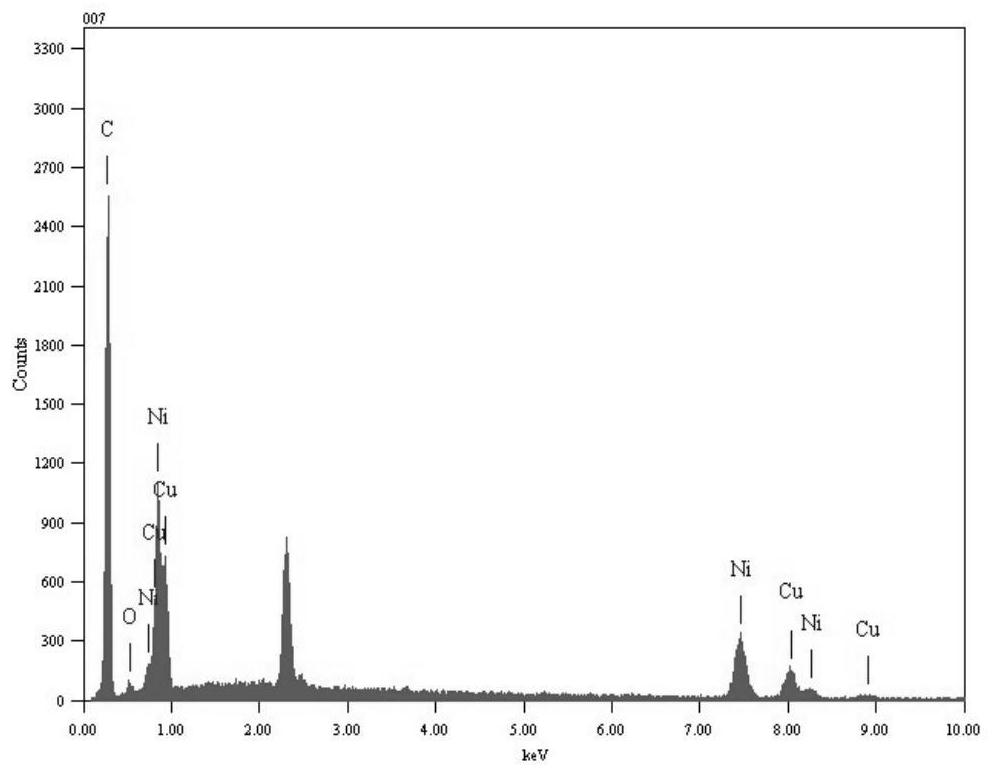

A kind of c/c-ni-cu composite material and its preparation method and application

ActiveCN110066972BAchieve densificationAchieve graphitizationPower current collectorsFiberCarbon layer

The present invention provides a preparation of C / C-Ni-Cu composite material and its preparation method and application. The method uses chopped carbon fiber as a skeleton, and adopts microwave hydrothermal reaction to deposit a carbon layer on the surface of the carbon fiber. Glucose is the carbon source. Nickel nitrate hydrate was used as the nickel source, and urea was used as the precipitating agent to deposit C and NiO particles in the carbon fiber preform by hydrothermal technology. The hydrothermally deposited C / C‑NiO composites were sintered by vacuum carbothermal reduction reaction to obtain C / C‑Ni composites, and the catalytic graphitization of matrix carbon was realized. Using the infinite mutual solubility of Ni and Cu, the C / C-Ni-Cu composite material was prepared by molten copper infiltration technology, and the C / C-Ni-Cu composite material with excellent performance was obtained.

Owner:SHAANXI UNIV OF SCI & TECH

A kind of preparation method of magnesium/L-polylactic acid composite bone scaffold

ActiveCN108721702BImprove bindingPromote proliferationTissue regenerationProsthesisSelective laser sinteringFluid phase

The invention discloses a preparation method of a magnesium / poly-L-lactic acid composite bone scaffold. The method comprises mixing poly-L-lactic acid powder, magnesium powder and amphiphilic phospholipid powder in a liquid phase, separating the solid from the liquid, and drying and grinding the solid. A composite powder is obtained; the composite powder is prepared by a selective laser sintering technology for a composite bone scaffold. The method utilizes the good binding ability between the amphiphilic molecule phospholipid and metal magnesium and poly-L-lactic acid to improve the interface performance between the metal magnesium and the polymer--poly-L-lactic acid, thereby improving the biological properties of the magnesium / poly-L-lactic acid composite bone scaffold. properties and mechanical properties.

Owner:西安勃奥生物科技有限公司

A kind of high-strength heat-resistant graphene-aluminum composite conductor material and preparation method thereof

ActiveCN110331316BAchieving Diffuse DistributionImprove thermal stabilityConductive materialMetal/alloy conductorsAl powderElectrical conductor

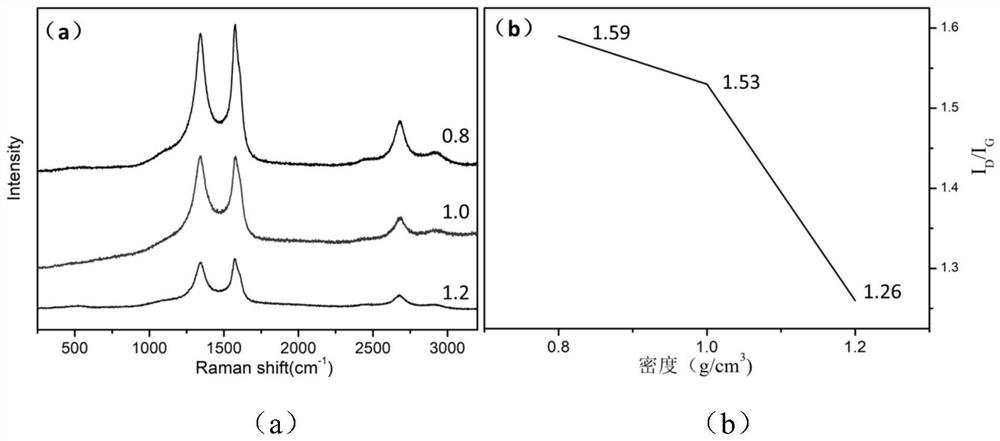

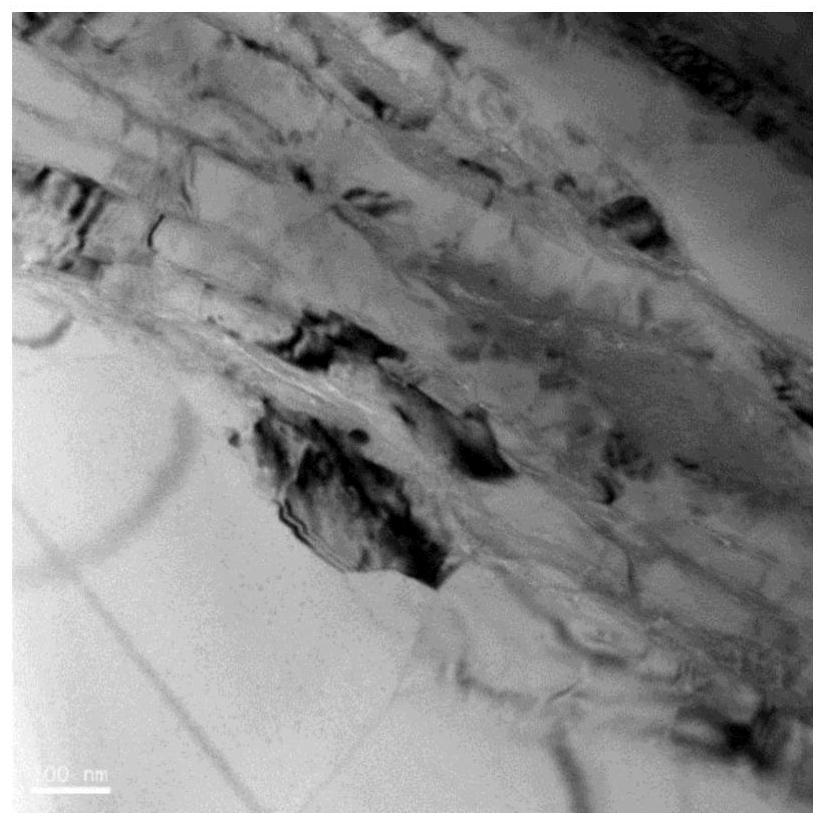

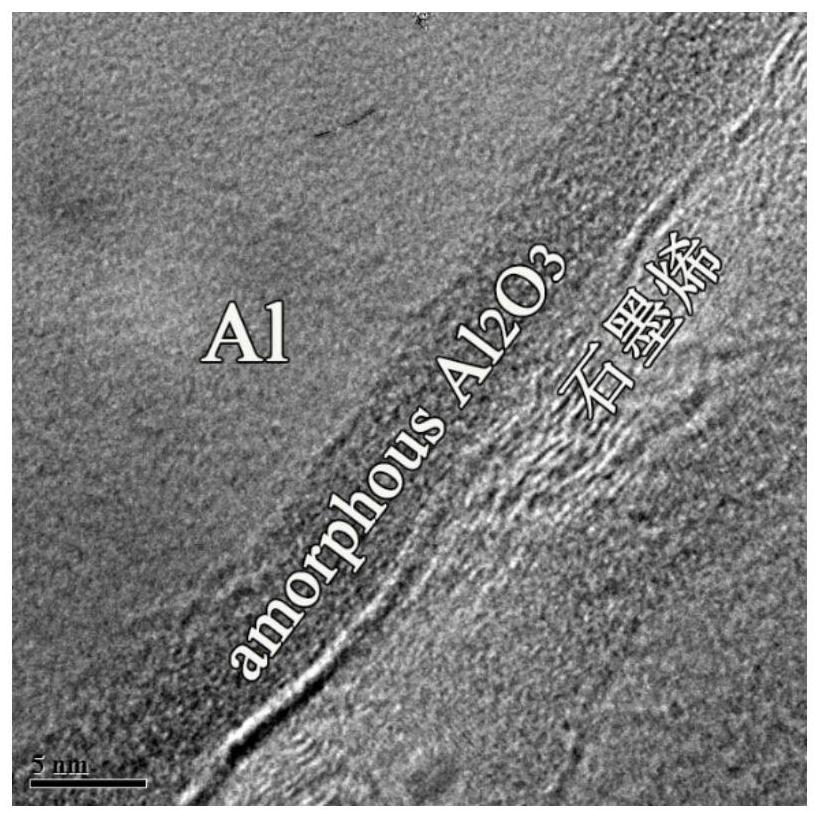

The invention provides a high-strength heat-resistant graphene-aluminum composite conductor material and a preparation method thereof. The composite conductor material is composed of the following components in mass percentage: graphene is 0.2-1%, and the rest is aluminum; powder and graphene powder are evenly mixed, and the weak oxygen content in the ball mill tank is used in the ball milling process to obtain uniform nano-scale amorphous Al on the surface of the aluminum powder 2 o 3 , and then the mixed powder is sintered to obtain a billet, and further deformed by extrusion or rolling to obtain a dense composite material. The present invention uses air as an oxygen source to react in situ to form dispersed amorphous Al 2 o 3 , effectively realized the dispersed distribution of nano-scale strengthening phase, combined with the thermal stability of high-strength and high-conductivity graphene, the composite material has good mechanical properties and heat resistance, and maintains good electrical conductivity. The tensile strength is greater than 250MPa, The highest reaches 328MPa.

Owner:SHANGHAI JIAOTONG UNIV

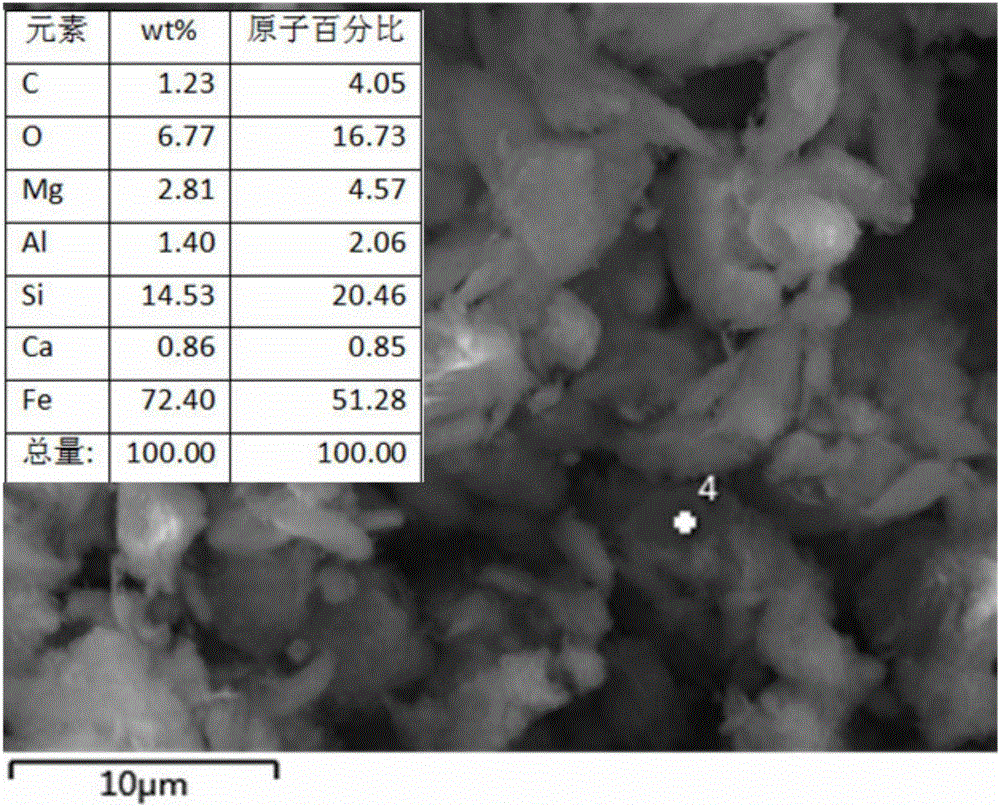

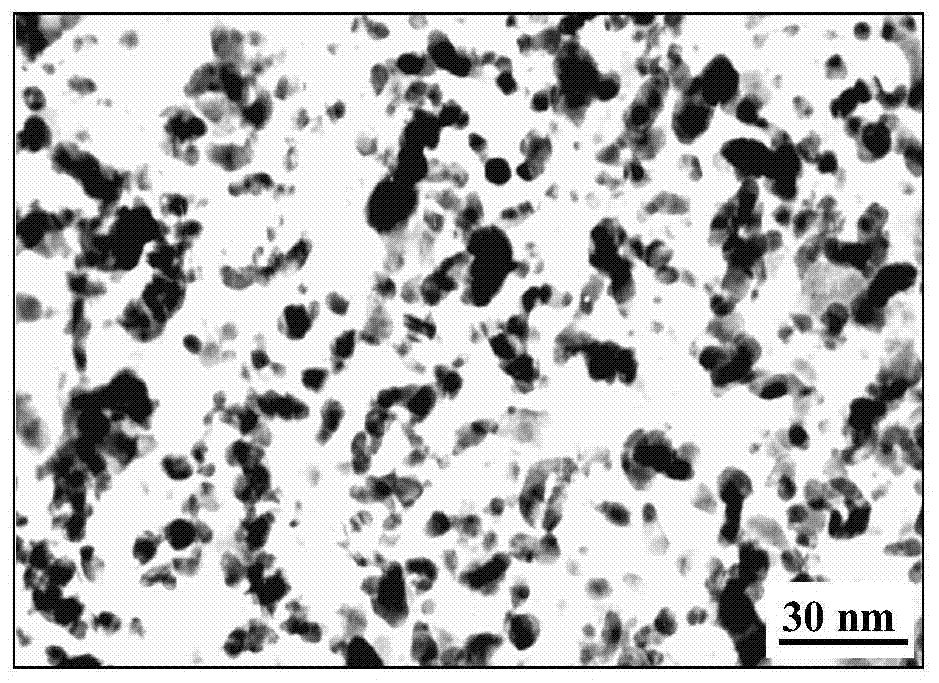

A kind of nanoparticle uniformly dispersed aluminum-based intermediate and its preparation and application method

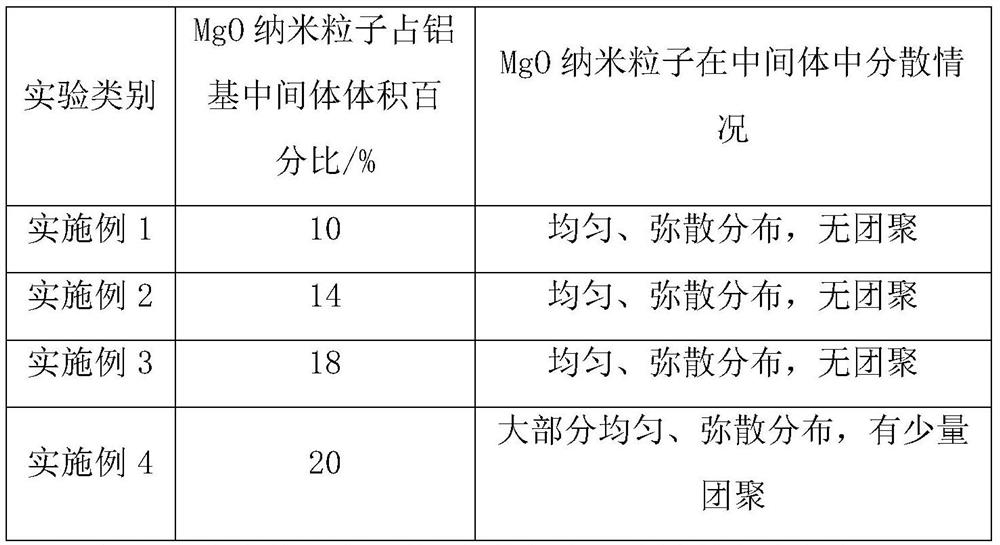

The invention relates to a uniformly dispersed aluminum-based intermediate of nanoparticles, which comprises uniformly dispersed oxide nanoparticles with a volume fraction of 10% to 20%, the particle size of the oxide nanoparticles is between 25nm and 50nm, and the oxide nanoparticles are CaO nanopowder, MgO nanopowder and Al 2 o 3 One of the nano powders, the rest is Al. The invention combines the ultrasonic dispersion technology and the spiral electromagnetic stirring technology to uniformly disperse the nanoparticles into the aluminum liquid to prepare an aluminum-based intermediate, so as to solve the agglomeration of the nanoparticles. The process is simple and the cost is low, and the dispersed distribution of nanoparticles in the aluminum matrix is realized. In the process of steelmaking, aluminum-based intermediates are used to participate in the final deoxidation, and nanoparticles are added to molten steel to increase the nucleation core of finely dispersed foreign solids, which serve as the precipitation core of nascent alumina inclusions, disperse the quality of inclusions, and reduce inclusions Size, refine aluminum oxide inclusions in molten steel, and eliminate the damage of inclusions to steel performance. Improve the mechanical properties and surface quality of steel.

Owner:ANGANG STEEL CO LTD

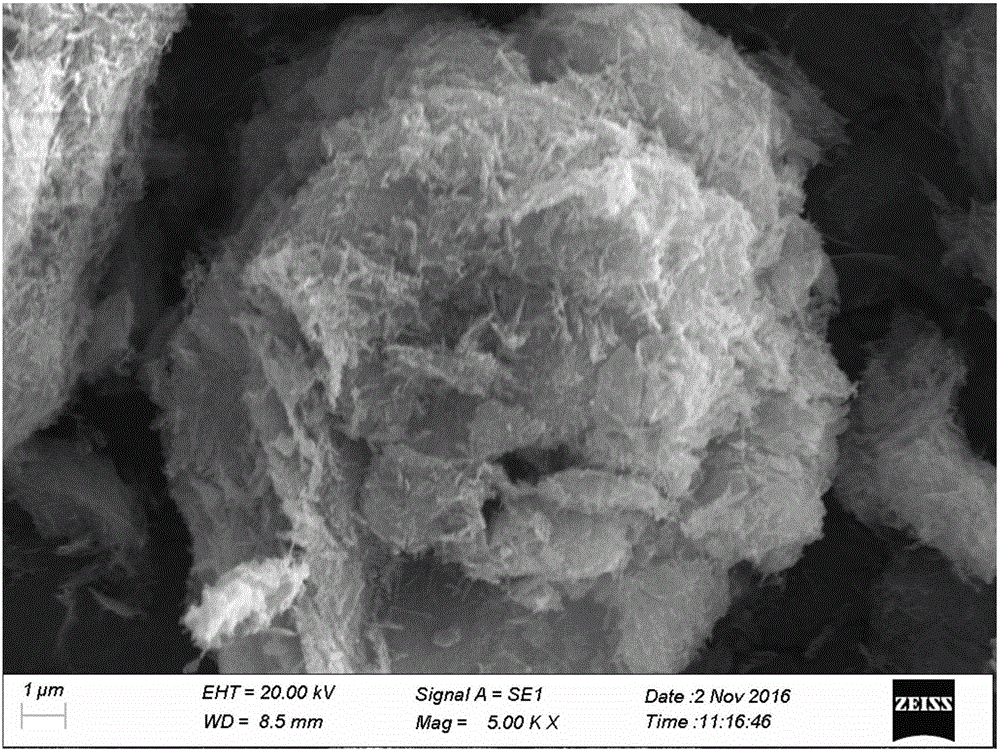

A kind of preparation method of magnetic metal sepiolite composite powder or fiber

ActiveCN106583752BFully absorbedImprove adsorption capacityTransportation and packagingMetal-working apparatusFiberOrganic matter

The invention discloses a method for preparing a magnetic metal-loaded sepiolite composite powder or fiber. The method comprises burning the sepiolite powder or sepiolite fiber, or burning the sepiolite powder or sepiolite The stone fiber is soaked in the silane coupling agent solution to obtain pretreated sepiolite powder or sepiolite fiber, and after the pretreated sepiolite powder or sepiolite fiber is mixed with the magnetic metal organic solution, the In the sealed reaction kettle, carry out pyrolysis reaction, and the magnetic metal in the prepared composite material is evenly distributed on the surface of sepiolite or in the pores, and the magnetic metal loading capacity is high, and its electromagnetic matching performance can be adjusted through the loading amount and metal ratio ; The preparation method is simple in process and low in cost, and is conducive to large-scale production.

Owner:CENT SOUTH UNIV

Solar energy collection device with rapid heat dissipation function

InactiveCN108880463AReduce the temperatureEfficient and long-life workConductive layers on insulating-supportsPhotovoltaicsEngineeringSolar energy harvesting

The invention discloses a solar energy collection device with a rapid heat dissipation function. The solar energy collection device comprises a mounting base and a plurality of solar cells, wherein each solar cell comprises a silicon wafer printed with back field aluminum paste; strip collecting chutes are oppositely and vertically formed in the mounting base; a liquid heat dissipation unit and agas heat dissipation unit are arranged in the mounting base; the solar cells, the liquid heat dissipation unit and the gas heat dissipation unit are sequentially connected from top to bottom; two strip collecting chutes communicate with the liquid heat dissipation unit separately; and the flow direction of medium in the liquid heat dissipation unit is vertical to that in the gas heat dissipation unit. Compared with the prior art, the solar energy collection device has the advantages that the structure is compact; rainwater circuiting heat dissipation is efficiently combined with cooling air circulating heat dissipation, so that the temperature of a solar cell backboard is effectively reduced and the heat dissipation efficiency is improved on the whole, thereby improving the power generation efficiency of a solar cell panel and prolonging the service life of the solar cell panel; the solar cells are low in cell series resistance, high in photoelectric conversion efficiency, flat and smooth in surfaces, good in adhesive force and low in warp rate; and the solar energy collection device has a broad application prospect.

Owner:YANGZHOU XINJING PHOTOVOLTAIC TECH

Powder metallurgy high speed steel and preparation method thereof

Owner:长沙市萨普新材料有限公司

A method for adding nano particles to steel and refining its structure and strengthening and toughening steel

The invention relates to a method for adding nanoparticles to steel and its refined structure and strengthening and toughening steel, comprising the following steps: (1) pre-dispersing nanoparticles, weighing oxide nanoparticles and pure metal nanopowder, and or mixed, and pre-dispersed in a planetary ball mill under vacuum and liquid nitrogen cooling conditions to obtain a mixed nano-powder; (2) prepare an aluminum-based intermediate, use a medium-frequency induction furnace to heat and melt metal aluminum, add a mixed nano-powder, in a spiral electromagnetic field and Under the joint action of ultrasonic waves, disperse and mix nano-powders into molten aluminum to obtain aluminum-based intermediates; (3) Add nanoparticles. During the deoxidation alloying process in the later stage of RH refining, silicon, manganese, aluminum or their alloys are first used to react with molten steel Deoxidation is carried out, and then aluminum-based intermediates are added. During the continuous casting production process, continuous casting slabs with uniform distribution of nanoparticles are prepared. The invention realizes the aluminum alloying, and releases nano particles to disperse into the molten steel after the aluminum is dissolved.

Owner:ANGANG STEEL CO LTD

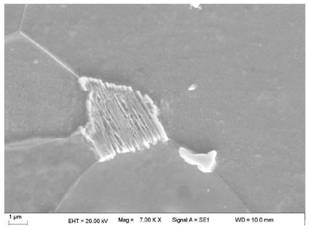

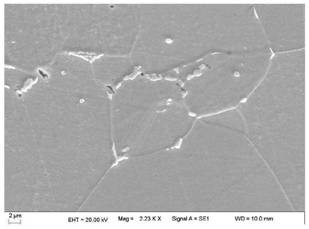

A kind of sic/m2 powder high-speed steel composite material and preparation method thereof

The invention relates to a SiC / M2 powder high-speed steel composite material. The composite material has a relative density of greater than 99% and hardness of 66-69HRC, and comprises nano-scale enhanced-phase particles SiC, submicron-scale hard-phase SiC and separated submicron-scale M6C type composite carbide, wherein the average particle size of the enhanced-phase particles SiC is 200nm, and the particle sizes of the hard-phase SiC and the M6C type composite carbide are not greater than 1[mu]m; and the matrix of the composite material is M2 high-speed steel, the particles SiC are uniformly distributed into the matrix in a dispersed manner as additional mass points, the composite material comprises the following raw material components with contents by volume percent: 85%-90% of M2 high-speed steel and 10%-15% of the particles SiC, the volume fraction of the particles SiC with particle sizes of not greater than 200nm in the particles SiC is 10%-20%, and the balance is particles with particle sizes of greater than 200nm and less than 1[mu]m. A preparation technology for a pre-alloyed composite powder is beneficial to obtaining the composite powder with a small and uniform particle size, preventing the agglomeration of the powder SiC, and realizing adequate alloying for the particles SiC and the matrix powder.

Owner:ANGANG STEEL CO LTD

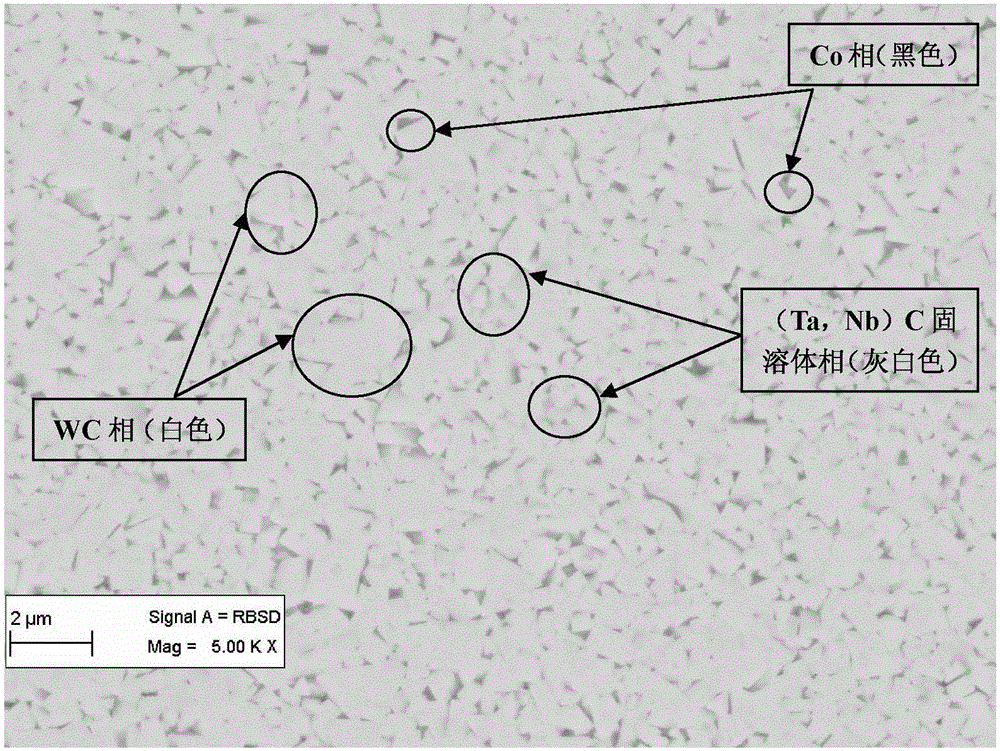

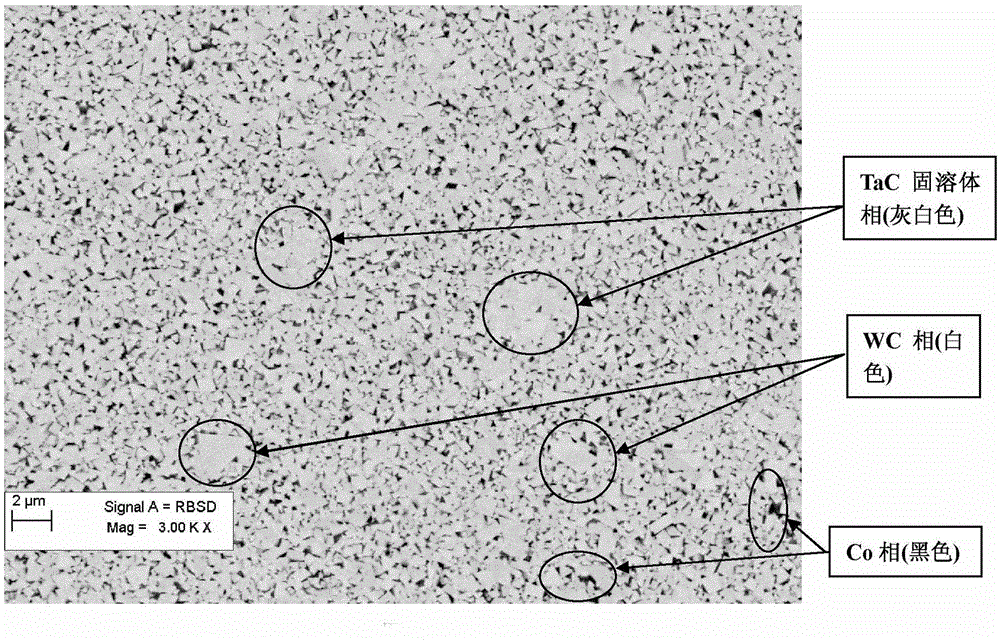

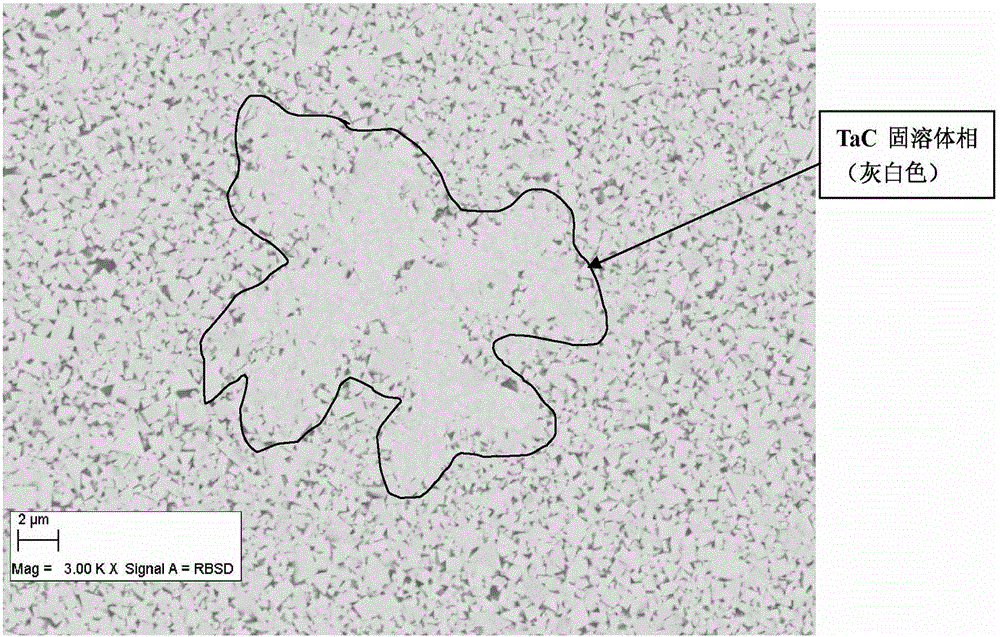

WC-Co (Wolfram Carbide-Cobalt) hard alloy with Ta/Nb (Tantalum/Niobium) solid solution dispersedly distributed and preparation method thereof

The invention discloses a WC-Co (Wolfram Carbide-Cobalt) hard alloy with Ta / Nb (Tantalum / Niobium) solid solutions dispersedly distributed and a preparation method thereof. The WC-Co hard alloy comprises a WC hard phase, a metal Co binder phase and a Ta / Nb solid solution phase, wherein the mass fraction of the metal Co binder phase is a more than or equal to 3% and less than or equal to 15%; the Ta / Nb solid solution phase comprises at least one of a TaC (Tantalum Carbide ) solid solution, an NbC (Niobium Carbide) solid solution or a (Ta, Nb)C solid solution, and (mTa+mNb) / mCo is more than or equal to 0.004 and less than or equal to 0.083; and Ta / Nb solid solutions are dispersedly distributed in a point shape in the WC-Co hard alloy. The preparation method of the WC-Co hard alloy comprises the following steps of: preparing a semi-finished product; and carrying out sintering temperature rise, sintering heat preservation and sintering cooling on the semi-finished product. The WC-Co hard alloy disclosed by the invention realizes the dispersed distribution of the TaC, NbC or (Ta, Nb) C solid solutions on the basis without changing alloy components, thereby enhancing the alloy structure uniformity and the alloy property.

Owner:ZHUZHOU CEMENTED CARBIDE CUTTING TOOLS CO LTD

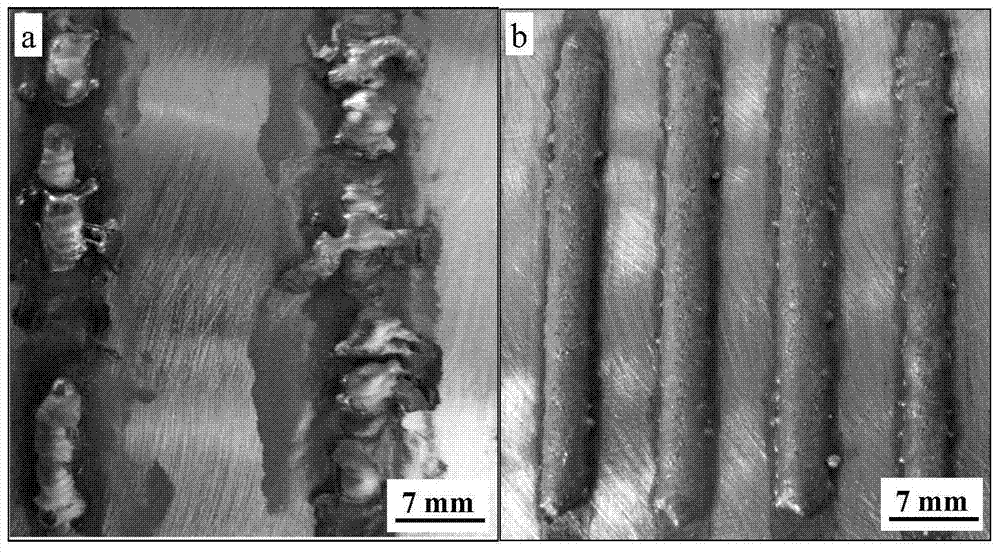

Copper-based coating for laser cladding on iron-based alloy surface and preparation method thereof

ActiveCN104746068BImprove cladding qualityImprove performanceMetallic material coating processesMetal/alloy conductorsCopper coatingLaser scanning

The invention discloses a copper-based coating for iron-based alloy surface laser cladding and a preparation method thereof, belonging to the technical field of material surface modification. The 0.4-2 mass percent of nano oxides such as CeO2, Al2O3, Sm2O3 and Y2O3 are added into pure copper powder, so that the problems that the cladding quality is low, the binding property with the iron-based alloy is poor when a pure copper coating is subjected to laser cladding on the surface of the iron-based alloy and the like are solved. In addition, cladding is performed by adopting extremely high laser scanning speed of 600-1000mm per minute, the problem that the additional nano-particles are easily aggregated in the coating coagulation process is solved, and uniform distribution of the nano-particles in the copper coating is realized. Meanwhile, according to the high surface effect and heterogeneous nucleation effect of the nano oxides, the coagulation tissues at the coating interface can be refined by 10 times or more. Compared with a laser cladding pure copper coating, the copper-based coating prepared by the invention has high cladding quality, the hardness is improved by nearly 40 percent, and the conductivity reaches 82% IACS (International Annealed )soft) Copper Standard).

Owner:菏泽市金沃泰化工有限公司

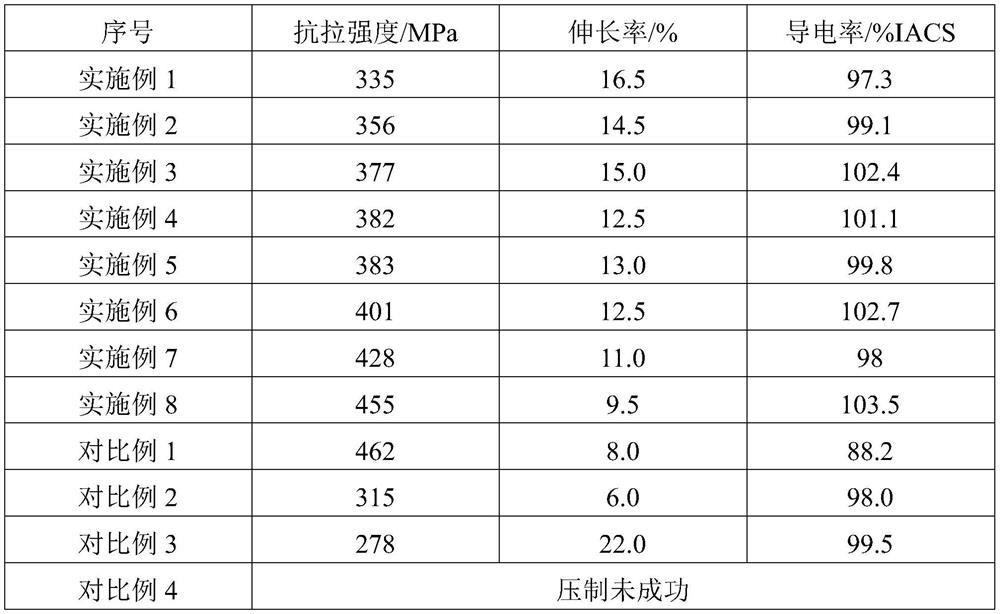

A kind of high-strength and high-conductivity graphene-copper composite wire and preparation method thereof

ActiveCN112359244BHigh strengthImprove conductivityFurnace typesHeat treatment furnacesWire rodGraphite

The invention discloses a high-strength and high-conductivity graphene-copper composite wire and a preparation method thereof, which belong to the technical field of composite material processing and heat treatment. In the graphene-copper composite wire, the graphene content is 0.05-0.8wt.%, the total content of impurity elements is ≤0.1wt.%, and the balance is copper. The high-strength and high-conductivity graphene-copper composite wire prepared by the present invention has uniform graphene Dispersed and oriented distributed in the copper matrix, its tensile strength reaches 330-480MPa, elongation 6%-20%, electrical conductivity 95-105% IACS, and has excellent comprehensive performance.

Owner:GRIMAT ENG INST CO LTD

Cobalt-less multi-element high speed tool steel and its manufacturing method

InactiveCN100575528CReasonable range of performanceLow content of alloying elementsFurnace typesHeat treatment furnacesChemical compositionAlloy

Owner:JIUQUAN IRON & STEEL GRP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com