Rotatablely cleaned photovoltaic power generation device

A photovoltaic power generation, clean technology, applied in the field of solar cells, to achieve the effect of simple structure, reduce the consumption of manpower and material resources

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

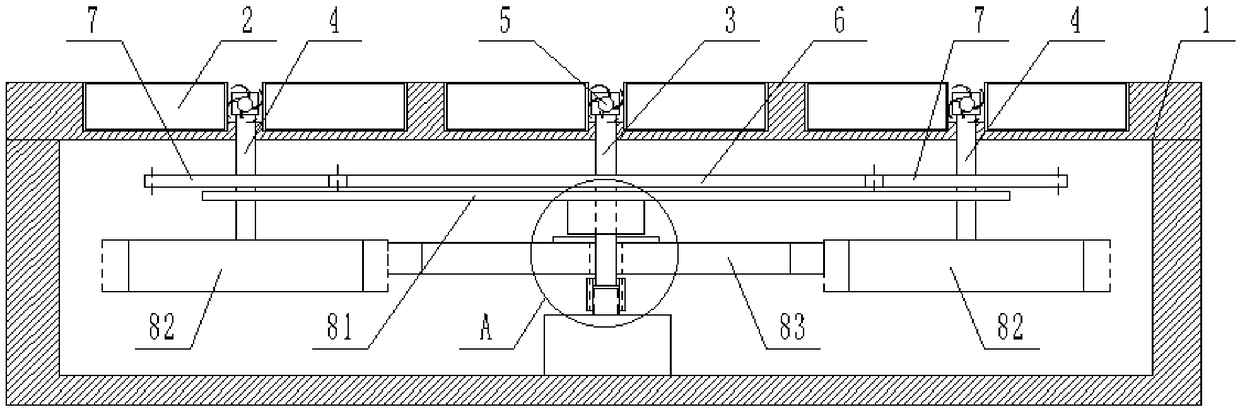

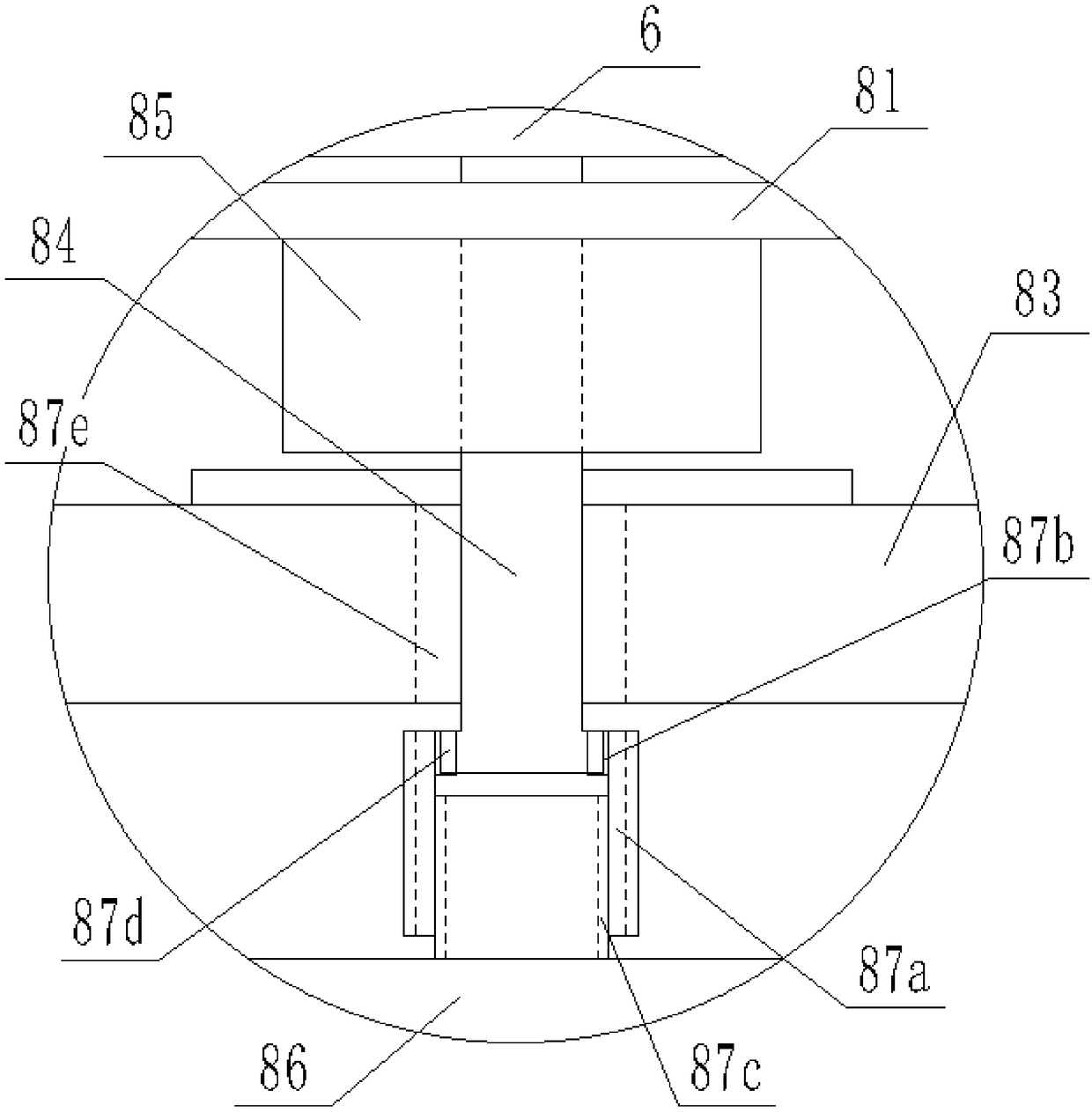

[0026] Embodiment 1 Rotatable and clean photovoltaic power generation device

[0027] Figure 1-6 As shown, a photovoltaic power generation device that can be rotated and cleaned includes a mount 1 on which a plurality of solar cells 2 are installed, and the solar cells 2 include a silicon wafer and an aluminum back mounted on the silicon wafer The aluminum back field is obtained by screen-printing the back field aluminum paste I on a silicon wafer, and then drying and sintering. The center of the mounting seat 1 is vertically pierced with a main rotation axis 3, and the The main rotating shaft 3 is vertically provided with at least one auxiliary rotating shaft 4, and a plurality of solar cells 2 are evenly distributed between the main rotating shaft 3 and the auxiliary rotating shaft 4, and the main rotating shaft 3 and the auxiliary rotating shaft 4 are respectively movably installed in the mounting seat 1, and the upper ends of the main rotating shaft 3 and the auxiliary r...

Embodiment 2

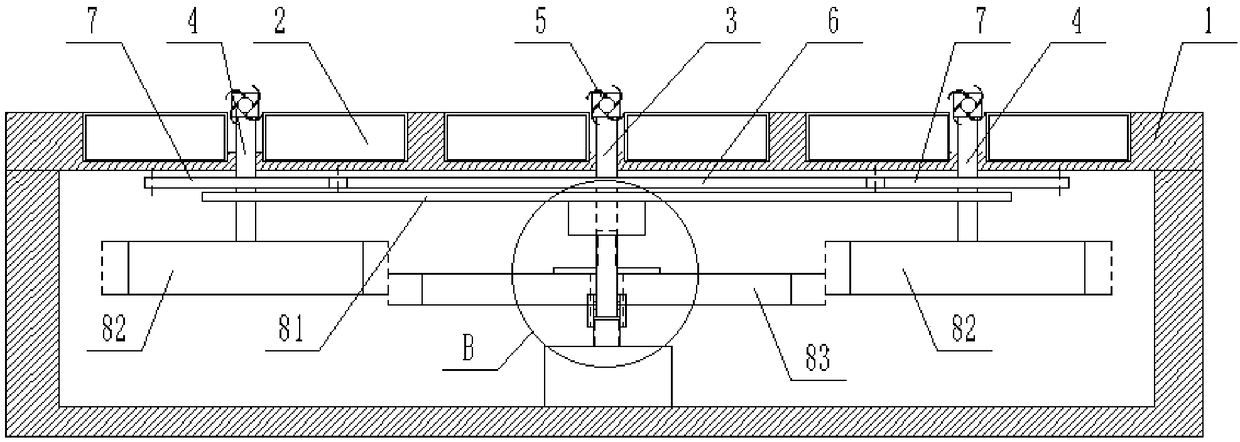

[0038] Embodiment 2 The photovoltaic power generation device II that can be rotated and cleaned

[0039] Figure 1-5As shown, a photovoltaic power generation device that can be rotated and cleaned includes a mount 1 on which a plurality of solar cells 2 are installed, and the solar cells 2 include a silicon wafer and an aluminum back mounted on the silicon wafer The aluminum back field is obtained by screen-printing the back field aluminum paste II on the silicon wafer, and then drying and sintering. The center of the mounting seat 1 is vertically pierced with a main rotation axis 3, and the The main rotating shaft 3 is vertically provided with at least one auxiliary rotating shaft 4, and a plurality of solar cells 2 are evenly distributed between the main rotating shaft 3 and the auxiliary rotating shaft 4, and the main rotating shaft 3 and the auxiliary rotating shaft 4 are respectively movably installed in the mounting seat 1, and the upper ends of the main rotating shaft ...

Embodiment 3

[0049] Embodiment 3 The photovoltaic power generation device III that can be rotated and cleaned

[0050] Figure 1-5 As shown, a photovoltaic power generation device that can be rotated and cleaned includes a mount 1 on which a plurality of solar cells 2 are installed, and the solar cells 2 include a silicon wafer and an aluminum back mounted on the silicon wafer The aluminum back field is obtained by screen-printing the back field aluminum paste II on the silicon wafer, and then drying and sintering. The center of the mounting seat 1 is vertically pierced with a main rotation axis 3, and the The main rotating shaft 3 is vertically provided with at least one auxiliary rotating shaft 4, and a plurality of solar cells 2 are evenly distributed between the main rotating shaft 3 and the auxiliary rotating shaft 4, and the main rotating shaft 3 and the auxiliary rotating shaft 4 are respectively movably installed in the mounting seat 1, and the upper ends of the main rotating shaf...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com