Method for optimizing steel structure by adding nano particles into steel liquid

A technology of nanoparticles and molten steel, applied in the field of adding nanoparticles to molten steel to optimize the steel structure, can solve the problems of loss of nano powder, inability to disperse, low bulk density, etc., to ensure the original size, optimize the steel structure, To achieve the effect of diffuse distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A method of adding nanoparticles to molten steel in this embodiment to optimize the steel structure, the steps are:

[0038] (1) Mixing and dispersing

[0039] Take magnesium oxide powder with a particle size of 100nm and pure iron powder with a particle size of 5 microns, the mass percentages are 25% and 75% respectively, and they are ground for 60 minutes by mechanical ball milling for mixing and dispersing;

[0040] (2) Preparation of nano powder rods

[0041] The mixture obtained in step (1) is sintered into a nano-powder rod by hot pressing technology under an inert gas atmosphere. The core material of the nano-powder rod is a steel rod, and the outer layer of the nano-powder rod is a mixture. The diameter of the powder rod is 150mm, the diameter of the steel rod is 100mm, the thickness of the mixture is 25mm, the pressure of hot pressing sintering is 20MPa, the sintering temperature is 1350°C, and the holding time is 10 minutes;

[0042] (3) Nano powder rod inse...

Embodiment 2

[0046] A method of adding nanoparticles to molten steel in this embodiment to optimize the steel structure, the steps are:

[0047] (1) Mixing and dispersing

[0048] Take calcium oxide powder with a particle size of 50nm and pure iron powder with a particle size of 2 microns, the mass percentages are 20% and 80% respectively, and they are ground by mechanical ball milling for 50 minutes for mixing and dispersing;

[0049] (2) Preparation of nano powder rods

[0050] The mixture obtained in step (1) is sintered into a nano-powder rod by hot pressing technology under an inert gas atmosphere. The core material of the nano-powder rod is a steel rod, and the outer layer of the nano-powder rod is a mixture. The diameter of the powder rod is 160mm, the diameter of the steel rod is 80mm, and the thickness of the mixture is 40mm. The pressure of hot pressing sintering is 30MPa, the sintering temperature is 1200°C, and the holding time is 15 minutes;

[0051] (3) Nano powder rod ins...

Embodiment 3

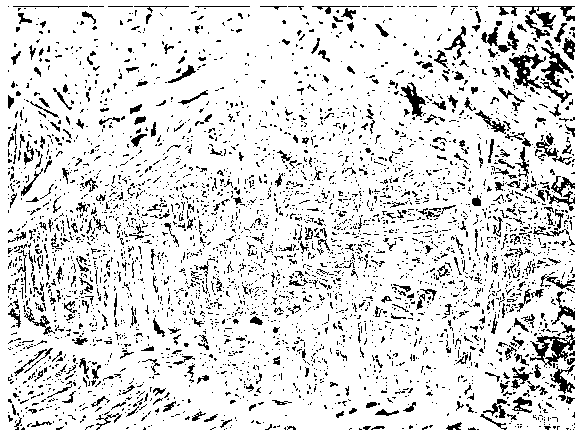

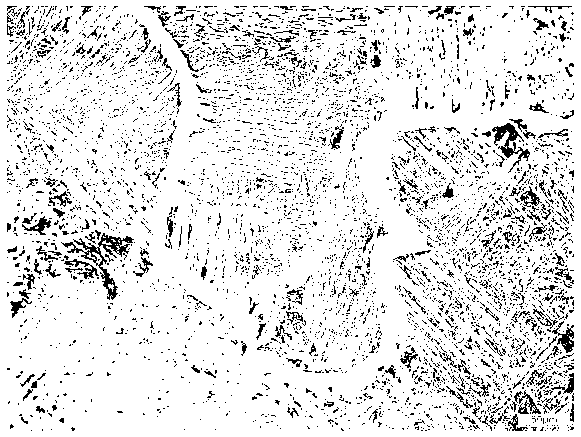

[0055] The basic processing steps of this embodiment are the same as those of Example 1, the difference being that in the process of mixing and dispersing, the nanopowder with a particle size of 10nm is taken (the nanopowder includes titanium nitride and silicon carbide, each of which accounts for 50% of the mass percentage) and pure iron powder with a particle size of 1 micron, the mass percentages are 40% and 60% respectively, and are ground for 90 minutes by manual grinding for mixing and dispersing; during the preparation of nano powder rods, The pressure of hot pressing sintering is 5MPa, the sintering temperature is 1350°C, and the holding time is 15min. After the nano-powder rods are completely melted, the steel clamping rods can be moved out of the molten steel using a mechanical hydraulic device. After the smelting is completed, the molten steel is sampled at high temperature. The quenched structure is similar to that of Example 1. There are a lot of acicular ferrite ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com