WC-Co (Wolfram Carbide-Cobalt) hard alloy with Ta/Nb (Tantalum/Niobium) solid solution dispersedly distributed and preparation method thereof

A cemented carbide, dispersion distribution technology, applied in the field of WC-Co cemented carbide, can solve problems such as changing alloy composition, increasing raw material cost, and adverse effects on performance, and achieves improved alloy hardness, simple and convenient preparation method, and aggregated morphology Improved effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

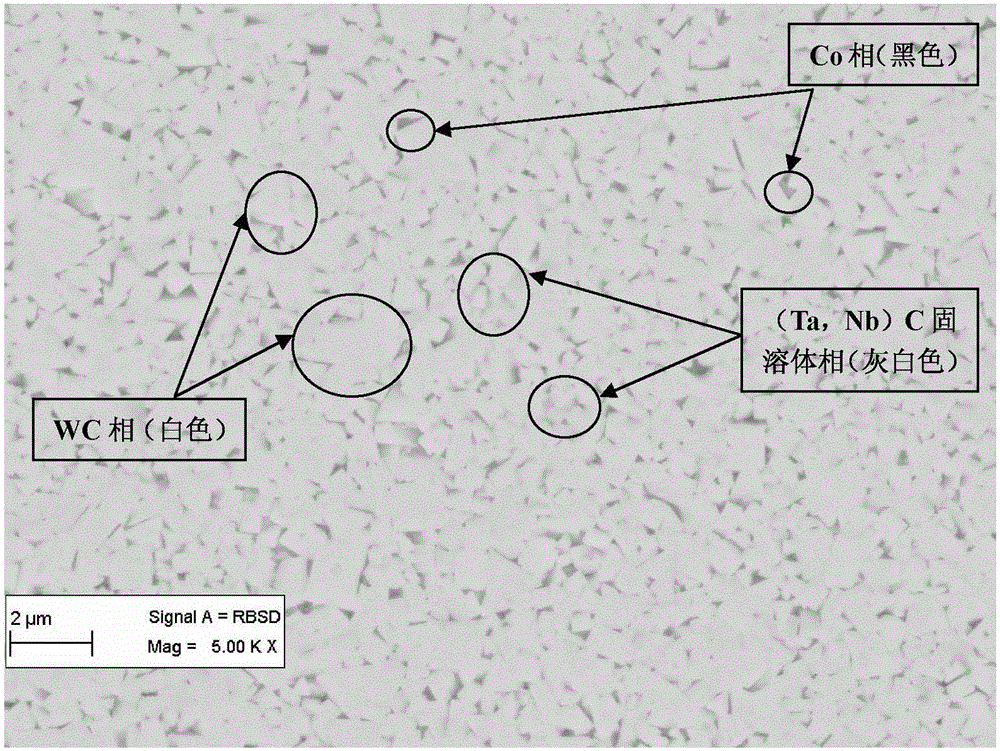

[0031]A (Ta, Nb) C solid solution dispersed WC-Co cemented carbide of the present invention, including a WC-Co hard phase, a metal Co binder phase and a (Ta, Nb) C solid solution phase, wherein the metal Co binder The content of the junction phase is 5.2wt.% (unless otherwise specified, all are in mass fraction, and the following examples are explained here), the content of (Ta, Nb) C solid solution phase is 0.3wt.%, (m Ta +m Nb ) / m Co =0.056, where m Ta is the total mass of Ta elements, m Nb is the total mass of Nb elements, m Co is the total mass of Co element, the content of WC hard phase is 94.5wt.%, and the average grain size of WC in WC hard phase is 0.8 μm. (Ta, Nb) C solid solution is distributed in point form in WC-Co cemented carbide, and the particle size of (Ta, Nb) C solid solution (that is, the equivalent circle diameter of its point area area) is less than 2 μm.

[0032] A method for preparing WC-Co cemented carbide with dispersed distribution of (Ta, Nb)C ...

Embodiment 2

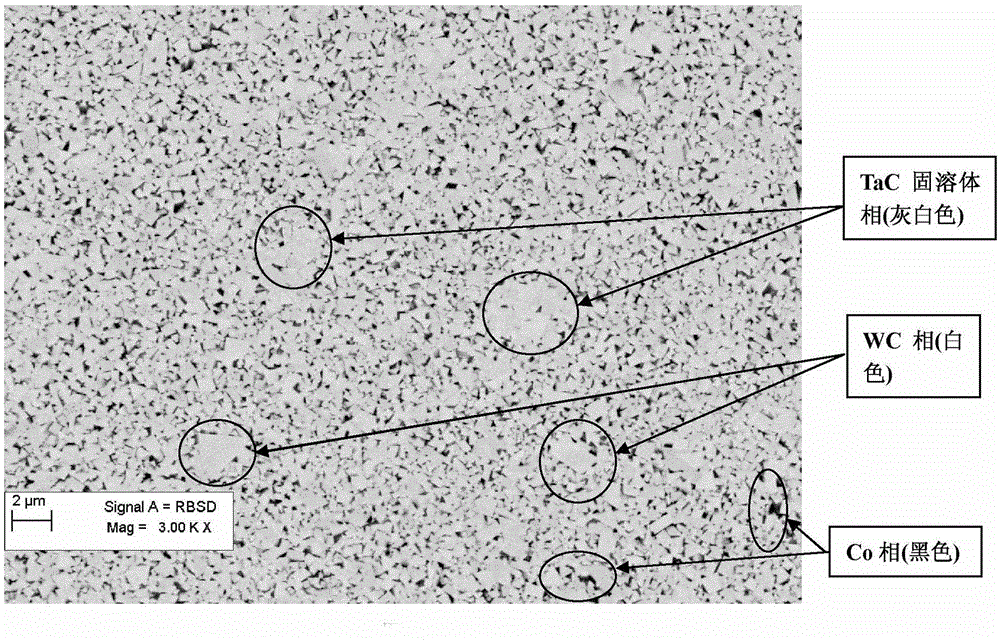

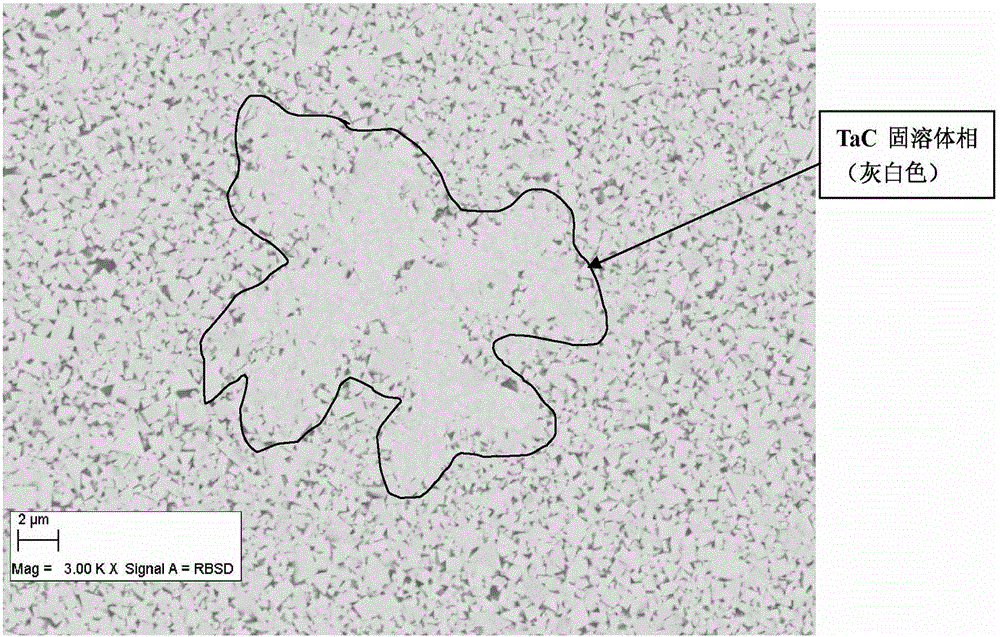

[0037] A kind of WC-Co cemented carbide of the present invention dispersed distribution of TaC solid solution, comprises WC-Co hard phase, metal Co binding phase, TaC solid solution phase and Cr 3 C 2 Phase, wherein, the content of metal Co binder phase is 10wt.%, the content of TaC solid solution phase is 0.5wt.%, m Ta / m Co =0.047, where m Ta is the total mass of Ta elements, m Co is the total mass of Co elements, Cr 3 C 2 The content of phase is 0.4wt.%, the content of WC hard phase is 89.1wt.%, and the average particle size of WC in WC hard phase is 0.8μm. The TaC solid solution is distributed in a point-like dispersion in the WC-Co cemented carbide, and the particle size of the TaC solid solution (that is, the equivalent circle diameter of the point-like area) does not exceed 2 μm.

[0038] A kind of preparation method of the WC-Co cemented carbide of above-mentioned TaC solid solution dispersion distribution of the present invention, comprises the following steps: ...

Embodiment 3

[0046] A (Ta, Nb) C solid solution dispersed WC-Co cemented carbide of the present invention, including a WC-Co hard phase, a metal Co binder phase and a (Ta, Nb) C solid solution phase, wherein the metal Co binder The content of junction phase is 6.5wt.%, the content of (Ta, Nb) C solid solution phase is 0.4wt.%, (m Ta +m Nb ) / m Co =0.056, where m Ta is the total mass of Ta elements, m Nb is the total mass of Nb elements, m Co is the total mass of Co element, the content of WC hard phase is 93.1wt.%, and the average particle size of WC in WC hard phase is 1 μm. The (Ta, Nb) C solid solution phase is diffusely distributed in WC-Co cemented carbide, and the particle size of (Ta, Nb) C solid solution (that is, the equivalent circle diameter of its point-like area) is less than 2 μm.

[0047] A method for preparing WC-Co cemented carbide with dispersed distribution of (Ta, Nb)C solid solution of the present invention, comprising the following steps:

[0048] (1) Mixing of r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com