A kind of high-strength and high-conductivity graphene-copper composite wire and preparation method thereof

A composite wire and graphene technology, applied in manufacturing tools, heat treatment equipment, furnaces, etc., can solve the problems of reducing the electrical conductivity of materials, reducing the density of materials, and difficult to completely discharge gas, so as to overcome the reduction of electrical conductivity and improve the dispersibility. , to ensure the effect of conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

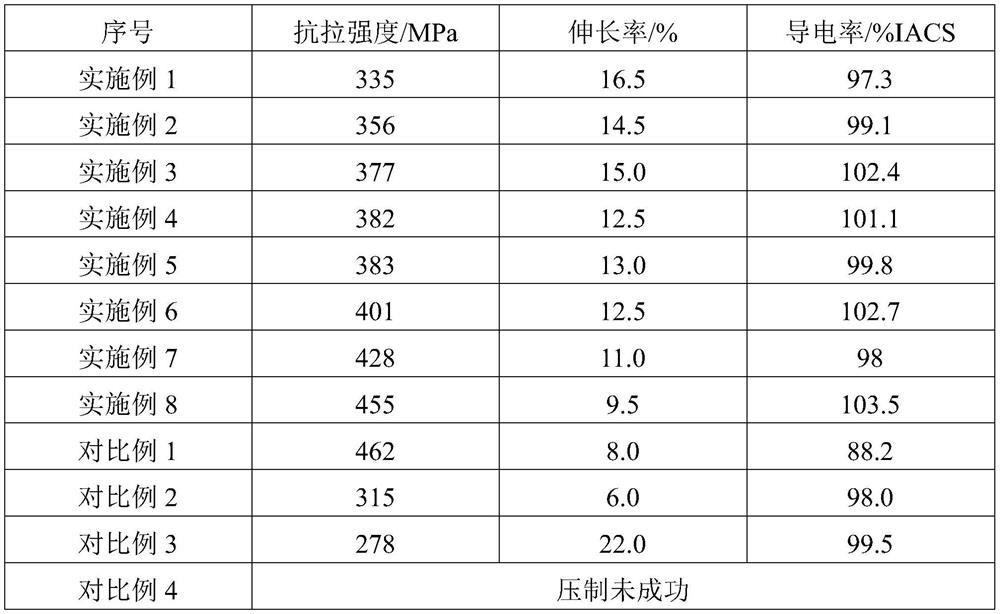

Examples

Embodiment 1

[0050] In this embodiment, high-purity graphene (abbreviation: GR) and copper powder are used as raw materials. The number of layers of high-purity graphene is 1-10 layers, and the composition is shown in Table 1 below.

[0051] (1) Powder mixing: use a drum mixer to mix powder, and the powder mixing time is 6 hours;

[0052] (2) Cold isostatic pressing: the composite powder is pressed on a cold isostatic press, the pressing process is: pressure 200MPa, holding time 30 minutes, three-stage pressure relief;

[0053] (3) Vacuum sintering: The vacuum sintering process described is: temperature 900 ° C, heat preservation for 2 hours, vacuum degree ≤ 3 × 10 - 2 Pa;

[0054] (4) hot extrusion: the above vacuum sintered ingot is hot extruded to make a bar, the extrusion temperature is 900 ° C, and the extrusion ratio is 15;

[0055] (5) Continuous extrusion: the hot-extruded bar is continuously extruded, the continuous extrusion machine speed is 8r / min, and the extrusion ratio is 40...

Embodiment 2

[0062] In this embodiment, high-purity graphene and copper powder are used as raw materials, and the ingredients are shown in Table 1 below.

[0063] (1) Powder mixing: use a drum mixer to mix powder, and the powder mixing time is 6 hours;

[0064] (2) Cold isostatic pressing: the composite powder is pressed on a cold isostatic press, the pressing process is: pressure 200MPa, holding time 30 minutes, three-stage pressure relief;

[0065] (3) Vacuum sintering: The vacuum sintering process described is: temperature 900 ° C, heat preservation for 2 hours, vacuum degree ≤ 3 × 10 - 2 Pa;

[0066] (4) hot extrusion: the above vacuum sintered ingot is hot extruded to make a bar, the extrusion temperature is 900 ° C, and the extrusion ratio is 15;

[0067] (5) Continuous extrusion: the hot-extruded bar is continuously extruded, the continuous extrusion machine speed is 8r / min, and the extrusion ratio is 30;

[0068] (6) cold drawing: the above-mentioned wire rod after continuous e...

Embodiment 3

[0074] In this embodiment, high-purity graphene and copper powder are used as raw materials, and the ingredients are shown in Table 1 below.

[0075] (1) Powder mixing: use a drum mixer to mix powder, and the powder mixing time is 6 hours;

[0076] (2) Cold isostatic pressing: the composite powder is pressed on a cold isostatic press, the pressing process is: pressure 200MPa, holding time 30 minutes, three-stage pressure relief;

[0077] (3) Vacuum sintering: The vacuum sintering process described is: temperature 860 ° C, heat preservation for 2 hours, vacuum degree ≤ 3 × 10 - 2 Pa;

[0078] (4) hot extrusion: the above vacuum sintered ingot is hot extruded to make a bar, the extrusion temperature is 900 ° C, and the extrusion ratio is 15;

[0079] (5) Continuous extrusion: the hot-extruded bar is continuously extruded, the continuous extrusion machine speed is 8r / min, and the extrusion ratio is 40;

[0080] (6) cold drawing: the above-mentioned wire rod after continuous e...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistivity | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com