Copper-based coating for laser cladding on iron-based alloy surface and preparation method thereof

An iron-based alloy and laser cladding technology, which is applied to the coating process of metal materials, coatings, metal/alloy conductors, etc., can solve the problems of poor cladding quality of pure copper coatings and poor bonding performance of iron substrates, and achieve Good continuity, good surface quality, effect of promoting uniform mixing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

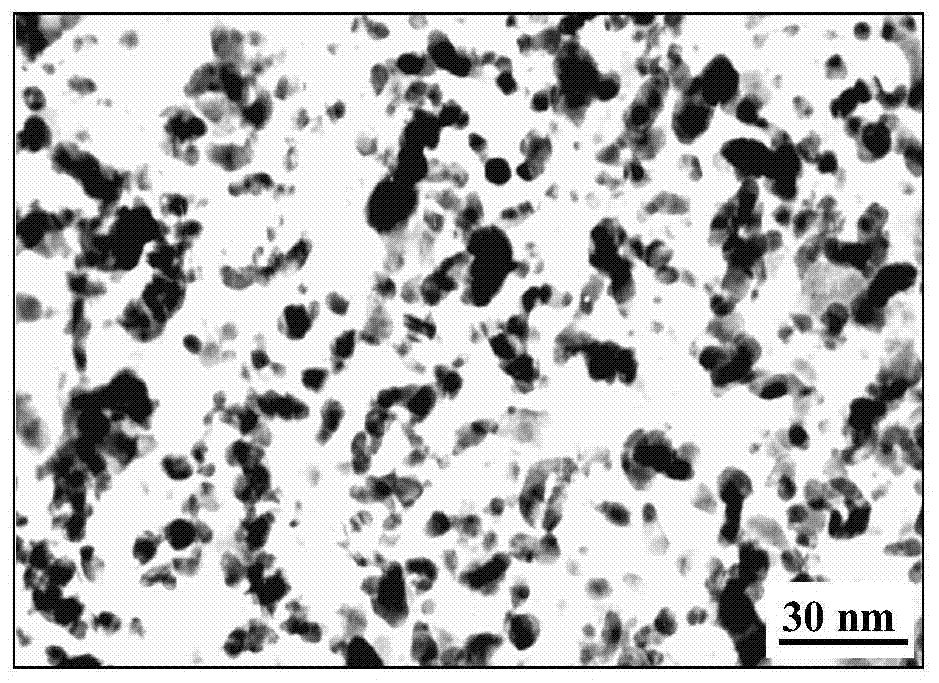

[0033] First, configure Cu-0.4%Y according to weight percentage 2 o 3 (indicating Y 2 o 3 The mass fraction is 0.4%, the same reason behind), Cu-1.2%Y 2 o 3 , Cu-2%Y 2 o3 , Cu-0.4%CeO 2 , Cu-0.8% Al 2 o 3 and Cu-1.2%Sm 2 o 3 100 grams of alloy powders with six components each, the purity of the added Cu powder is ≥99.5%, the particle size distribution is 10-104 μm, and the particle size distribution of the added nano-oxide is 20-100 nm.

[0034] Subsequently, alcohol (absolute ethanol) was added to the configured alloy powder and wet-milled for 30 minutes in a planetary ball mill (Germany, PM100). The rotational speed of the planetary ball mill was 200 rpm, and the added alcohol and alloy powder The volume ratio is 3:1, and the mixed alloy powder is dried in a vacuum drying oven at 60°C for use.

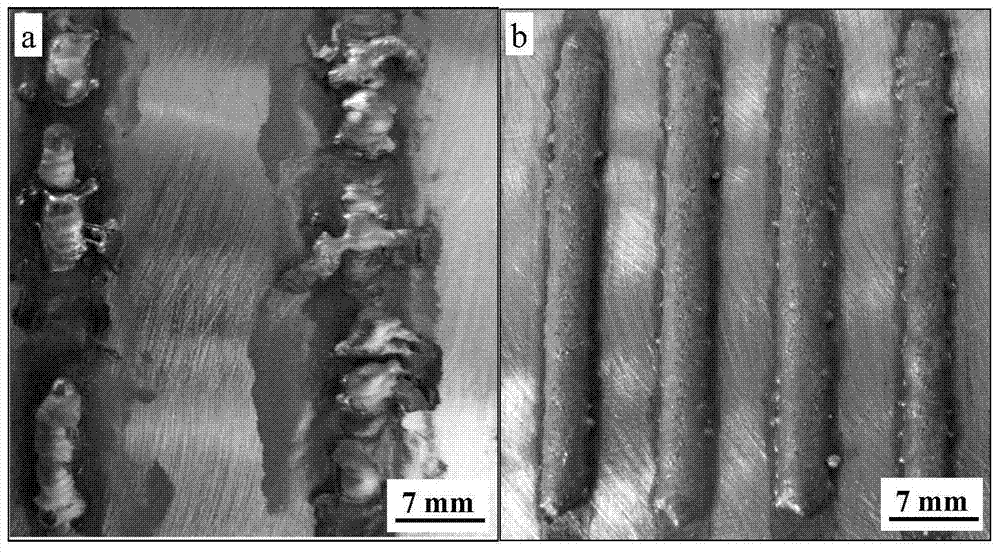

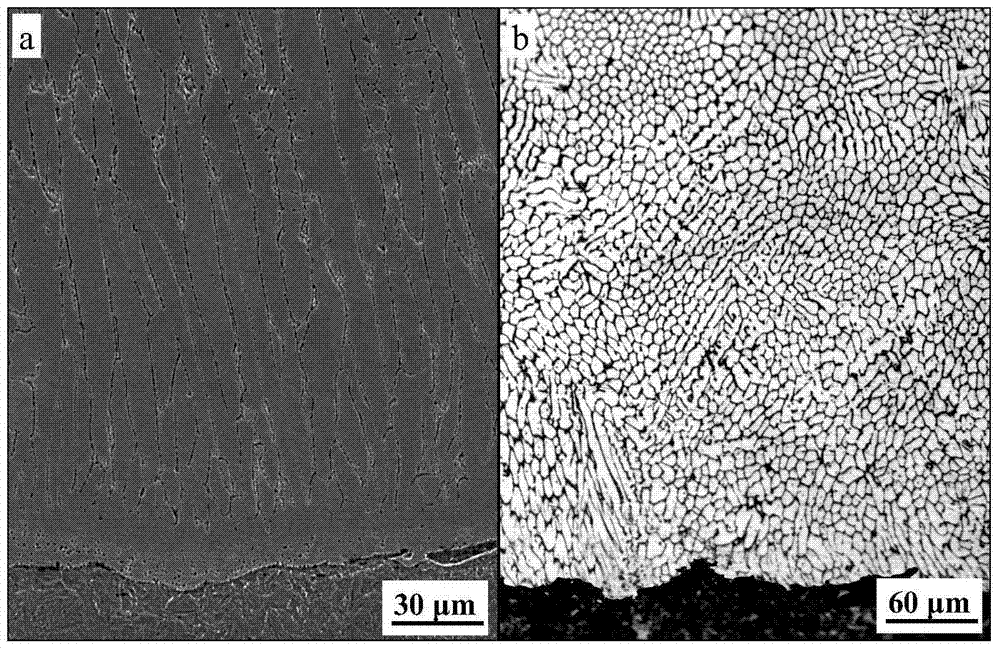

[0035] Thirdly, decontaminate and derust the surface of No. 45 steel-based alloy to be laser clad, and preheat it at 400° C. for 2 hours. Then, using the cross-flow CO pr...

Embodiment 2

[0041] First, configure Cu-0.4%Y according to weight percentage 2 o 3 -0.5%CeO 2 (indicating Y 2 o 3 The mass fraction is 0.4%, CeO 2 The mass fraction is 0.5%, the same reason behind) and Cu-1.0%Y 2 o 3 -0.6% Al 2 o 3 The alloy powders of the two components are 100 grams each, the purity of the added Cu powder is ≥99.5%, the particle size distribution is 10-100 μm, and the particle size distribution of the added nano-oxide is 20-100 nm.

[0042] Subsequently, alcohol (ethanol aqueous solution with a volume fraction of 80%) was added to the configured alloy powder to carry out wet grinding in a planetary ball mill (Germany, PM100) for 20 minutes, and the rotational speed of the planetary ball mill was 500 rpm. The volume ratio of alcohol to powder is 2:1, and the mixed powder is dried in a vacuum drying oven at 50°C for use.

[0043] Again, decontaminate and derust the total surface of the No. 45 steel substrate to be laser clad, and preheat it at 600°C for 1.5 hours....

Embodiment 3

[0046] First, configure Cu-0.3%Y according to weight percentage 2 o 3 -1.5% Sm 2 o 3 (indicating Y 2 o 3 The mass fraction is 0.3%, Sm 2 o 3 The mass fraction is 1.5%, the same reason behind) and Cu-1.0%CeO 2 -1.0% Al 2 o 3 The alloy powders of the two components are 100 grams each, the purity of the added Cu powder is ≥99.5%, the particle size distribution is 10-100 μm, and the particle size distribution of the added nano-oxide is 20-100 nm.

[0047] Subsequently, alcohol (aqueous ethanol solution with a volume fraction of 50%) was added to the configured alloy powder to carry out wet grinding for 60 minutes in a planetary ball mill (Germany, PM100), and the speed of the planetary ball mill was 100 rpm. The volume ratio of alcohol to powder is 2:1, and the mixed powder is dried in a vacuum drying oven at 50°C for use.

[0048] Thirdly, decontaminate and derust the surface of No. 45 steel-based alloy to be laser clad and preheat at 800°C for 1.0 hour. Then, using th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com