Method for evaluating coating quality of passivated NTO prepared by supercritical method

A quality evaluation and supercritical technology, applied in the direction of offensive equipment, measuring devices, fuel oil testing, etc., can solve the problems of inaccurate quantification, unfavorable determination of coating process parameters, fine adjustment of insensitivity agent formula, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

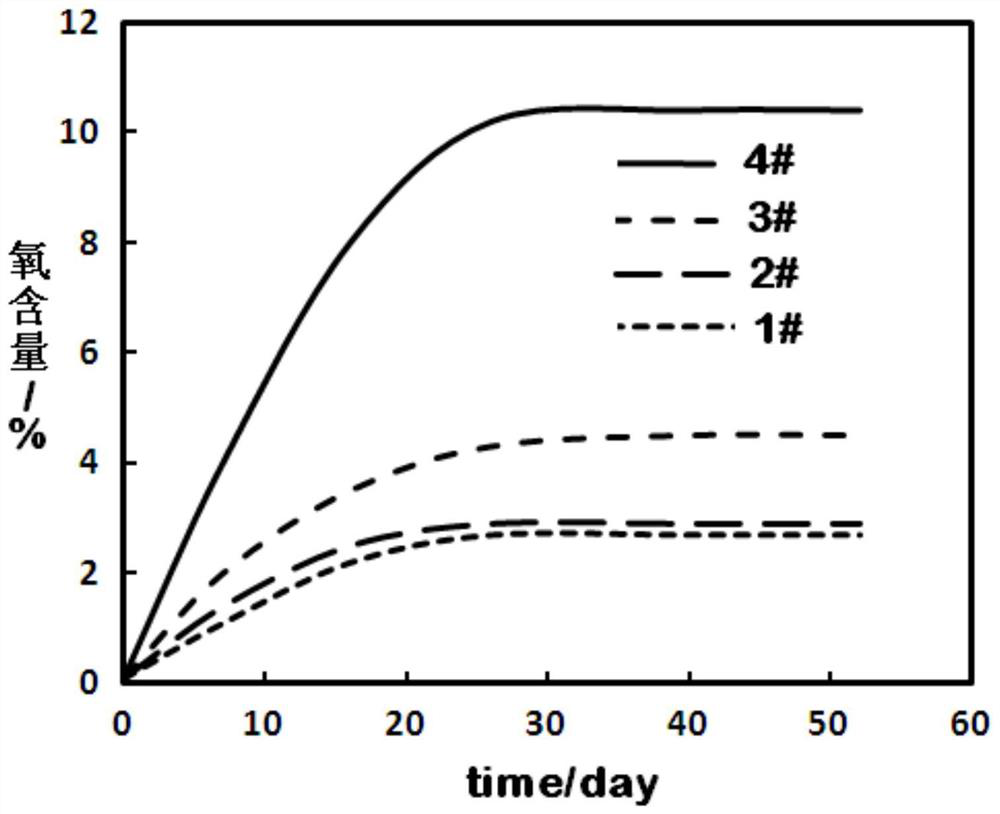

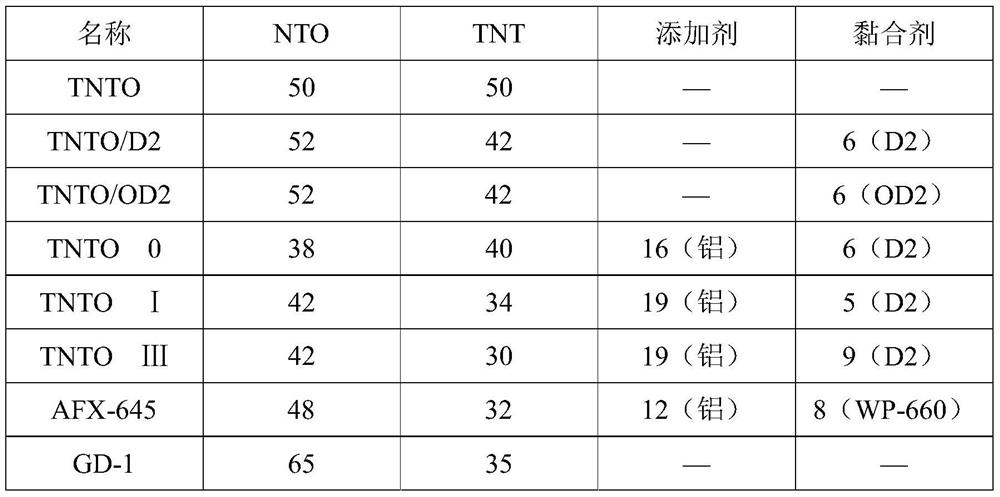

[0049] The desensitizing agent has no acidity or alkalinity and is insoluble in water. NTO (chemical name is 3-nitro-1,2,4-triazol-5-one) is white or light yellow crystal particles with certain acidity. According to the crystal reflectivity and acidity of NTO, the coating quality of passivated NTO insensitive agent can be distinguished, and the evaluation method can be established.

[0050] Taking a certain batch of passivated NTO prepared by the supercritical heat preservation method as an example, the idea of the invention of this patent is explained in detail.

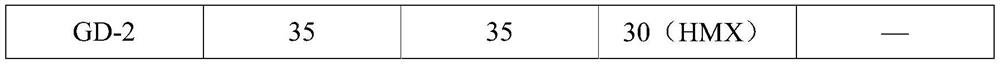

[0051] The preparation method of the passivated NTO to be detected is: mix the NTO recrystallization products in the two particle size intervals of 30-60 mesh and 60-80 mesh according to the mass ratio of 3:1 to obtain the mixed particle size NTO recrystallization product; the mass ratio is 1:1 polyvinyl acetate and purified ceresinate to prepare desensitizing agent, adding ethyl acetate to the desensitizing agen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com