Method and nozzle improving laser cladding effect

A technology of laser cladding and nozzle, which is applied in the coating process and coating of metal materials, can solve the problems of cladding surface collapse, insufficient surface tension, and uneven cladding layer surface, so as to improve the compactness and quality , Improve the effect of cladding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 2

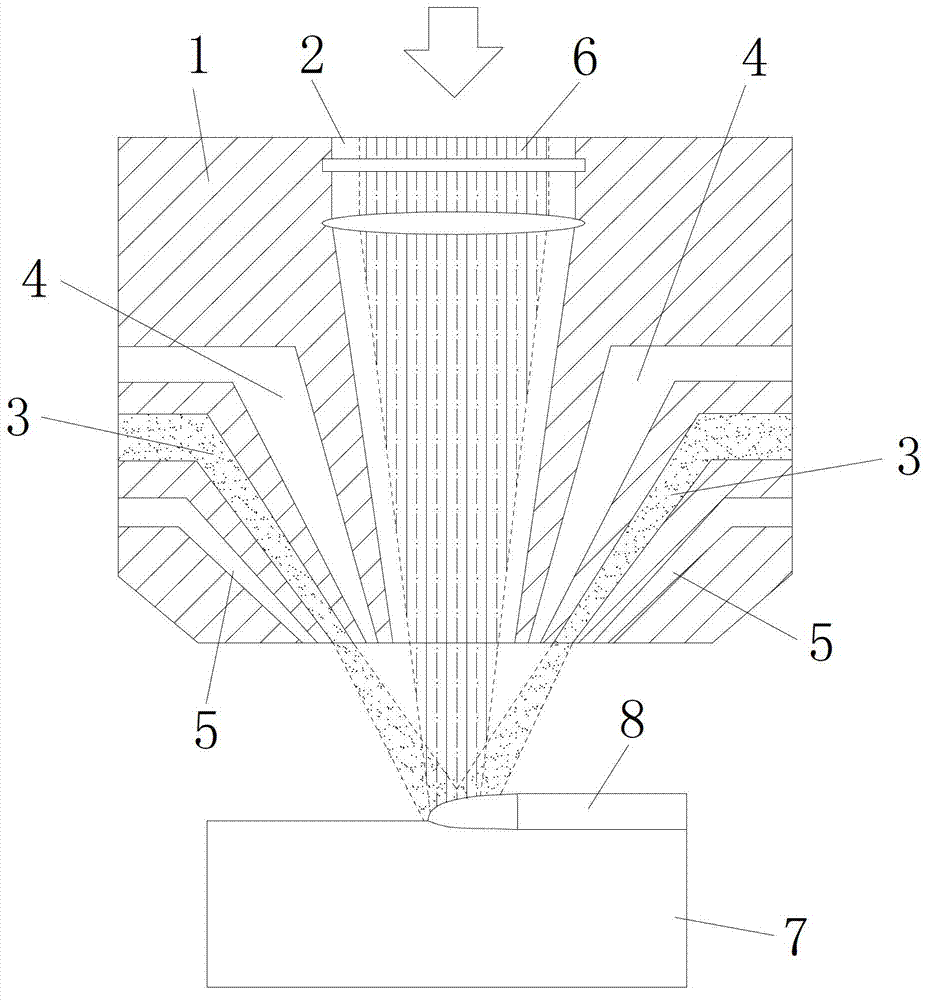

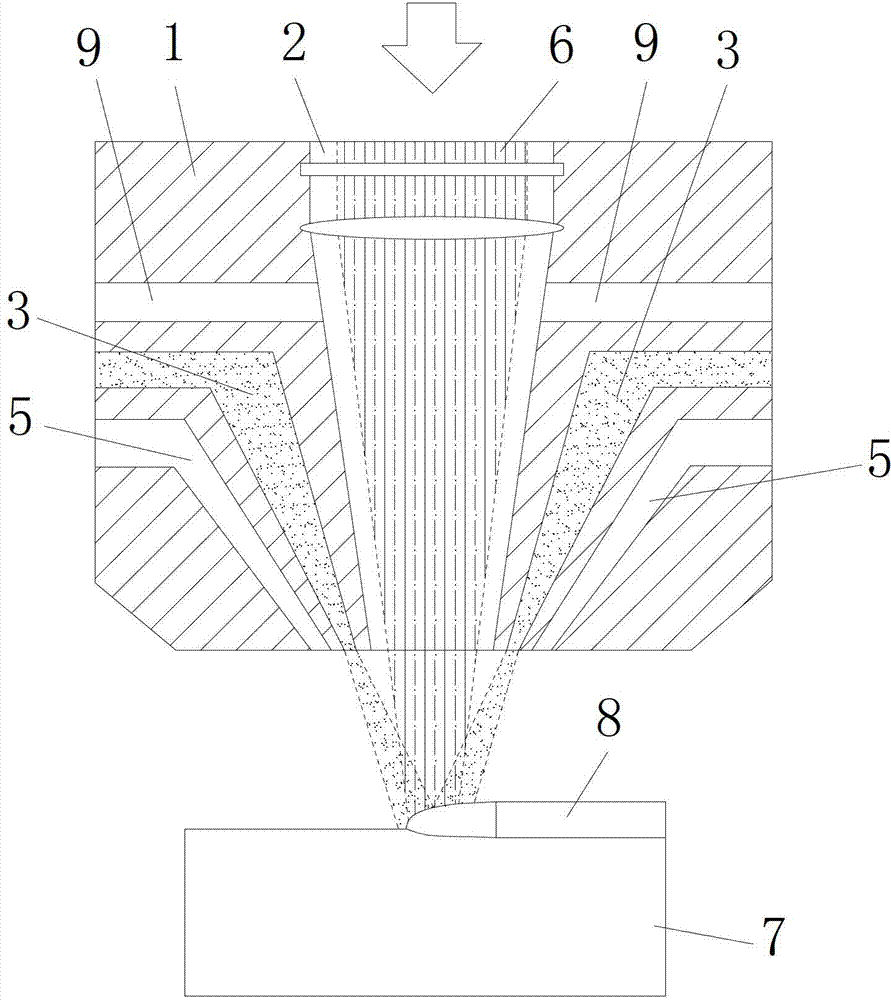

[0032] The difference between this embodiment and Embodiment 1 is: a nozzle used for the method for improving the effect of laser cladding, as attached figure 2 , it has a laser channel 2 opened in the center of the shower head 1, a first protective gas inlet 9 opened on the shower head 1 connected to a protective gas adding device and connected to the laser channel 2 at the other end, and opened around the laser channel 2 One end is connected with the powder adding device and the other end runs through the powder channel 3 on the bottom surface of the shower head 1, and one end opened on the periphery of the powder channel 3 is connected to another protective gas adding device and the other end runs through the second protective gas channel 5 on the bottom surface of the shower head 1 .

[0033] One end of the first protective gas inlet 9 is connected to the mixed gas adding device, and the second protective gas channel 5 is connected to the high-pressure nitrogen adding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com