Electric wire and cable coating device capable of improving product performances

A wire and cable and coating device technology, which is applied in the manufacture of cables/conductors, insulation of conductors/cables, circuits, etc., can solve the problems of low wire strength and slow production efficiency, and achieve high coating efficiency, convenient use, and guaranteed The effect of the wrapping effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The following will clearly and completely describe the technical solutions in the embodiments of the present invention with reference to the accompanying drawings in the embodiments of the present invention. Obviously, the described embodiments are only some, not all, embodiments of the present invention.

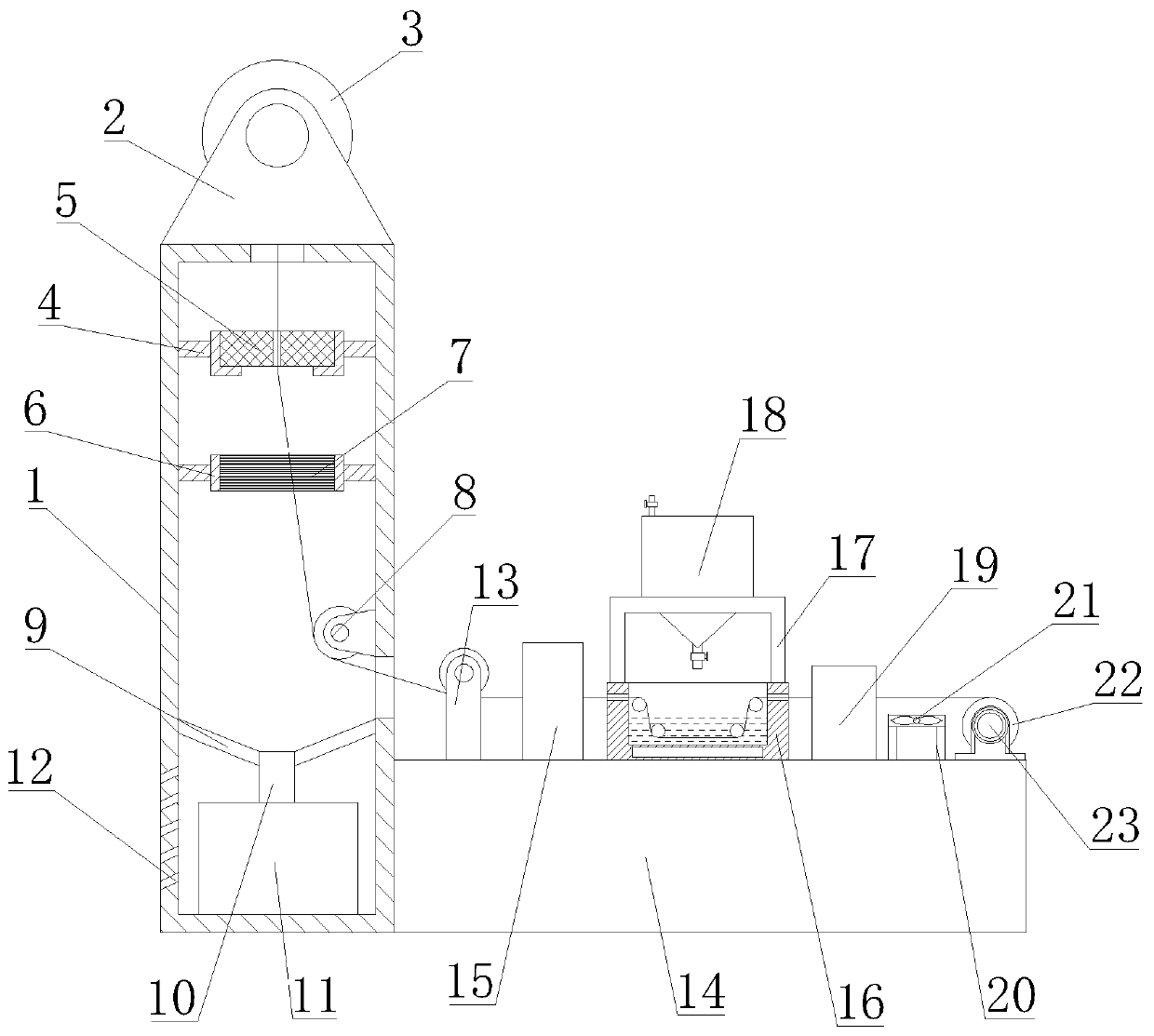

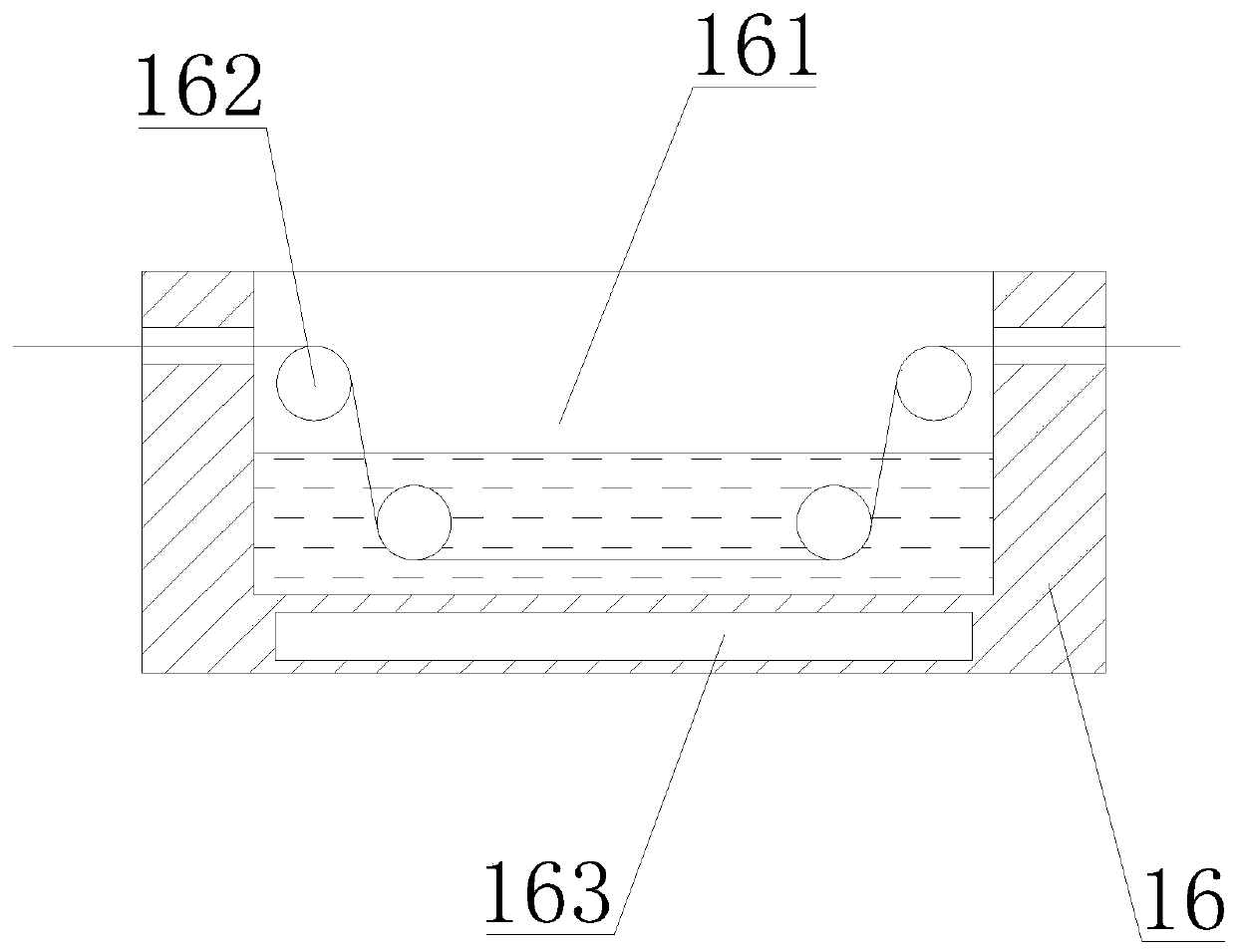

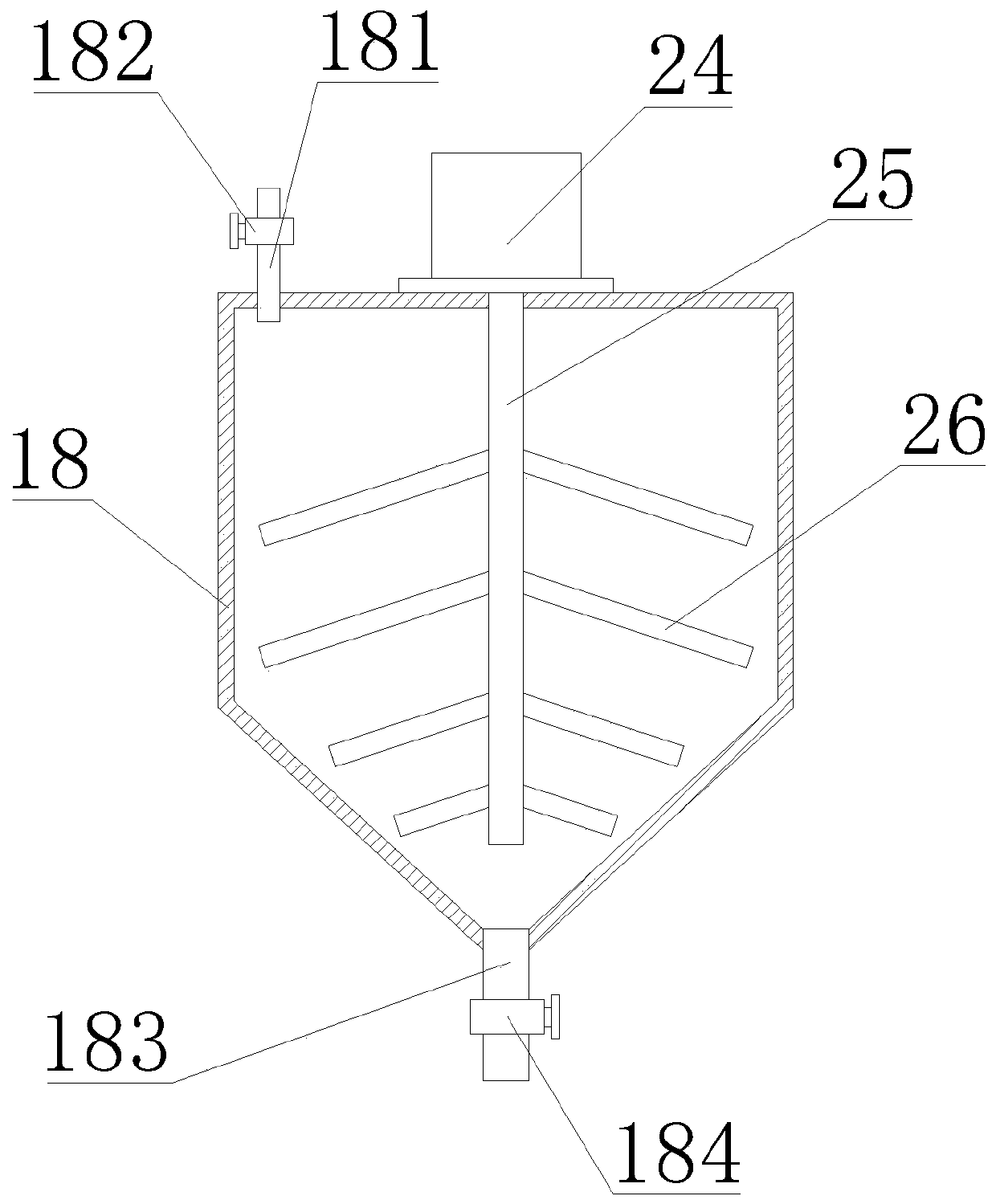

[0024] refer to Figure 1-3 , a wire and cable coating device for improving product performance, comprising a coating pretreatment box 1, a connecting frame 2, a burr removal member 4, a dust removal member 6, a first guide roller 8, a second guide roller 13, a base 14, Covering box 16, support frame 17, take-up roller 22 and take-up motor 23;

[0025] The connecting frame 2 is arranged on the cladding pretreatment box 1, and the pay-off roller 3 is rotatably connected to the connecting frame 2; the burr removal part 4 and the dust removal part 6 are all arranged in the cladding pretreatment box 1, and the burr removal part 4 The deburring filler 5 is provided, and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com