Powder metallurgy high-speed steel and preparation method thereof

A technology of powder metallurgy and high-speed steel, applied in the field of powder metallurgy high-speed steel and its preparation, can solve the problems of high price of powder metallurgy high-speed steel, difficult and expensive control of material impurity content, etc. Performance, the effect of improving hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

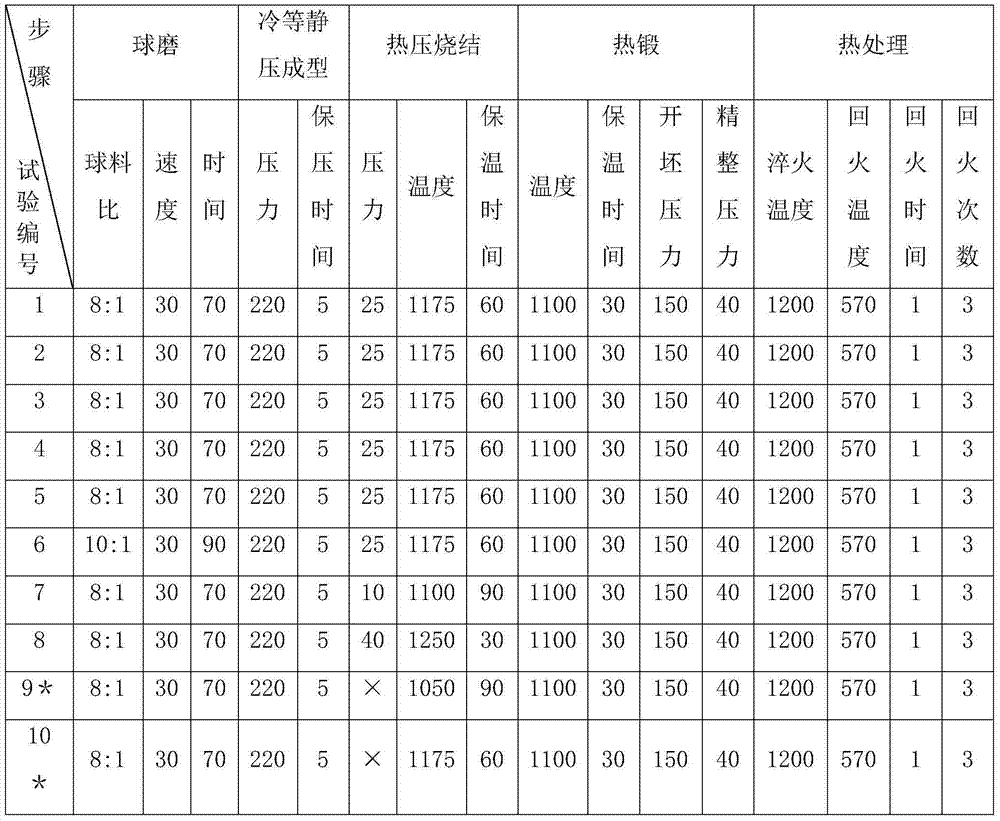

[0041] The preparation methods of powder metallurgy high-speed steel and the powder metallurgy high-speed steel obtained by these methods will be described in detail through experiments. Through these descriptions, those skilled in the art can clearly understand the outstanding features of the powder metallurgy high-speed steel preparation method of the present invention.

[0042] 1. Preparation of powder metallurgy high speed steel

[0043] 1.1. Basic process steps

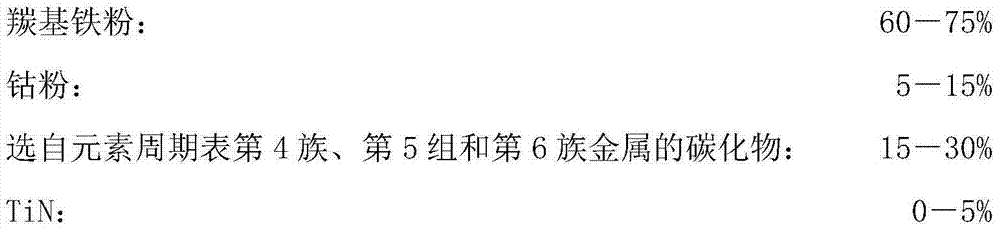

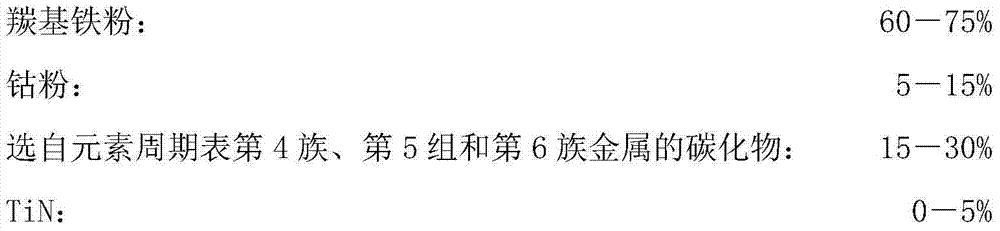

[0044] 1) Prepare the powder mixture

[0045] Weigh the raw materials according to the set components and proportions, and carry out mixed ball milling for 70-90 hours in a drum ball mill at a ball-to-material ratio (8-10):1, at a speed of 20-40 rpm, to prepare powder mixture;

[0046] 2) Molding

[0047] The powder mixture is made into a compact by cold isostatic pressing, the cold isostatic pressing pressure is 150MPa-350MPa, and the holding time is 1-10 minutes;

[0048] 3) Sintering

[0049] The above-m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| flexural strength | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com