Cold-rolled enamelled steel for deep-drawing liner and manufacturing method thereof

A manufacturing method and enamelled steel technology, applied in the field of metal materials and their manufacture, can solve the problems of inability to meet the pressure requirements of the enamel liner, low yield strength of the substrate, and decreased yield strength, and achieve excellent anti-scaling performance and excellent welding performance, high-strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

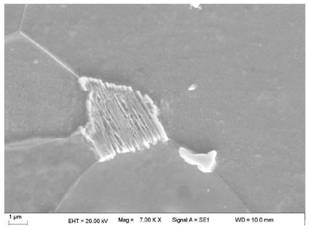

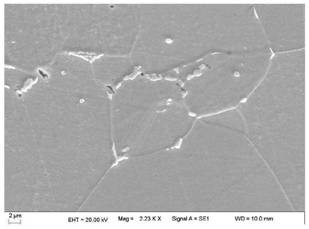

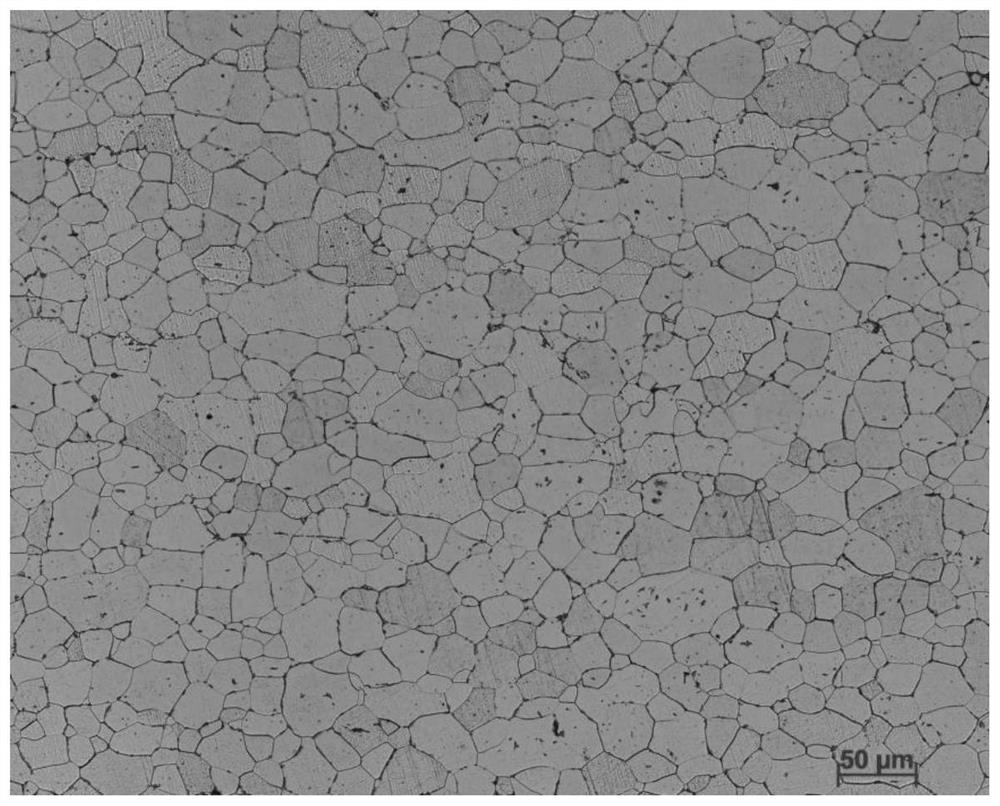

Image

Examples

Embodiment 1-6 and comparative example 1-2

[0081] Table 1 lists the mass percentages of each chemical element in the cold-rolled enamelled steel for deep-drawing liners of Examples 1-6 and the enamelled steel of Comparative Example 1-2.

[0082] Table 1. (wt%, the balance is Fe and other unavoidable impurities except S and P)

[0083]

[0084] The cold-rolled enamelled steel for the deep-drawing liner of Example 1-6 of the present invention and the enamelled steel of Comparative Example 1-2 all adopt the following steps to make:

[0085] (1) Smelting, refining and continuous casting;

[0086] (2) Slab heating: the heating temperature is 1100-1250°C, and the heating time is controlled to make the slab fully austenitized before hot rolling;

[0087] (3) Hot rolling and coiling: the final rolling temperature of hot rolling is controlled to be 880-920°C, water cooling, air cooling or slow cooling is carried out after rolling, and then coiling is carried out, and the coiling temperature is controlled to be 680-720°C;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com