High-strength steel plate with excellent double-face enamelling performance and used for glass lining, and manufacturing method thereof

A technology of high-strength steel plate and manufacturing method, which is applied in the field of high-strength steel plate for glass lining and its manufacturing, can solve the problems such as the reduction or disappearance of tiny gaps, the reduction of hydrogen storage traps, etc., and achieve excellent double-sided enamelling performance and save manufacturing Effect of cost, good plasticity and weldability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

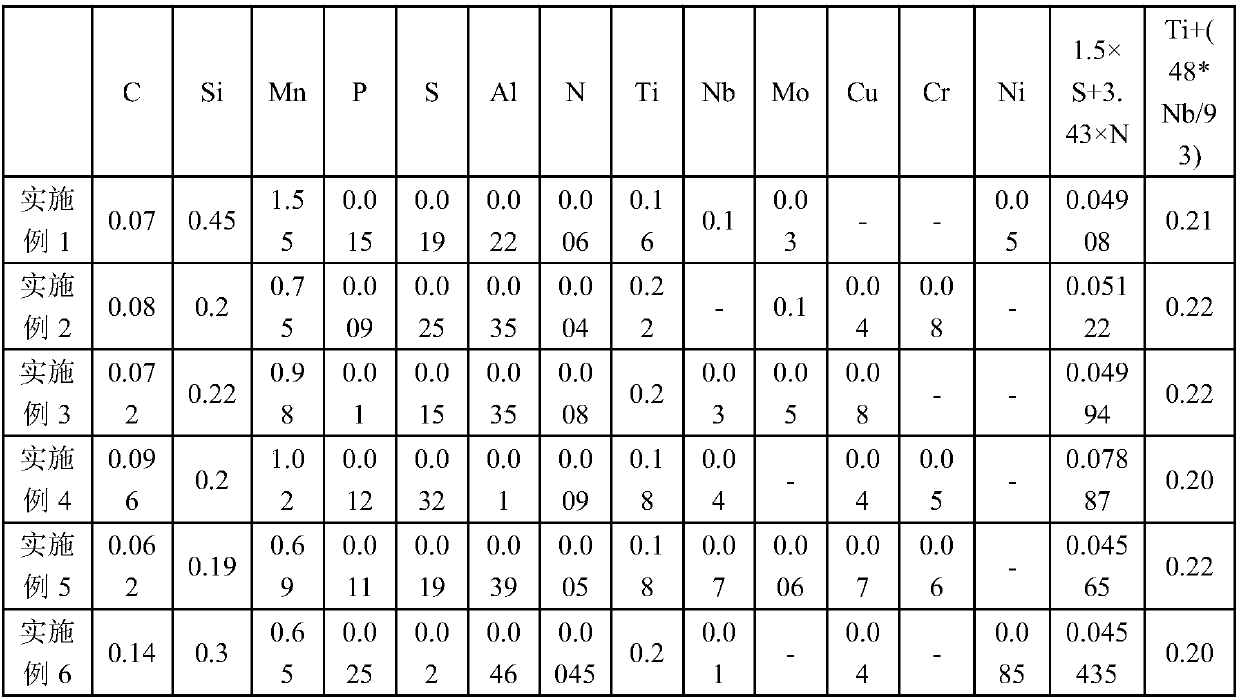

Embodiment 1-7

[0055] The high-strength steel sheet for glass lining in the above-mentioned embodiment is prepared by the following steps:

[0056] (1) Smelting and casting: 300t top-bottom combined blowing converter is used for smelting steel, and molten steel is cast into slabs by continuous casting machine;

[0057] (2) Hot rolling: the heating temperature before the casting billet rolling is 1150~1250℃, the holding time=t×(0.5~1.5), where t is the thickness of the slab, the unit is mm, and the unit of holding time is min; control The rolling temperature of rough rolling is 1100~1200℃, and the deformation is ≥50%; after the rough rolling, water is sprayed to cool, and the finish rolling temperature is controlled to 920~1000℃, the final rolling temperature is 870~920℃, and the deformation is ≥60%;

[0058] (3) Cooling: control the average cooling rate ≤ 10℃ / s. The cooling method can adopt water spray cooling or slow cooling.

[0059] In addition, it should be noted that in other embodiments, in o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Yield strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com