Glassed steel with good fish scaling resistance and manufacturing method of steel plate of glassed steel

A technology for anti-scale explosion and enamel steel is applied in the field of manufacturing hot-rolled enamel steel and its steel plate, which can solve the problems of increasing smelting difficulty, increasing process cost, long production cycle, etc. Widely adaptable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following examples are used to specifically illustrate the contents of the present invention, and these examples are only general descriptions of the contents of the present invention, and do not limit the contents of the present invention. The steel referred to in the present invention includes cast slabs, steel plates, steel pipes and the like.

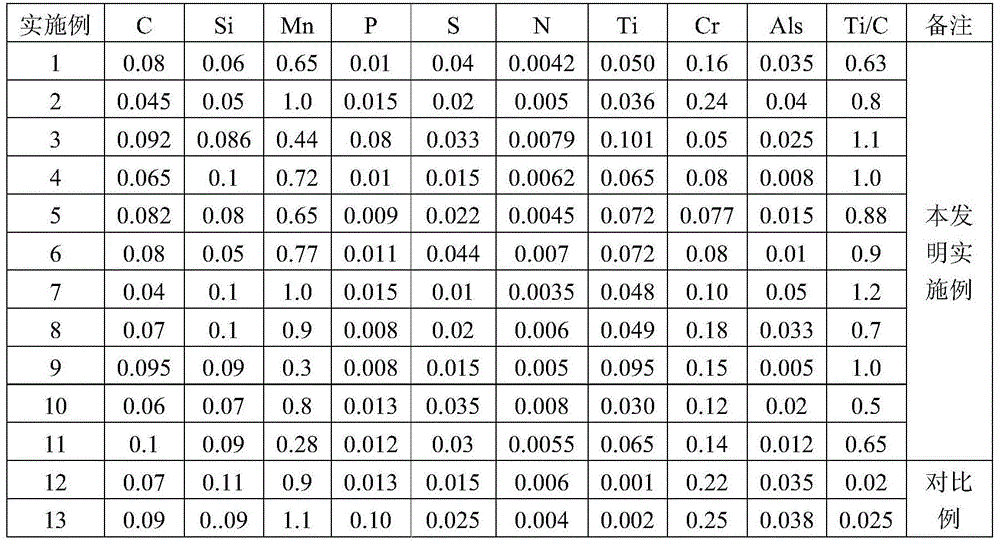

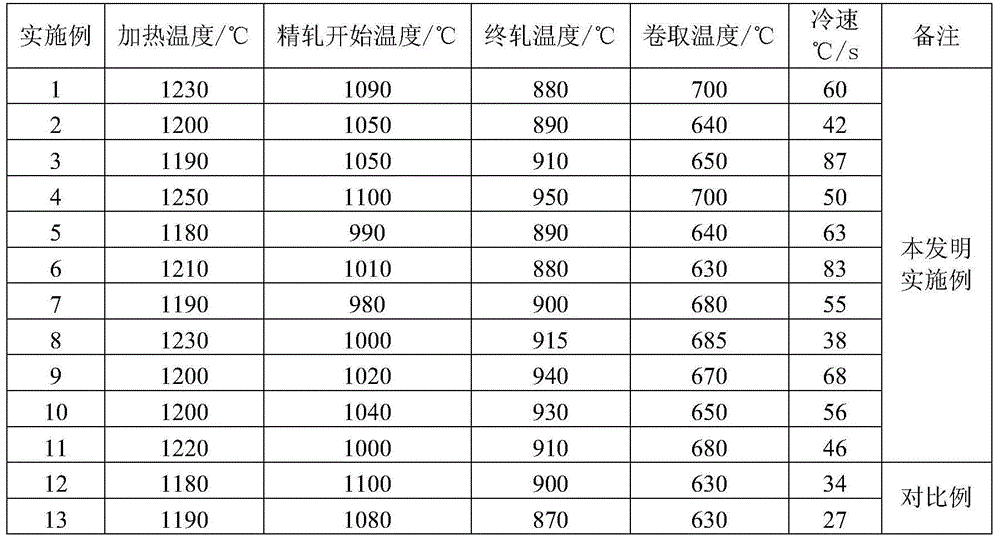

[0031] Table 1 is the smelting composition of the steel of the embodiment of the present invention and the steel of the comparative example, Table 2 is the production process parameters of the steel of the embodiment of the present invention and the steel of the comparative example, and Table 3 is the performance of the steel of the embodiment of the present invention and the steel of the comparative example.

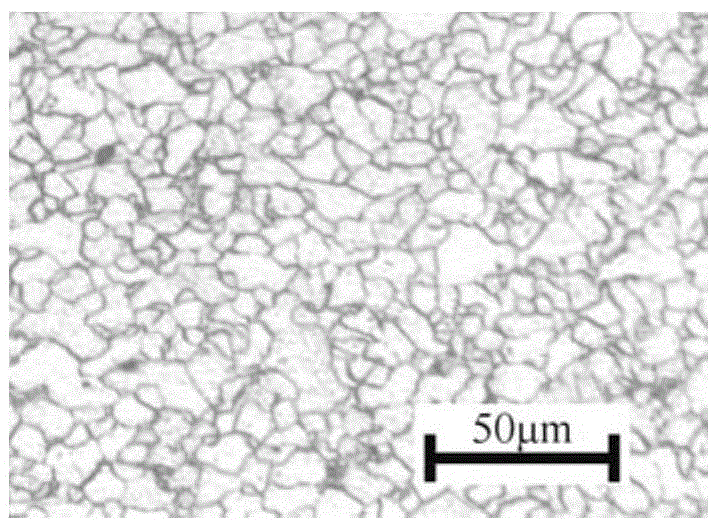

[0032] The test of anti-scale explosion performance is to place the steel plate for one month after enamelling, and observe the scale explosion point with a 100 times microscope.

[0033] Table 1 The smelting compo...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com