Hot-rolled pickled steel plate with excellent enameling performance for double-sided enameling and manufacturing method thereof

A hot-rolled pickling and manufacturing method technology is applied to the hot-rolled pickling steel sheet for double-sided enamel and its manufacturing field, which can solve the problems of low production cost, pinhole defects, and less alloy usage, and improve the enamel adhesion. , the effect of smooth surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

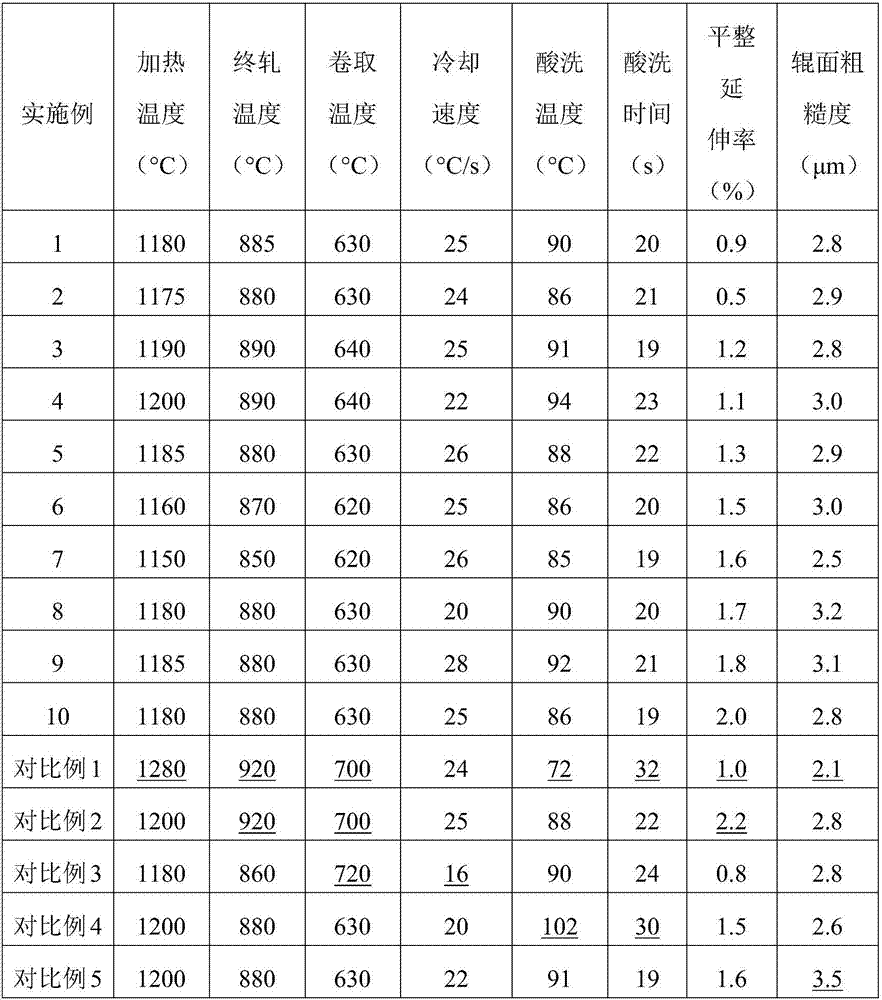

[0043] In order to better explain the present invention, the main content of the present invention is further clarified below in conjunction with specific examples, but the content of the present invention is not limited to the following examples.

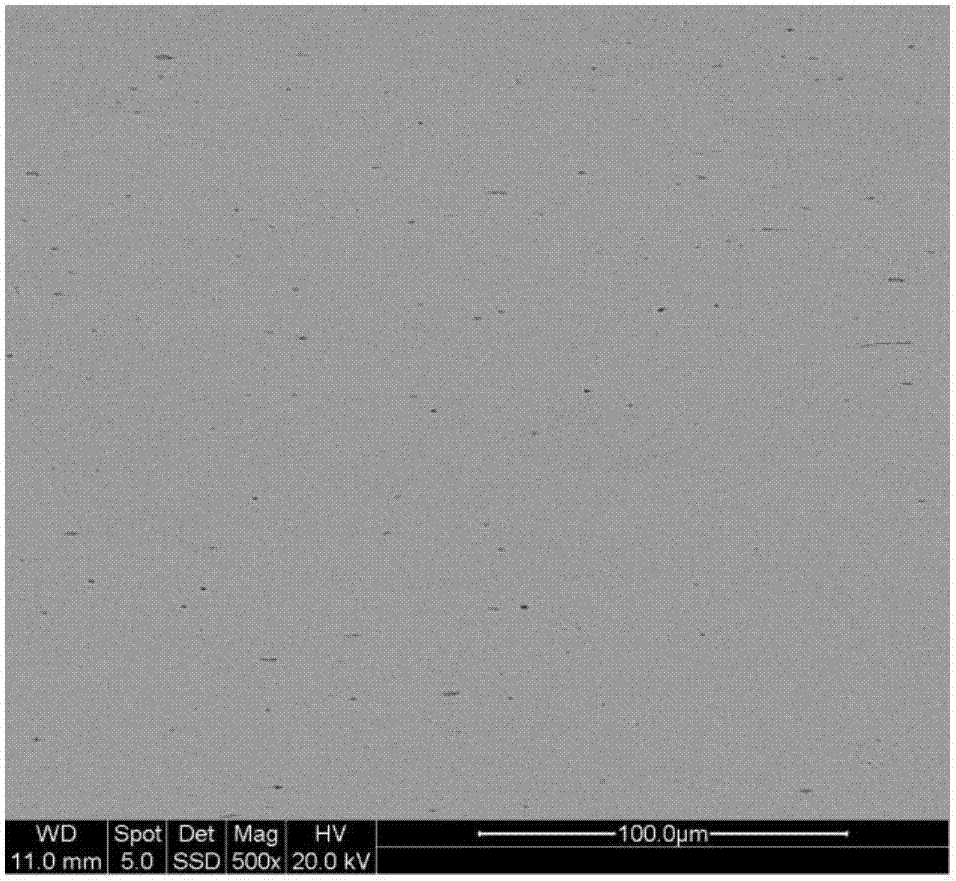

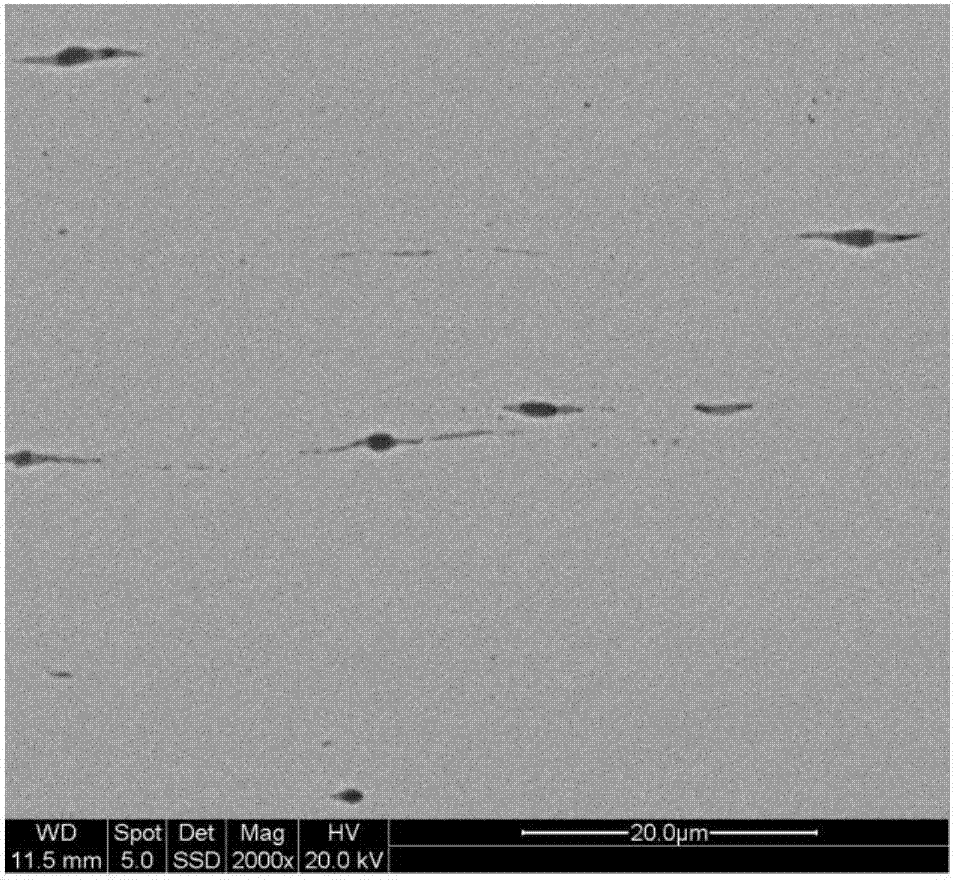

[0044] A hot-rolled pickled steel sheet for double-sided enamel with excellent enamelling performance, the chemical composition of the hot-rolled pickled steel sheet for double-sided enamel is: C: 0.01-0.02%, Mn: 0.5-1.0%, Si 1~0.0%, Pi 1~2%, S0.03~0.05%, Als 03~0.0, Cu: 0.20~0.40%, Nb: 0.03~0.06%, O: 0.004~0.010%, the balance is Fe and others Inevitable impurities; the structure is ferrite and a small amount of cementite, and a large number of spherical and linear composite inclusions are evenly distributed in the steel.

[0045] The method for manufacturing the above-mentioned hot-rolled pickled steel plate for double-sided enamel with excellent enamelling performance, the method is manufactured through seven steps of molten iron...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| surface roughness | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com