Method for performing thermal treatment on zirconium alloy

A heat treatment method and zirconium alloy technology, which is applied in the field of metal heat treatment, can solve problems such as the adverse effects of zirconium alloy related properties, and achieve the effects of eliminating structural defects, increasing driving force, and improving irregularities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

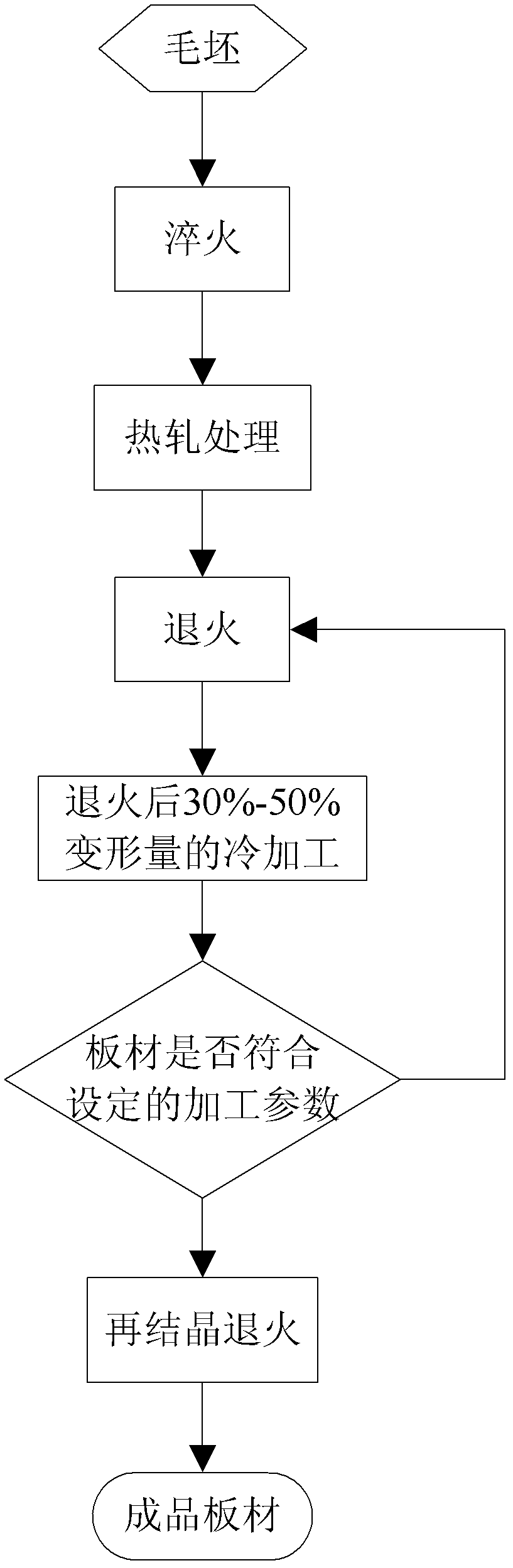

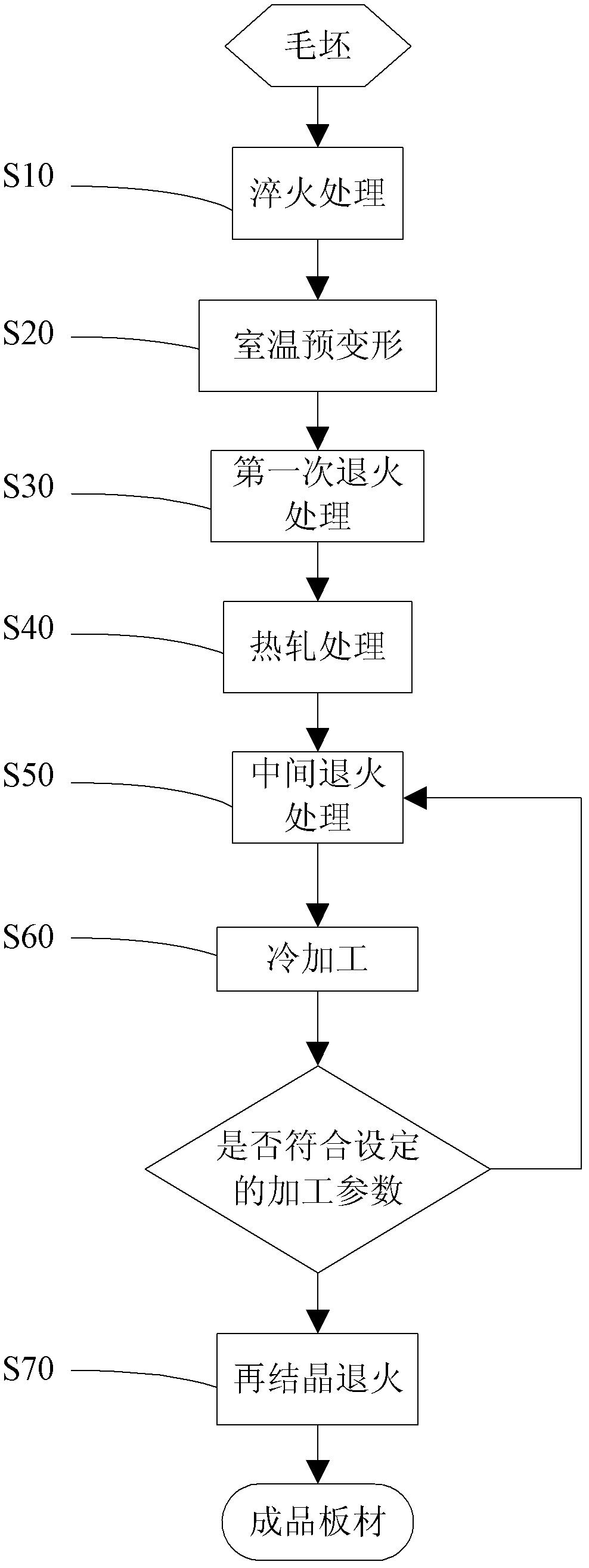

[0032] Please refer to figure 2 , the zirconium alloy heat treatment method provided by the embodiment of the present invention comprises the following steps:

[0033] S10) performing a quenching treatment on the zirconium alloy blank to obtain a quenched blank;

[0034] S20) cooling the quenched blank to room temperature, and then performing deformation treatment with a deformation amount of 20%, that is, pre-deformation treatment at room temperature, to obtain a pre-deformed blank;

[0035] S30) heating the pre-deformed blank to 650° C. for the first annealing treatment, and the annealing time is 30 hours;

[0036] S40) hot-rolling the pre-deformed blank after the first annealing treatment to obtain a plate blank;

[0037] S50) performing intermediate annealing on the plate blank, and performing cold working after the intermediate annealing;

[0038] S60) Repeat step S50) several times until the outer dimensions of the plate blank meet the processing requirements, and ob...

Embodiment 2

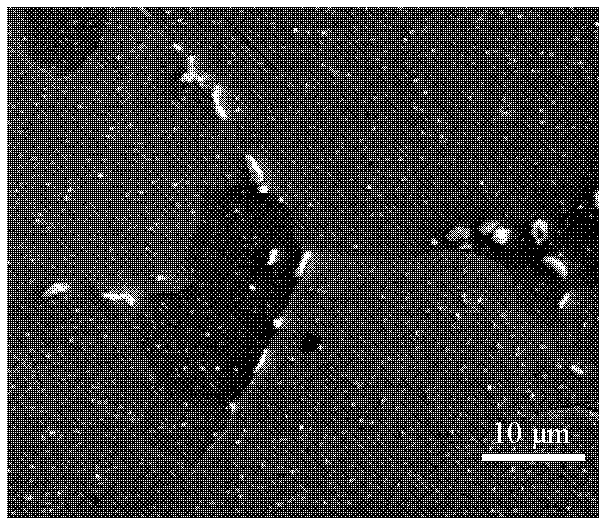

[0044] After the quenching treatment, the zirconium alloy blank is pre-deformed at room temperature with a deformation amount of 20%, and then annealed for the first time. The annealing temperature is set at 650° C. and the annealing time is 1.5 hours. After the above treatment, the zirconium alloy is subjected to hot rolling, 2 times of intermediate annealing, cold working after each intermediate annealing, and finally recrystallization annealing to obtain a finished plate. Similarly, by conducting metallographic analysis, we obtained Figure 5-1 , the metallographic diagram of the second phase distribution of the zirconium alloy, and Figure 5-2 , grain size metallographic diagram of zirconium alloys. Separate it with Figure 3-1 , Figure 3-2 In contrast, it is obvious that after the zirconium alloy is treated by the method provided in Example 2 of the present invention, the particles of the second phase of the zirconium alloy energy are diffusely distributed, and at the sa...

Embodiment 3

[0046] After the quenching treatment, the zirconium alloy blank is pre-deformed at room temperature with a deformation amount of 10%, and then annealed for the first time. The annealing temperature is set at 450° C. and the annealing time is 10 hours. After the above treatment, the zirconium alloy is subjected to hot rolling, 3 times of intermediate annealing and cold working after each intermediate annealing, and finally recrystallization annealing treatment to obtain a finished plate. Similarly, through metallographic analysis, it is found that after the zirconium alloy is treated by the method provided in the embodiment of the present invention, the second phase particles of the zirconium alloy energy are dispersedly distributed, and at the same time, the grain size of the zirconium alloy is fine and uniform.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com