A kind of high-strength heat-resistant graphene-aluminum composite conductor material and preparation method thereof

A conductive material, graphene technology, applied in the direction of conductive materials, conductive materials, metal/alloy conductors, etc., can solve the problems of composite materials such as the decline in tensile strength at room temperature, and achieve simple preparation methods, good mechanical properties and heat resistance, significant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

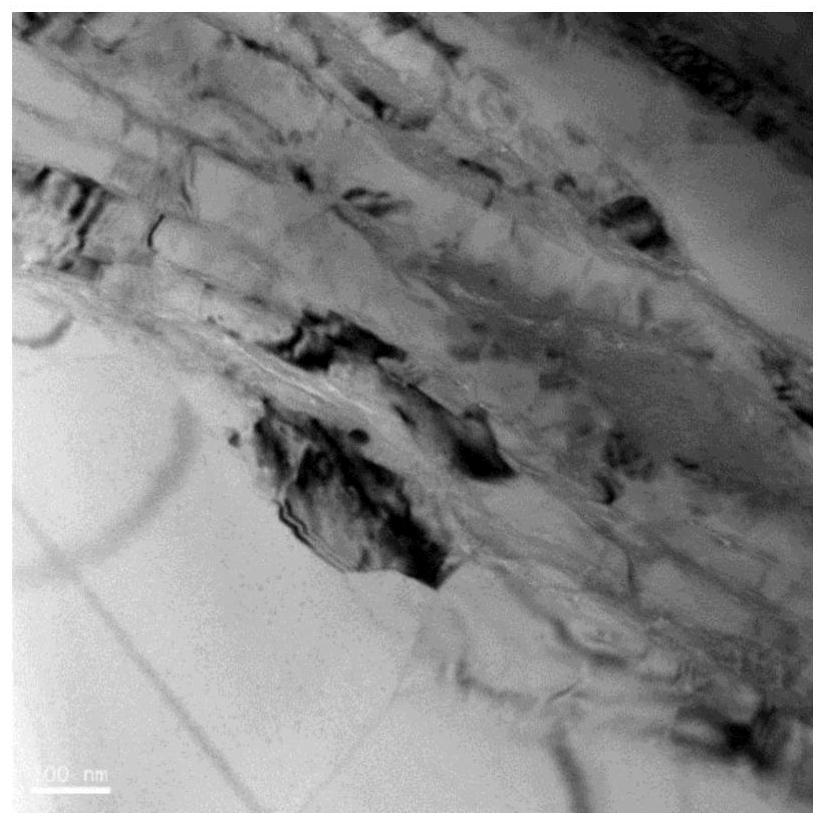

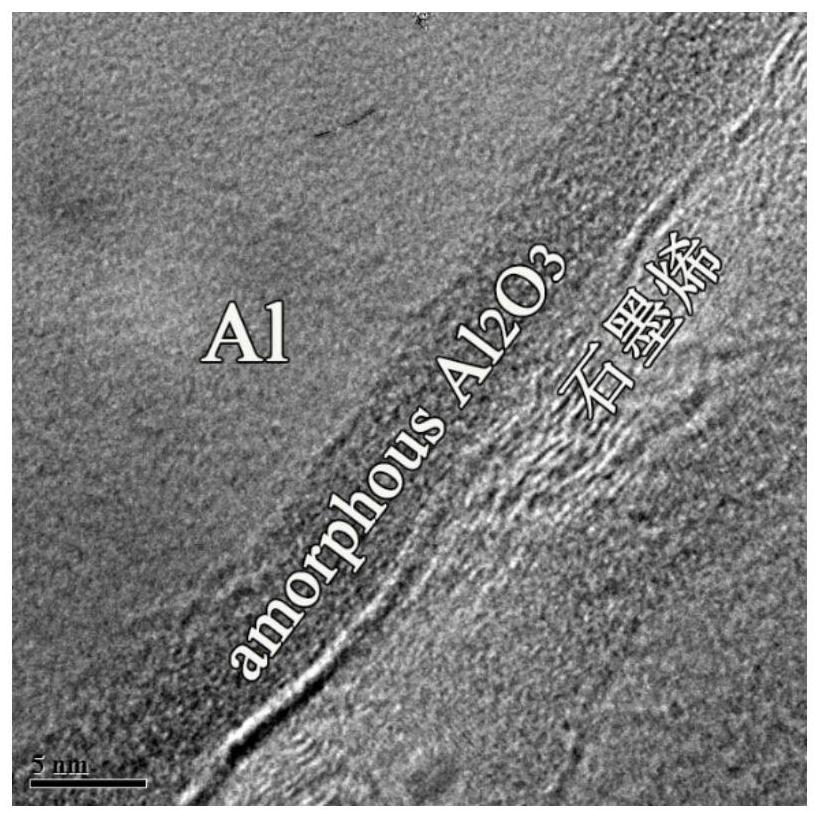

Image

Examples

Embodiment 1

[0031] This embodiment provides a high-strength heat-resistant graphene-aluminum composite conductor material. The composite conductor material is composed of the following components in mass percentage: graphene is 0.2%, and the rest is aluminum.

[0032] The above-mentioned high-strength heat-resistant graphene-aluminum composite conductor material can be prepared by the following method, and the specific preparation method includes the following steps:

[0033] Step 1, using aluminum powder with a sphere diameter of 0.5 μm and a graphene powder with a sheet diameter of 0.1 μm and a thickness of 5 nm with a purity of more than 99.9% as raw materials. The composite conductor material is formulated according to the mass percentage of the following components: 0.2% of graphene, and the rest is aluminum. Mix aluminum powder and graphene powder evenly by high-energy ball milling. During the ball milling process, the O content is 200ppm, the ball milling speed is 300rpm, and the b...

Embodiment 2

[0043] This embodiment provides a high-strength heat-resistant graphene-aluminum composite conductor material. The composite conductor material is composed of the following components in mass percentage: graphene is 0.2%, and the rest is aluminum.

[0044] The above-mentioned high-strength heat-resistant graphene-aluminum composite conductor material can be prepared by the following method, and the specific preparation method includes the following steps:

[0045] Step 1, using aluminum powder with a sphere diameter of 0.5 μm and a graphene powder with a sheet diameter of 0.1 μm and a thickness of 5 nm with a purity of more than 99.9% as raw materials. The composite conductor material is formulated according to the mass percentage of the following components: 0.2% of graphene, and the rest is aluminum. Mix aluminum powder and graphene powder evenly by high-energy ball milling method. During the ball milling process, the O content is 1000ppm, the ball milling speed is 300rpm, a...

Embodiment 3

[0051] This embodiment provides a high-strength heat-resistant graphene-aluminum composite conductor material. The composite conductor material is composed of the following components in mass percentage: graphene is 0.5%, and the rest is aluminum.

[0052] The above-mentioned high-strength heat-resistant graphene-aluminum composite conductor material can be prepared by the following method, and the specific preparation method includes the following steps:

[0053] Step 1, using aluminum powder with a spherical diameter of 325 mesh (44 μm) and graphene powder with a sheet diameter of 2 μm and a layer thickness of 10 nm as raw materials. The composite conductor material is formulated according to the mass percentage of the following components: 0.5% of graphene, and the rest is aluminum. Mix aluminum powder and graphene powder uniformly by high-energy ball milling method, and ball mill at 300rpm for 5h in an argon atmosphere with an O content of 700ppm during the ball milling pr...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com