A kind of c/c-ni-cu composite material and its preparation method and application

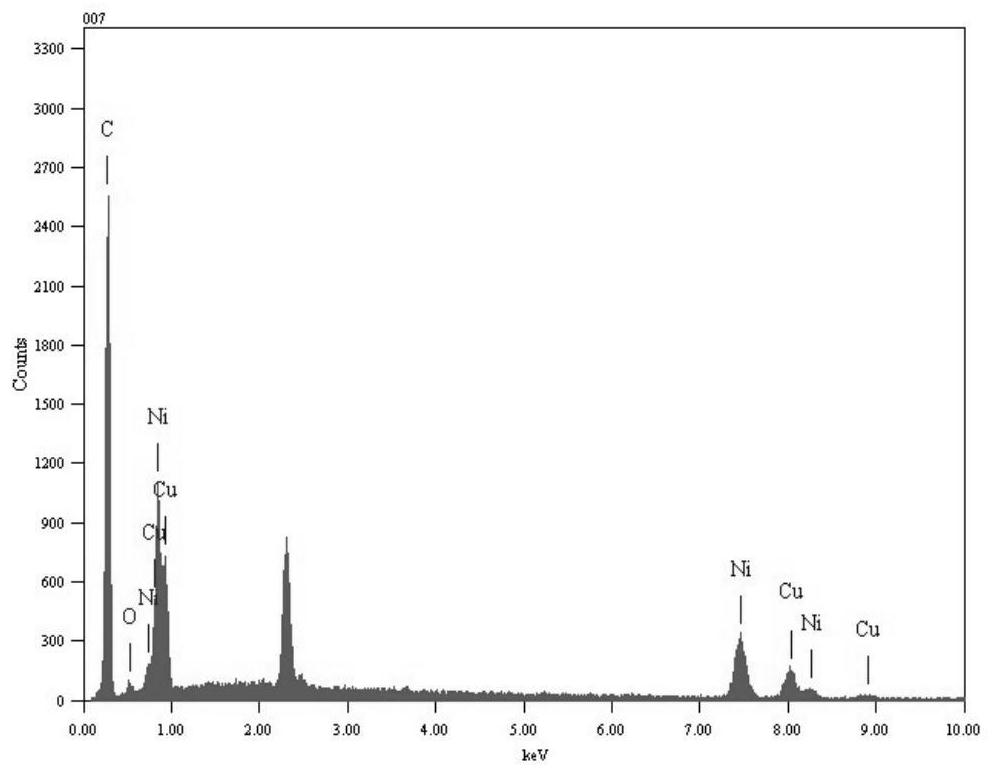

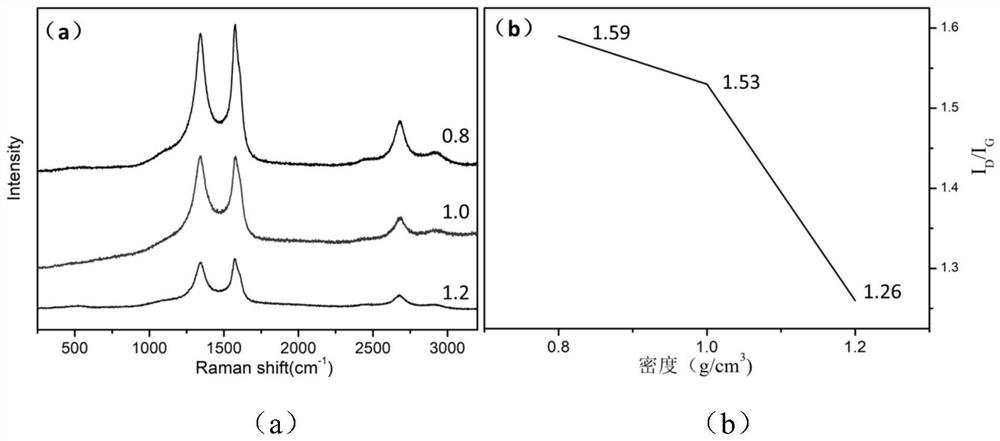

A composite material, c-ni-cu technology, applied in the field of C/C-Ni-Cu composite material and its preparation, can solve the problem of restricting the performance of C/C-Cu composite material, unfavorable electrical conductivity, friction and wear performance, matrix Carbon graphitization degree is not high, to achieve the effect of improving catalytic graphitization efficiency, excellent wear resistance, and improving graphitization degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0032] The preparation method of C / C-Ni-Cu composite material of the present invention, comprises the following steps:

[0033] 1) Dissolving the biomass carbon source in water to prepare a carbon source solution with a concentration of 250-400g / L;

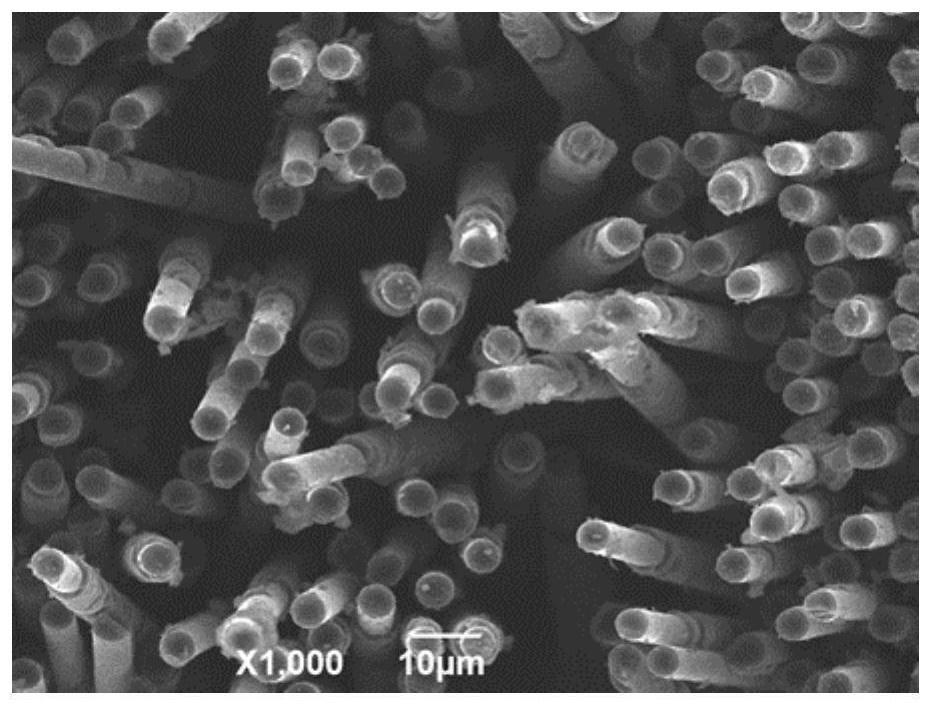

[0034] 2) Put the chopped carbon fiber preform and carbon source solution into a hydrothermal kettle and react in a microwave reactor. The reaction temperature is 160-200°C, and the reaction time is 2-3 hours. After the reaction is completed, naturally cool to room temperature and take out the carbon fiber preform Carrying out vacuum drying treatment to obtain carbon fiber preform A;

[0035] 3) dissolving the nickel source in water, and adding urea to mix to obtain a nickel source solution;

[0036] 4) Put nickel source solution and carbon fiber preform A into a beaker, soak for 12 hours, and carry out vacuum treatment to obtain carbon fiber preform B; take out carbon fiber preform B and put it into a hydrothermal kettle, use ed...

Embodiment 1

[0047] Step 1: Select carbon felt as a chopped carbon fiber preform as a skeleton; use glucose as a carbon source, and prepare a glucose solution with a concentration of 300g / L;

[0048] Step 2: Put the chopped carbon fiber preform and the carbon source solution into a hydrothermal kettle to react in a microwave reactor, the reaction temperature is 200°C, the reaction time is 3h, then naturally cool to room temperature, and dry to obtain a high-density carbon fiber prefabrication body;

[0049]Step 3: Mix the nickel source and urea according to the set molar ratio to prepare a nickel source solution of nickel source: urea = 0.8:1; put the nickel source solution and carbon fiber preform into a beaker, soak for 12 hours, and then vacuumize Processing: Take out the carbon fiber prefabricated body and put it into a hydrothermal kettle, use edible oil as a solvent, put it into a microwave reactor for reaction, the reaction temperature is 200°C, and the reaction time is 2h. Dry and...

Embodiment 2

[0055] Step 1: Select carbon felt as a chopped carbon fiber preform as a skeleton; use glucose as a carbon source, and prepare a glucose solution with a concentration of 300g / L;

[0056] Step 2: Put the chopped carbon fiber preform and the carbon source solution into a hydrothermal kettle to react in a microwave reactor, the reaction temperature is 200°C, the reaction time is 3h, then naturally cool to room temperature, and dry to obtain a high-density carbon fiber prefabrication body;

[0057] Step 3: Mix the nickel source and urea according to the set molar ratio to prepare a nickel source solution of nickel source: urea = 0.8:1; put the nickel source solution and carbon fiber preform into a beaker, soak for 12 hours, and then vacuumize Processing: Take out the carbon fiber prefabricated body and put it into a hydrothermal kettle, use edible oil as a solvent, put it into a microwave reactor for reaction, the reaction temperature is 200°C, and the reaction time is 2h. Dry an...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com