Preparation method of ablation resistant C/SiC ceramic matrix composite material

A composite material and ceramic-based technology, which is applied in the field of preparation of ablation-resistant C/SiC ceramic-based composite materials, can solve the problems of few researches on continuous carbon fiber impregnated multi-element amorphous ceramic composite materials, and improve high-temperature mechanical properties and expand Application range, effect of solving brittle problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a preparation method of an ablation-resistant C / SiC ceramic matrix composite material, the preparation method comprising the following steps:

[0032] (1) Provide a porous C / C composite material preform, preferably with a density of 0.8 to 1.0 g / cm 3 (can be any numerical value in this range, for example, can be 0.8g / cm 3 , 0.9g / cm 3 , 1.0g / cm 3 ) porous C / C composite preform.

[0033] The present invention can adopt the CVI densified carbon fiber prefabricated body, place the carbon fiber prefabricated body in a chemical vapor deposition furnace, use the CVI process to chemically deposit the green body, and the carbon source gas diffuses into the pores of the carbon fiber prefabricated body after cracking in a low vacuum environment, And deposited on the hole wall to obtain a porous C / C composite material prefabricated body. The densification process can be propylene as the carbon source gas, nitrogen as the carrier gas, and the deposition te...

Embodiment 1

[0048] (1) The green body is chemically deposited by the CVI process to obtain a porous C / C composite material preform, which is deposited to a density of 0.8g / cm 3 , the densification process uses propylene as the carbon source gas, nitrogen as the carrier gas, and a deposition temperature of 900°C.

[0049] (2) Use polycarbosilane solution to impregnate, solidify, and crack the precursor to prepare a C / SiC composite material, and perform multiple rounds of impregnation and cracking to obtain a density of 1.8g / cm 3 C / SiC composite materials.

[0050] (3) Using chloroform as a solvent, adding polysilazane and boron powder, the proportion of polysilazane in the mixed solution is 35wt%, and the proportion of boron powder in the mixed solution is 20wt%. Stir evenly to obtain a SiBCN precursor solution.

[0051] (4) Using the precursor solution obtained above, the C / SiC composite material prepared in step (2) is impregnated, solidified and cracked. The impregnation is vacuum im...

Embodiment 2 to 4

[0054] Preparation method is basically the same as Example 1, except that:

[0055] For Example 2, in step (2), multiple rounds of dipping and cracking were carried out to obtain a density of 1.9 g / cm 3 ceramic matrix composites.

[0056] For Example 3, in step (2), multiple rounds of dipping and cracking were carried out to obtain a density of 2.0 g / cm 3 ceramic matrix composites.

[0057] For Example 4, in step (2), multiple rounds of dipping and cracking were carried out to obtain a density of 2.5g / cm 3 ceramic matrix composites.

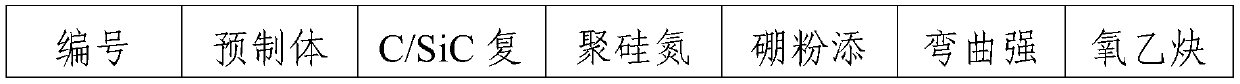

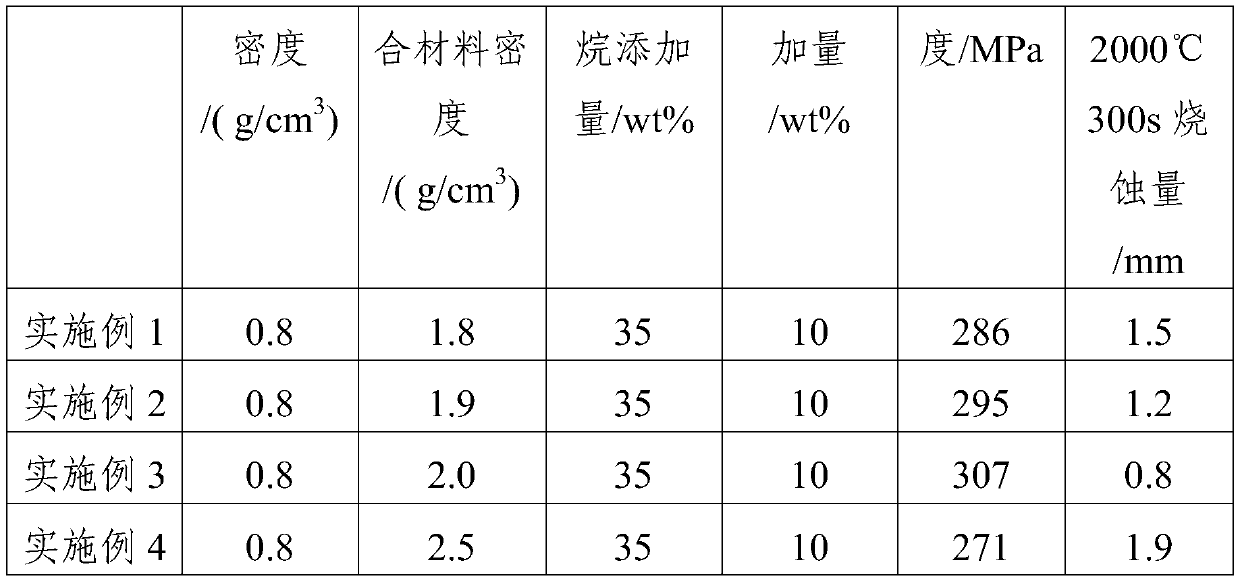

[0058] The test results of the test splines are shown in Table 1.

[0059] Table 1

[0060]

[0061]

[0062] Comparing the test results of Examples 1 to 4, the inventors found that with the increase of the density of the C / SiC composite material, the mechanical properties of the final composite material are getting better and better. The inventor speculates that this is because the relatively dense C / SiC composite material can well p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com