Method for increasing bismuth layer structure piezoelectricity ferroelectric ceramic material density

A ferroelectric ceramic, bismuth layer structure technology, applied in piezoelectric/electrostrictive/magnetostrictive devices, circuits, electrical components, etc., to achieve the effects of inhibiting grain boundary migration, improving density, and reducing oxygen vacancies

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

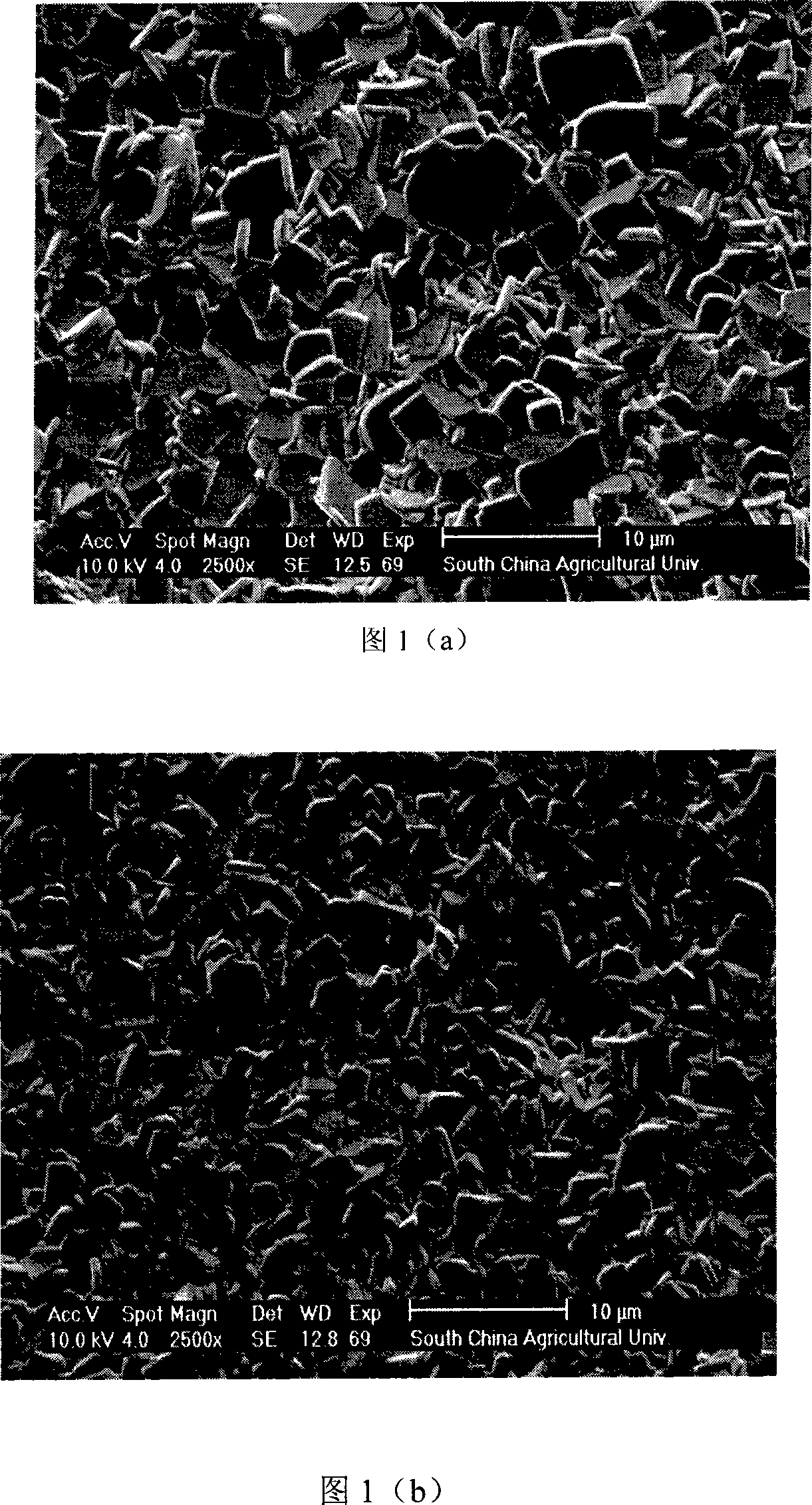

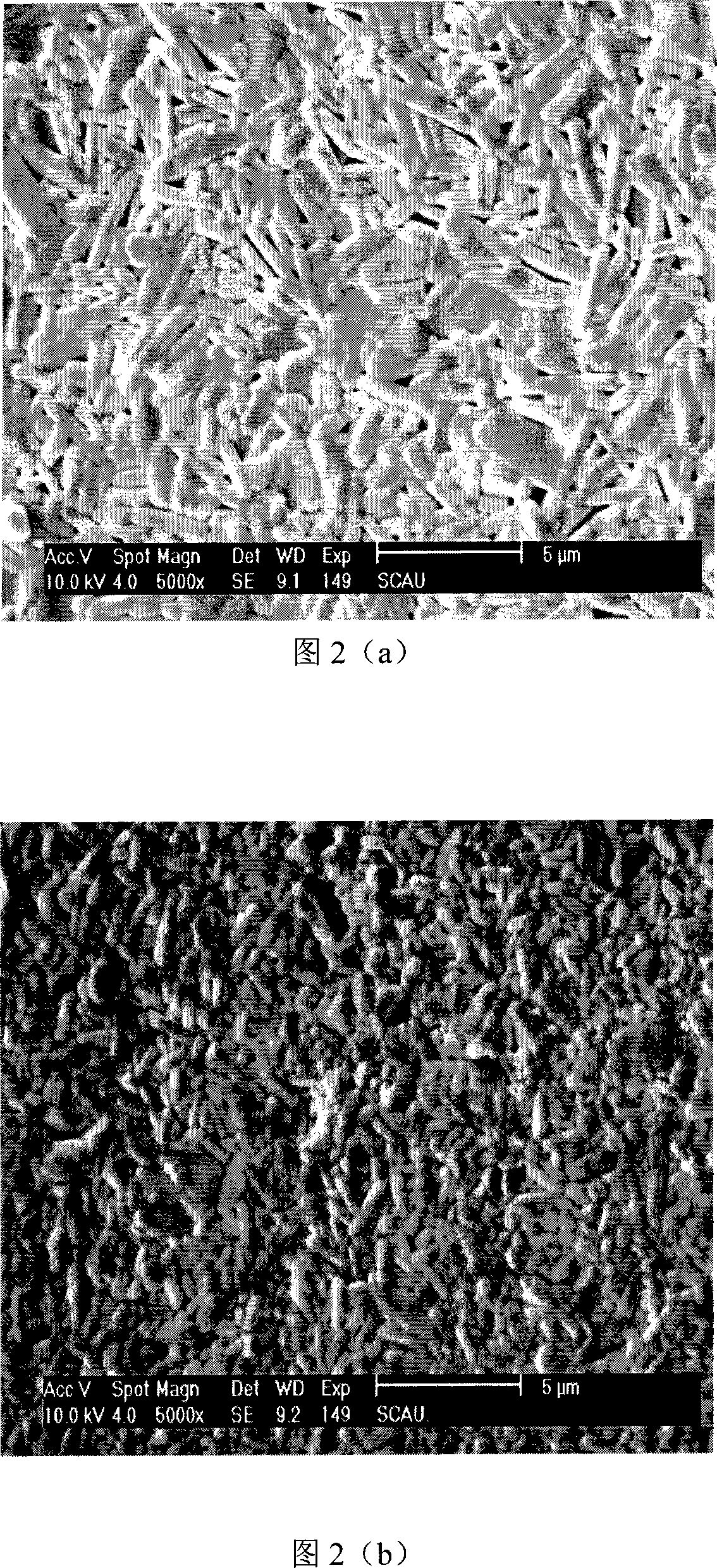

Image

Examples

Embodiment 1

[0024] Sr with m=4 0.3 Ba 0.7 Bi 4 Ti 3.95 V 0.05 o 15 For the base formula, the molar ratio Sr: Ba: Bi: Ti: V = 0.3: 0.7: 4: 3.95: 0.05 ingredients, the raw materials used are analytically pure strontium carbonate (SrCO 3 ), barium carbonate (BaCO 3 ), bismuth oxide (Bi 2 o 3 ), titanium oxide (TiO 2 ), vanadium oxide (V 2 o 5 ).

[0025] Calculate and weigh raw materials according to the formula. Using distilled water as the ball milling medium, use a planetary ball mill for 2 hours, dry at 120°C, and pass through an 80-mesh sieve. Then the mixture was sealed and pre-fired at 800°C for 2 hours. After crushing the pre-fired powder for 4 hours, dry it at 120° C. and pass through a 80-mesh sieve. Pre-compress the powder with a pressure of 10MPa, and then press the powder into a disc with a diameter of 15mm and a thickness of 2mm with a cold isostatic press under a pressure of 250MPa, and hold the pressure for 1min.

[0026] The shaped discs are sealed and sintere...

Embodiment 2

[0032] SrCaBi with m=5 4 Ti 5 o 18 For the base formula, the molar ratio Sr: Ca: Bi: Ti = 1: 1: 4: 5 ingredients, the raw materials used are analytically pure strontium carbonate (SrCO 3 ), calcium carbonate (CaCO 3 ), bismuth oxide (Bi 2 o 3 ), titanium oxide (TiO 2 ).

[0033] Calculate and weigh raw materials according to the formula. Using distilled water as the ball milling medium, use a planetary ball mill for 2 hours, dry at 120°C, and pass through an 80-mesh sieve. Then the mixture was sealed and pre-fired at 900°C for 4 hours. After crushing the pre-fired powder for 4 hours, dry it at 120° C. and pass through a 80-mesh sieve. Pre-compress the powder with a pressure of 20 MPa, and then press the powder into a disc with a diameter of 15 mm and a thickness of 2 mm with a cold isostatic press under a pressure of 300 MPa for a holding time of 20 s.

[0034] The shaped discs are sealed and sintered in a muffle furnace. The sintering is carried out in stages: firs...

Embodiment 3

[0037] Bi with m=3 3 LaTi 3 o 12 It is base formula, by molar ratio Bi: La: Ti=3: 1: 3 batching, used raw material is the bismuth oxide of analytical grade (Bi 2 o 3 ), lanthanum oxide (La 2 o 3 ), titanium oxide (TiO 2 ).

[0038] Calculate and weigh raw materials according to the formula. Using distilled water as the ball milling medium, use a planetary ball mill for 2 hours, dry at 120°C, and pass through an 80-mesh sieve. Then the mixture was airtightly calcined at 850°C for 3 hours. After crushing the pre-fired powder for 4 hours, dry it at 120° C. and pass through a 80-mesh sieve. Pre-compress the powder with a pressure of 5 MPa, and then press the powder into a disc with a diameter of 15 mm and a thickness of 2 mm with a cold isostatic press under a pressure of 150 MPa, and hold the pressure for 2 minutes.

[0039] The shaped discs are sealed and sintered in a muffle furnace. The sintering is carried out in stages: first, the temperature is raised to the high...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com