Patents

Literature

77results about How to "Reduced oxygen vacancies" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

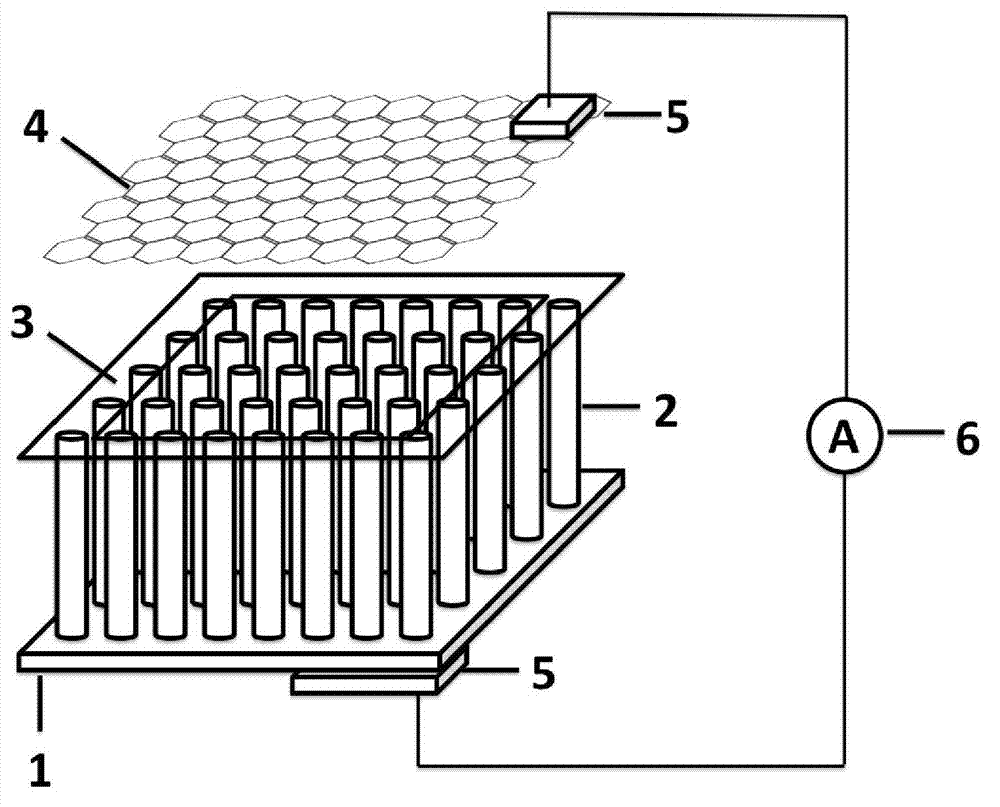

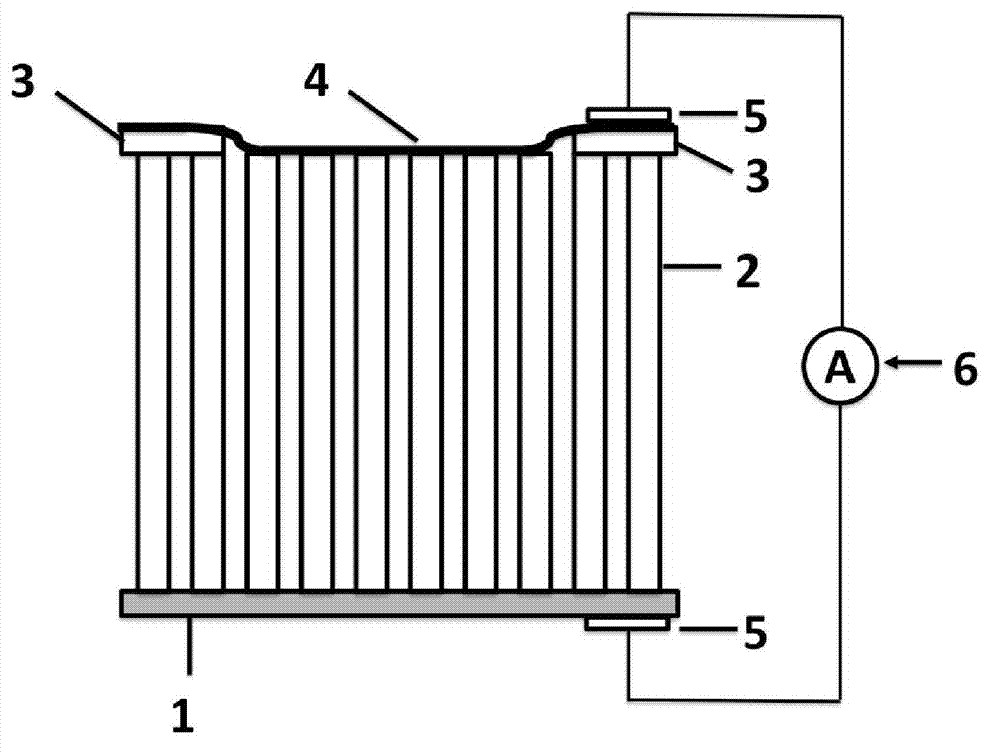

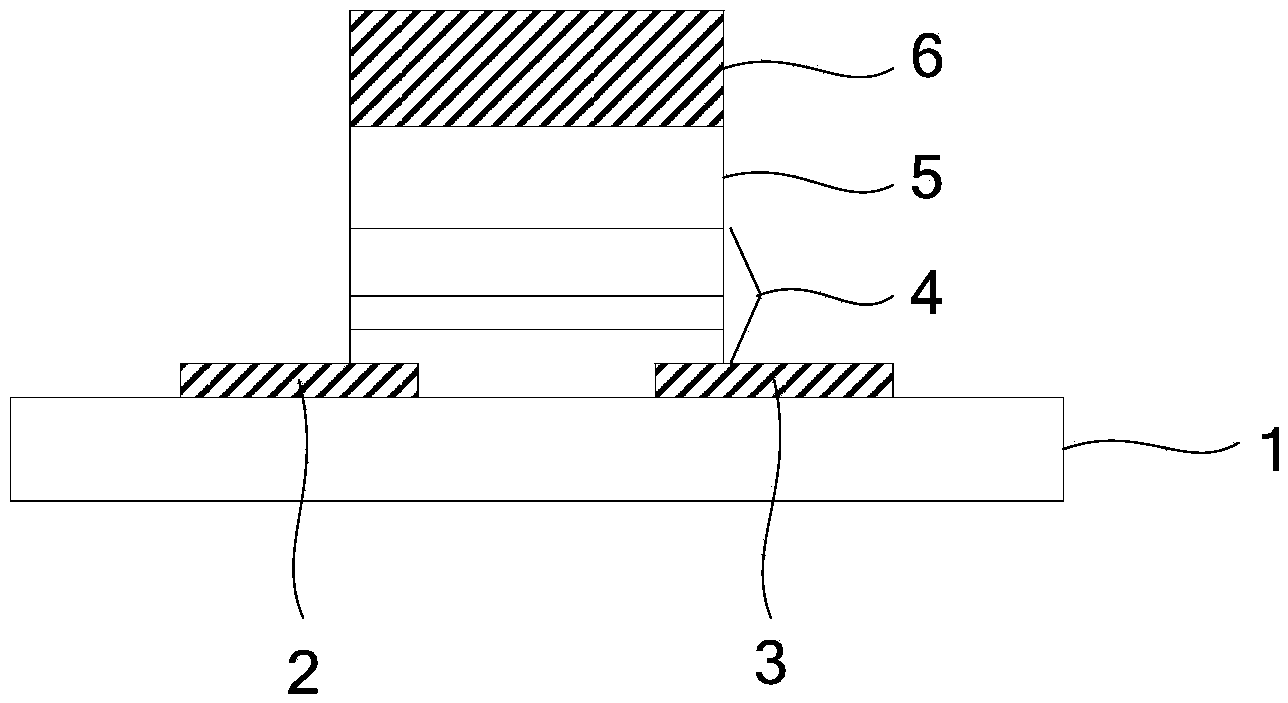

Ultraviolet light detector with titanium dioxide nanotube array serving as matrix and preparation method thereof

InactiveCN102856423AImprove responsivenessReduce dark currentFinal product manufactureSemiconductor devicesCvd grapheneOxygen vacancy

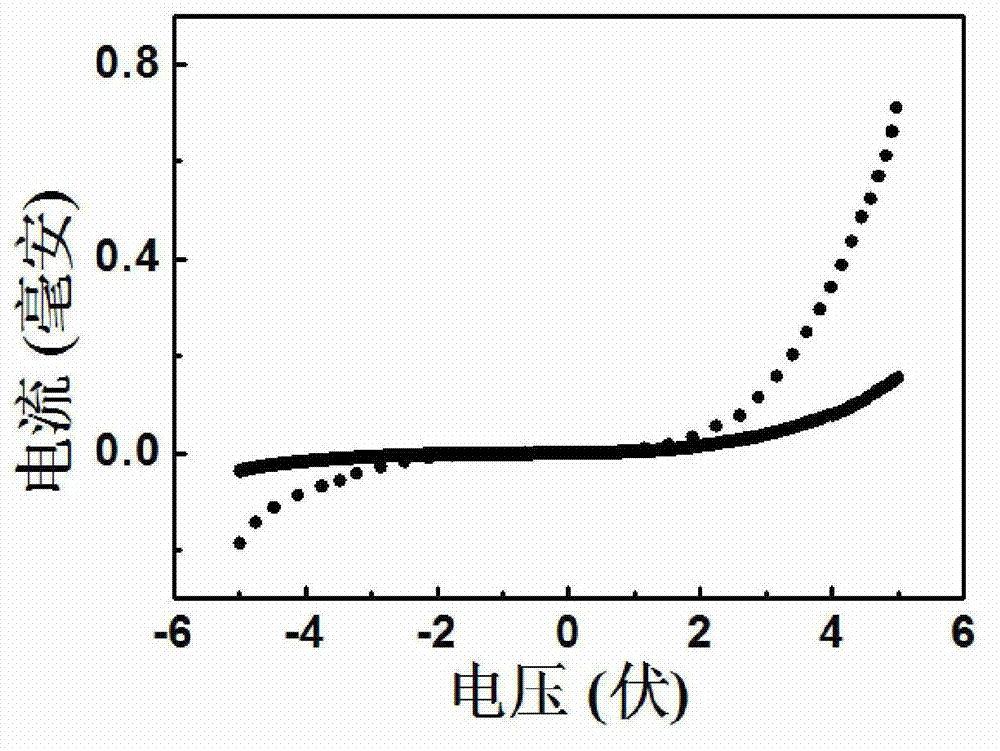

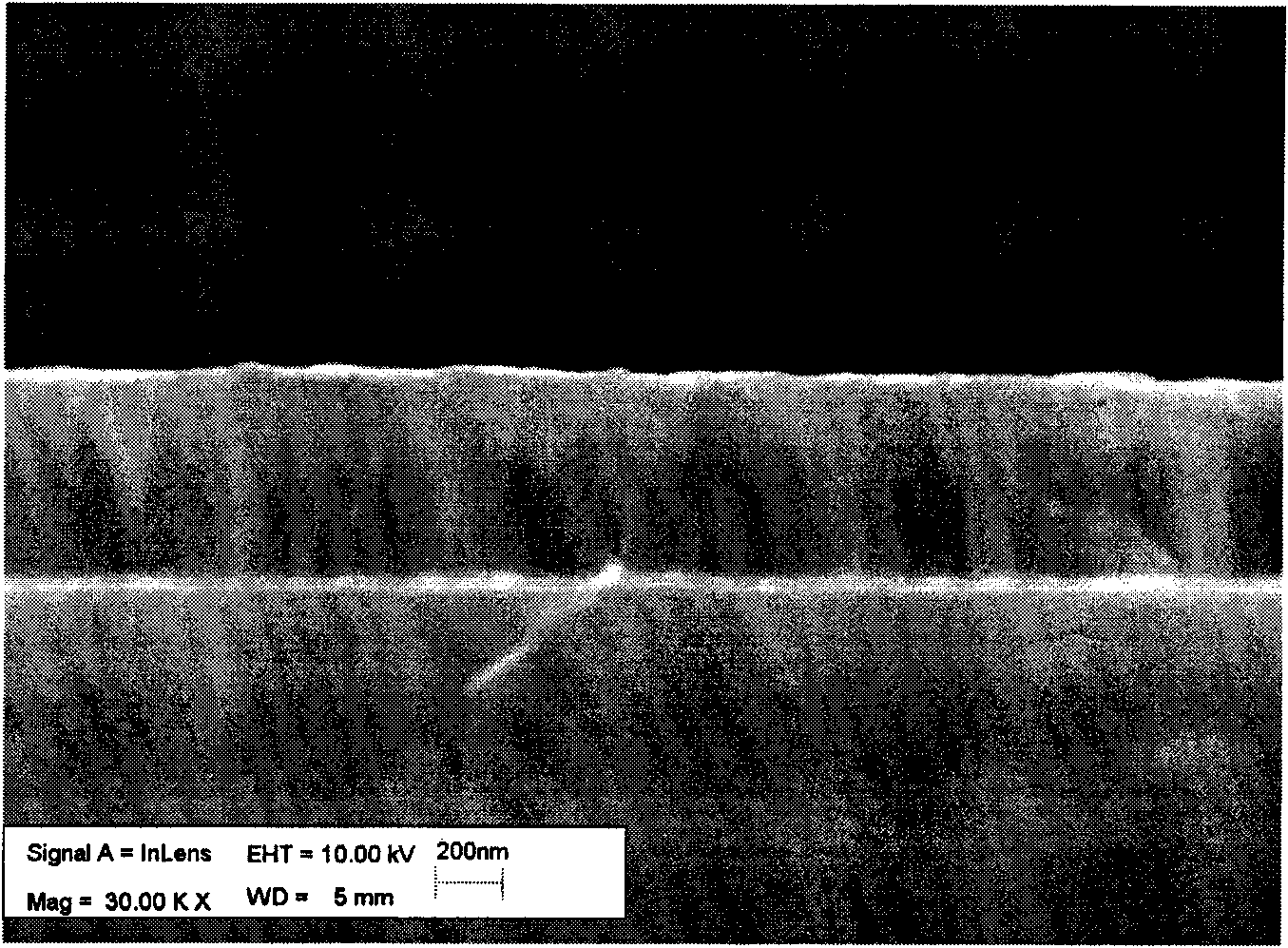

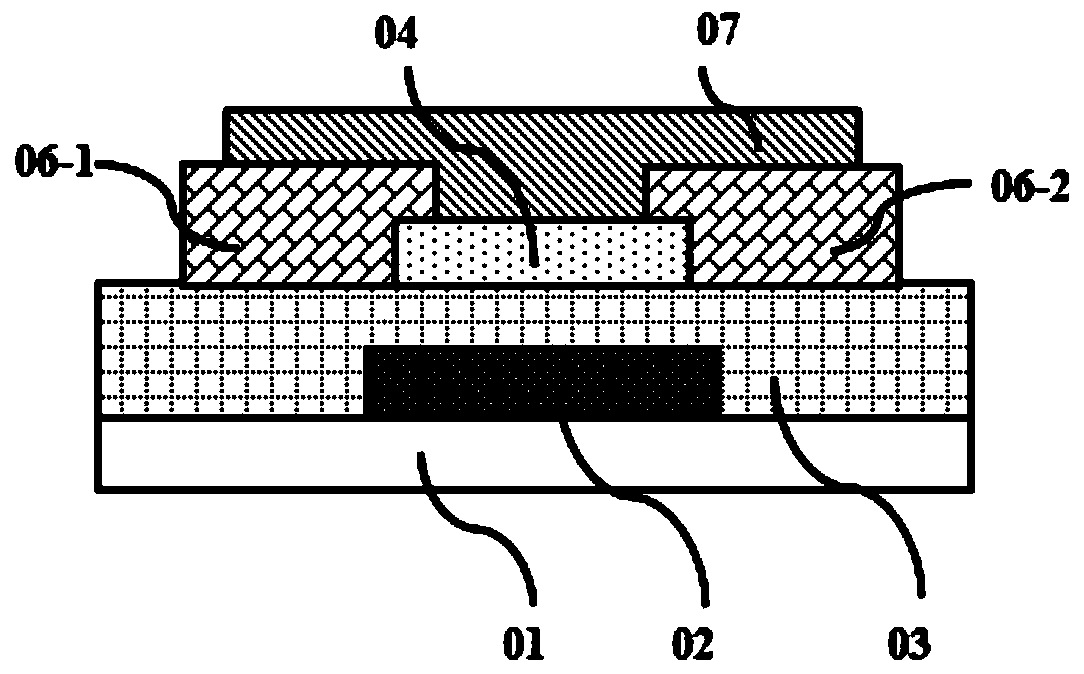

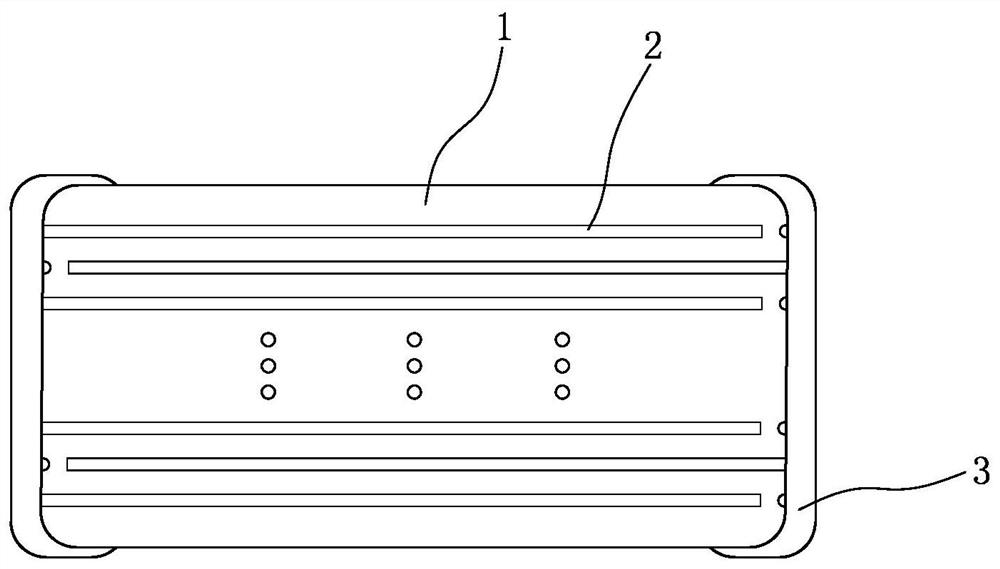

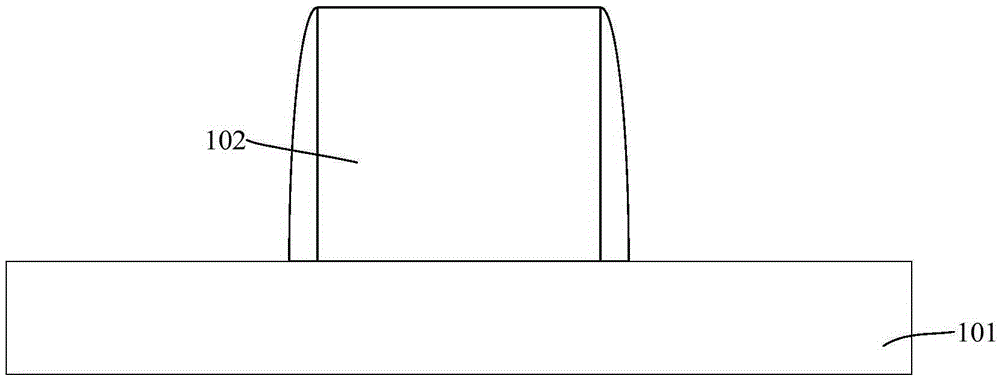

The invention discloses an ultraviolet light detector with a titanium dioxide nanotube array serving as a matrix and a preparation method thereof. The ultraviolet light detector comprises a titanium sheet substrate (1), the titanium dioxide nanotube array (2), an insulating layer (3) and a graphene film (4) sequentially from bottom to top, extraction electrodes (5) are arranged on the lower surface of the titanium sheet substrate (1) and the upper surface of the graphene film (4) respectively and are connected with a current measurer (6). The titanium dioxide nanotube array is prepared on the titanium sheet substrate by an anodizing method, oxygen vacancy of the array prepared by the method is less, and mismatch of stoichiometric ratio is avoided. Therefore, titanium dioxide is good in crystalline structure after annealing to lead to high response, low dark current and high ultraviolet-to-visible rejection ratio.

Owner:HEFEI UNIV OF TECH

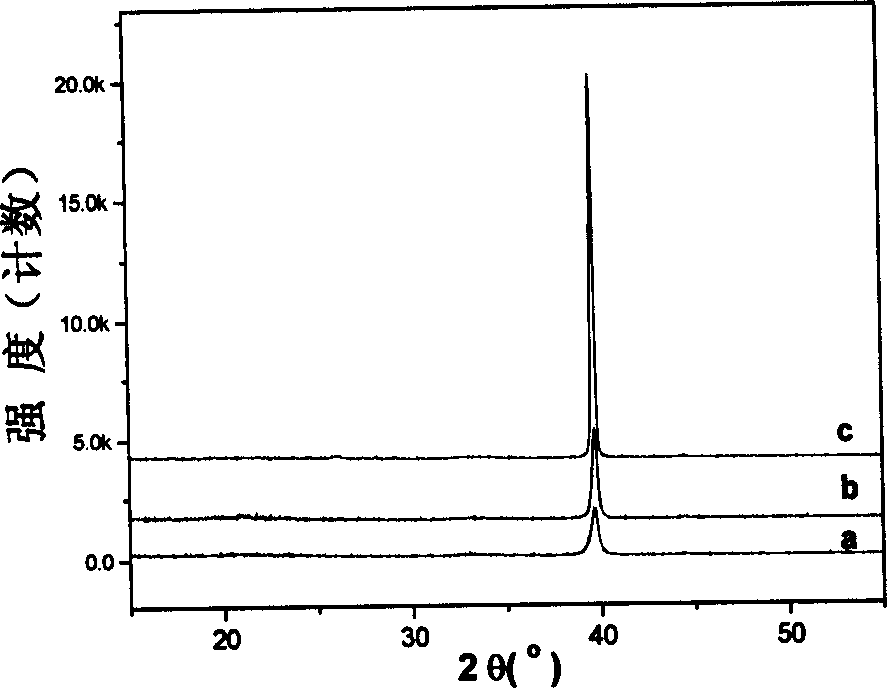

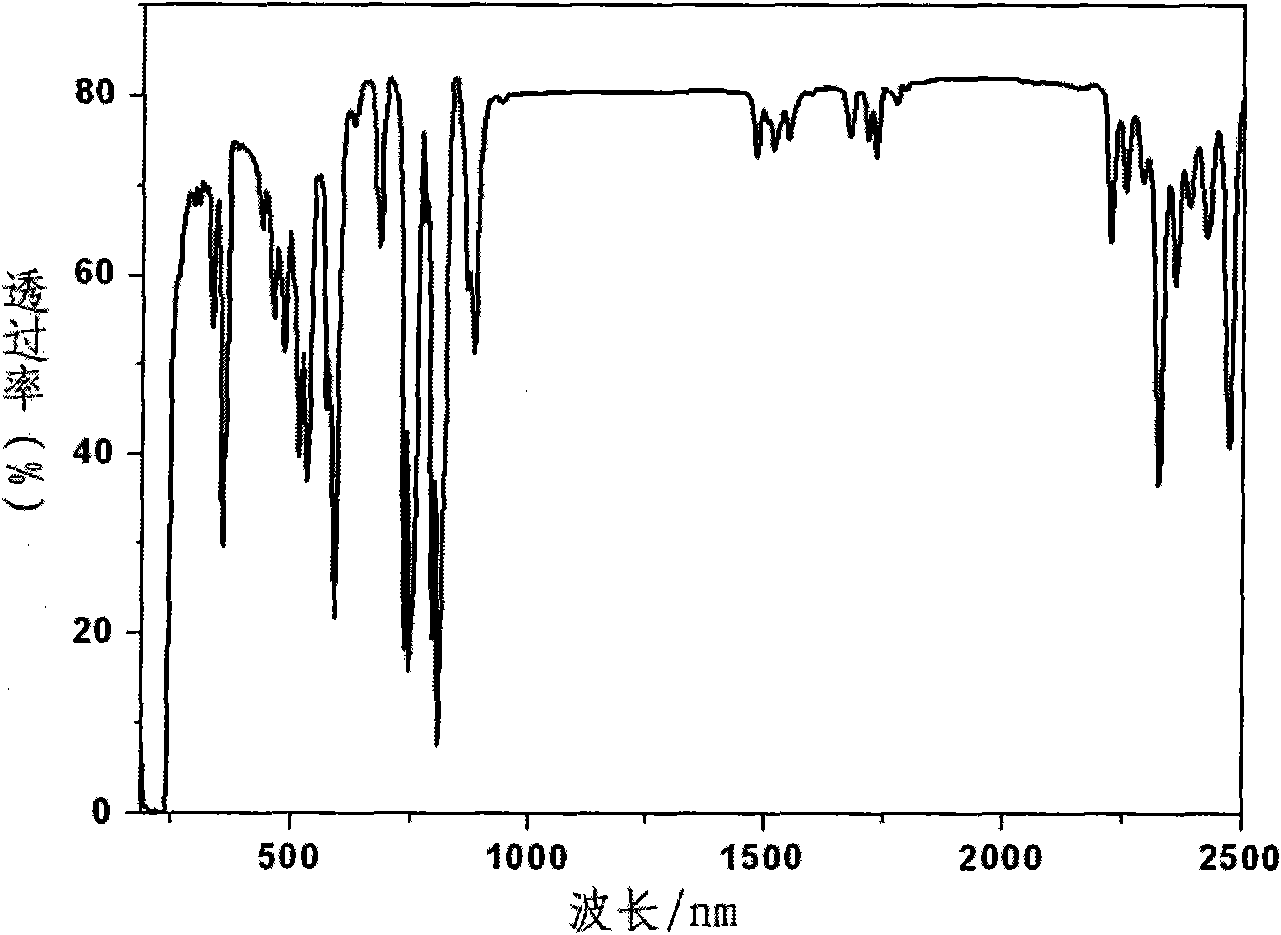

Cation-anion co-doping n-type zinc-oxide-base transparent conducting film and preparation method thereof

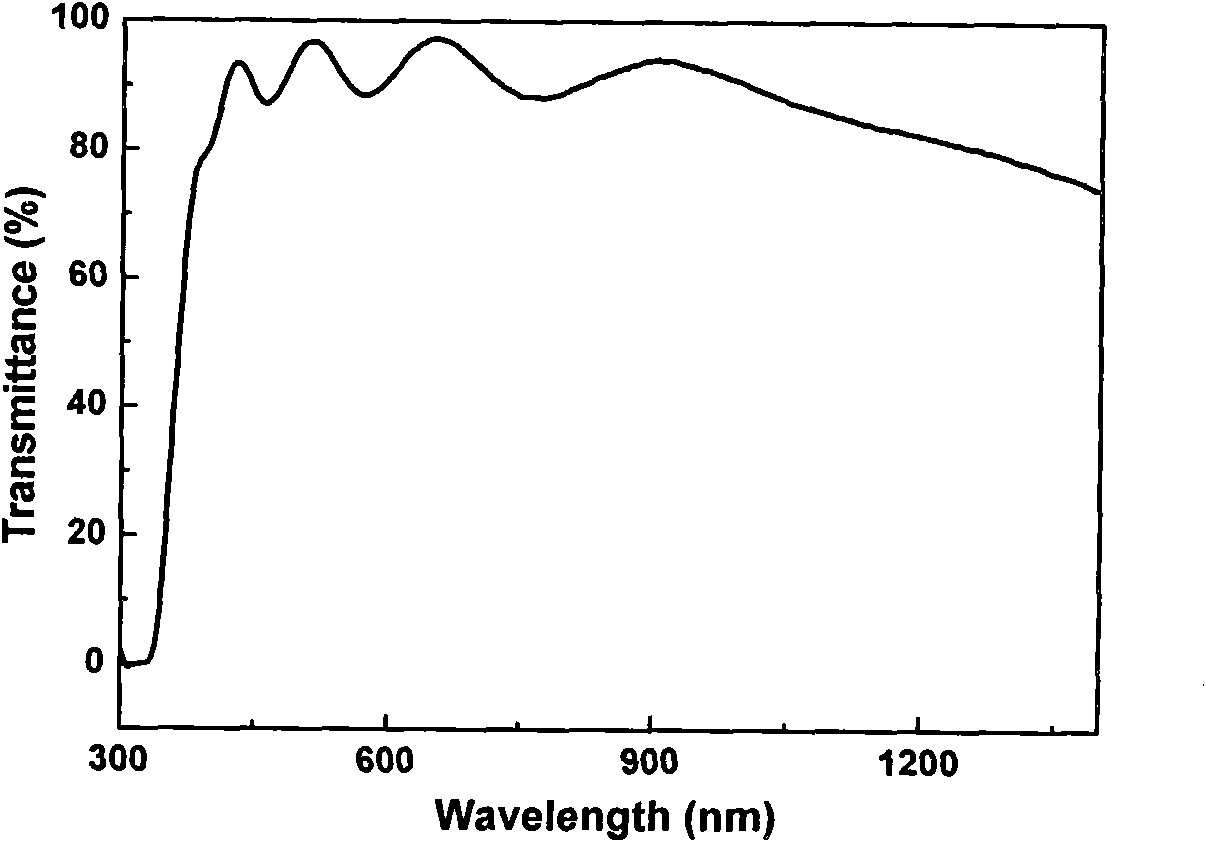

ActiveCN101660121APromote crystallizationHigh crystallinityVacuum evaporation coatingSputtering coatingTransparent conducting filmSolar cell

The invention provides a cation-anion co-doping n-type zinc-oxide-base transparent conducting film. The doped cation is a high-valency cation M<n+>, and n is 3, 4, 5 or 6; and the doped anion is a low-valency anion X<m->, and m is equal to 1. The preparation method adopts the High-vacuum Magnetron Sputtering technique and promotes the n-type transparent conductivity of the zinc-oxide film by utilizing high-valency cations and low-valency anions to prepare the high-performance cation-anion co-doping zinc-oxide polycrystal film. A compound containing low-valency anions can be used as a fluxing agent to promote the crystallization of the zinc-oxide-base polycrystal film and enhance the visible light transparency of the film and the electron conductivity. The high-performance zinc-oxide-base transparent conducting film has the advantages of simple preparation process, superior visible light transparency and conductivity, and low cost, and has wide application prospects in the fields of solar cells and photoconducting devices.

Owner:山东中科泰阳光电科技有限公司

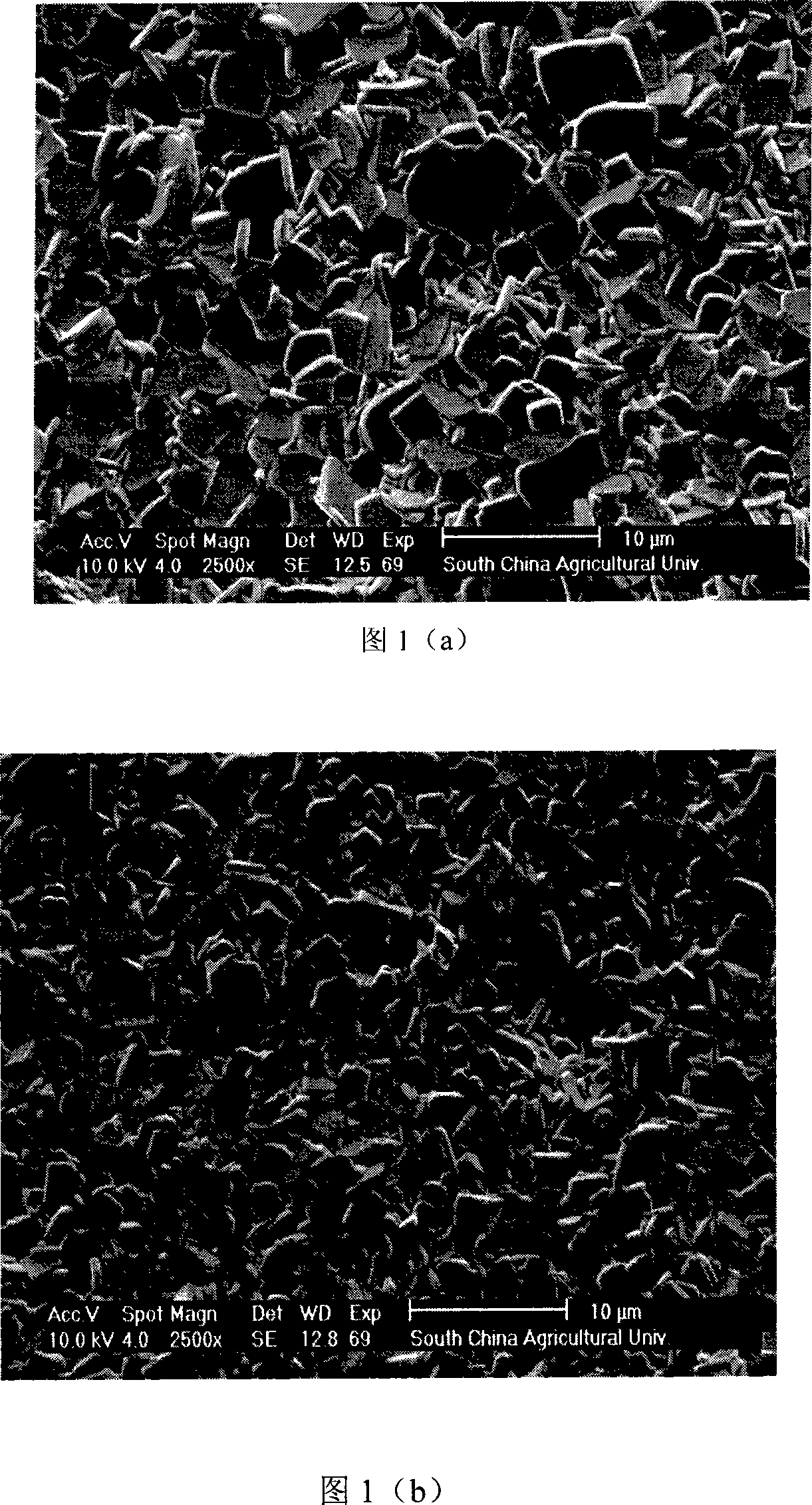

Method for increasing bismuth layer structure piezoelectricity ferroelectric ceramic material density

InactiveCN101186493AInhibit migrationGrowth inhibitionPiezoelectric/electrostrictive/magnetostrictive devicesVolumetric Mass DensityMaterial density

The invention discloses a density enhancing method of piezoelectric ferroelectric ceramic materials with bismuth layer structure. According to a chemical formula: (Am-1BmO3m+1) <2-> (Bi2O2) <2+>; and molar ratio A: B: Bi = m-1: m : 2, materials are calculated and weighted, wherein, the A is univalent, bivalent, trivalent or quadrivalent metal ion that is suitable for dodecahedral coordination; the B is trivalent, quadrivalent, pentavalent or sexivalent metal ion that is suitable for octahedral coordination; the production processes are that: mixing, pre-synthesizing, grinding, forming and sintering; the sintering process is that: the temperature of the obtained material from the last step is raised to 1100 to 1250 DEG C at a speed of 2 to 5 DEG C per minute, and is lowered to 50 to 150 DEG C within 1 to 5 minutes; under the temperature of 950 to 1150 EDG C, insulation at the low temperature is done for 5 to 20 hours; then the temperature is lowered to 500 DEG C at a speed of 3 to 7 DEG C per minute, and the obtained material is naturally cooled with a furnace. The invention can obtain the piezoelectric ferroelectric ceramic materials with grain-refining and density bismuth structure.

Owner:SOUTH CHINA UNIV OF TECH

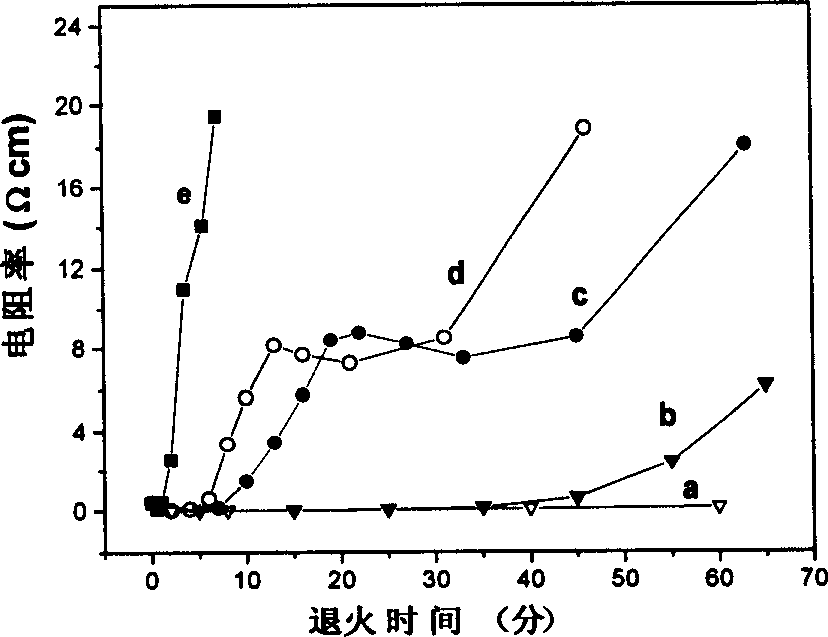

Preparation method of polycrystalline vanadium dioxide film with room temperature resistance temperature coefficient higher than 10%K

ActiveCN1800440APhase transition hysteresis is smallTCR improvementVacuum evaporation coatingSputtering coatingVanadium dioxideFilm material

The invention relates to a functional thin film material preparing technology, which adopts improved ion beam amplify deposited method to make the film and combines the subsequent crystallization and annealing to achieve the impurity element even immersing and the effective place-replacing to vanadium so that the phase starting temperature of the thin film reduces to 12-16 deg. It adjusts the argon / hydrogen ratio film craft and crystallizing heat treatment condition so that when the polycrystalline VO2 thin film transfers to the mental phase from the semiconductor phase, the change of the resistance ratio over 2 magnitude orders.

Owner:溧阳常大技术转移中心有限公司

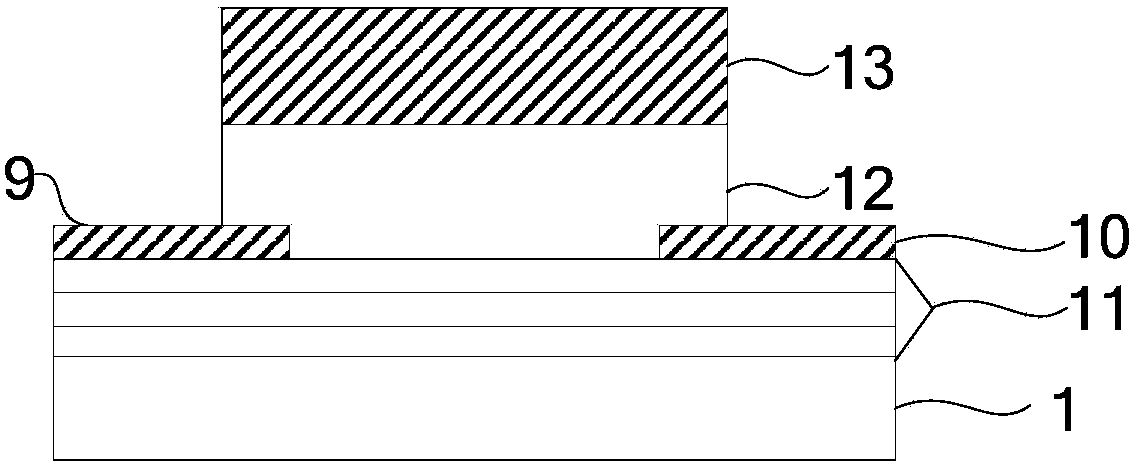

Composite metal oxide semiconductor, thin-film transistor and application

PendingCN110767745AReduced oxygen vacanciesMobility is not affectedTransistorSolid-state devicesYTTERBIUM OXIDEOxygen vacancy

The invention discloses a composite metal oxide semiconductor. The composite metal oxide semiconductor is formed by doping rare earth oxide in metal oxide, wherein the composite metal oxide can effectively inhibit the concentration of oxygen vacancy in a thin-film under the lower doping concentration of ytterbium oxide or praseodymium oxide, and meanwhile, the mobility of the composite metal oxidesemiconductor can be kept at a higher value; the key is that the formed film can avoid the influence on I-V characteristics and stability by illumination, and the stability of the metal oxide semiconductor device under illumination can be greatly improved. The invention also provides a thin-film transistor based on the composite metal oxide semiconductor and an application thereof.

Owner:SOUTH CHINA UNIV OF TECH

Li-O site lithium manganate doped lithium-enriched positive electrode material and preparation method thereof

ActiveCN108091858AIncrease energy densityImprove securityMaterial nanotechnologyCell electrodesLithiumOxygen vacancy

The invention provides a Li-O site lithium manganate doped lithium-enriched positive electrode material and a preparation method thereof. The Li-O site lithium manganate doped lithium-enriched positive electrode material is prepared through mixing a manganese source, a lithium source and an element lithium doped compound and then carrying out a process including solid-phase sintering, wet-processcladding, material mixing and calcination. The prepared positive electrode material realizes doping on a Li site and an O site of lithium manganate and the aims of effectively inhibiting oxygen evolution, improving the rate performance, keeping an oxygen vacancy in a charging process, improving the initial efficiency, improving the safety performance of a battery and improving the energy density of the material are realized.

Owner:余姚市海泰贸易有限公司

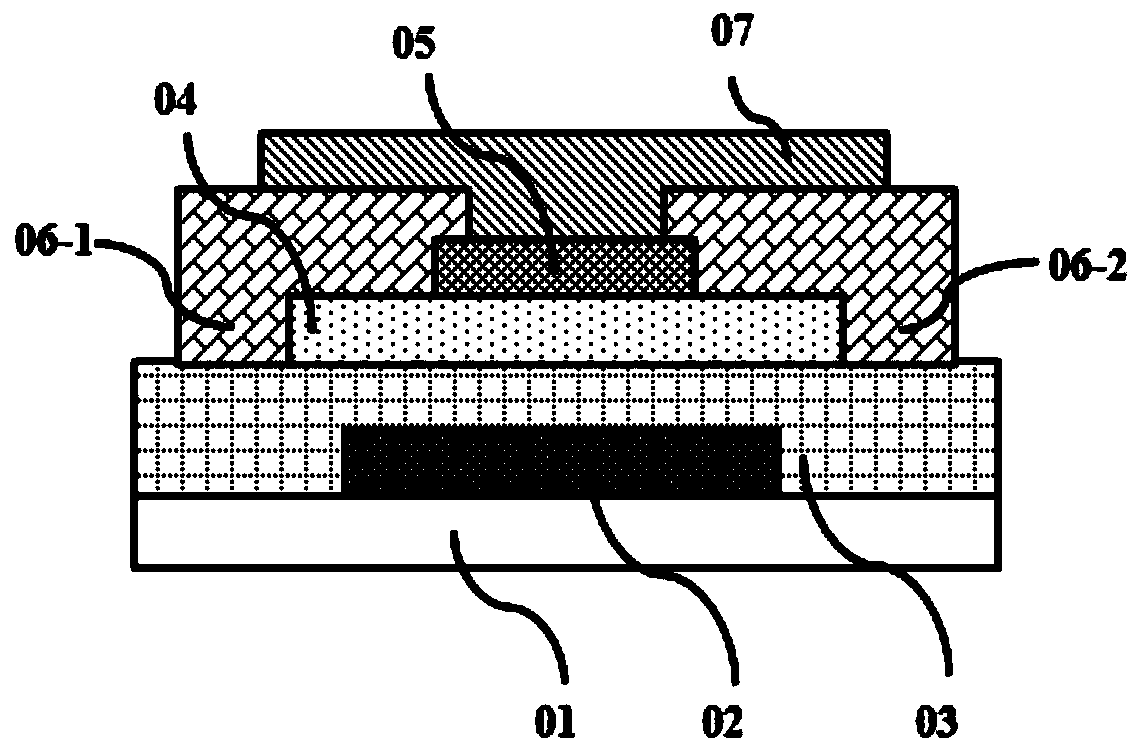

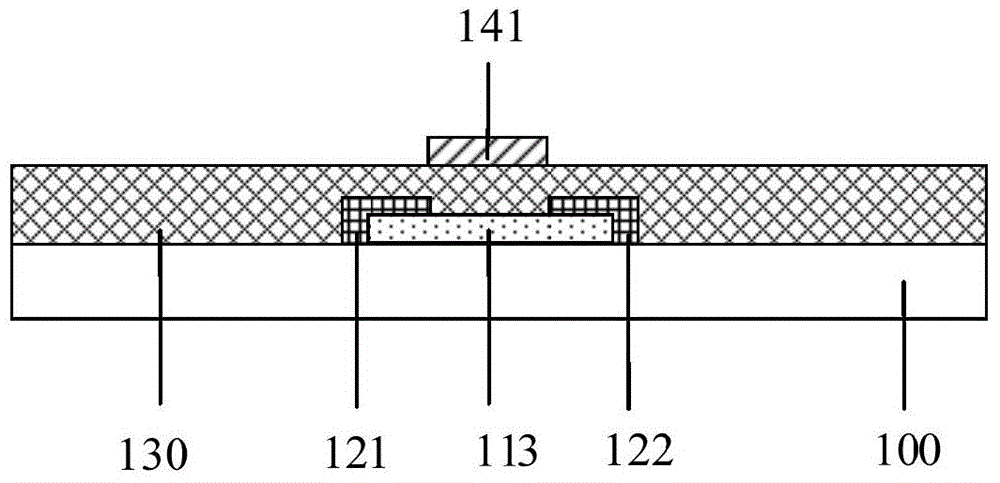

Thin-film transistor, array substrate, preparation method thereof, and display device

ActiveCN104979406AImprove stabilityReduced oxygen vacanciesTransistorSolid-state devicesOxygen vacancyDisplay device

The invention provides a thin-film transistor, an array substrate, a preparation method thereof, and a display device. The preparation method of the thin-film transistor comprises forming a gate electrode, a gate electrode insulating layer, an active layer, a source electrode and a drain electrode of the thin-film transistor, wherein the active layer is prepared by a metal oxide. Furthermore an electrochemical oxidation treatment is performed on a metal oxide film in the preparing process, and the metal oxide film after electrochemical oxidation treatment is patterned for forming the active layer of the thin-film transistor. According to the preparation method, the number of oxygen vacancies of the metal oxide film can be reduced and the concentration of free carriers of the metal oxide film can be controlled, and the prepared thin-film transistor has high stability. Furthermore, an additional photolithographic process is not required and a little cost influence is realized.

Owner:BOE TECH GRP CO LTD +1

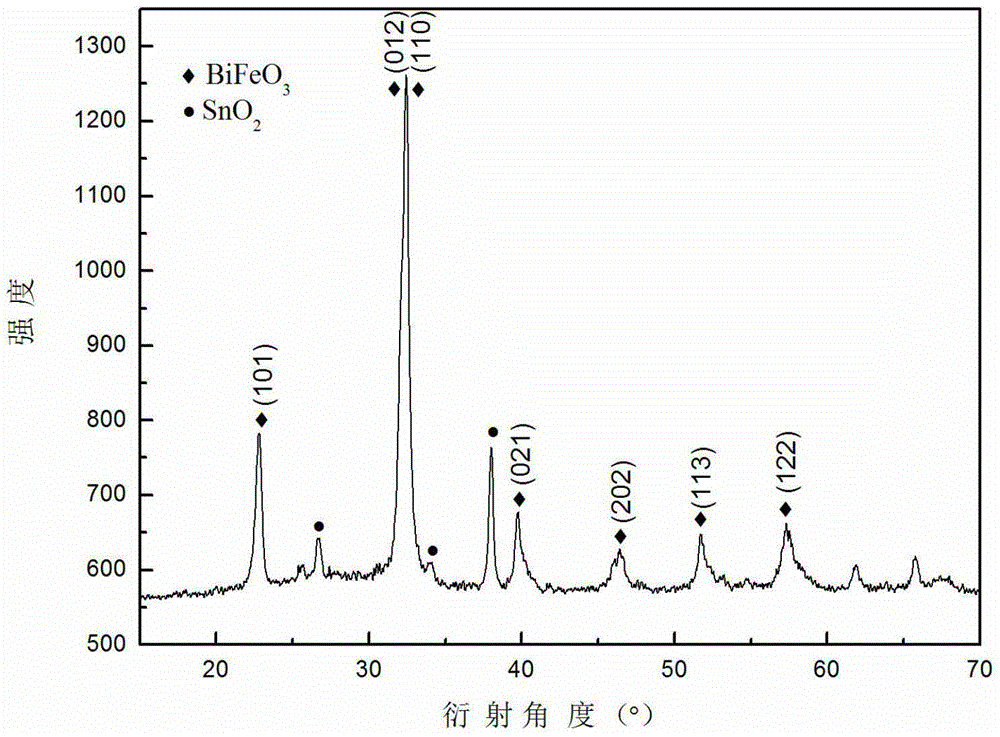

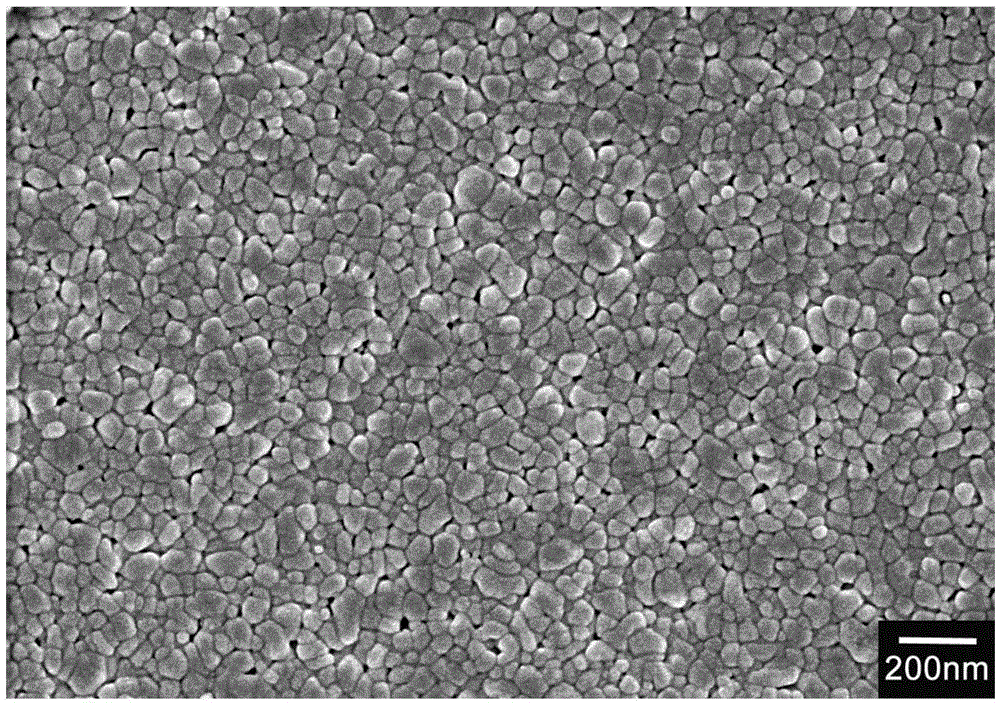

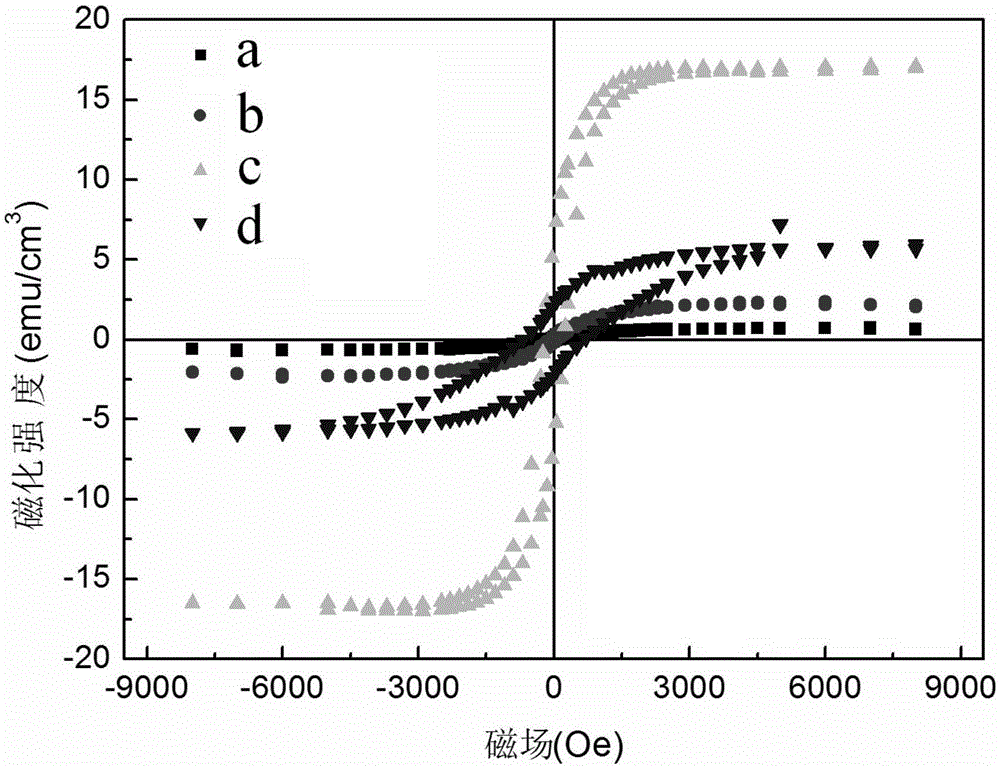

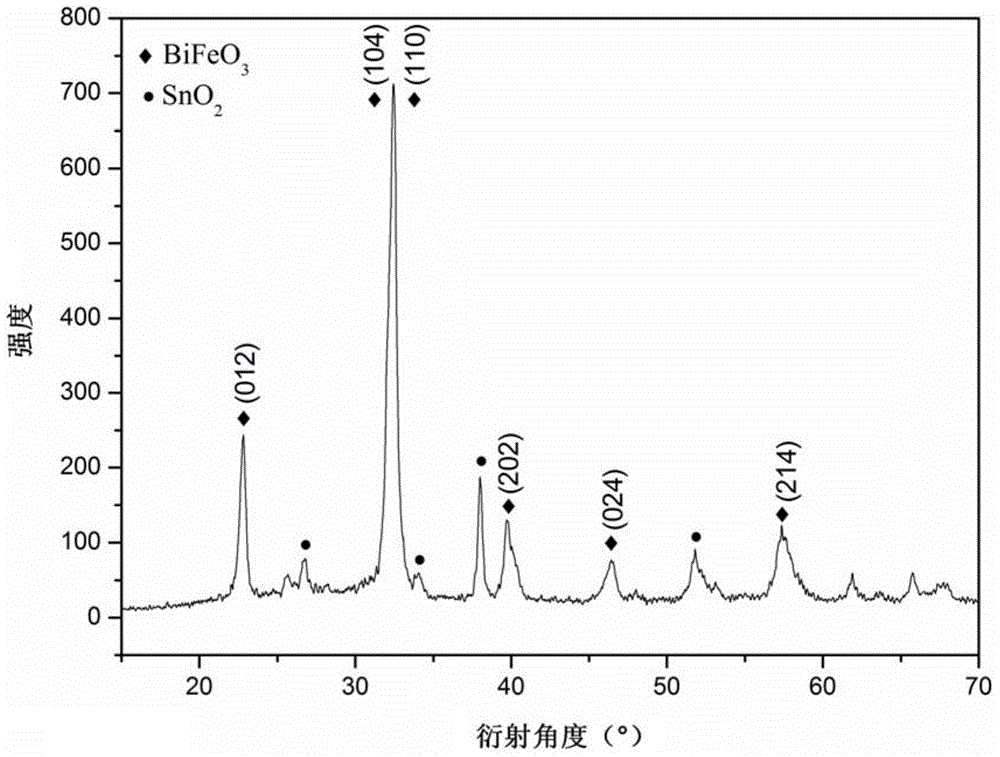

Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and making method thereof

The invention provides a Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity, and a making method thereof. The method comprises the following steps: preparing a Bi0.9Er0.1Fe1-xCoxO3 precursor solution from bismuth nitrate, iron nitrate, cobalt nitrate and erbium nitrate, spin-coating a substrate with the Bi0.9Er0.1Fe1-xCoxO3 (x is 0.01-0.03) precursor solution, uniformly sizing, drying, and annealing to obtain the Bi0.9Er0.1Fe1-xCoxO3 film with high ferromagnetism and ferroelectricity. The method has the advantages of simple device requirements, easy reaching of experiment conditions, easy control of the doping amount, and great improvement of the ferromagnetism of a BiFeO3 film, and the Bi0.9Er0.1Fe1-xCoxO3 film made in the invention has the advantages of good uniformity, high magnetic intensity and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

Preparation method of manganese-doped potassium-sodium-niobate-base lead-free piezoelectric film

The invention discloses a preparation method of a manganese-doped potassium-sodium-niobate-base lead-free piezoelectric film. The invention provides a simple and controllable technique on the basis of a non-alcohol niobium salt sol-gel method. The method comprises the following steps: preparing a stable manganese-doped KNN sol, carrying out spin coating on the KNN sol on a (Pt / TiO2 / Ti / SiO2 / Si) substrate for 30 seconds at the rotation speed of 3200 r / min, drying the wet film at 150 DEG C, and keeping the temperature at 600 DEG C for 10 minutes; repeating the previous step 8 times under the same heat treatment conditions to obtain 8 spin coatings; and carrying out annealing treatment at 700 DEG C for 10 minutes. The final film thickness is 2-4 mu m; and the prepared film has the advantages of favorable compactness and improved drain current property.

Owner:QIQIHAR UNIVERSITY

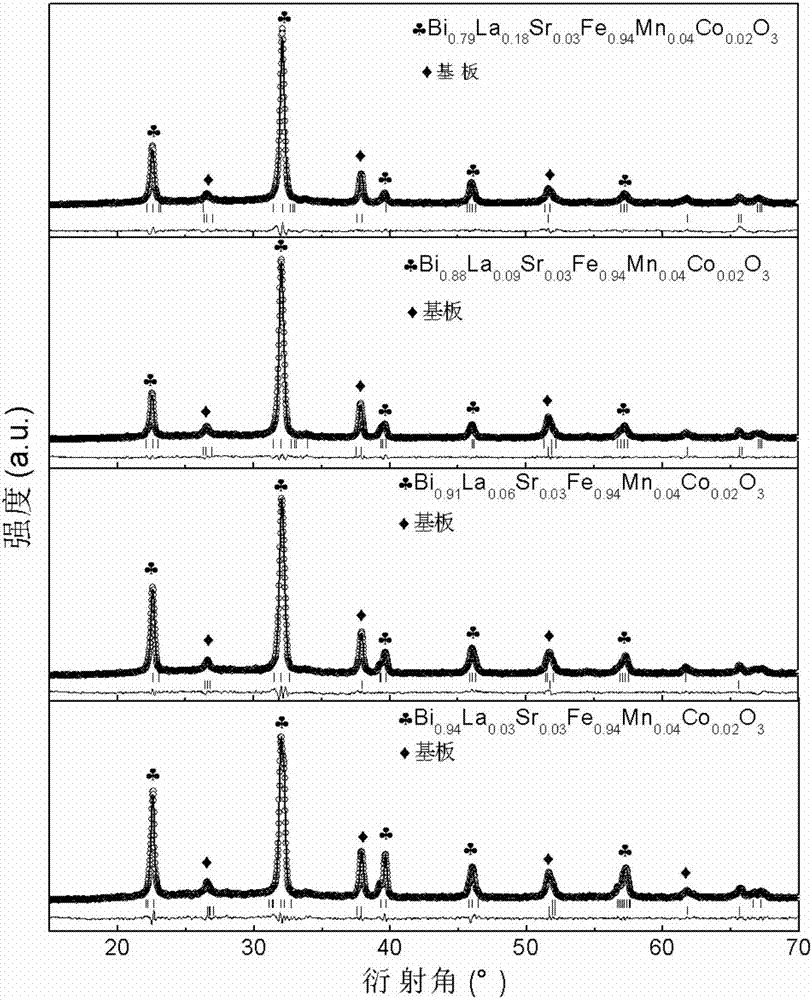

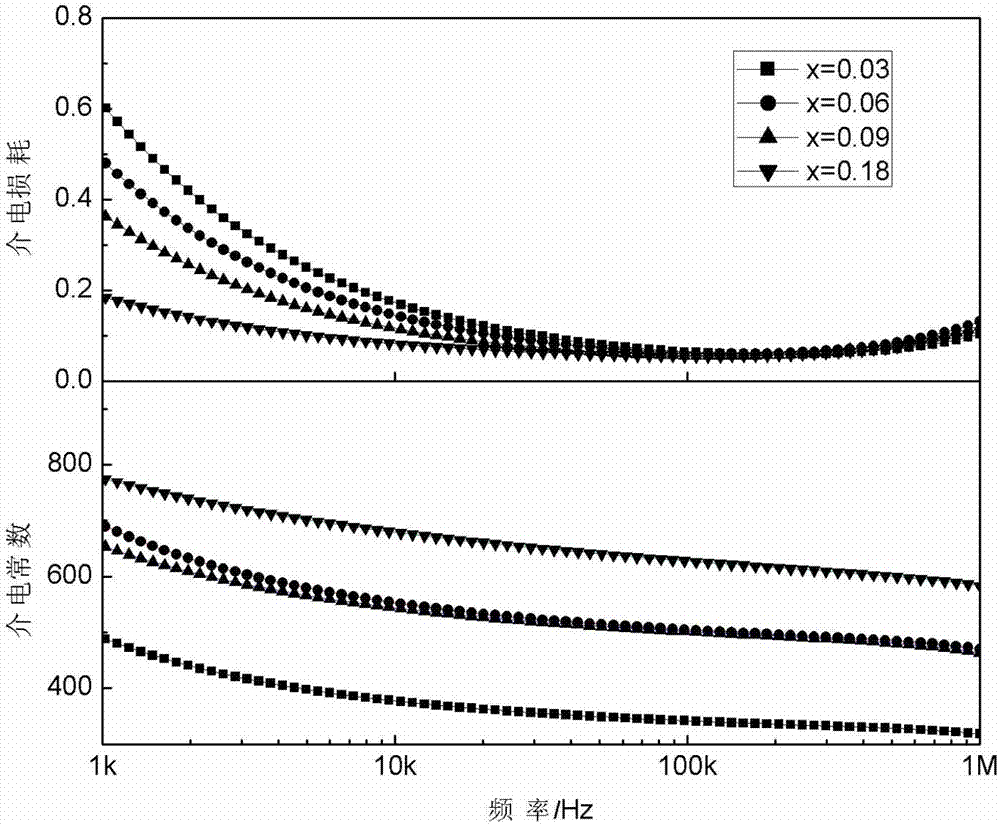

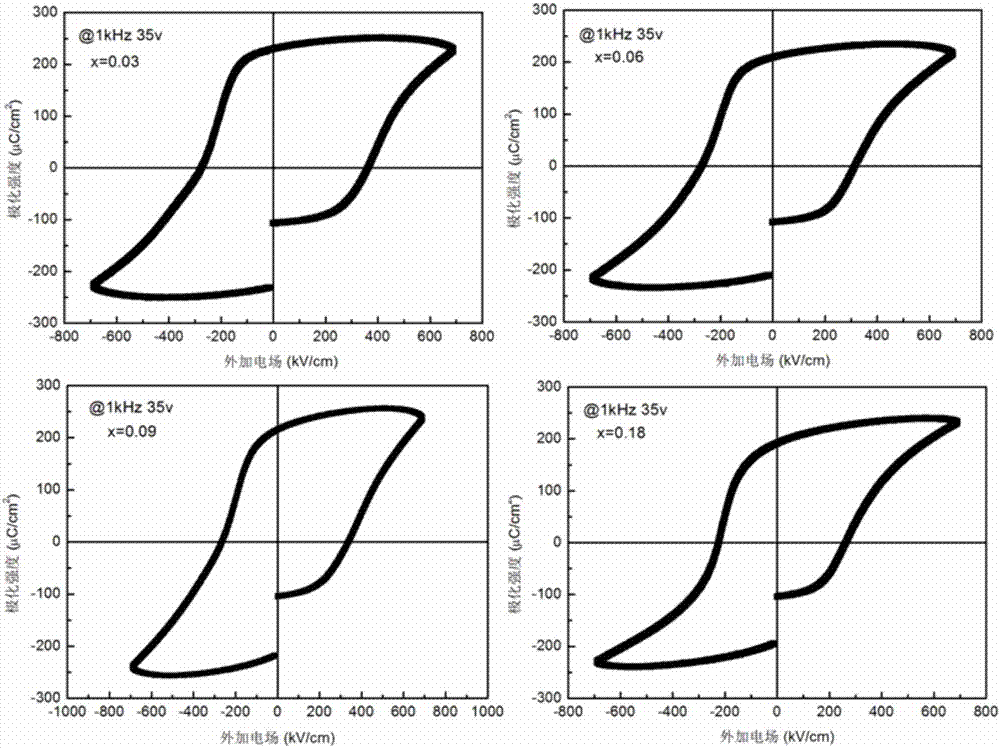

LaSrMnCo codoped bismuth ferrite multiferroic film and preparation method thereof

ActiveCN107117830AGood dielectricImprove ferroelectric propertiesCoatingsMANGANESE ACETATEAcetic anhydride

The invention provides a LaSrMnCo codoped bismuth ferrite multiferroic film and a preparation method thereof. A Bi(0.97-x)LaxSr0.03Fe0.94Mn0.04Co0.02O3 multiferroic film, namely the LaSrMnCo codoped bismuth ferrite multiferroic film, is prepared by taking bismuth nitrate, lanthanum nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate as raw materials (bismuth nitrate of excessive 5 percent), taking ethylene glycol monomethyl ether and acetic anhydride as solvents and using a spin-coating method and a layer-by-layer annealing process. A sol-gel process is adopted, spin-coating and layer-by-layer annealing methods are adopted, equipment requirements are simple, experimental conditions are easy to realize, the film is suitably prepared on a large surface and an irregularly shaped surface, chemical components are accurately controllable, the multiferroic property of the BiFeO3 film can be improved, the prepared the LaSrMnCo codoped bismuth ferrite multiferroic film has high uniformity and is a multiferroic film with high residual polarization value and low coercive field, and the ferroelectric and dielectric properties of the film are effectively enhanced.

Owner:SHAANXI UNIV OF SCI & TECH

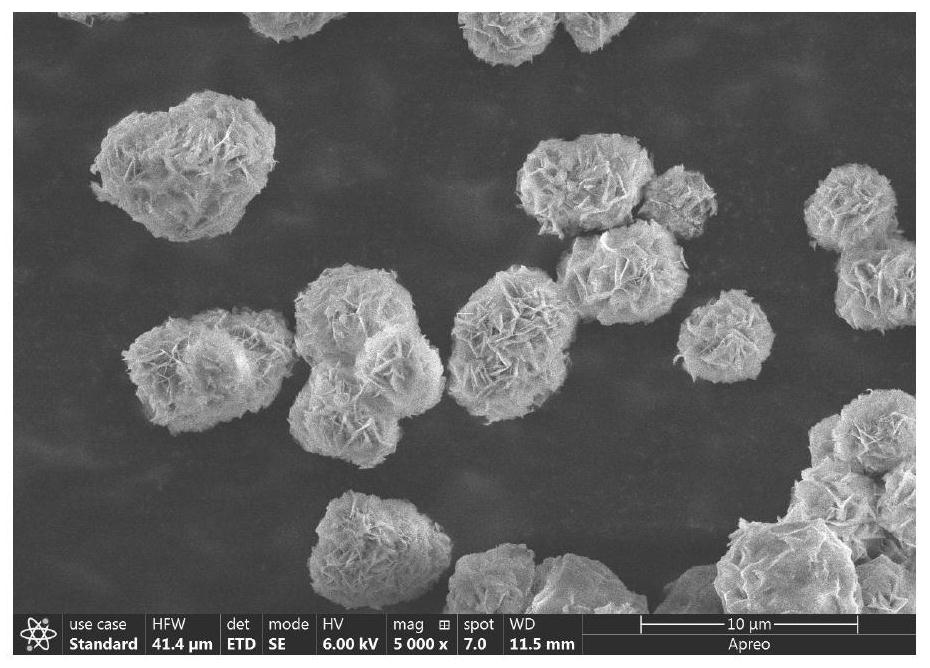

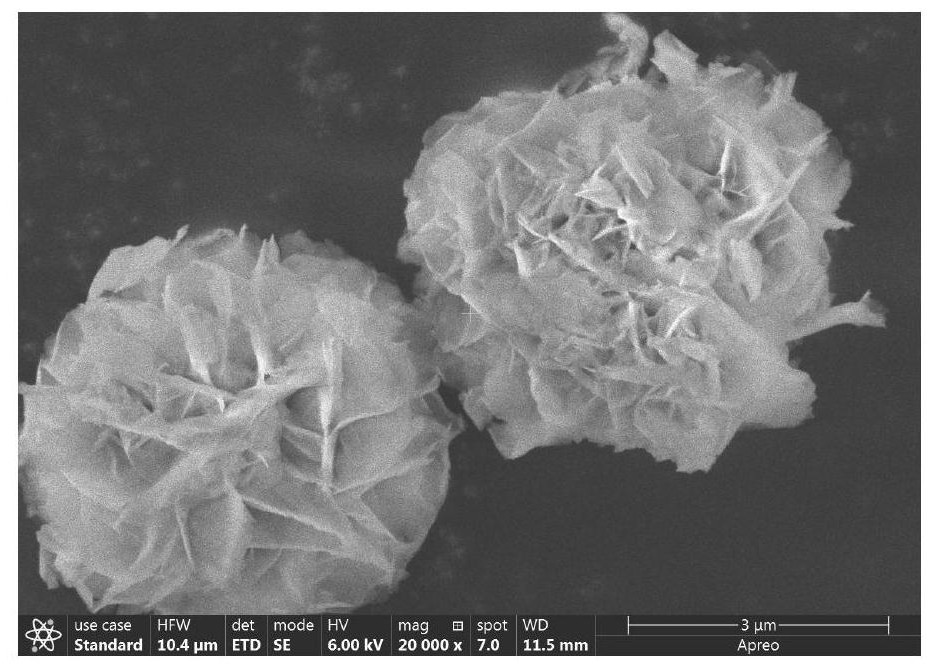

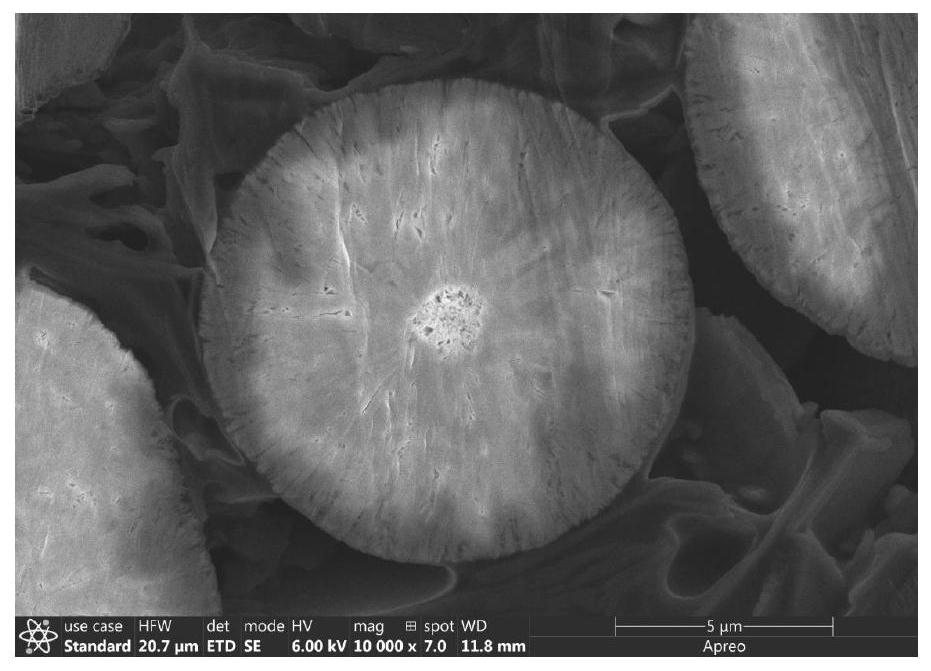

Nanometer lithium-rich manganese-based positive electrode material and precursor, base material and preparation method thereof

ActiveCN111943285ALarge specific surface areaShort migration channelMaterial nanotechnologySecondary cellsManganeseLithium-ion battery

The invention belongs to the field of lithium ion battery positive electrode materials, and particularly relates to a nanometer lithium-rich manganese-based positive electrode material, and a precursor and a base material thereof. The chemical general formula of the lithium-rich manganese-based positive electrode material precursor is MnxM<1-x>(OH)2, x is more than 0.5 and less than 1, and M is one or two of Ni and Co. Primary particles of the precursor are nanosheets, and the thicknesses of the nanosheets are similar; the crystal faces of the nanosheets face the same direction and are stackedwith one another to form a nanoflower-shaped morphology; the interior is of a radial structure with a core in the center. The lithium-rich manganese-based positive electrode material precursor is calcined to obtain a nanometer lithium-rich manganese-based positive electrode material base material which is provided with oxygen-containing vacancies, with primary particles being nanosheets with thethickness of about 10 nm. According to the present invention, during the lithium mixing sintering of the base material, the primary particles are the ultra-thin nanosheets, such that the specific surface area is large, the contact with a lithium source is complete, the uniform mixing of the base material and the lithium source is easily achieved, the problems of unbalanced reaction and insufficient reaction are avoided, and the performance of the ternary positive electrode material can be easily and completely provided.

Owner:ZHUJI PAWA NEW ENERGY

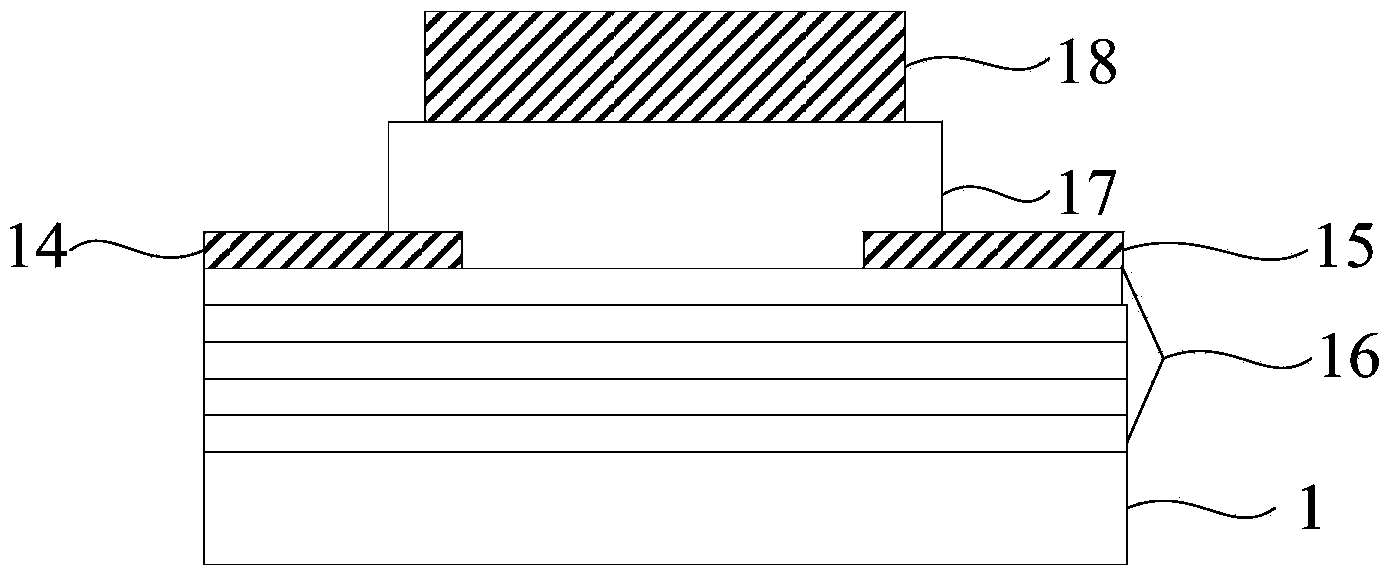

Oxide thin film transistor and manufacturing method thereof

ActiveCN103545377AImprove electrical stabilityImprove bindingTransistorSemiconductor/solid-state device manufacturingOxide thin-film transistorAlloy thin film

The invention discloses an oxide thin film transistor and a manufacturing method of the oxide thin film transistor. The transistor comprises a source electrode, a drain electrode and an IGZO thin film layer and further comprises a hafnium neodymium alloy thin film layer, wherein a first surface of the IGZO thin film layer makes contact with the source electrode and the drain electrode, and the other surface back on to the first surface of the IGZO thin film layer makes contact with the hafnium neodymium alloy thin film layer. The oxide thin film transistor has stable electrical properties.

Owner:SHENZHEN DANBANG INVESTMENT GROUP

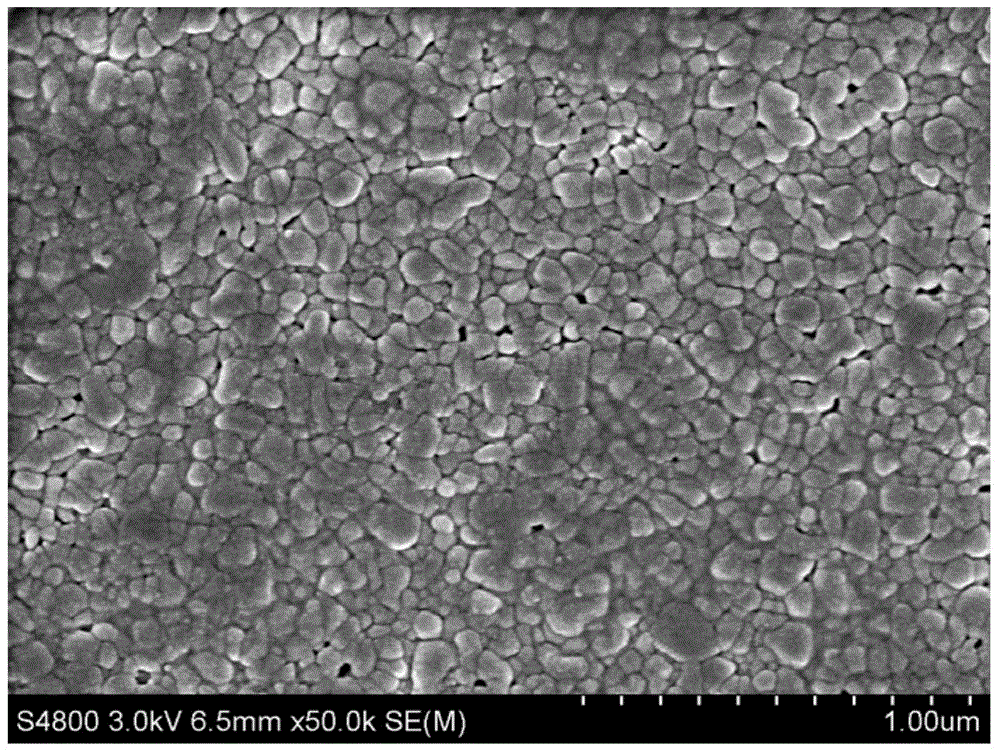

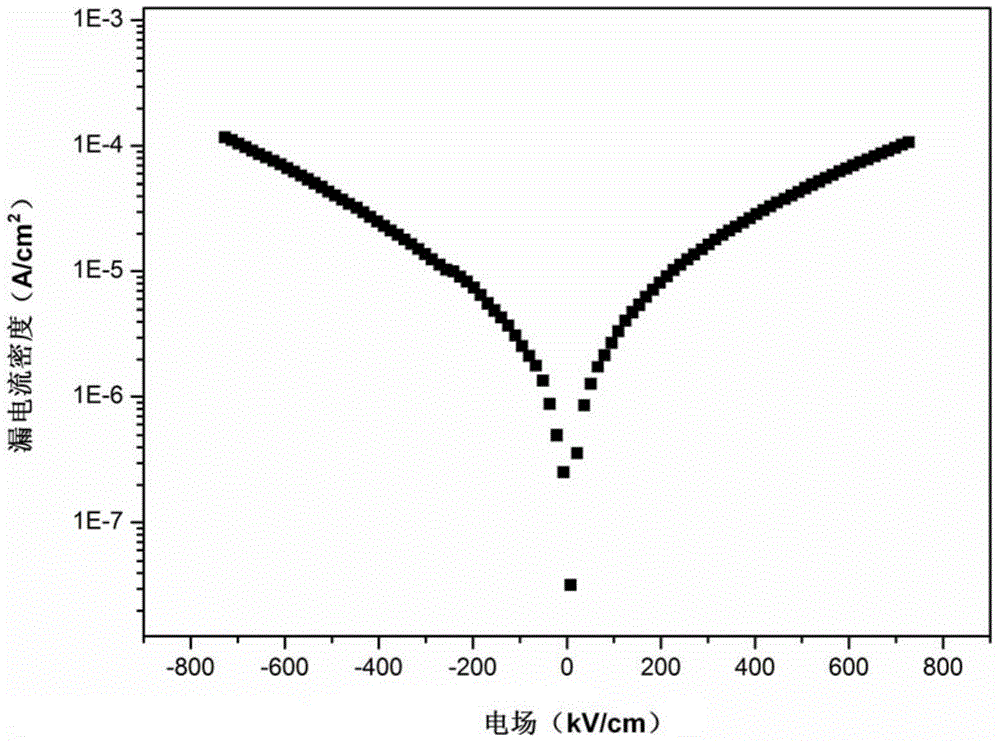

Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film and preparation method thereof

The invention provides a Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film and a preparation method thereof. The preparation method comprises the following steps: preparing a Bi(1-x)RExFe0.96Co0.02Mn0.02O3 precursor solution from bismuth nitrate, ferric nitrate, cobalt nitrate, manganese acetate and nitric acid RE which serve as raw materials, wherein x is 0.06-0.12, and RE is La, Eu or Er; and coating the precursor solution on a substrate in a spinning manner, uniformly coating, baking and annealing to obtain the Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film. By adopting the method, requirement for equipment is simple, the experiment condition can be easily achieved, the doping amount can be easily controlled, and the ferroelectric performance of the film can be greatly improved, so that the prepared Bi(1-x)RExFe0.96Co0.02Mn0.02O3 ferroelectric film has good uniformly, less current leakage and high remanent polarization.

Owner:SHAANXI UNIV OF SCI & TECH

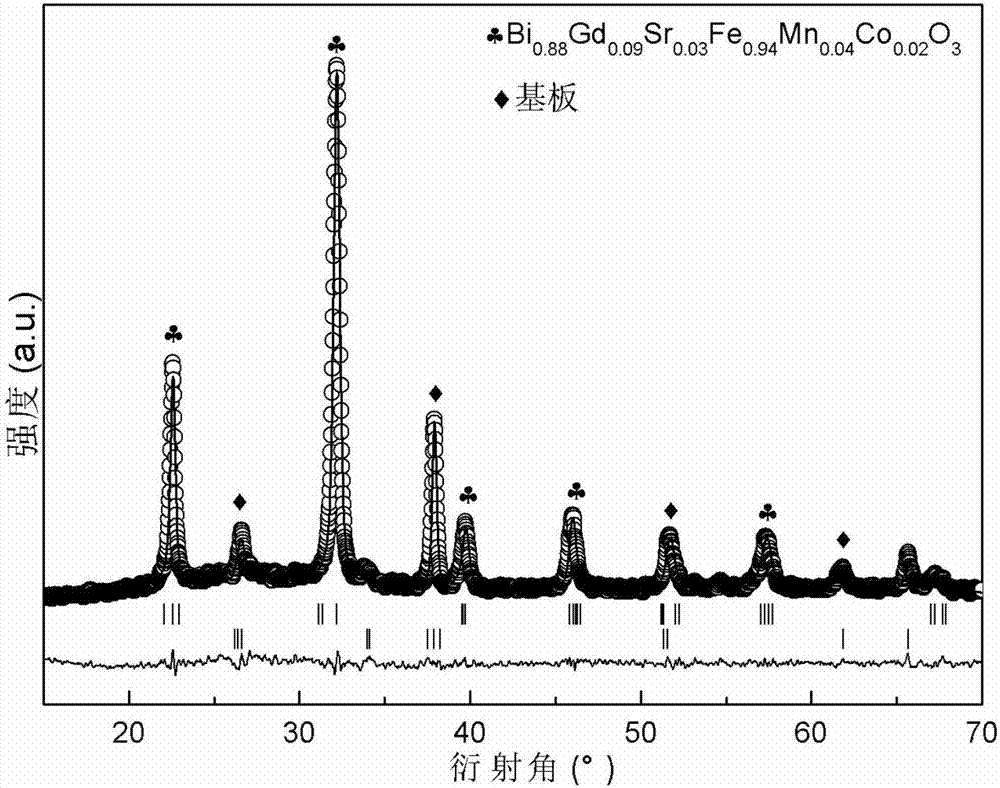

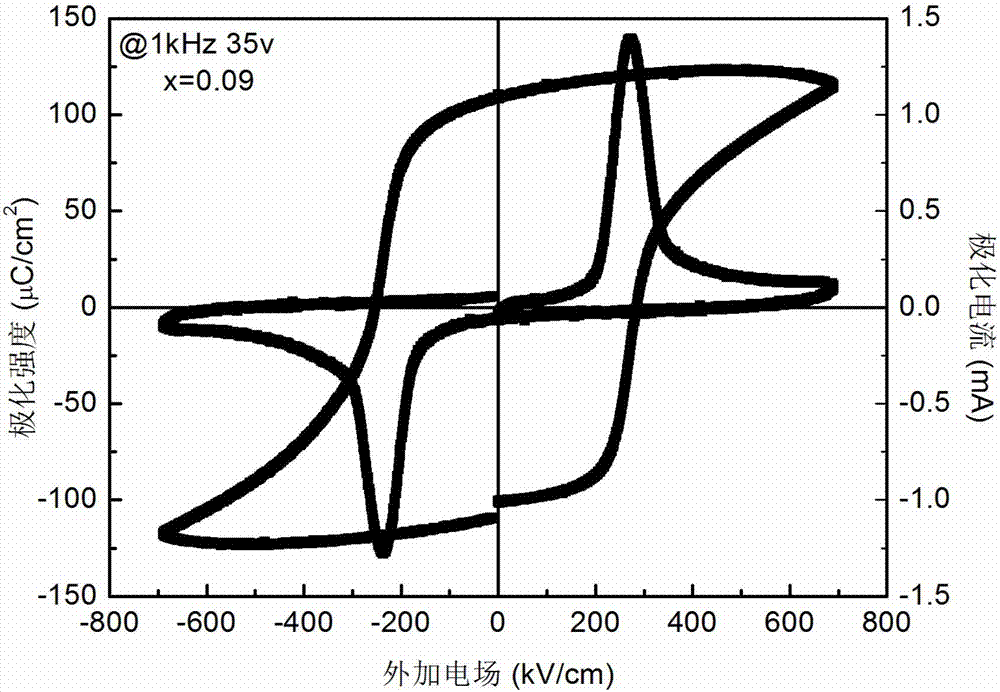

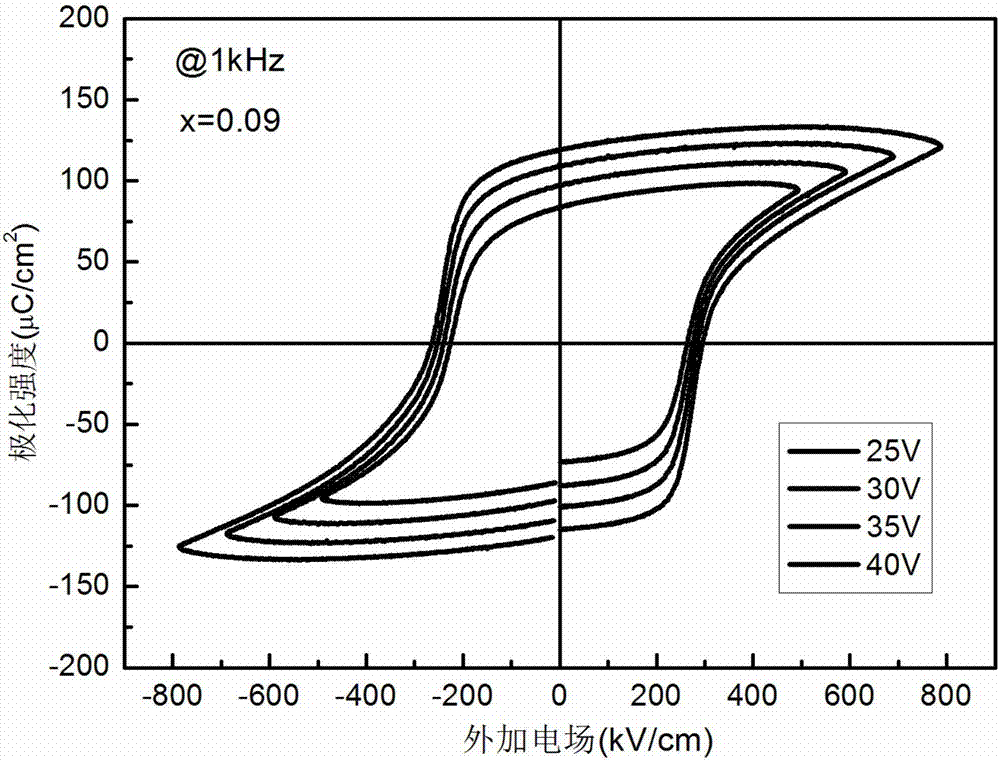

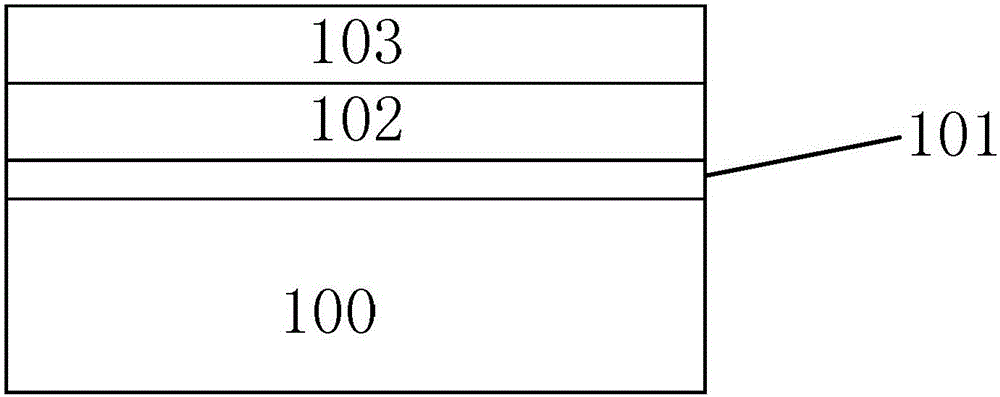

GdSrMnCo codoped bismuth ferrite multiferroic film and making method thereof

ActiveCN107032631AGood dielectricImprove ferroelectric propertiesCoatingsMANGANESE ACETATEAcetic anhydride

The invention provides a GdSrMnCo codoped bismuth ferrite multiferroic film and a making method thereof. The Bi0.97-xGdxSr0.03Fe0.94Mn0.04Co0.02O3 multiferroic film that is the GdSrMnCo codoped bismuth ferrite multiferroic film is made from bismuth nitrate, gadolinium nitrate, strontium nitrate, ferric nitrate, manganese acetate and cobalt nitrate (5% excessive bismuth nitrate) through a spin coating technology and a layer-by-layer annealing technology by using ethylene glycol monomethyl ether and acetic anhydride as a solvent. The method which adopts a sol-gel process and the spin coating and layer-by-layer annealing technologies has the advantages of simple device requirements, easiness in realization of experimental conditions, suitableness for making a film on a large surface and a surface with an irregular shape, accurate and controllable chemical components, and improvement of the multiferroic performance of a BiFeO3 film; and the produced GdSrMnCo codoped bismuth ferrite multiferroic film has good uniformity and has the ferroelectric stability changing with the applied voltage.

Owner:SHAANXI UNIV OF SCI & TECH

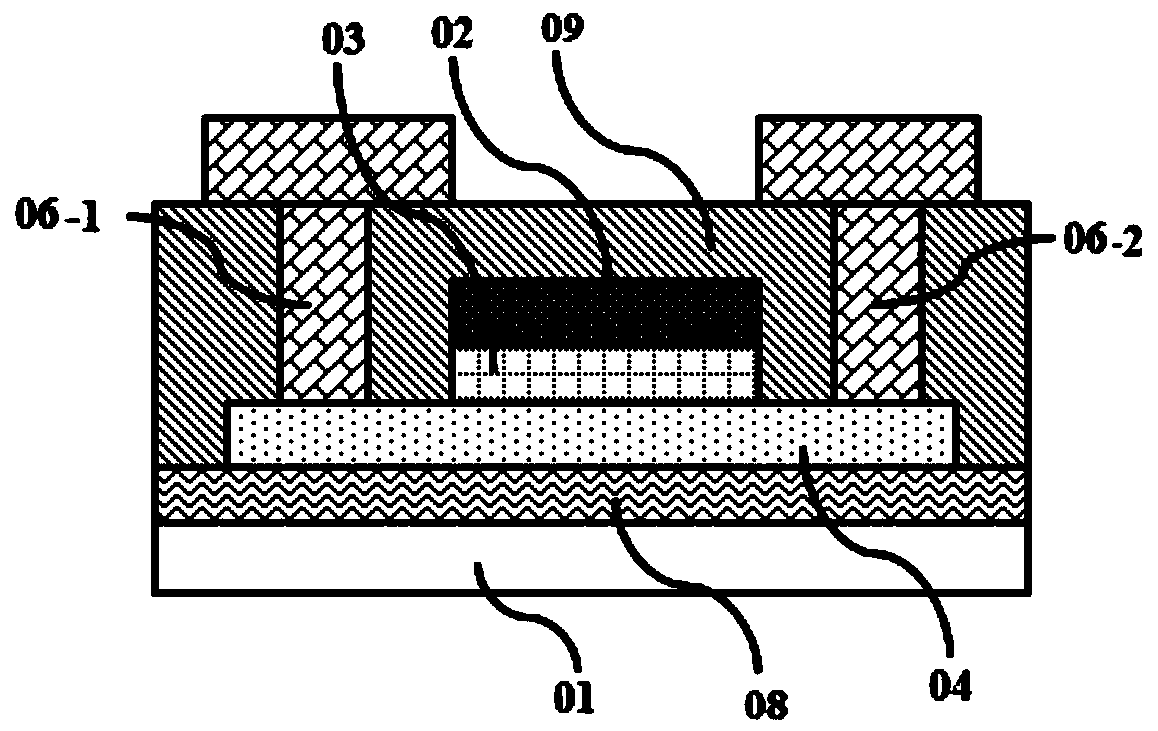

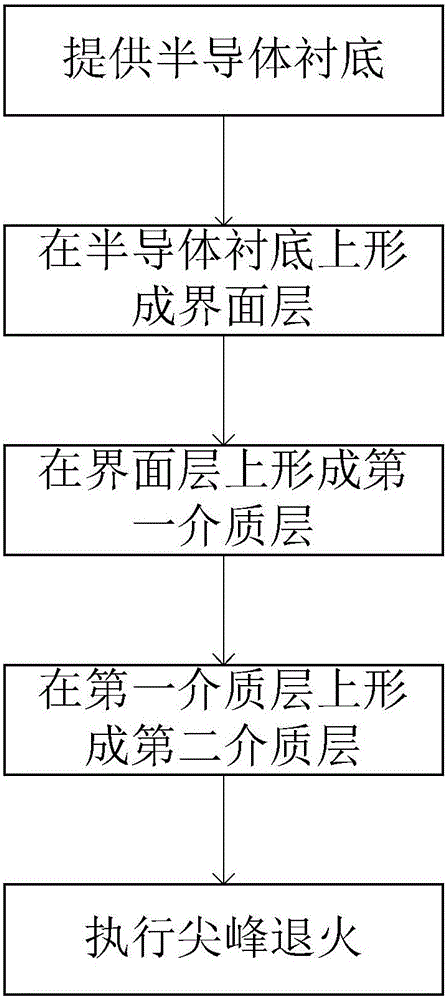

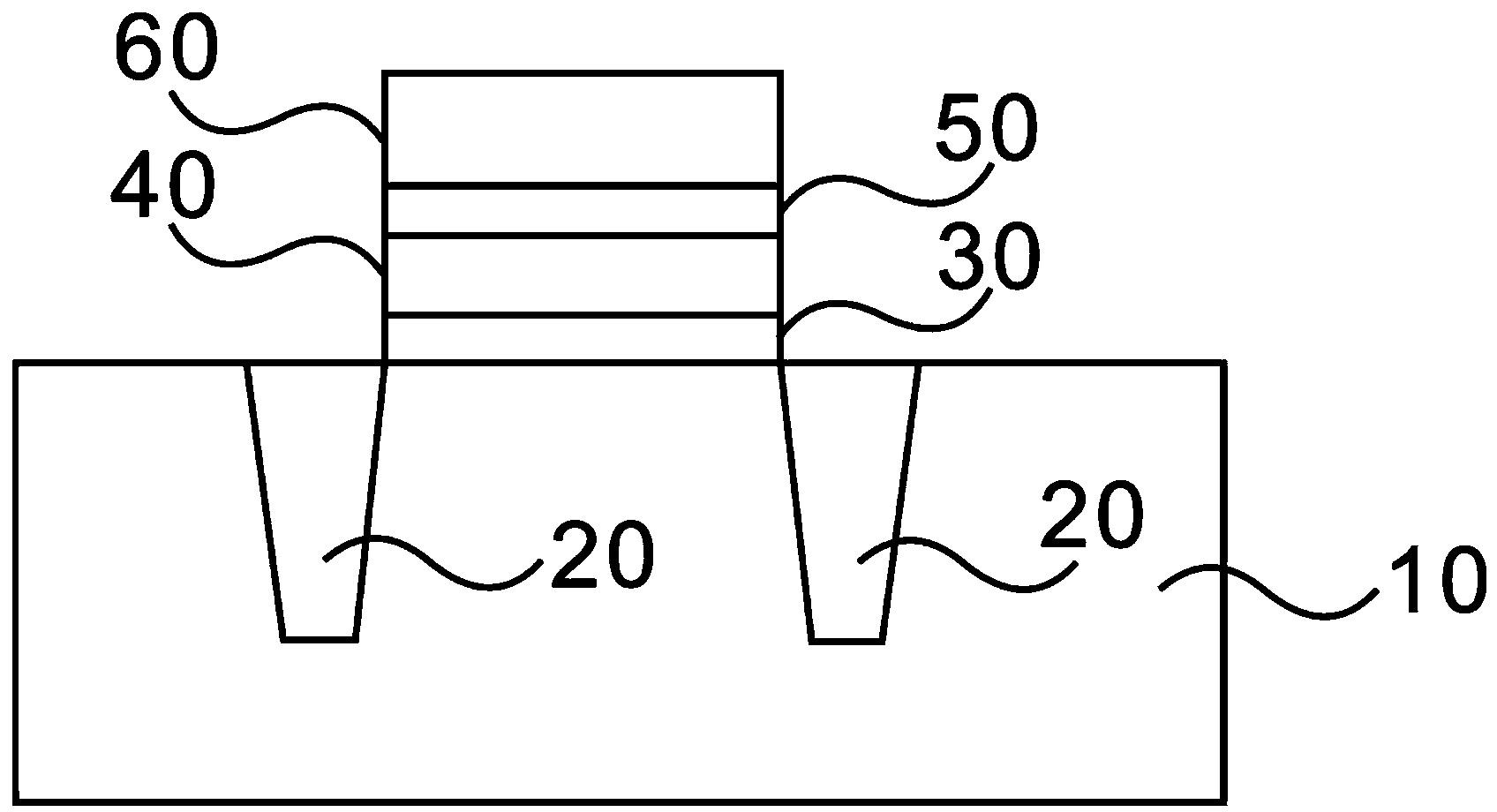

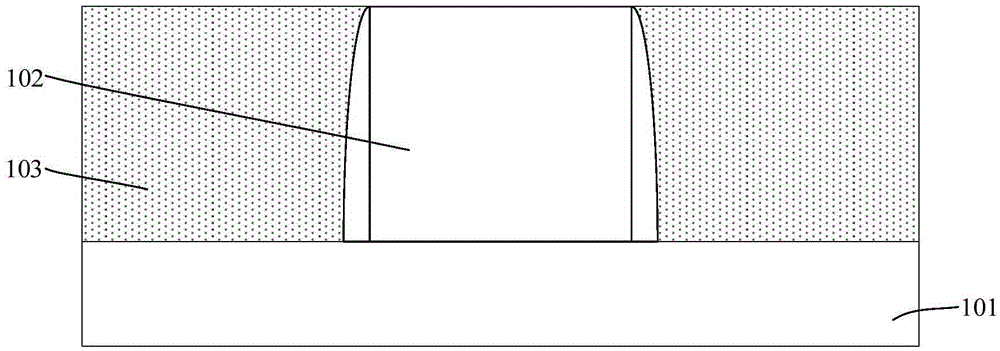

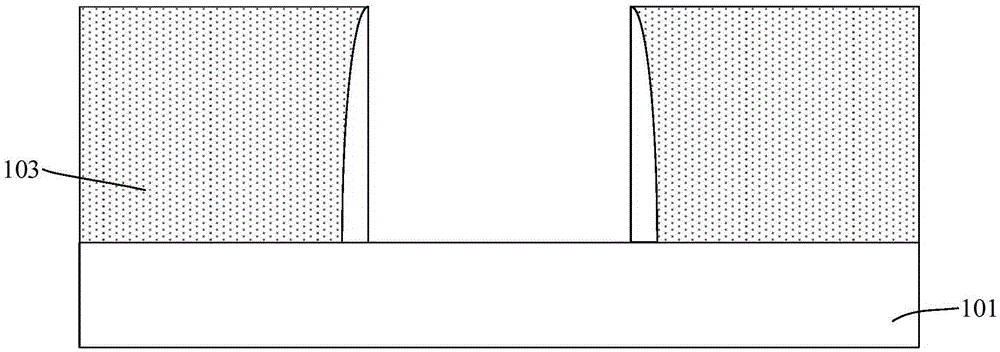

Semiconductor structure and forming method thereof

ActiveCN105932053AReduced oxygen vacanciesReduce gate leakage currentSemiconductor/solid-state device manufacturingSemiconductor devicesGate leakage currentOxygen vacancy

The invention provides a semiconductor structure, which comprises a semiconductor substrate, an interface layer, a first dielectric layer and a second dielectric layer, wherein the interface layer is formed on the semiconductor substrate; the first dielectric layer is formed on the interface layer; the second dielectric layer is formed on the first dielectric layer; and the phase-transition temperature of the second dielectric layer is lower than that of the first dielectric layer. By the semiconductor structure and the forming method thereof provided by the invention, the condition that external oxygen diffuses and passes through the second dielectric layer and enters the first dielectric layer is facilitated when dielectric constants of the dielectric layers are improved; and oxygen vacancies in the first dielectric layer are reduced, so that a gate leakage current is reduced.

Owner:INST OF MICROELECTRONICS CHINESE ACAD OF SCI

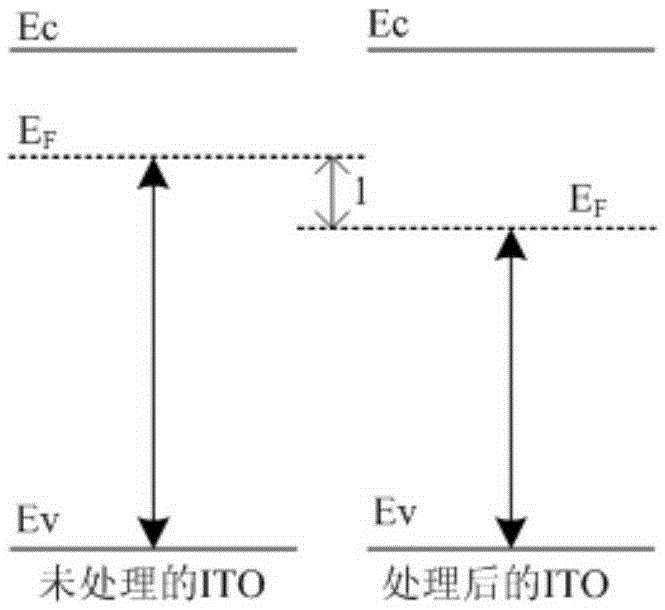

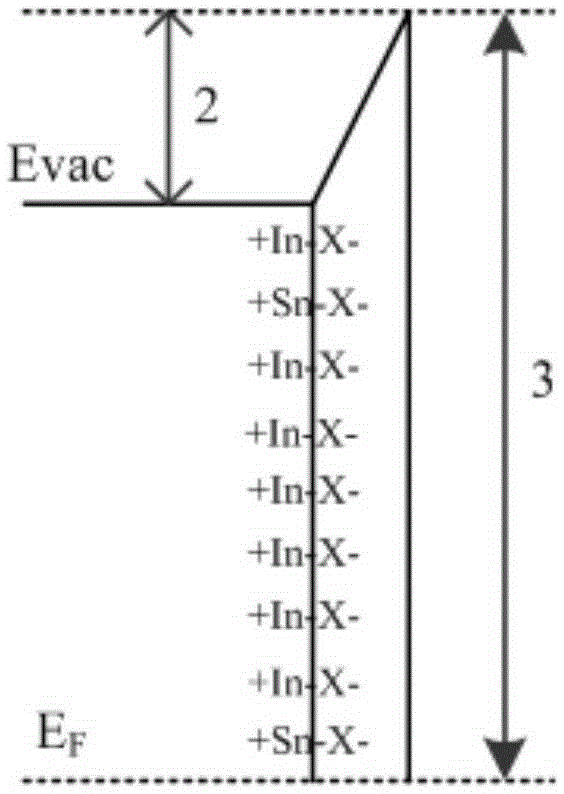

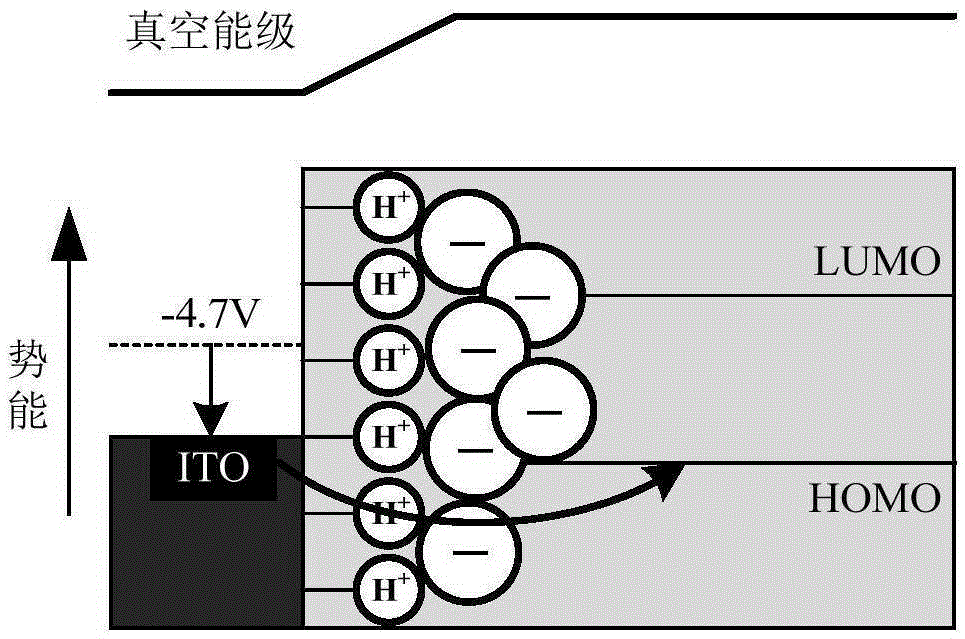

Modified ITO anode and preparation method and application thereof

ActiveCN105355803AEasy to operateEasy injectionSolid-state devicesSemiconductor/solid-state device manufacturingChemical treatmentFlat panel display

The invention is suitable for the flat panel display technology field, and provides a modified ITO anode and a preparation method and applications thereof. The preparation method comprises the following steps: providing an ITO substrate, the ITO substrate comprising a substrate and an ITO film formed on the substrate through deposition, and cleaning and drying the ITO substrate in sequence; taking an HF solution or an HC1 solution as an electrolyte, the ITO substrate as an electrolytic bath anode and a molybdenum electrode as an electrolytic bath cathode, and then placing the ITO substrate and the molybdenum electrode side by side in a reaction container, conducting constant voltage electrochemical processing on the ITO film, and obtaining a surface-modified ITO electrode; and cleaning and drying the surface-modified ITO electrode.

Owner:TCL CORPORATION

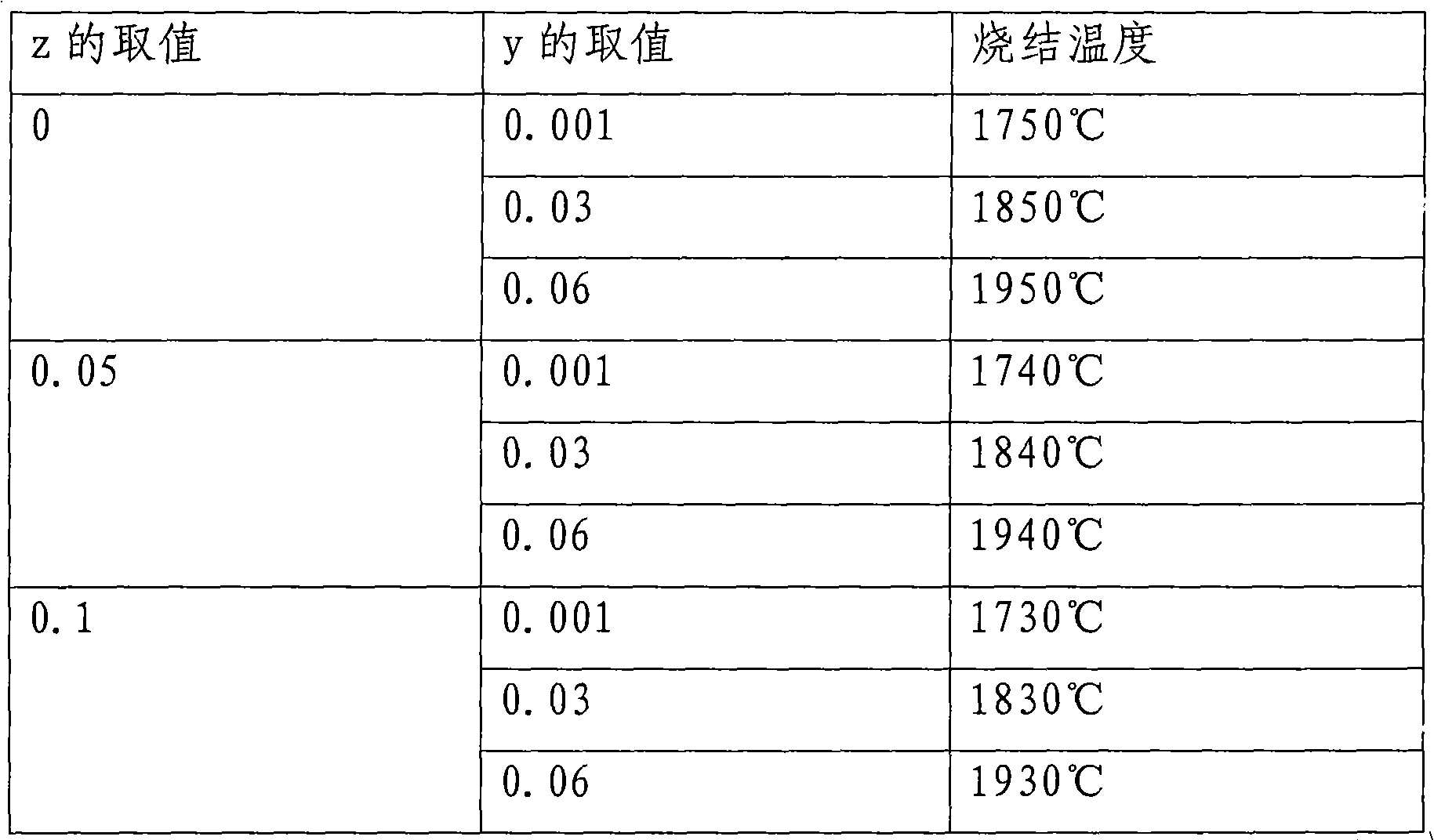

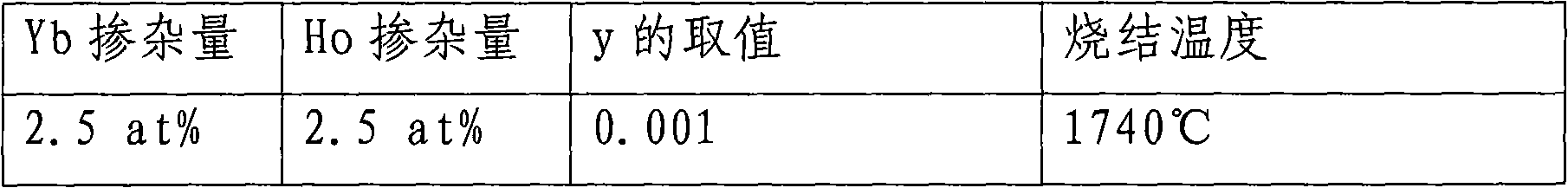

Lanthanum-zirconium codoped rare-earth sesquioxide transparent ceramic and preparation method thereof

The invention discloses lanthanum-zirconium codoped rare-earth sesquioxide transparent ceramic and a preparation method thereof. The chemical formula of the lanthanum-zirconium codoped rare-earth sesquioxide transparent ceramic is R(2-2X-2Y-2Z)La2xZr2yLn2zO3, wherein x is more than or equal to 0.01 and less than or equal to 0.2; y is more than or equal to 0.001 and less than or equal to 0.06; z is more than or equal to 0 and less than or equal to 0.1; R refers to one of rare-earth elements such as Y, Lu, Sc and Gd which are usually taken as doping substrates; and Ln refers to one or the combination of a plurality of lanthanum-series elements such as Nd, Tm, Ho, Er, Yb, Tb and Pr which are usually taken as activated ions. Due to the adoption of lanthanum-zirconium codoping in the method for preparing transparent ceramic with a lanthanum-zirconium codoping method, the growth of crystal grains is suppressed to a certain degree while sintering is facilitated, and transparent ceramic with fine crystal grains, a single size and low porosity is finally obtained.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

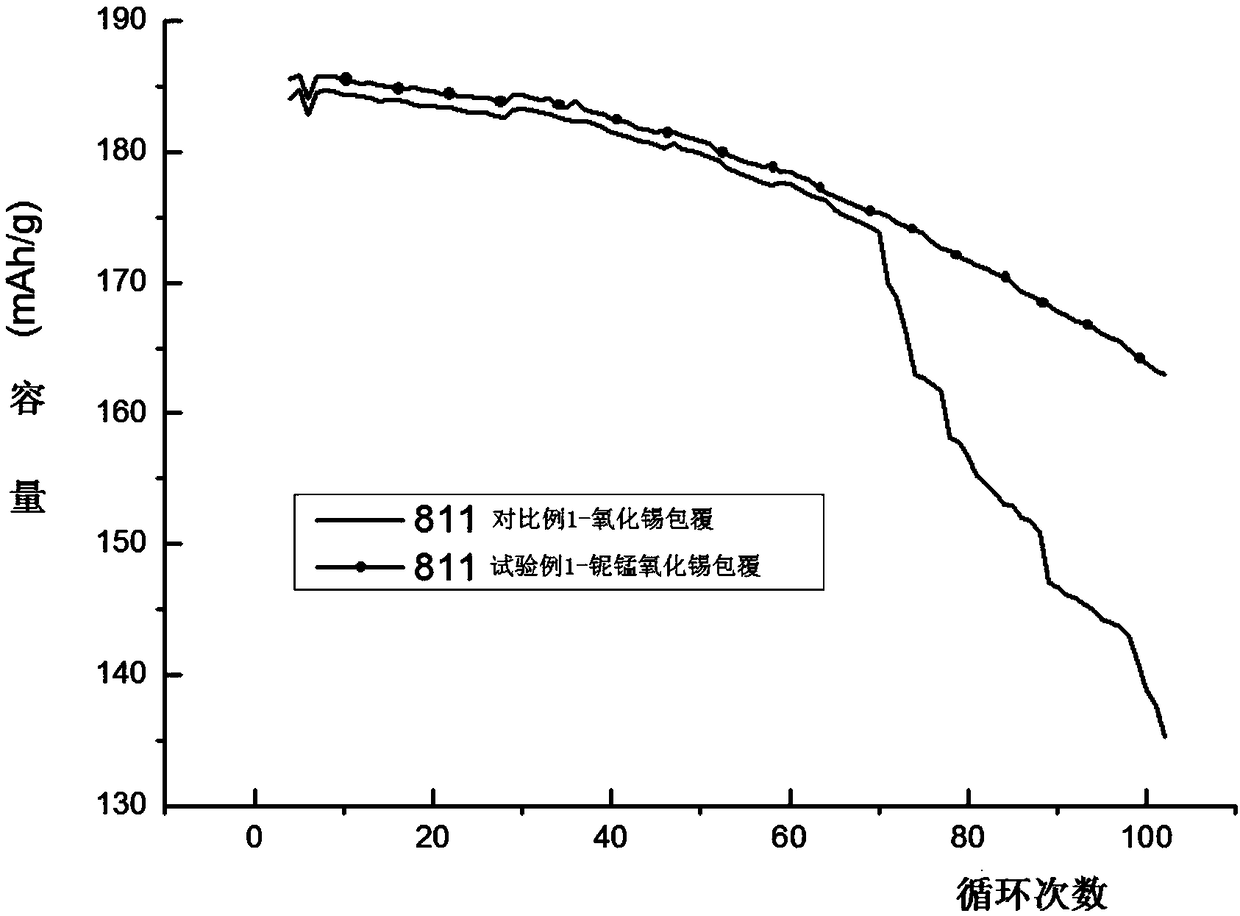

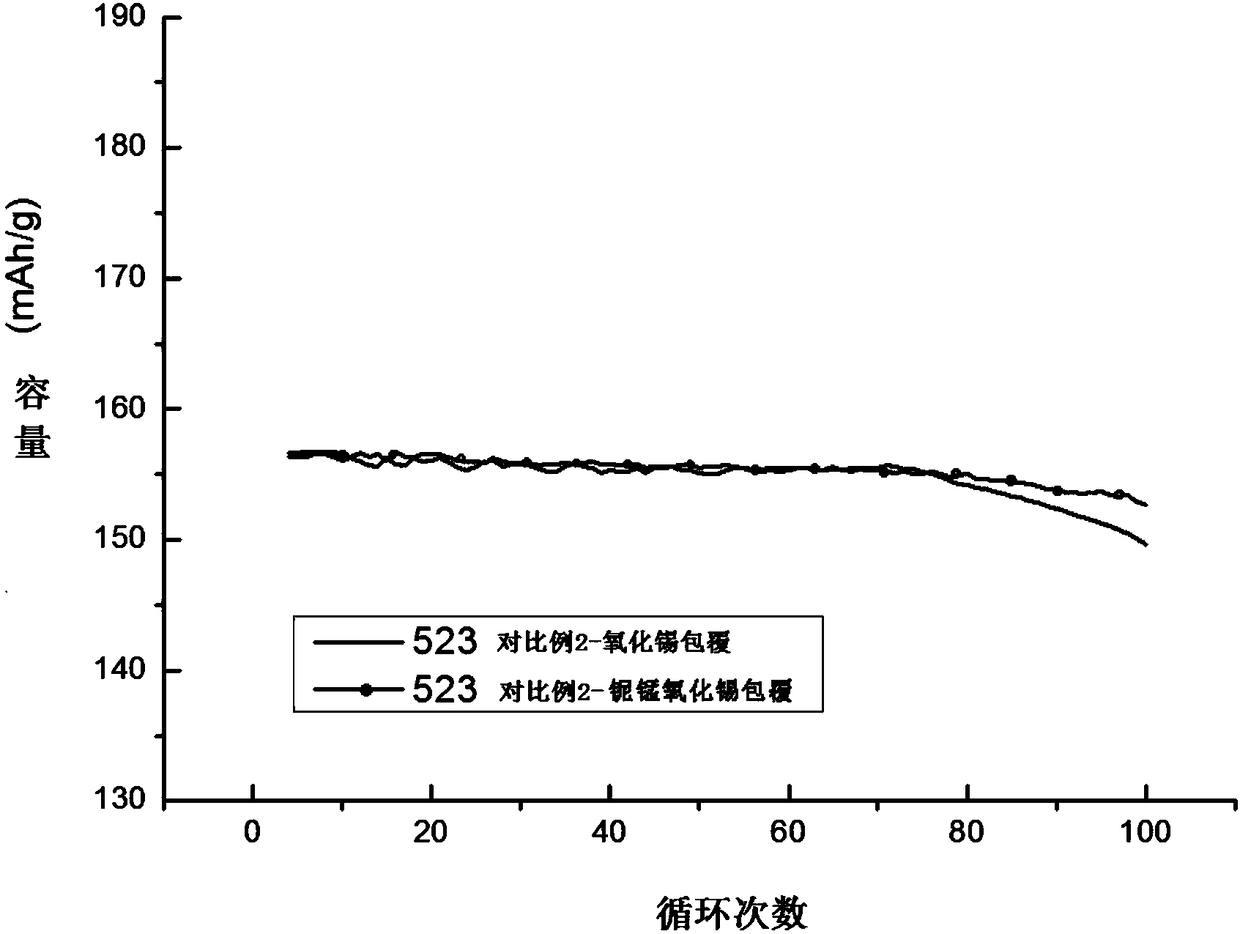

Niobium and manganese modified tin oxide-coated lithium nickel cobalt manganate positive electrode material and preparation method thereof

ActiveCN108417783AVolume expansion inhibition and mitigationLower internal resistanceCell electrodesSecondary cellsNiobiumLattice oxygen

The invention is suitable for the technical field of a lithium battery, and provides a niobium and manganese modified tin oxide-coated lithium nickel cobalt manganate positive electrode material and apreparation method thereof. The method comprises the steps of S1, weighing tin oxide and a niobium and manganese oxide, performing low-temperature treatment after mixing to obtain a niobium and manganese tin oxide mixture; S2, weighing a nickel cobalt manganate ternary material, fully and uniformly mixing the nickel cobalt manganate ternary material and the niobium and manganese tin oxide mixtureto obtain a mixed material; and S3, loading the mixed material obtained in the step S2 to a sagger, and performing sintering to obtain the niobium and manganese modified tin oxide-coated lithium nickel cobalt manganate positive electrode material. The ternary positive electrode material is coated by employing niobium and manganese modified tin oxide, the surface structure of the material can be effectively protected, Ni<2+> generation is reduced, de-intercalation of lattice oxygen is effectively prevented, the cycle and rate performance of the material is improved, meanwhile, the side reaction brought by the defect of the tin oxide material also can be effectively reduced, and the material performance is more excellent.

Owner:GEM (HUBEI) NEW ENERGY MATERIALS CO LTD

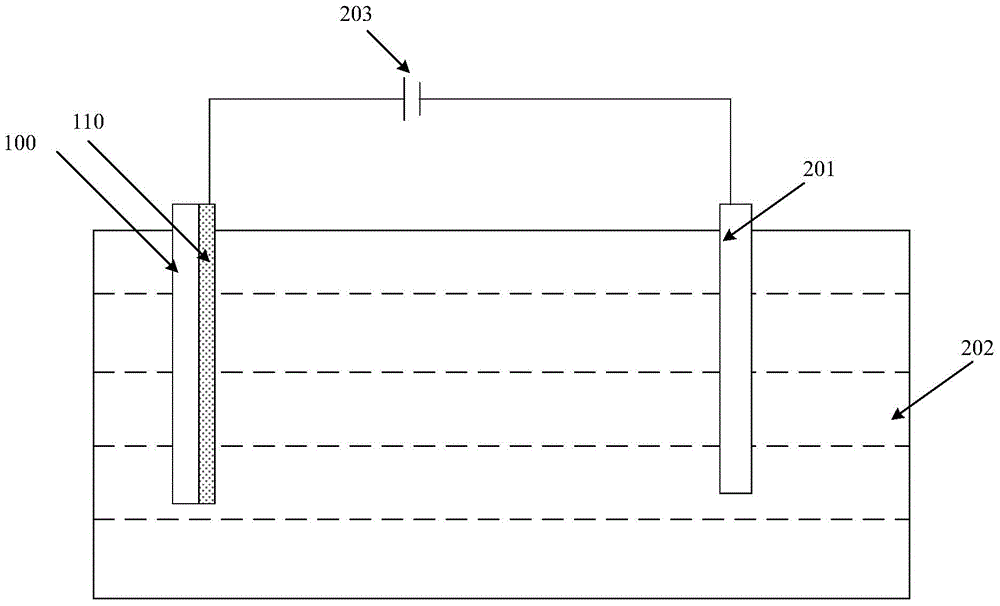

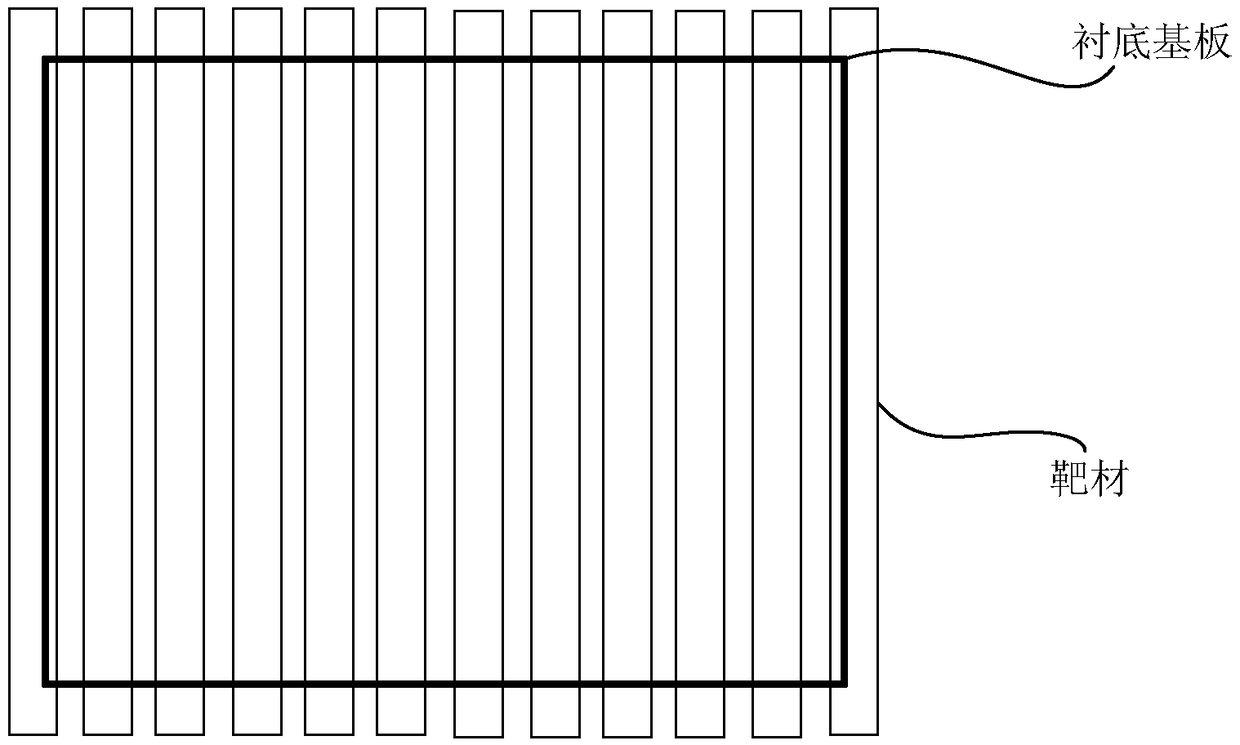

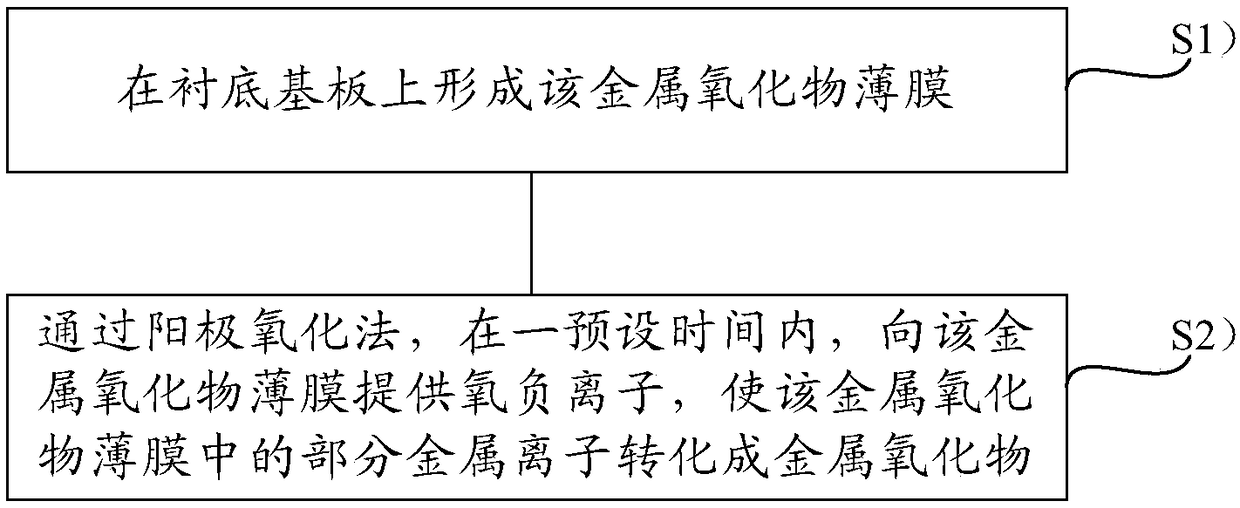

Metal oxide film and preparation method thereof, thin film transistor and array substrate

InactiveCN109461660AReduce concentrationSolve the problem of uneven brightness in different positionsTransistorSolid-state devicesOxygenAnodic oxidation

The invention relates to the field of a display technique, and in particular to a metal oxide film and a preparation method thereof, a thin film transistor and an array substrate. The metal oxide filmand the preparation method thereof, the thin film transistor and the array substrate are used for solving the problem of uneven brightness of different positions of the display panel in the related art. The embodiment of the present invention provides the preparation method of the metal oxide film. The preparation method comprises the steps of forming the metal oxide film on an underlayer substrate; and providing an oxygen anion to the metal oxide film by using an anodic oxidation method within preset time so that part of metal ions in the metal oxide film are converted into metal oxides. Theembodiment of the invention is used for manufacturing of the display panel.

Owner:HEFEI XINSHENG OPTOELECTRONICS TECH CO LTD +1

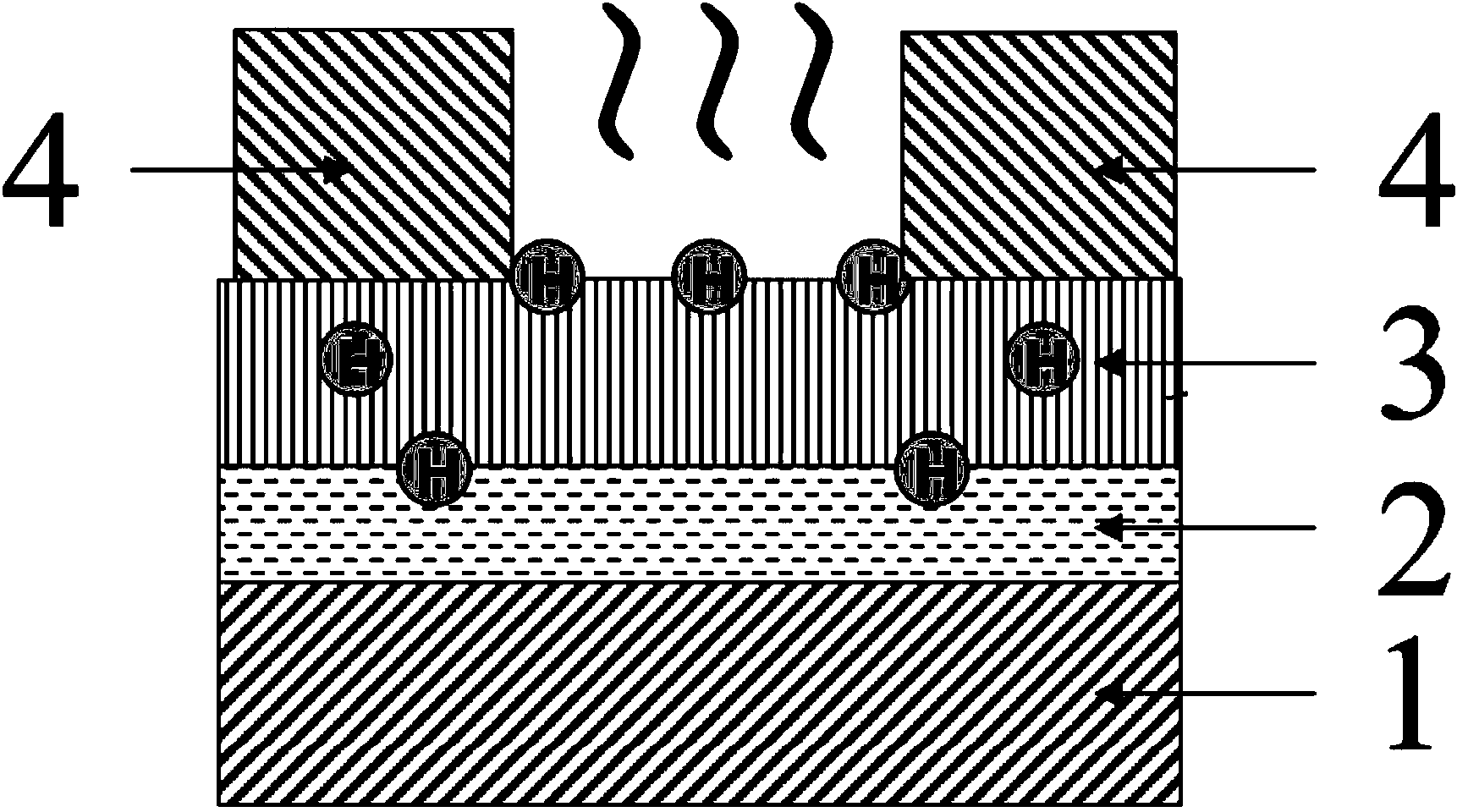

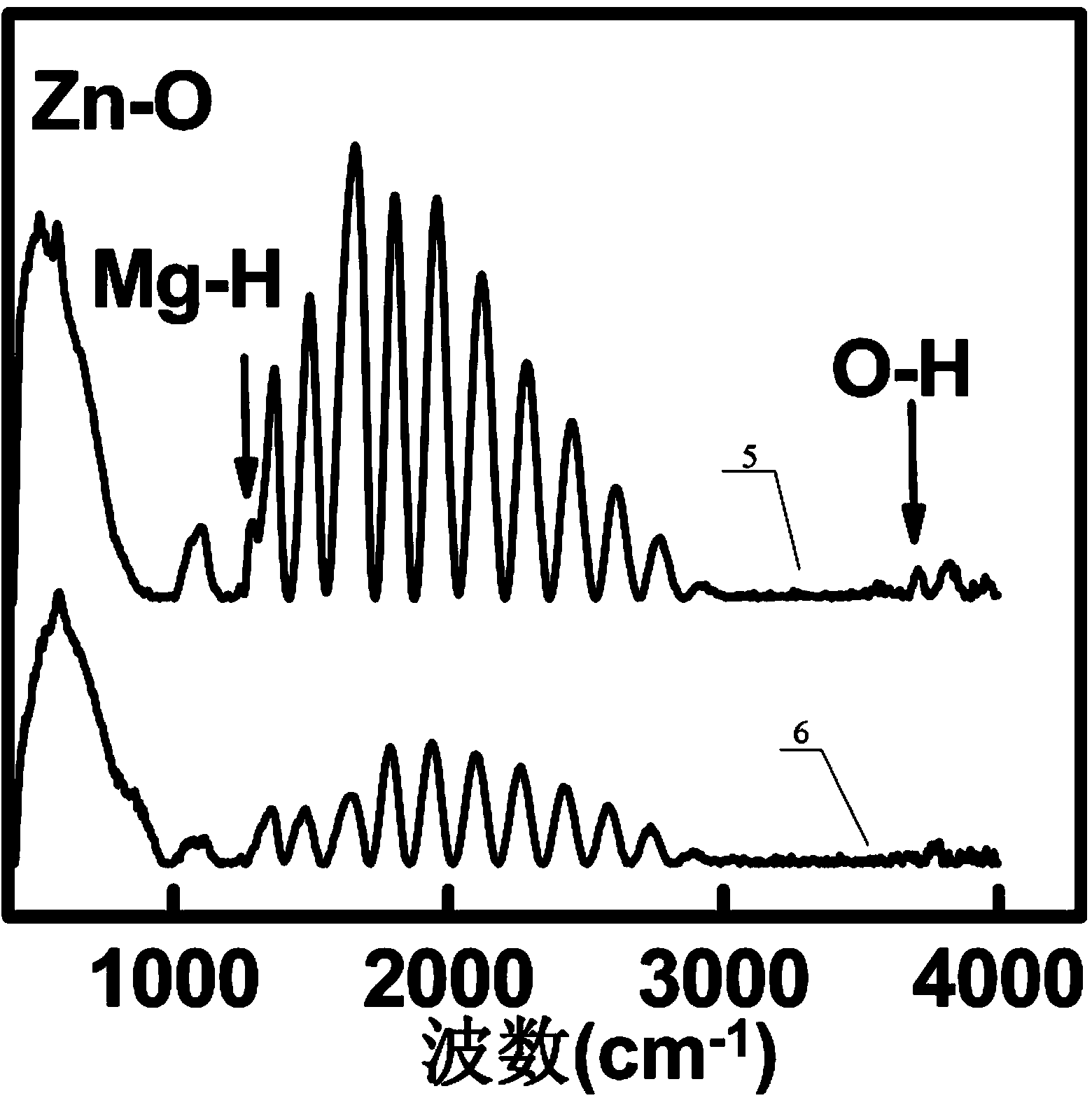

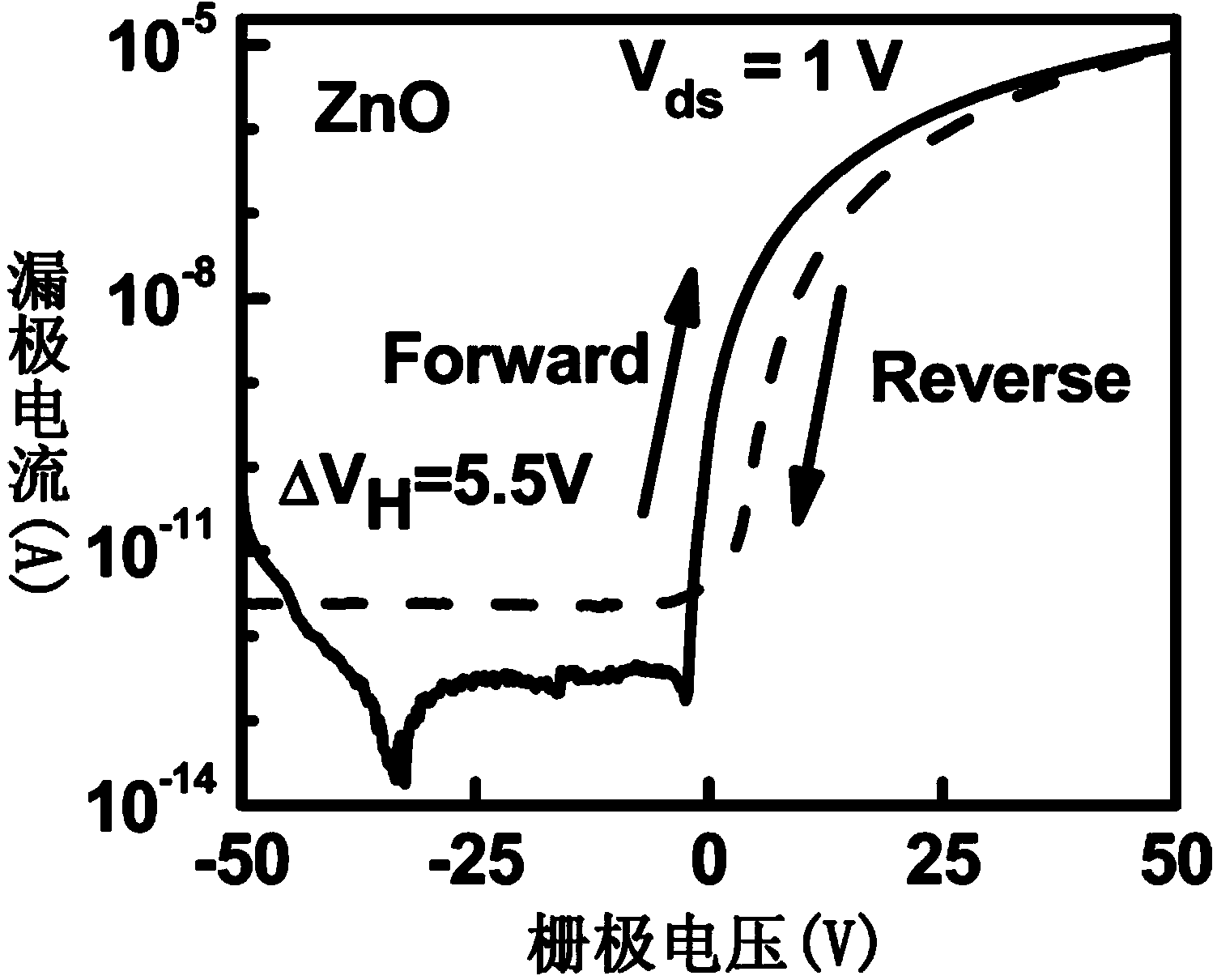

Hydrogen-passivated zinc oxide-base thin film transistor and preparation method thereof

InactiveCN104037234AReduced oxygen vacanciesReduce dangling keysTransistorVacuum evaporation coatingSemiconductor materialsRadio frequency magnetron sputtering

The invention discloses a hydrogen-passivated zinc oxide-base thin film transistor. According to the hydrogen-passivated zinc oxide-base thin film transistor, a zinc oxide-base semiconductor material doped with titanium or magnesium and passivated through hydrogen plasma is used as a channel layer. A preparation method of the hydrogen-passivated zinc oxide-base thin film transistor includes the steps that a highly-doped P-type silicon wafer on which silicon dioxide grows is used as a substrate, radio frequency magnetron sputtering is conducted on a composite target of Ti and zinc oxide or Mg and zinc oxide, and meanwhile a small zinc oxide thin film layer doped with Ti or Mg is formed on the substrate through first masking deposition; in-situ hydrogen plasma processing is conducted; direct current sputtering is conducted on the zinc oxide-base thin film layer on which in-situ hydrogen plasma processing is conducted, an Al electrode is prepared through secondary masking deposition, and then the hydrogen-passivated zinc oxide-base thin film transistor is obtained. The hydrogen-passivated zinc oxide-base thin film transistor has the advantages of being high in electron mobility, good in electrical stability, high in switch ratio and the like. The preparation method is simple in process and low in cost, and threshold voltage of a device can be adjusted through hydrogen passivation time and the content of dopants.

Owner:WUHAN UNIV

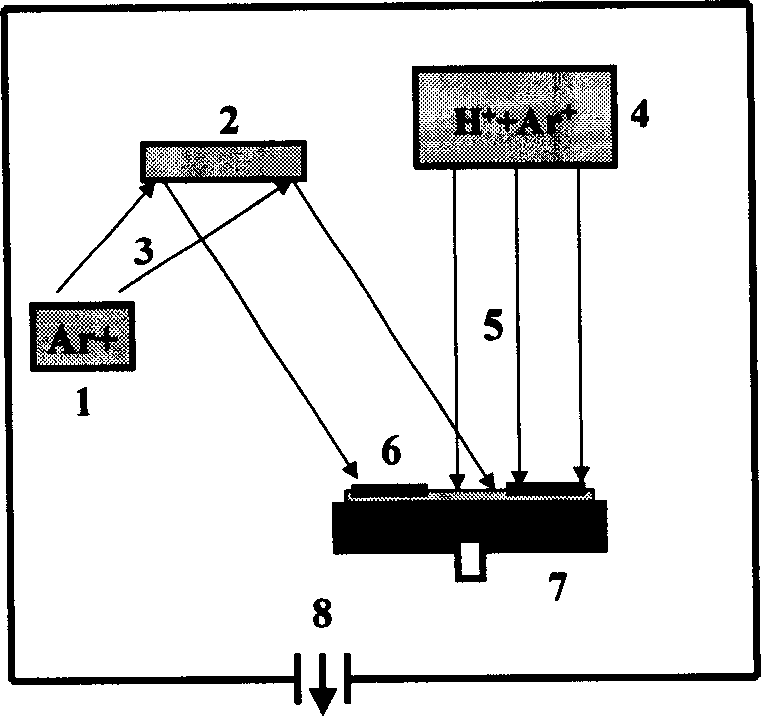

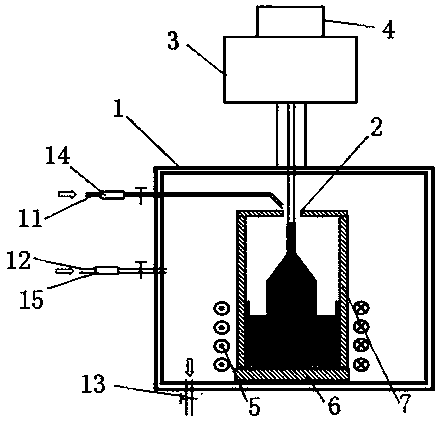

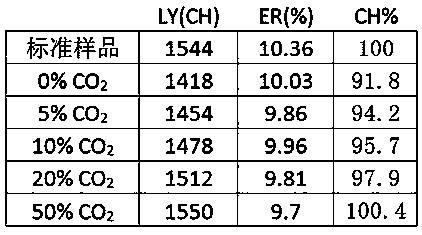

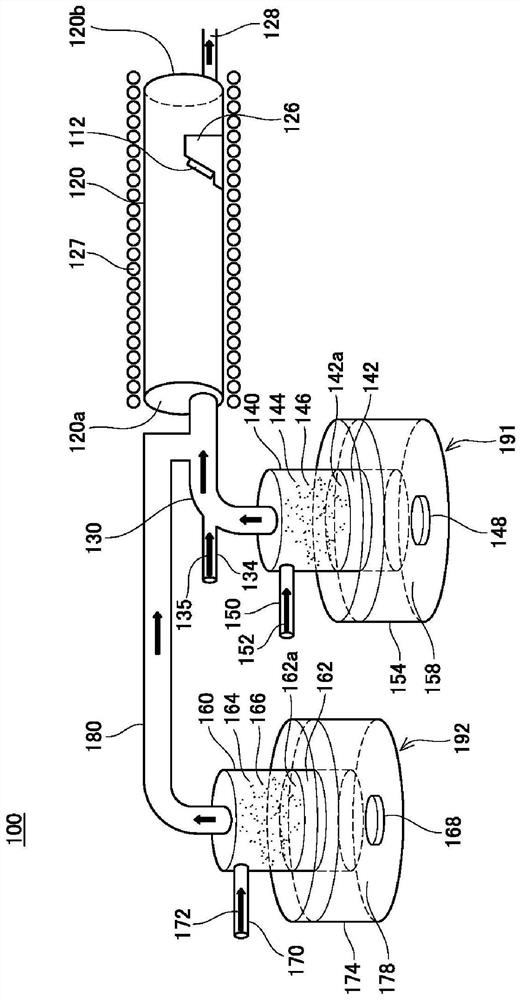

A device and production method for improving performance of cerium-doped scintillation crystal

ActiveCN106011998BImprove performanceImprove integrityPolycrystalline material growthBy pulling from meltOxygen vacancyCrucible

The invention discloses a device and a production method for improving performance of cerium-doped flashing crystals. The device comprises a furnace cavity and a crucible arranged in the furnace cavity, a heat insulating shell is arranged outside the crucible, a heating device is arranged outside the heat insulating shell, and an opening is formed in the top of the heat insulating shell; a lift rotating mechanism extending into the heat insulating shell is arranged at the top of the furnace cavity, a first air incoming pipe and a second air incoming pipe are arranged on the outer side of the furnace cavity, an exhaust pipe is arranged at the bottom of the furnace cavity, and the cerium-doped flashing crystals are obtained through blanking, inflating, growing, sample treating and testing. A certain amount of CO2 is fed, and CO2 is thermally decomposed at high temperature to obtain O2, so that oxygen vacancy of the crystals is reduced, completeness of crystal lattices is improved, and performance of the cerium-doped flashing crystals is improved.

Owner:江苏晶特晶体科技有限公司

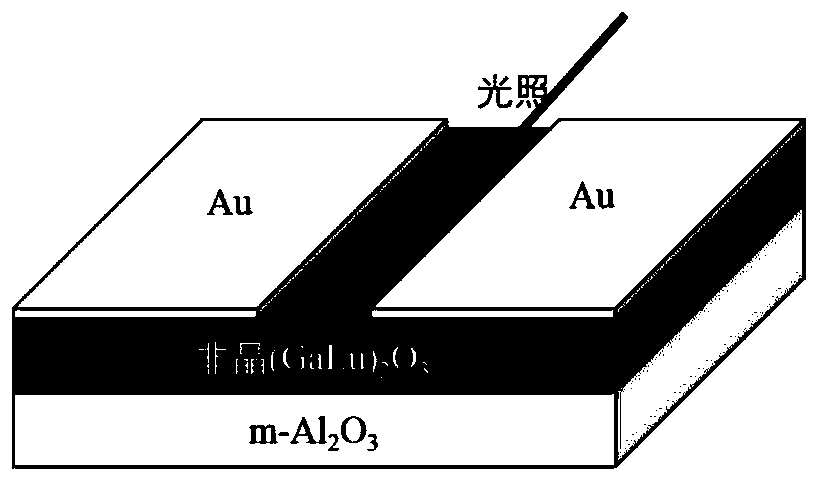

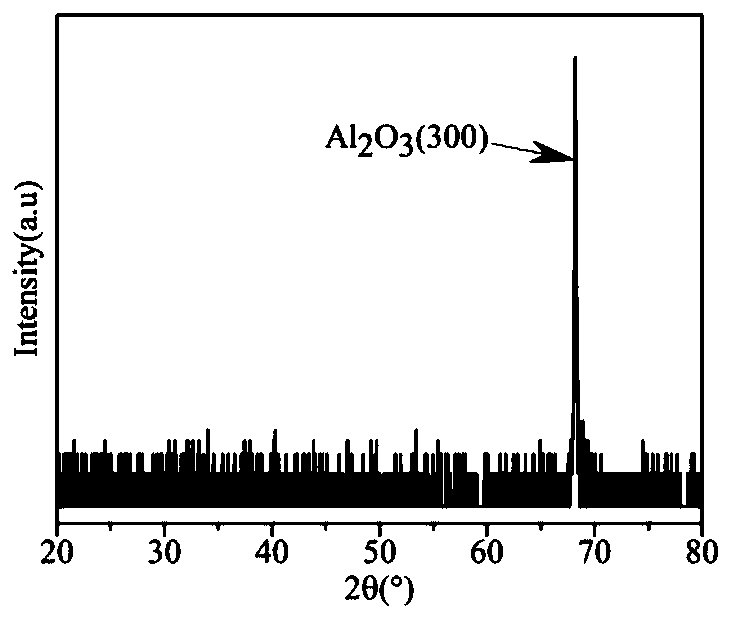

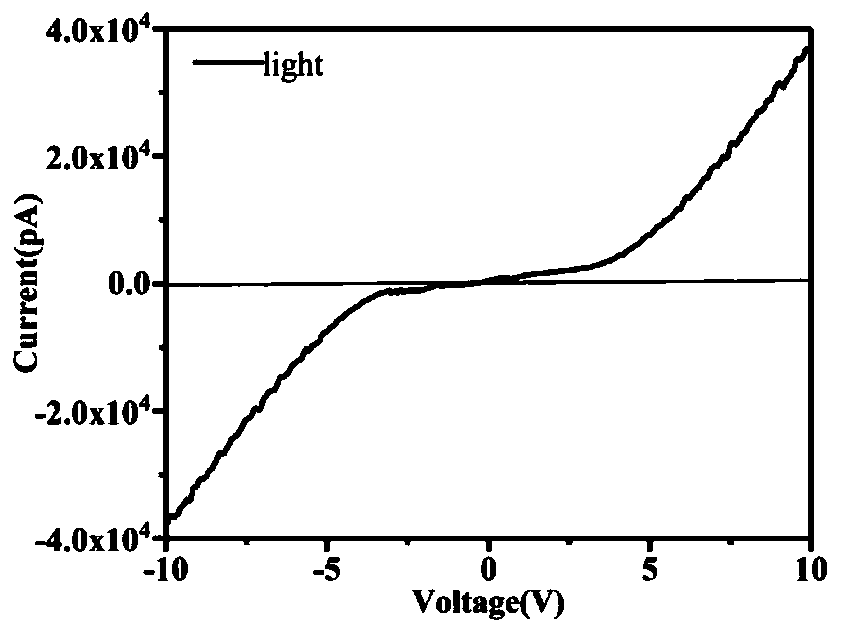

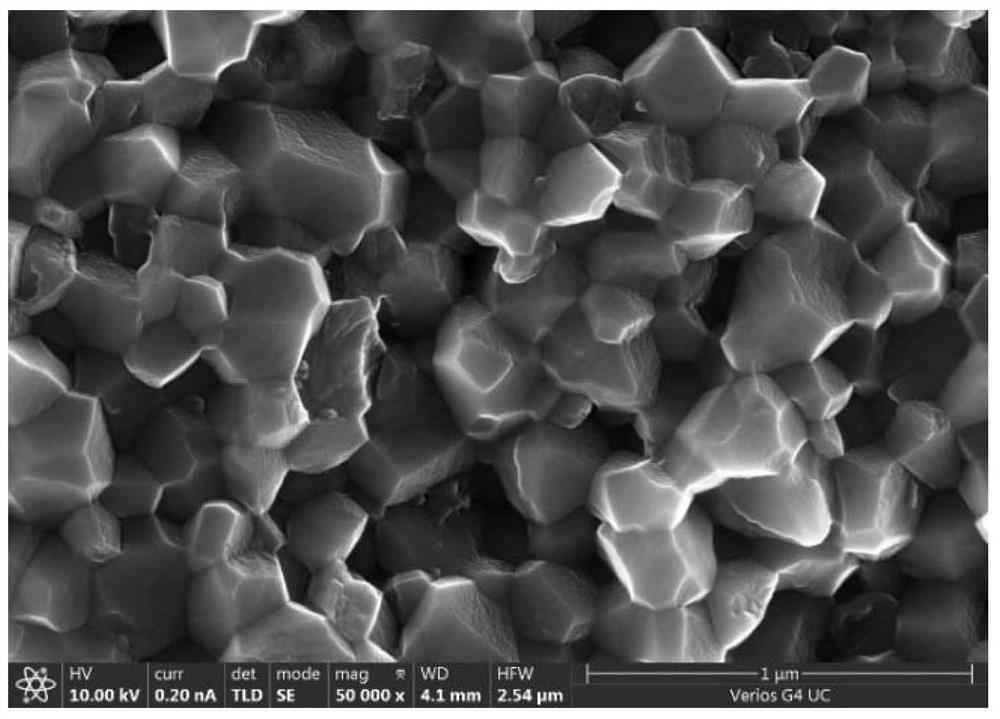

Solar blind ultraviolet light detector based on amorphous (GaLu)2O3 film

ActiveCN111276573AIncreased optical bandgapReduce dark currentFinal product manufactureSemiconductor devicesPhysicsThin membrane

The invention discloses a solar blind ultraviolet light detector based on an amorphous (GaLu)2O3 film and a preparation method of the solar blind ultraviolet light detector. The detector sequentiallycomprises an m-surface sapphire substrate, an active layer and a pair of parallel metal electrodes from bottom to top, and the active layer is an amorphous (GaLu)2O3 film. According to the invention,Lu2O3 and Ga2O3 are utilized to form the (GaLu)2O3 alloy, so that the optical band gap of Ga2O3 is increased, the (GaLu)2O3 film with a higher band gap can effectively reduce the dark current of the device, and the cut-off wavelength is blue-shifted to be within 280nm. In addition, an amorphous (GaLu)2O3 film grows on the m-plane sapphire, and a plurality of dangling bonds and surface states existin the film and can be used as a composite center to accelerate the response speed of the device. Benefited from this, compared with a pure Ga2O3 device, the amorphous (GaLu)2O3 thin film device hasthe advantage that the deep ultraviolet light detection capability of the amorphous (GaLu)2O3 thin film device is greatly improved.

Owner:HUBEI UNIV +1

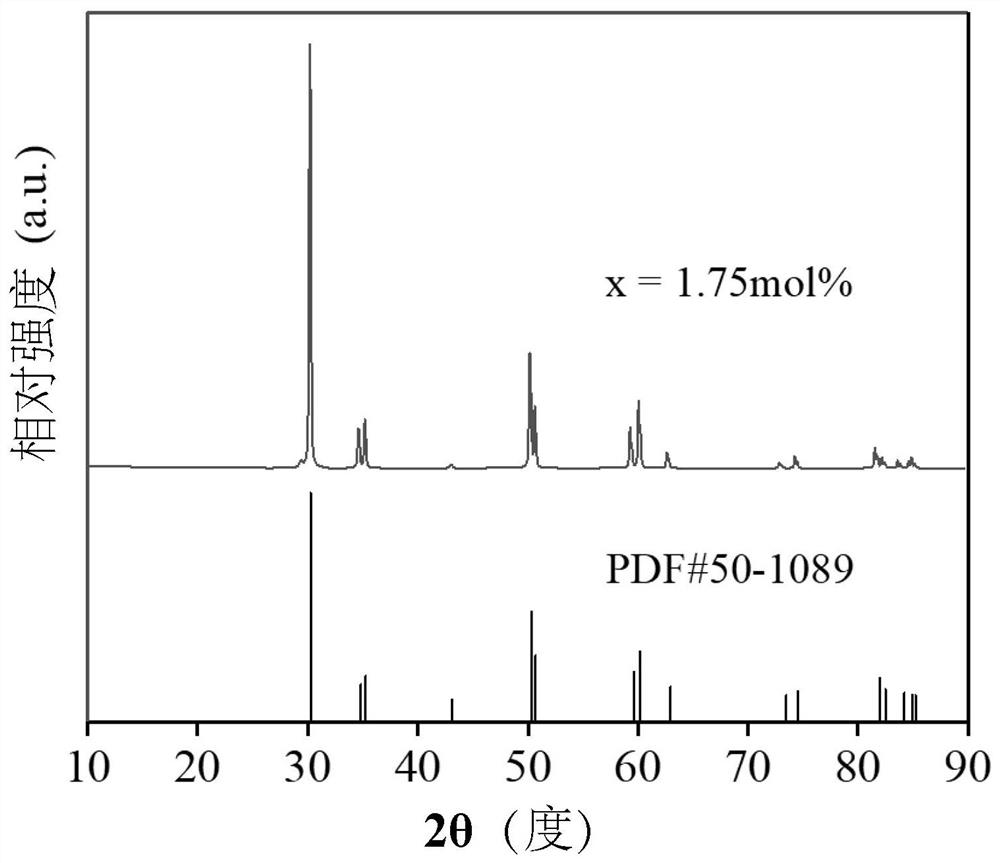

High-quality-factor yttrium-doped zirconium oxide microwave dielectric ceramic material and preparation method thereof

The invention relates to a high-quality-factor yttrium-doped zirconium oxide microwave dielectric ceramic material and a preparation method thereof. The yttrium-doped zirconium oxide microwave dielectric ceramic material has a tetragonal phase structure, the chemical composition is that: of ZrO2-x mol% Y2O3-y wt% Al2O3-z wt% SiO2, the x is greater than or equal to 1.5 and less than or equal to 2.0, the y is greater than or equal to 0.04 and less than or equal to 0.06, and the z isgreater than or equal to 0.001 and less than or equal to 0.002; and the x mol% is the molar content of the Y2O3, the y wt% is the mass percentage content of the Al2O3, and the z wt% is the mass percentage content of the SiO2.

Owner:SHANGHAI INST OF CERAMIC CHEM & TECH CHINESE ACAD OF SCI

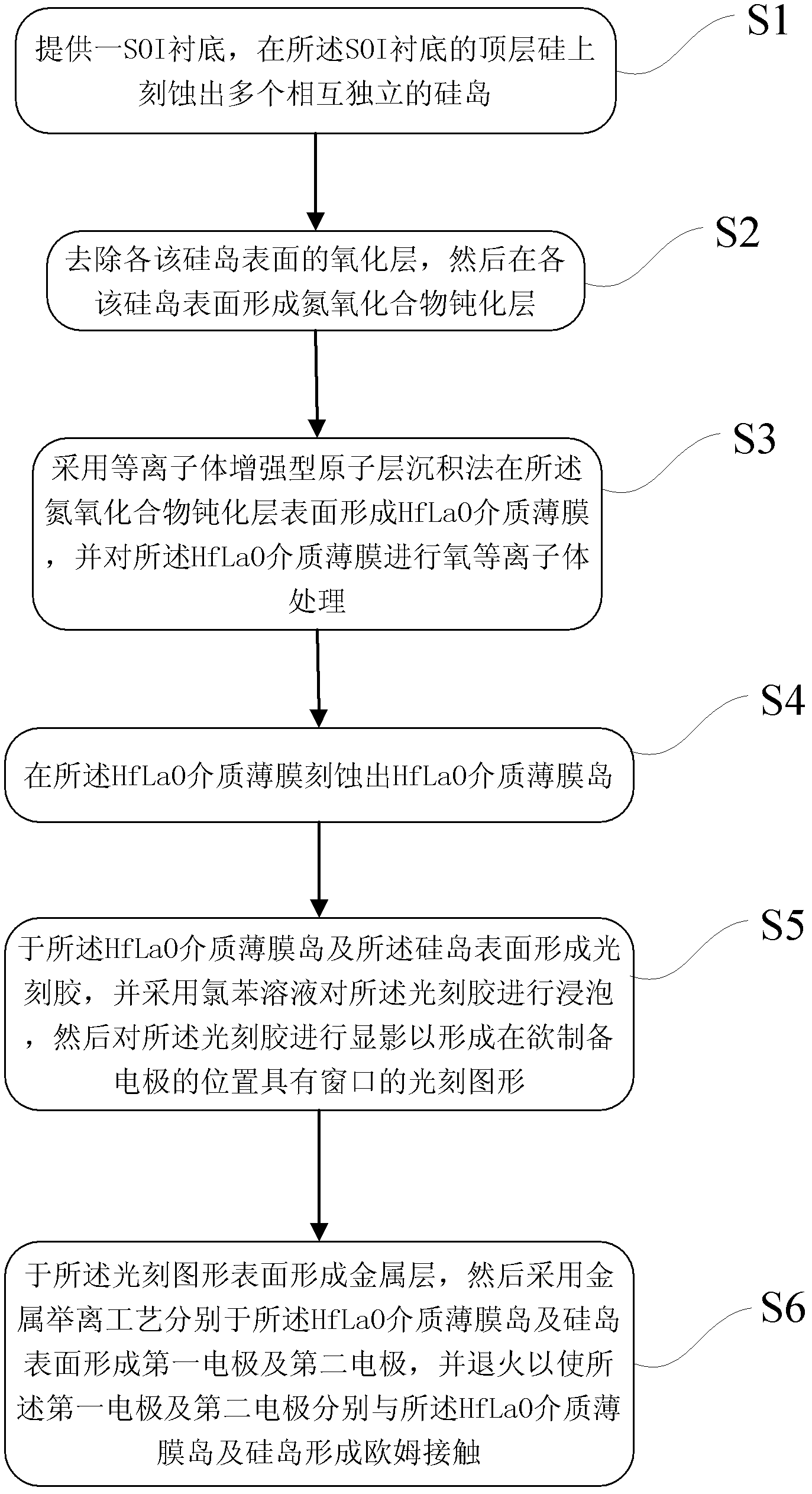

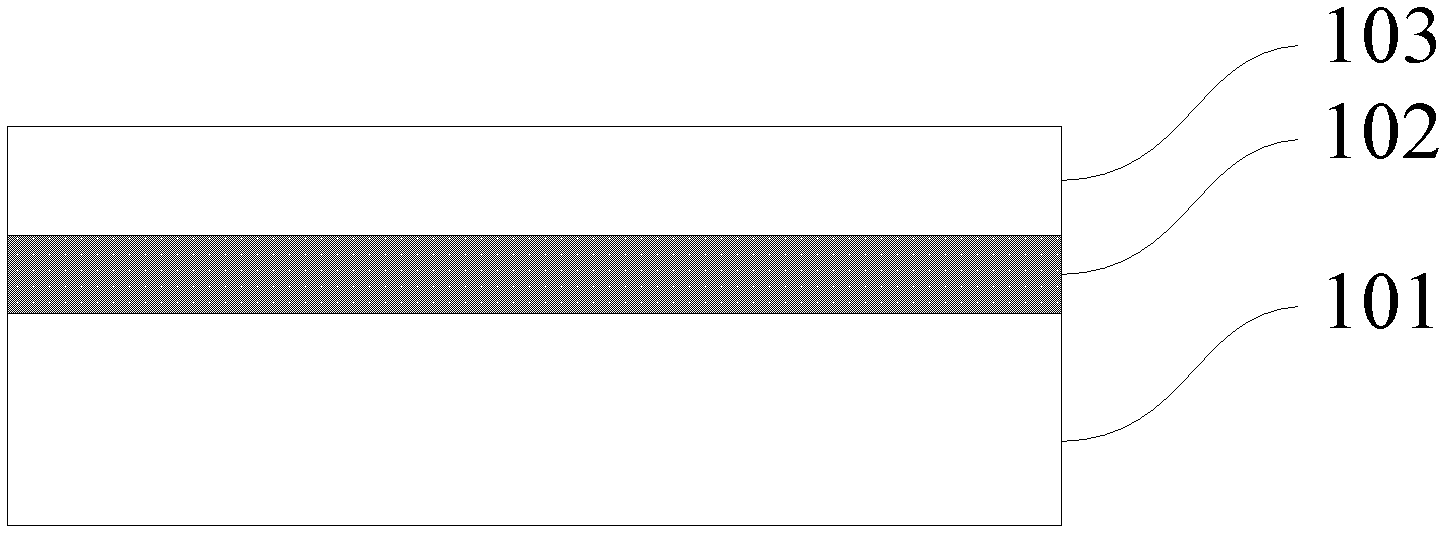

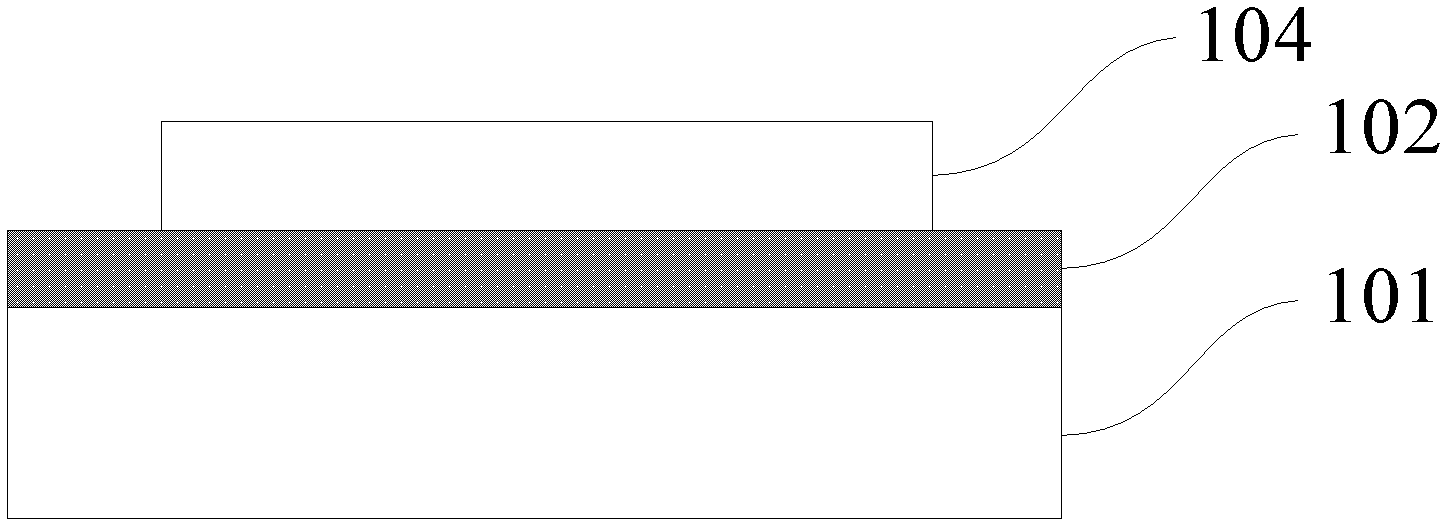

Method for manufacturing MIS (Metal-Insulator-Semiconductor) capacitor

InactiveCN102569070AReduce thicknessReduced oxygen vacanciesSemiconductor/solid-state device manufacturingOxygen vacancyCapacitance

The invention provides a method for manufacturing an MIS (Metal-Insulator-Semiconductor) capacitor, which can effectively reduce the thickness of a film interface layer by etching a silicon island on an SOI (Silicon On Insulator) substrate and removing an oxide layer on the surface of the silicon island by adopting HF. The method comprises the following steps of: firstly, growing a thin oxynitride passivation layer on the Si surface by using a plasma atomic layer deposition method and adopting in-situ O2 and NH3 plasma so as to restrict the growth of the interface layer; and secondly, growing an HfLaO dielectric film by using a plasma growth manner, carrying out oxygen plasma aftertreatment on the HfLaO dielectric film in situ to reduce oxygen vacancy in the film; and thirdly, processing photoresist by using a chlorobenzene solution, so that burrs on the edge of the photoresist can be modified to ensure that the subsequent metal lifting process is simpler and more accurate. The MIS capacitor manufactured by adopting the method disclosed by the invention is beneficial to reduction of the quantity of additional interface layers, thinning of thickness of each interface layer, reduction of roughness of the interface layers, restriction of element dispersion between the substrate and the film and reduction of equivalent gate oxide thickness, and thus the electric property of the MIS capacitor is effectively improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

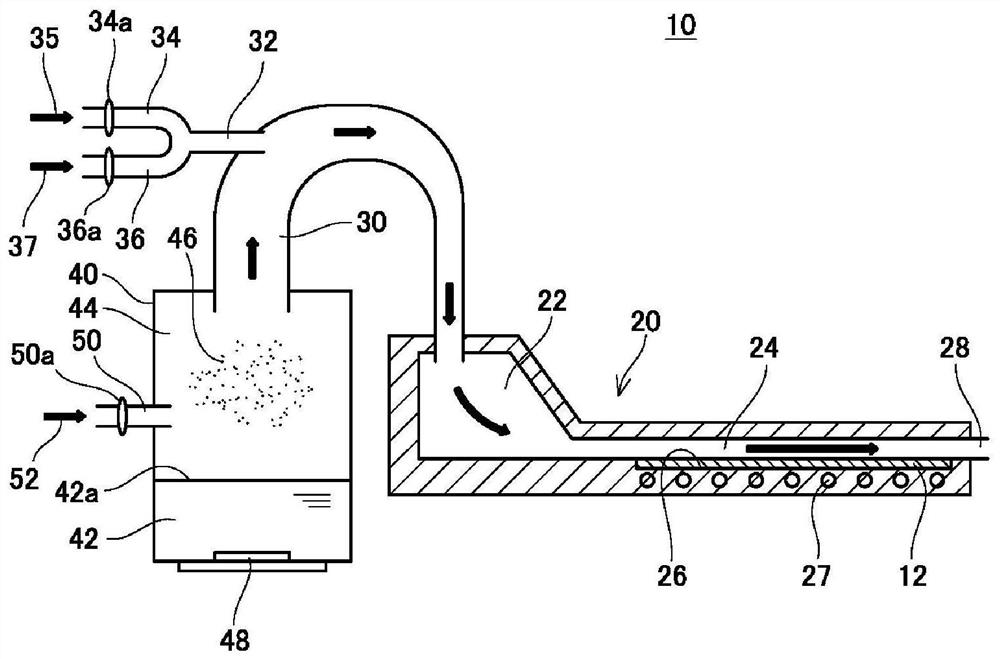

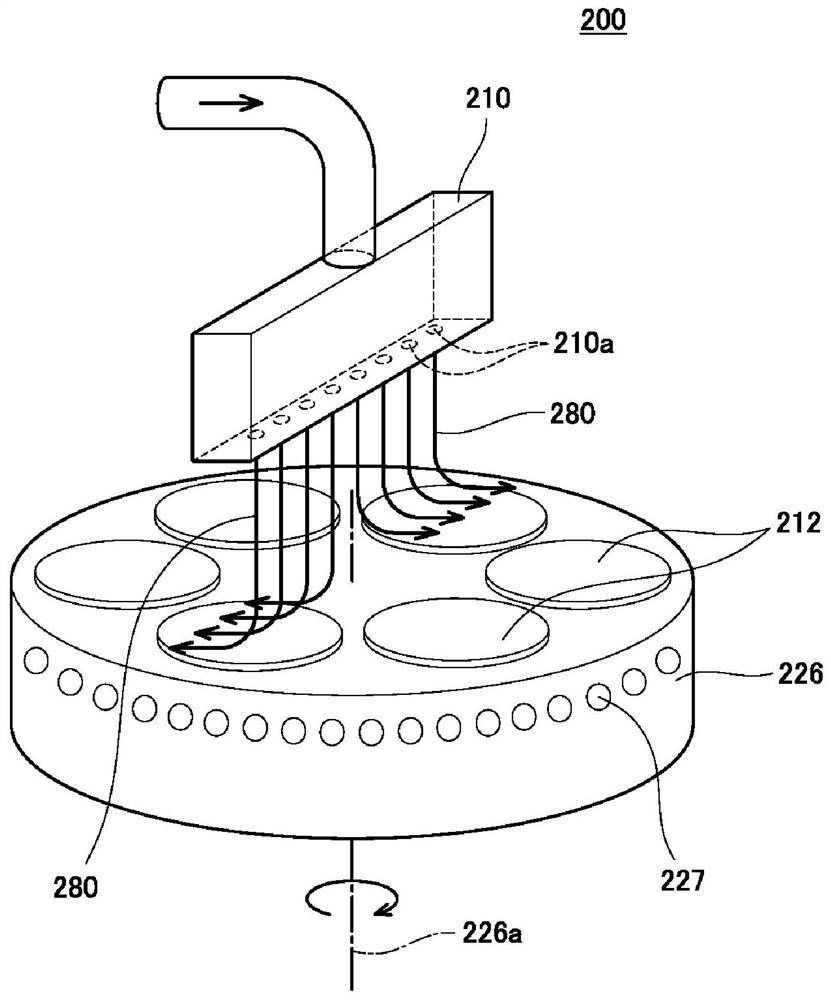

Method of forming oxide film, method of manufacturing semiconductor device, and film forming apparatus configured to form oxide film

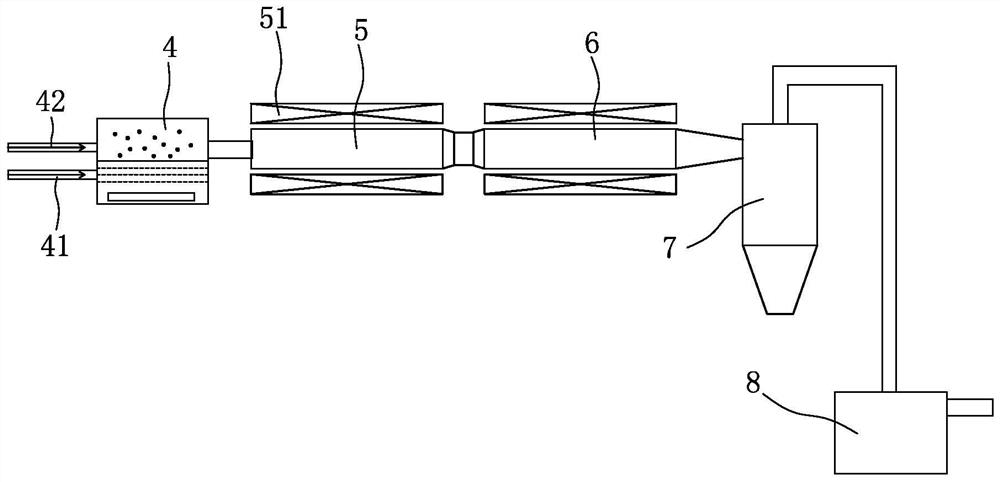

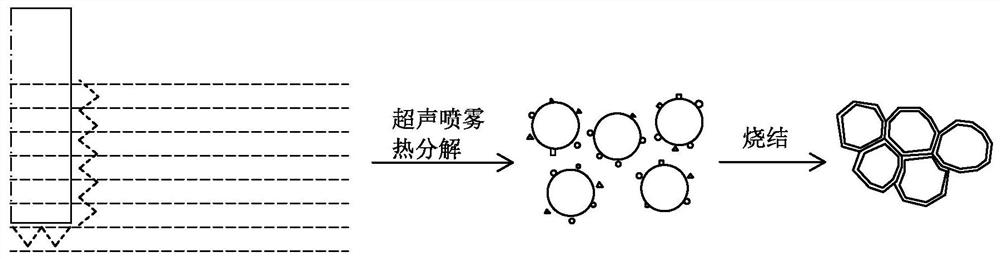

PendingCN112048765AHigh crystallinityEasy to spreadPolycrystalline material growthAfter-treatment detailsDevice materialPhysical chemistry

The invention provides a method of forming an oxide film, a method of manufacturing a semiconductor device, and a film forming apparatus configured to form an oxide film. An oxide film having a high degree of crystallinity can be formed in a short period of time. The method of forming an oxide film includes: supplying mist of a solution including a material of the oxide film dissolved therein to asurface of a substrate while heating the substrate at a first temperature so as to epitaxially grow the oxide film on the surface of the substrate; and bringing the oxide film into contact with a fluid comprising oxygen atoms while heating the oxide film at a second temperature higher than the first temperature after the epitaxial growth of the oxide film.

Owner:DENSO CORP +1

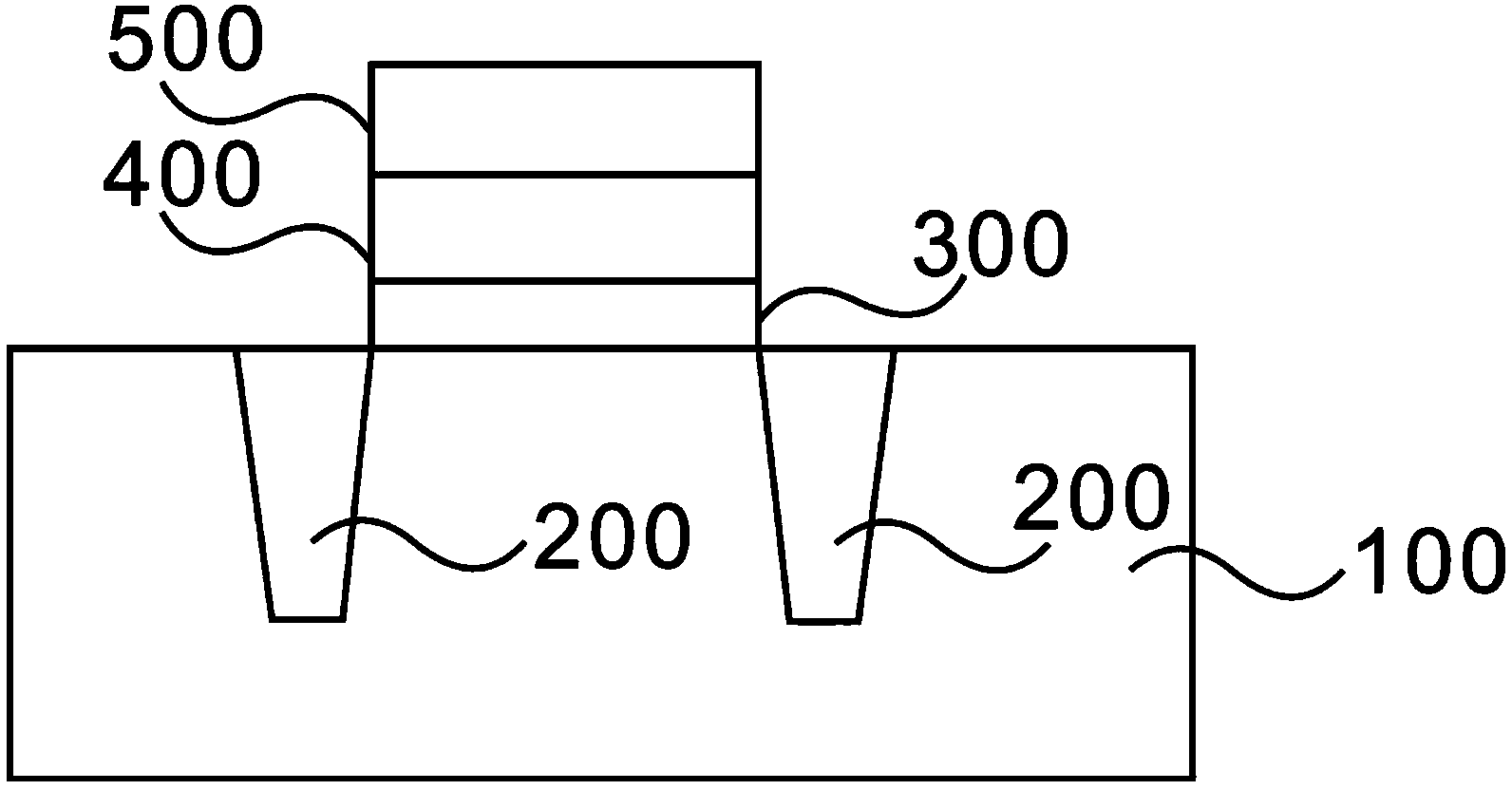

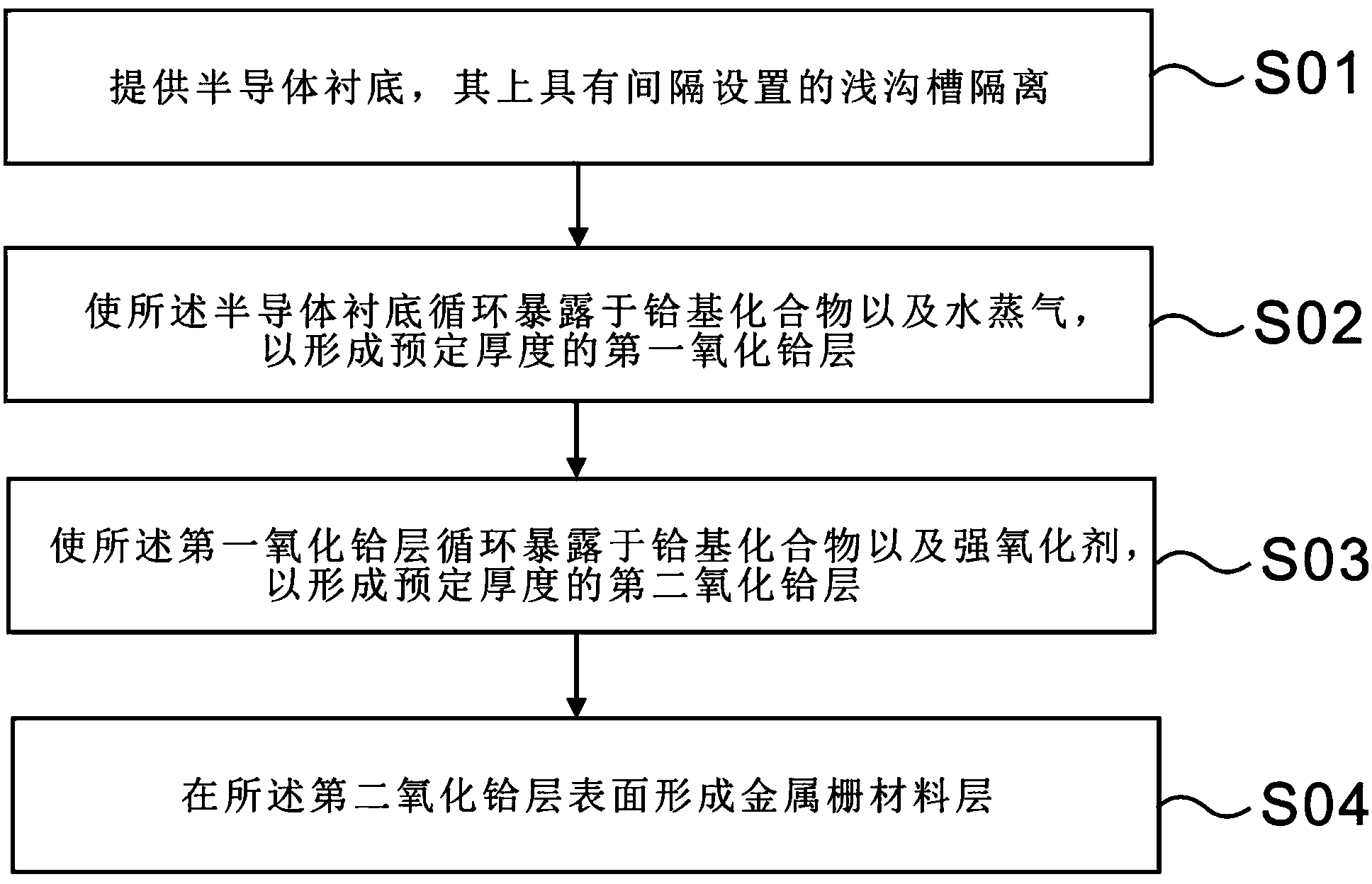

Method for manufacturing double-layer high-K dielectric structure

InactiveCN104183474AReduced oxygen vacanciesReduce thicknessSemiconductor/solid-state device manufacturingSemiconductor devicesWater vaporSurface oxidation

The invention provides a method for manufacturing a double-layer high-K dielectric structure. The method comprises the step S01 that a semiconductor substrate is provided, and spaced shallow trench isolations are arranged on the semiconductor substrate, the step S02 that the semiconductor substrate is exposed to hafnium-based compounds and steam in a circulating mode to form a first hafnium oxide layer of the preset thickness, the step S03 that the first hafnium oxide layer is exposed to the hafnium-based compounds and strong oxidants in a circulating mode to form a second hafnium oxide layer of the preset thickness, and the step S04 that a metal gate material layer is formed on the surface of the second hafnium oxide layer. According to the method for manufacturing the double-layer high-K dielectric structure, on the one hand, the thickness of silicon oxide on the surface of the semiconductor substrate is reduced, and the EOT parameter of gate dielectrics is within the reasonable range; on the other hand, the second hafnium oxide layer has fewer oxygen vacancies, and the current leakage phenomenon of the finally-formed hafnium oxide dielectric layer is controlled.

Owner:SHANGHAI HUALI MICROELECTRONICS CORP

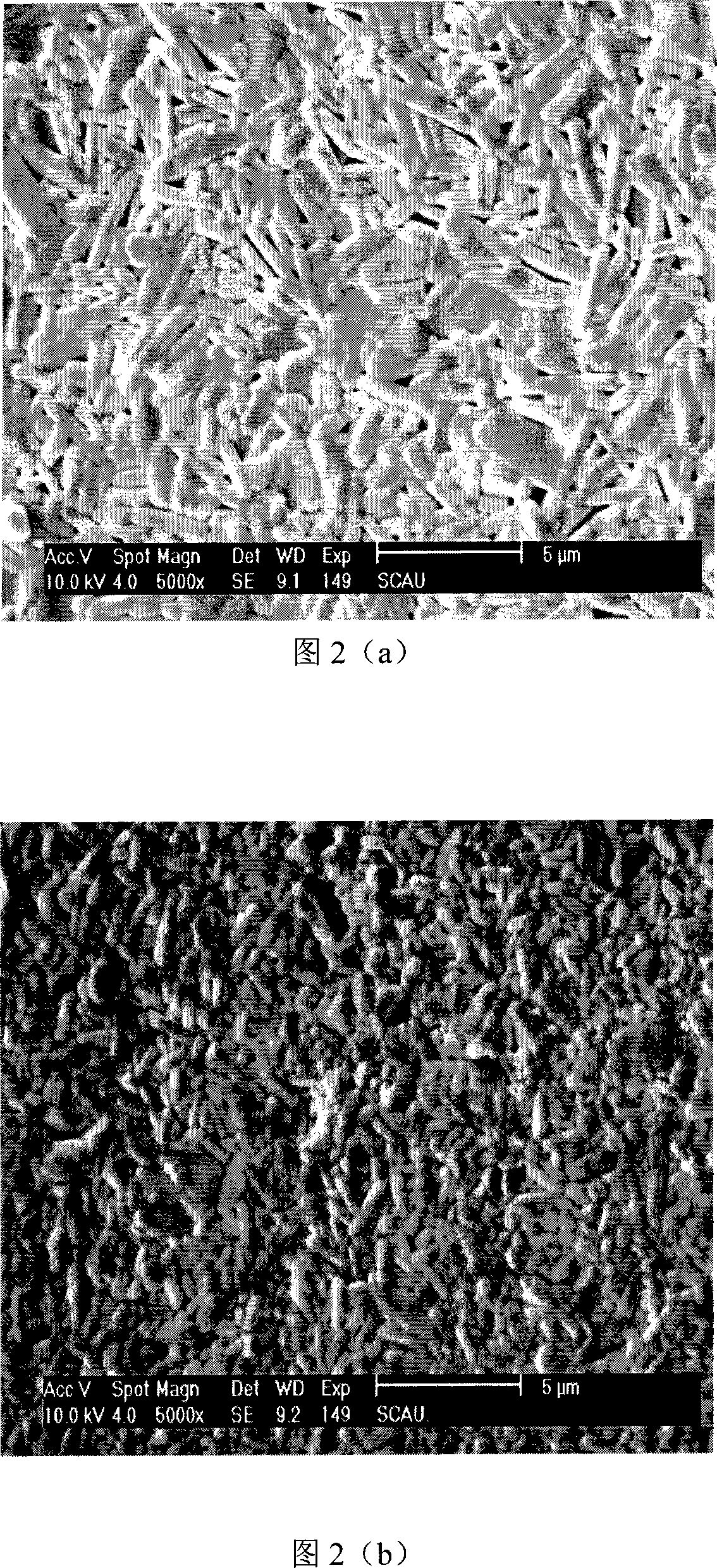

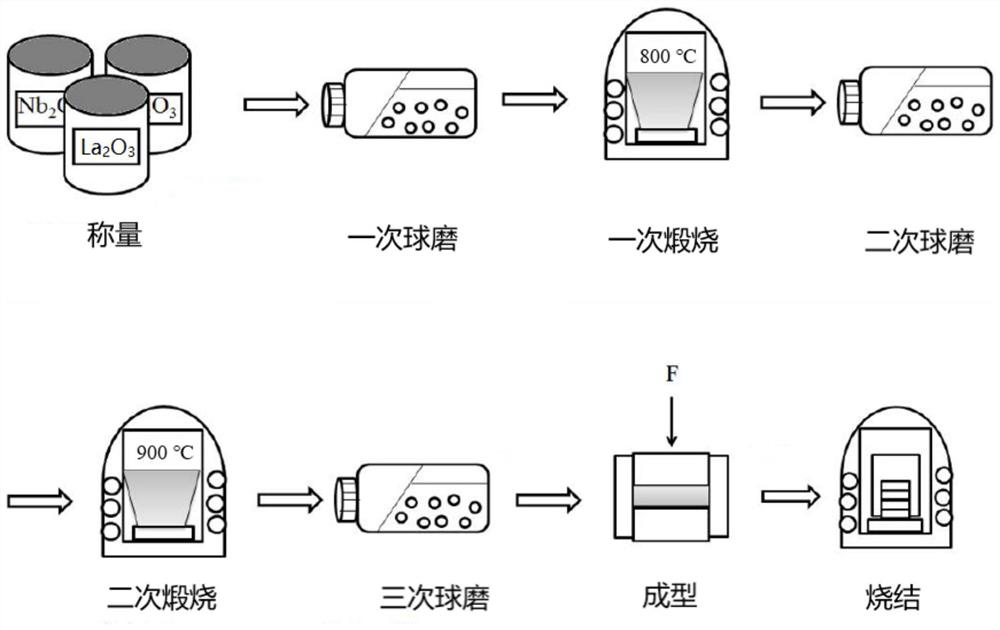

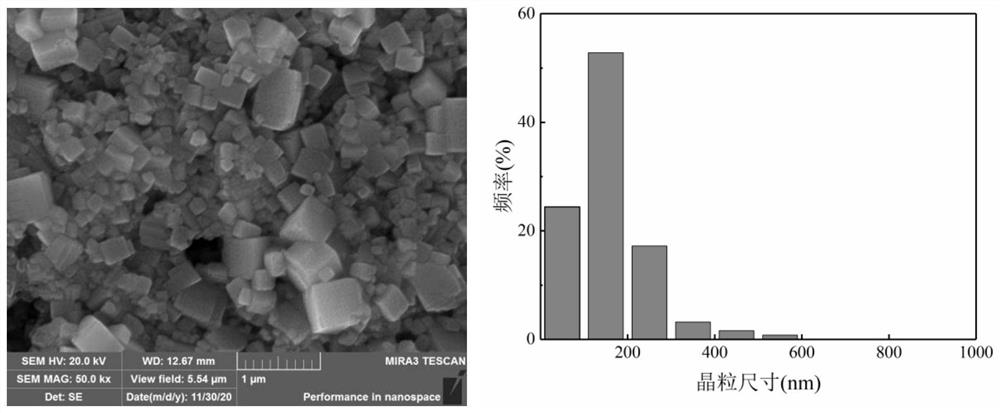

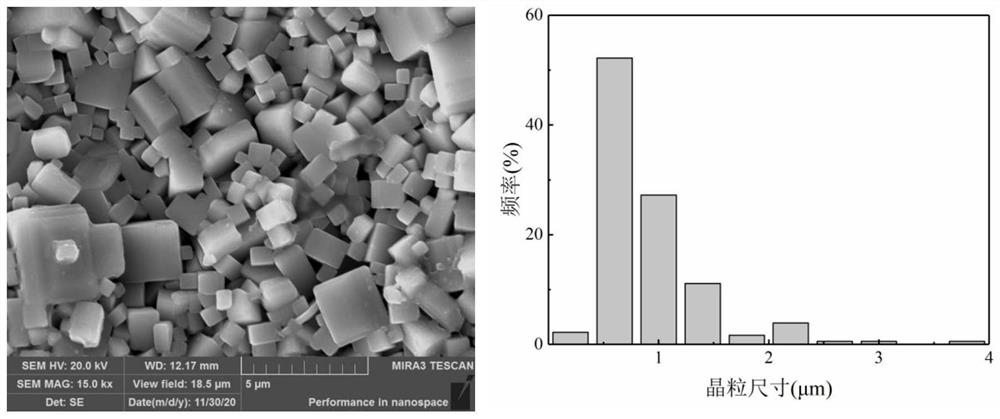

Preparation method of potassium-sodium niobate-based nano fine-grain ceramic with average grain size of 160nm

InactiveCN112898020AGrowth retardationReduced oxygen vacanciesScanning electron microscopeLanthanoid Series Elements

The invention relates to a preparation method of potassium-sodium niobate-based nano fine-grain ceramic with the average grain size of 160nm. 0.5 mol% of lanthanum oxide is added into raw materials, so that oxygen vacancies generated by volatilization of alkali metal elements can be reduced, meanwhile, growth of grains is hindered, and the purpose of refining the grains is achieved. The preparation method comprises the following steps: calcining dried powder subjected to ball milling for 12-18 hours at 800-900 DEG C for 2-4 hours, carrying out secondary ball milling for 12-18 hours, performing calcining at 800-900 DEG C again after drying for 2-4 hours, carrying out tertiary ball milling for 12-18 hours, performing drying, and carrying out multiple times of ball milling and calcining to enable raw materials to fully react and refine, so the sintering temperature and the heat preservation time can be reduced, and the purpose of grain refinement is achieved due to insufficient grain growth. Through doping modification of a rare earth element lanthanum and an improved traditional solid phase method, a scanning electron microscope diagram and a particle size distribution diagram of the finally obtained potassium-sodium niobate-based ceramic are shown in a figure 2, the average grain size of the potassium-sodium niobate-based ceramic is 160nm, and the grain size distribution is uniform and very fine.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Bismuth ferrite-lead tungstate multiferroic ceramic and preparation method thereof

The invention discloses bismuth ferrite-lead tungstate multiferroic ceramic and a preparation method thereof. The general formula of the chemical composition of the bismuth ferrite-lead tungstate multiferroic ceramic is (1-x)BiFeO3-xPb(W1 / 3Fe2 / 3)O3, wherein 0<x<0.4 and x represents molar fraction. The preparation method comprises the following steps: taking ferric oxide, bismuth trioxide, lead oxide and tungsten trioxide at a stoichiometric ratio of (1-x)BiFeO3-xPb(W1 / 3Fe2 / 3)O3 (0<x<0.4); performing ball milling, granulating, moulding, discharging rubber, and performing high temperature sintering and other working procedures to finally prepare the bismuth ferrite-lead tungstate multiferroic ceramic with good ferroelectric-ferromagnetic property. By adopting the method disclosed by the invention, the problems that the bismuth ferrite ceramic has weak magnetism and the technology is unstable can be solved, and the multiferroic material with good ferroelectric and ferromagnetic properties can be obtained.

Owner:XINING KEJIN INDUSTRIAL DESIGN CO LTD

Anti-reduction BME ceramic dielectric capacitor and ceramic material for capacitor

ActiveCN112645708AReduced oxygen vacanciesImprove resistance to reductionFixed capacitor dielectricCalcium bicarbonateBarium titanate

The invention discloses an anti-reduction BME ceramic dielectric capacitor and a ceramic material for the capacitor. The ceramic material for the anti-reduction BME ceramic dielectric capacitor consists of the following raw materials: barium titanate, vanadyl oxalate, manganous nitrate, magnesium nitrate, strontium nitrate, rare earth nitrate A, rare earth nitrate B, chromic nitrate, barium nitrate, calcium bicarbonate, nano silicon dioxide and nano hafnium dioxide. By adding additives such as vanadyl oxalate, barium nitrate, calcium bicarbonate, nano silicon dioxide, nano hafnium dioxide and the like, the loss is reduced, the insulation resistance is improved, the dielectric withstand voltage is improved, and good electrical properties are obtained.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Semiconductor structure forming method

ActiveCN106611788AImprove electrical performanceImprove performanceSemiconductor/solid-state device manufacturingSemiconductor devicesGate dielectricSemiconductor structure

The invention discloses a semiconductor structure forming method. The method comprises steps: a substrate is provided; an interface layer is formed on the surface of the substrate; first annealing treatment is carried out on the interface layer, and the first annealing treatment is carried out in a nitrogen-containing atmosphere to enable a nitrogen-containing layer to be formed on the surface of the interface layer; a high k gate dielectric layer is formed on the surface of the nitrogen-containing layer; second annealing treatment is carried out on the high k gate dielectric layer to enable nitrogen ions to be diffused to the high k gate dielectric layer; and a gate electrode layer is formed on the surface of the high k gate dielectric layer. The dielectric relaxation problem of the high k gate dielectric layer is improved, and thus, the electrical performance of the formed semiconductor structure is improved.

Owner:SEMICON MFG INT (SHANGHAI) CORP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com