Patents

Literature

58results about How to "Improve resistance to reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

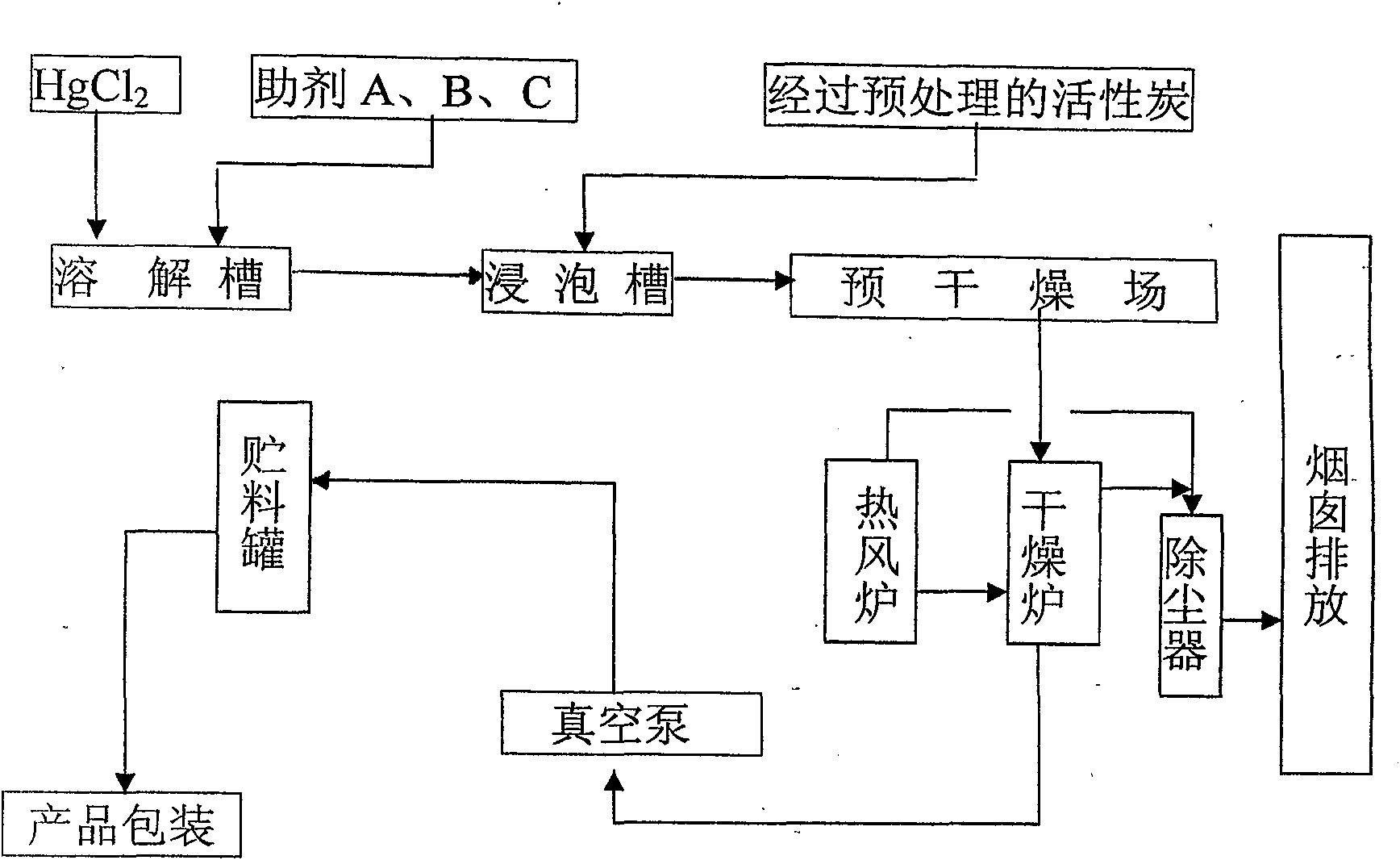

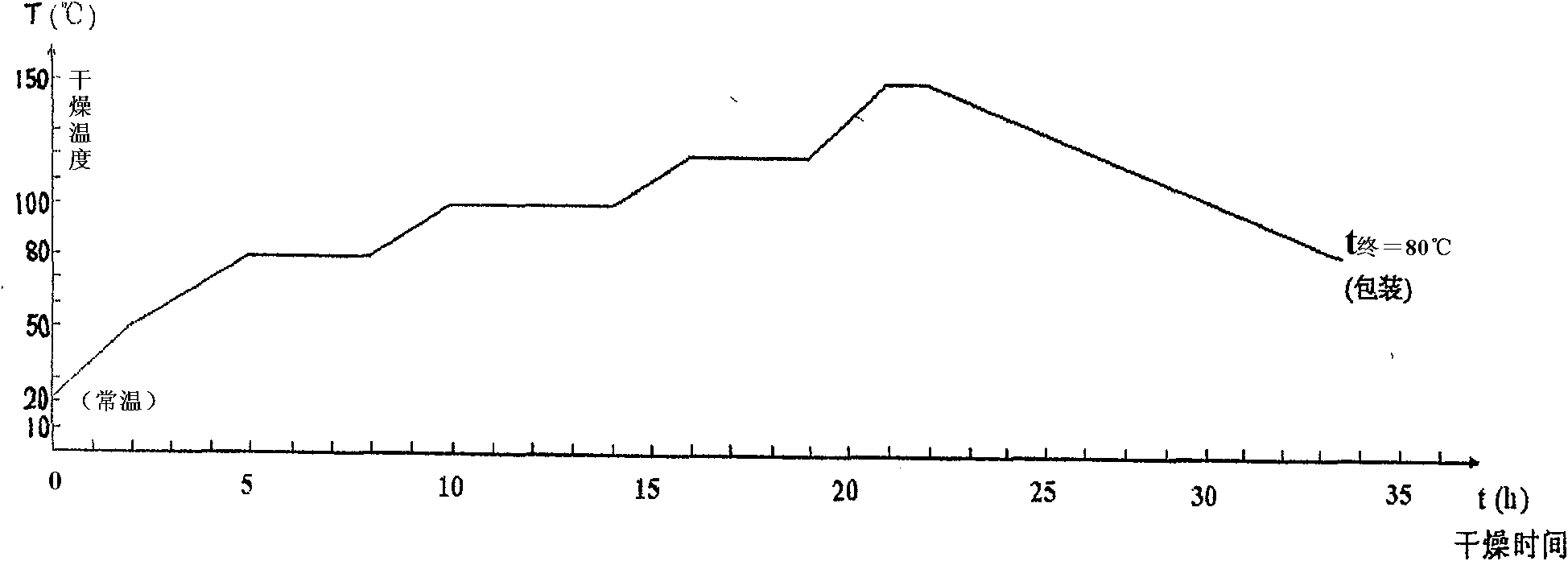

Mercuric chloride low-mercury catalyst and preparation method thereof

InactiveCN101596459AReduce resource consumptionRelieve pressurePhysical/chemical process catalystsHalogenated hydrocarbon preparationActivated carbonChemistry

The invention provides a mercuric chloride low-mercury catalyst and a preparation method thereof. The catalyst adopts active carbon as a carrier to adsorb mercuric chloride, and the formula of the catalyst comprises 8.0 to 10.0 percent of mercuric chloride, 8 to 13 percent of rare earth chloride assistant A, 5 to 25 percent of alkaline earth metal chloride assistant B, 10 to 20 percent of assistant C, and the balance of active carbon. The preparation method comprises the following steps: firstly, soaking the active carbon in hydrochloric acid solution at low temperature for standby; simultaneously dissolving the mercuric chloride, the assistant A, the assistant B and the assistant C together, and soaking the active carton in the solution; performing low-temperature pre-drying on an intermediate product; continuously drying the catalyst; and finally pumping a product at vacuum into a storage silo, packaging and leaving factory. The catalyst can reduce resource consumption and the pressure of treating mercury pollution; simultaneously the production cost is reduced, the poisoning resistance, reduction resistance and loss resistance are greatly improved, the catalytic performance of the catalyst is fully guaranteed, the using time can be prolonged and the using consumption can be reduced; and the catalyst is suitable for polyvinyl chloride manufacturers.

Owner:贵阳白云银星化工有限公司

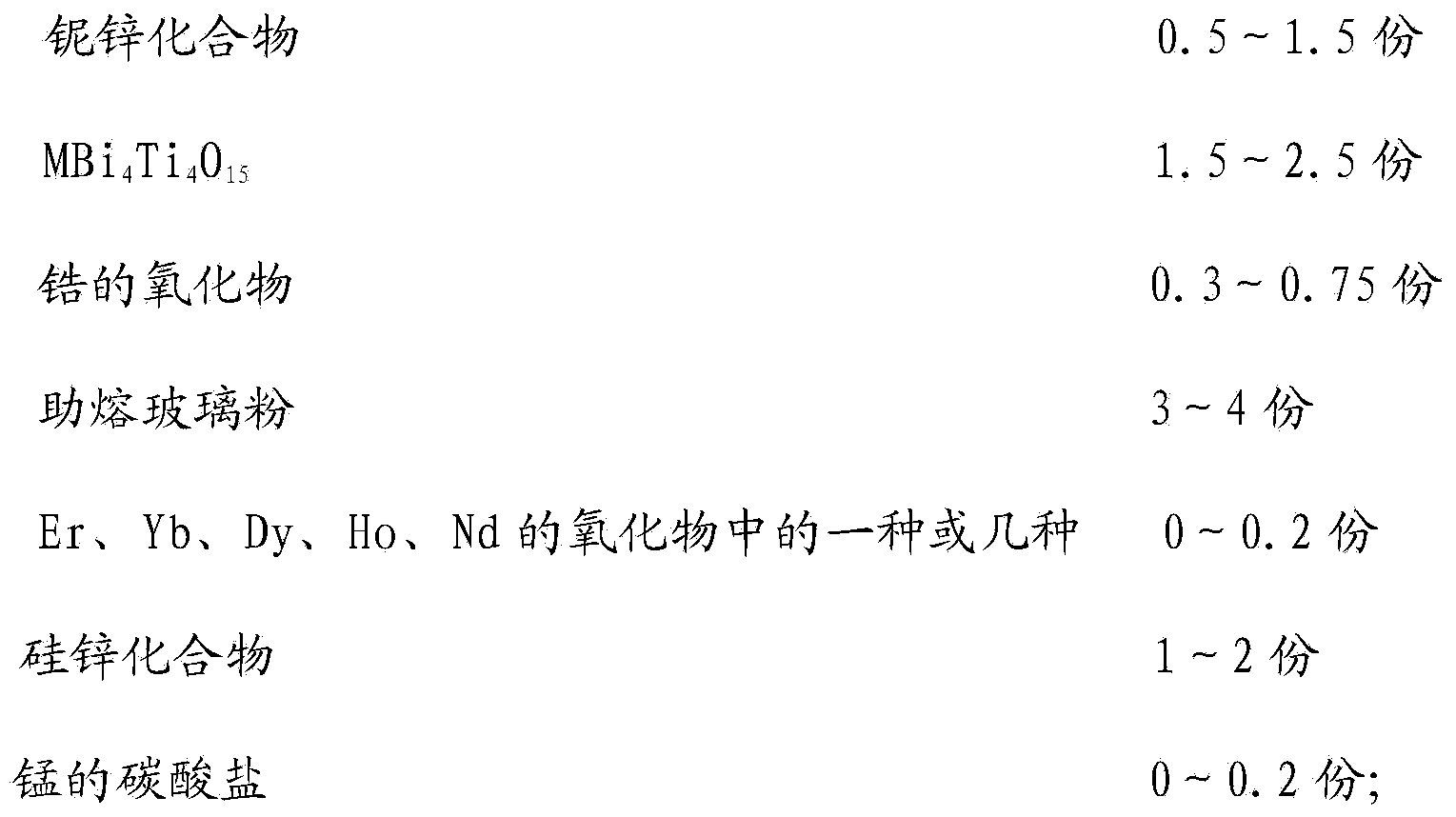

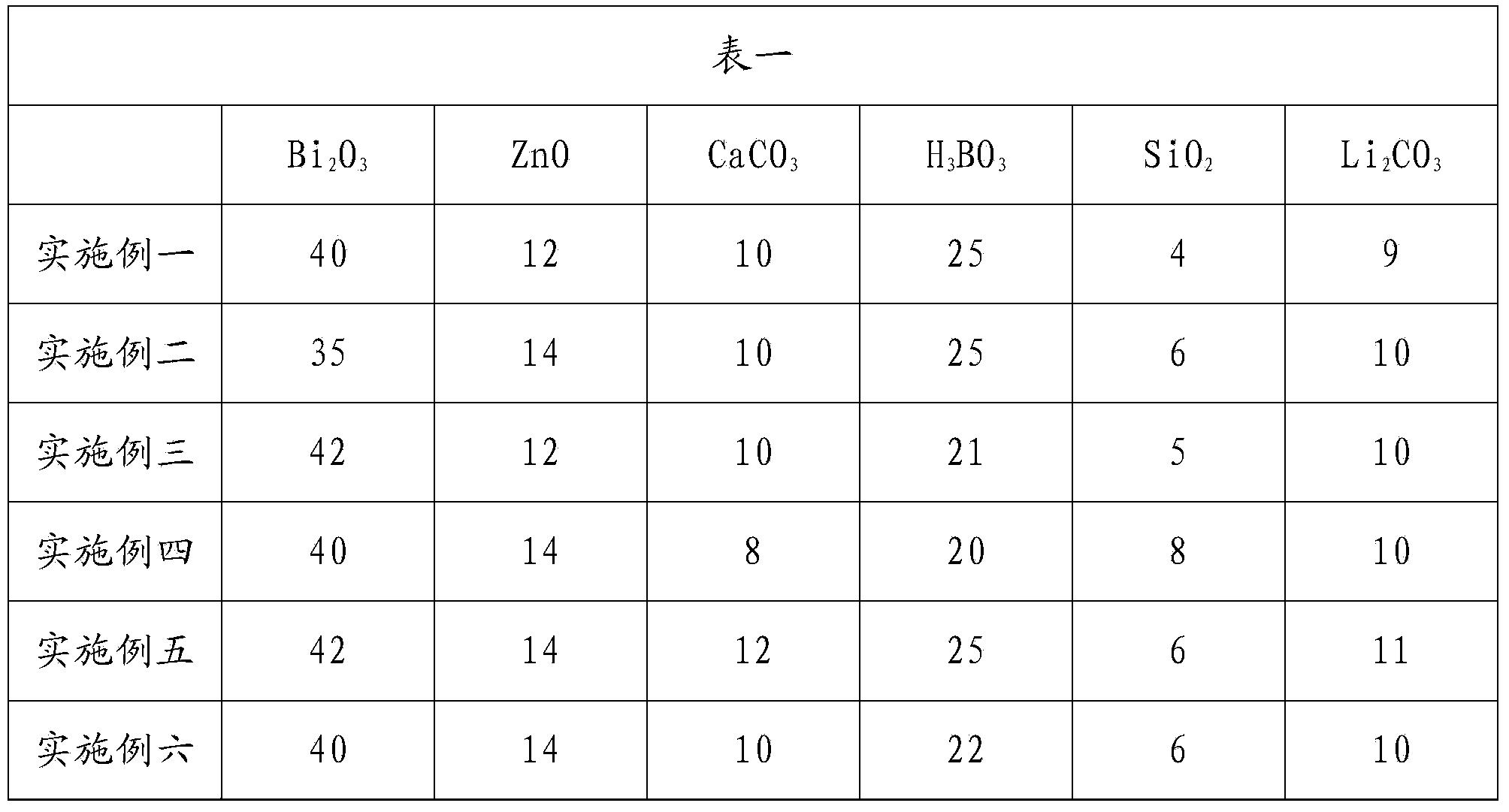

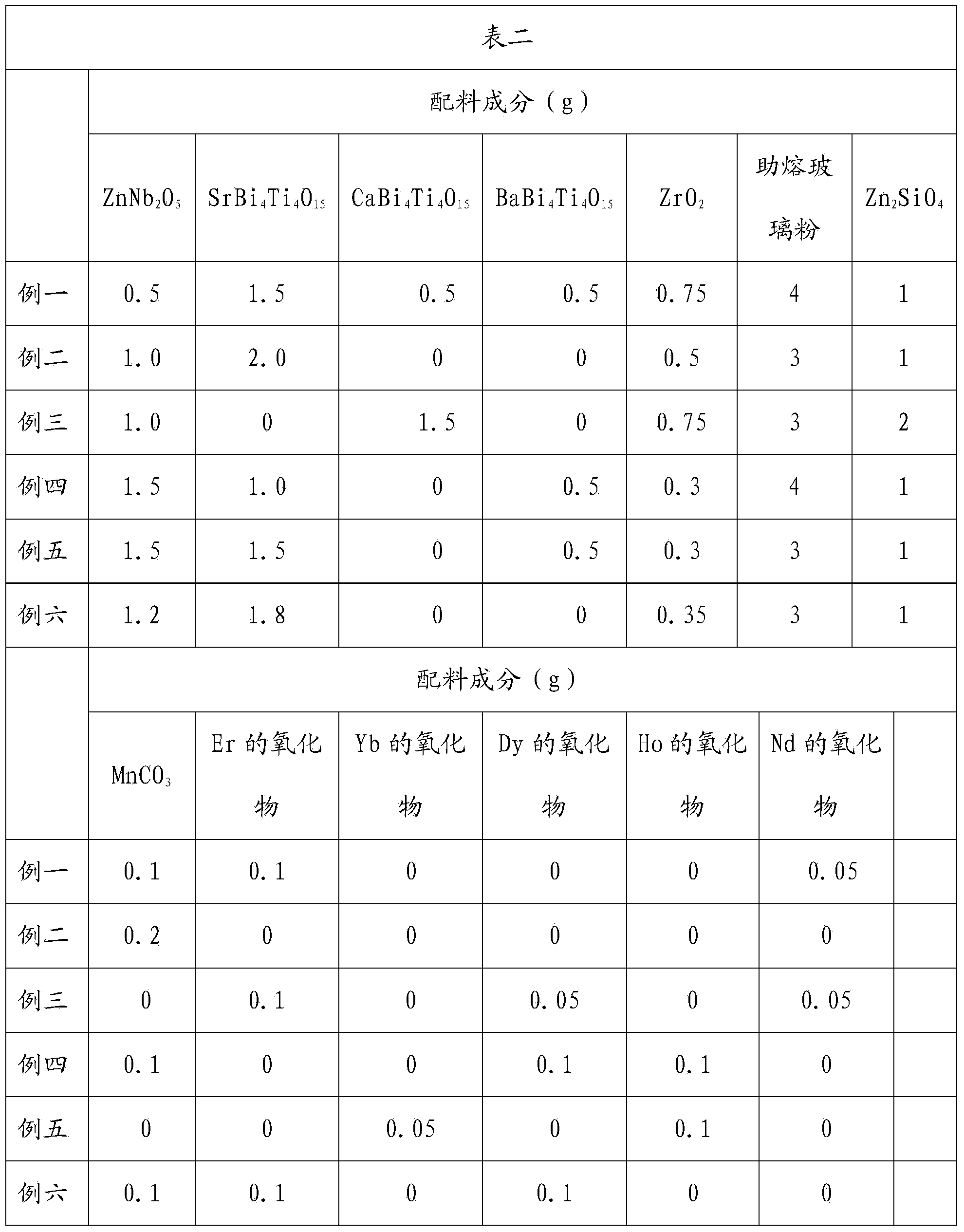

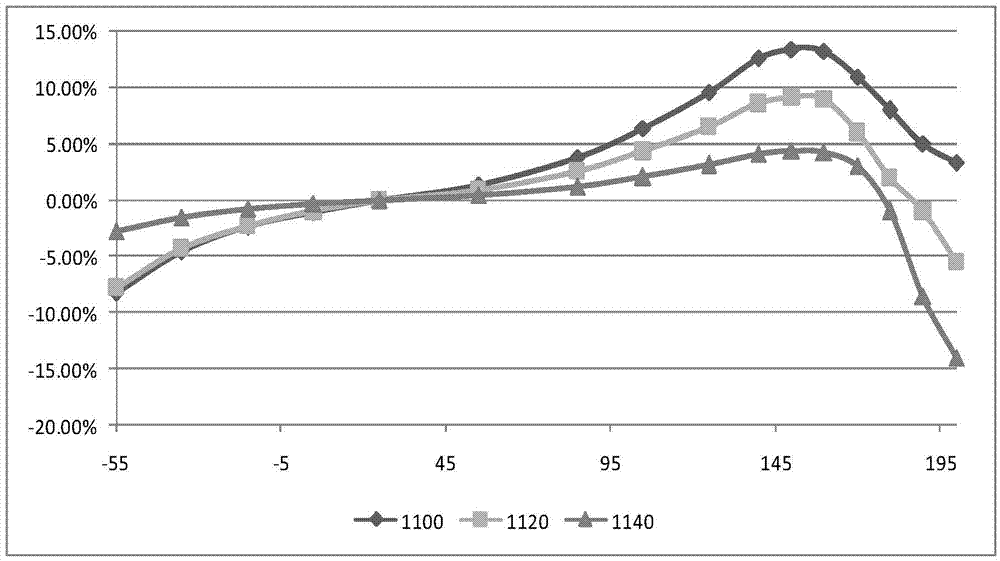

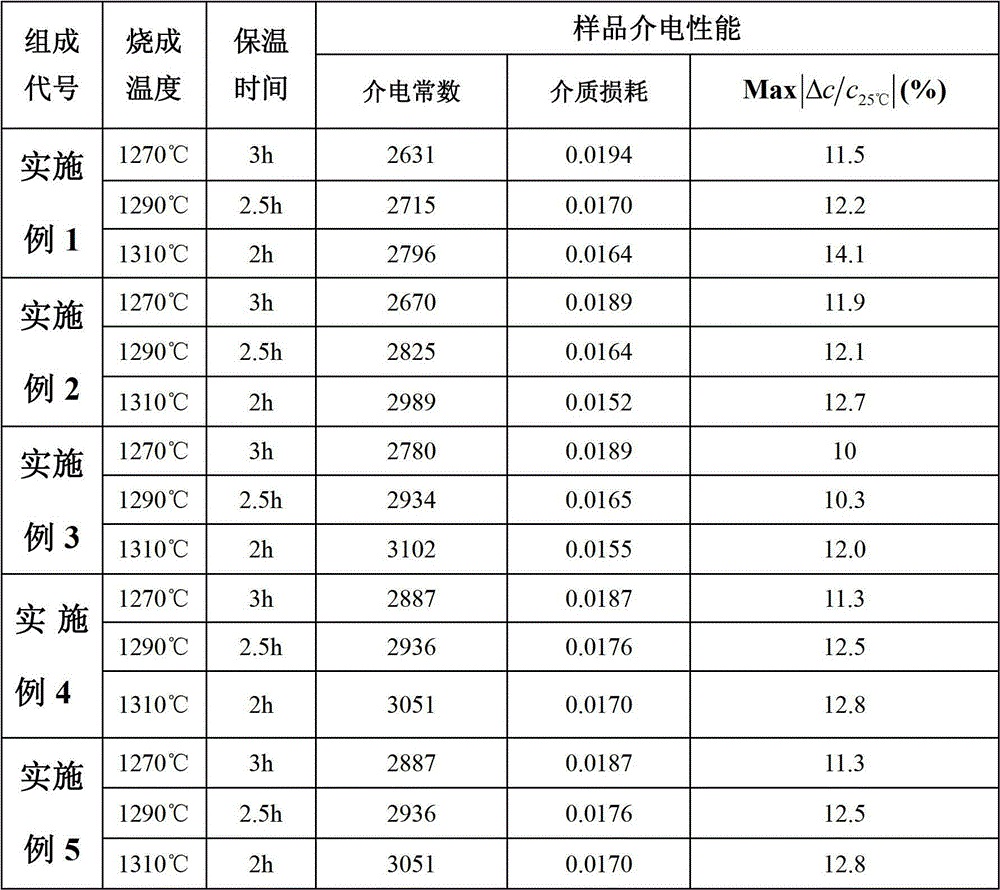

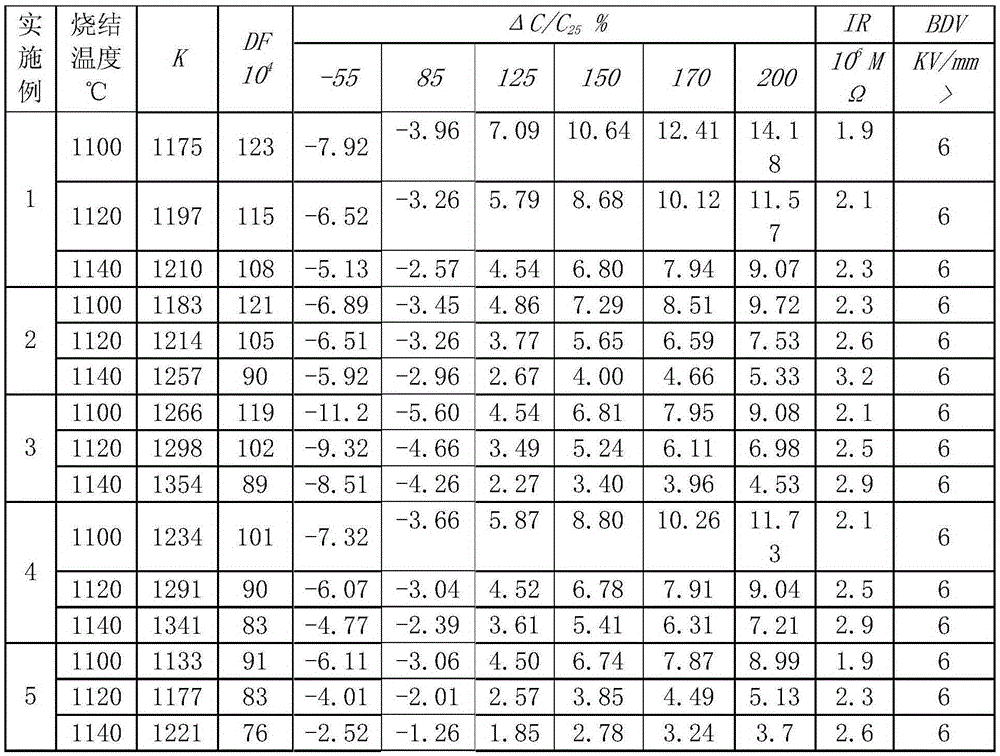

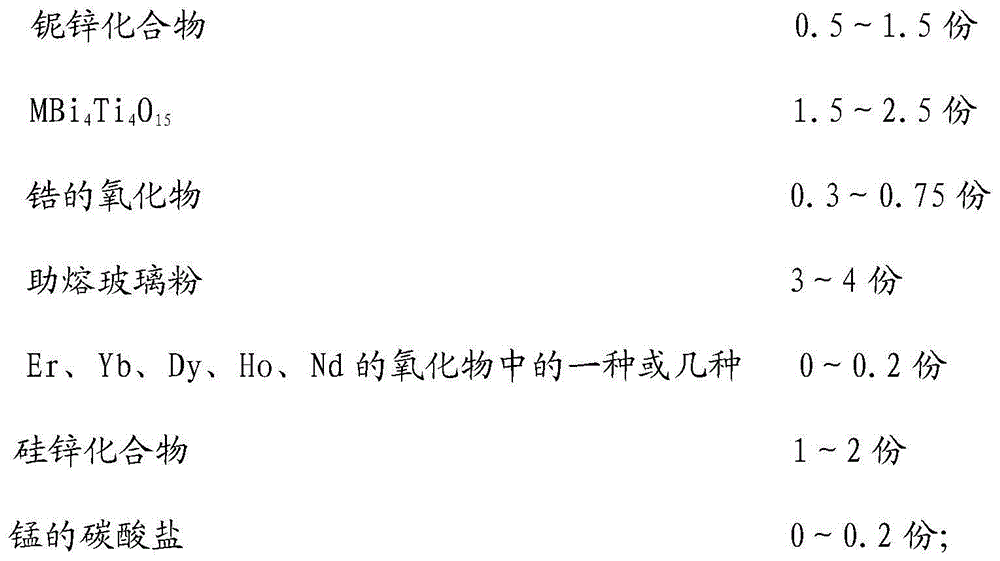

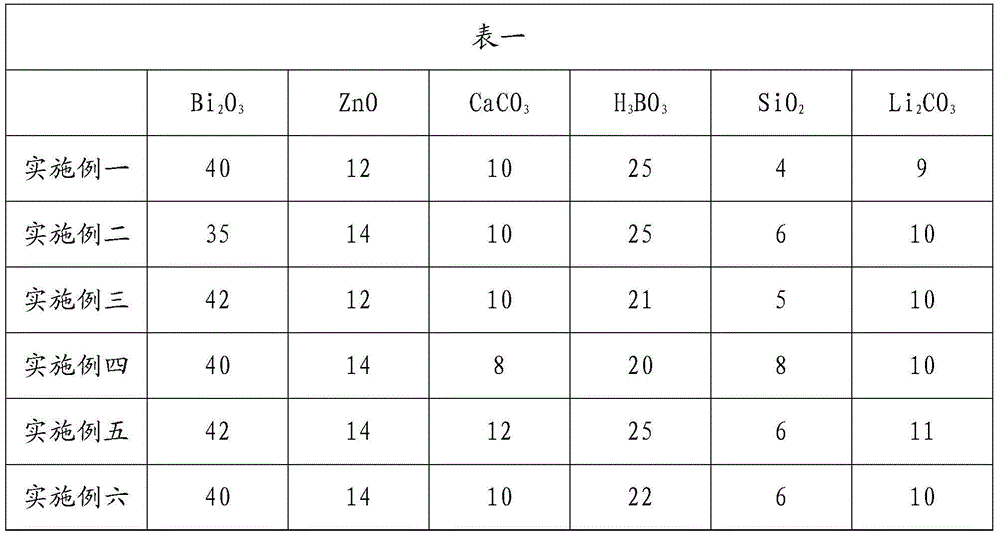

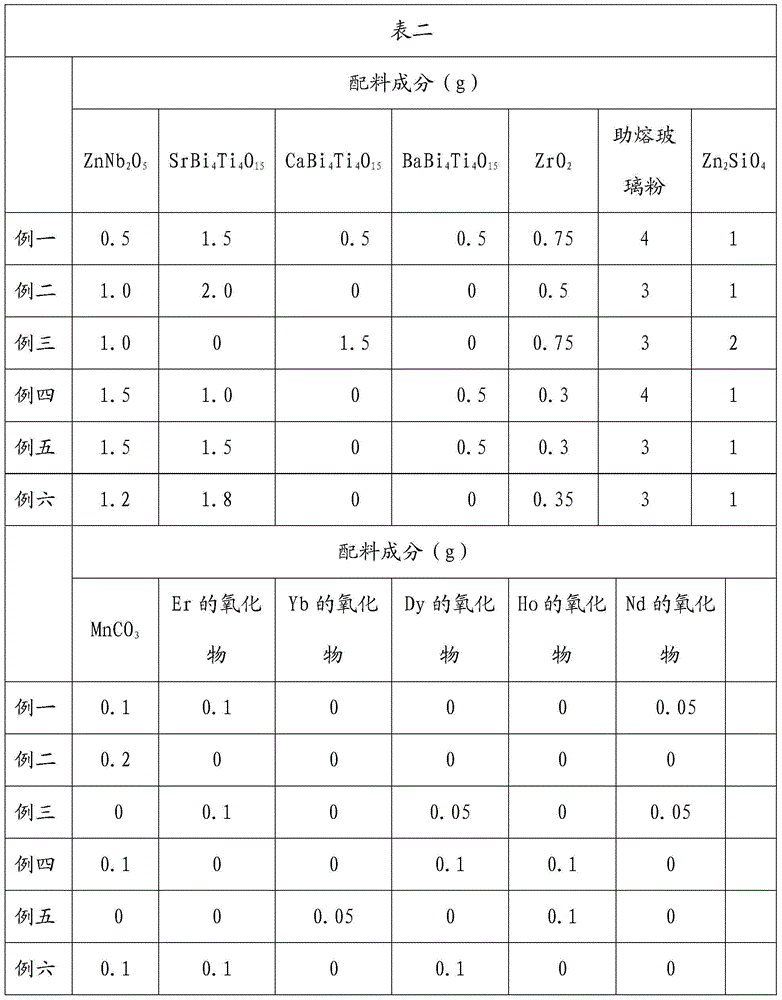

High-dielectric-constant X8R type MLCC medium material and preparing method thereof

ActiveCN103482975AImprove medium temperature stabilitySmall temperature change rateTemperature coefficientCapacitance

The invention discloses a high-dielectric-constant X8R type MLCC medium material. 100 parts, by weight, of barium titanate are used as base materials which are added with, by weight, 0.5-1.5 parts of niobium zinc compound, 1.5-2.5 parts of MBi4Ti4O15, 0.3-0.75 part of zirconic oxide, 3-4 parts of flux glass powder, 1-2 parts of silicon zinc compound, 0-0.2 part of manganic carbonate and 0-0.2 part of one or more of oxides of Er, Yb, Dy, Ho and Nd. M is one or more of Sr, Ca and Ba. According to the high-dielectric-constant X8R type MLCC medium material, a proper amount of niobium zinc compounds are added to easily form a core-shell structure. The core-shell structure can facilitate stability of the medium temperature of a medium material and reduce the temperature coefficient of capacitance of the material.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

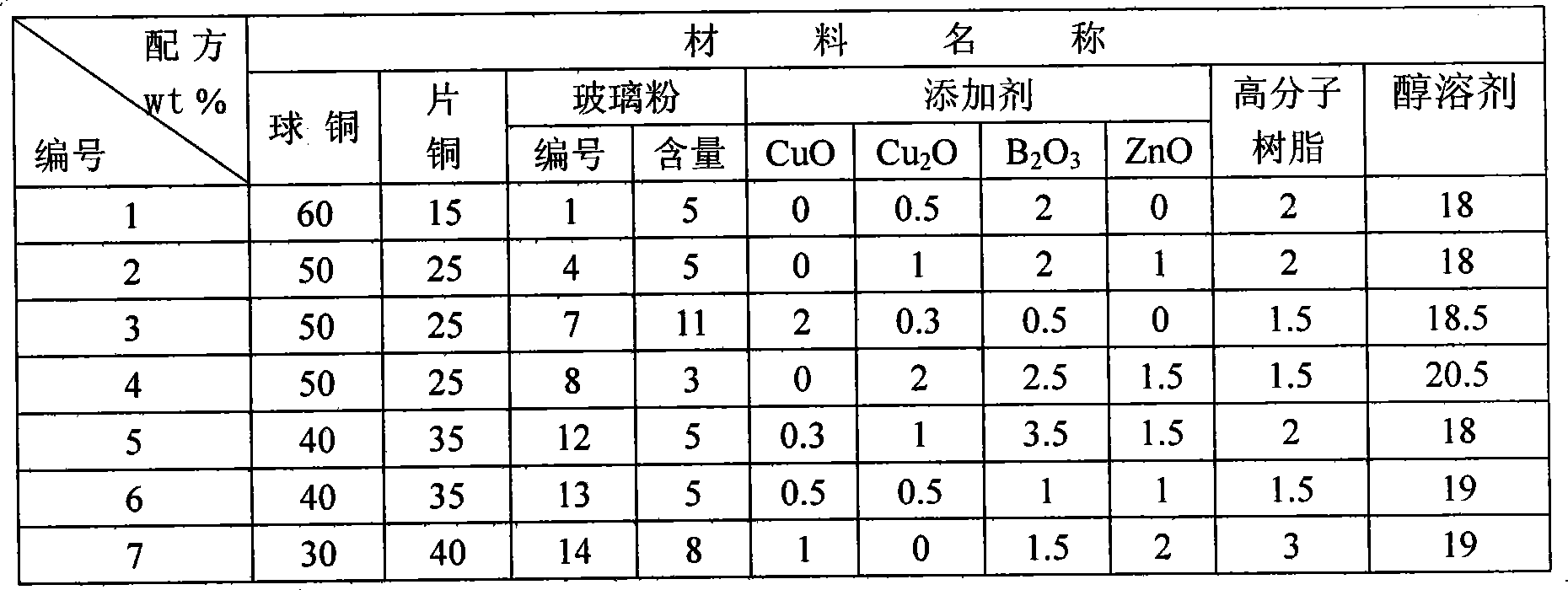

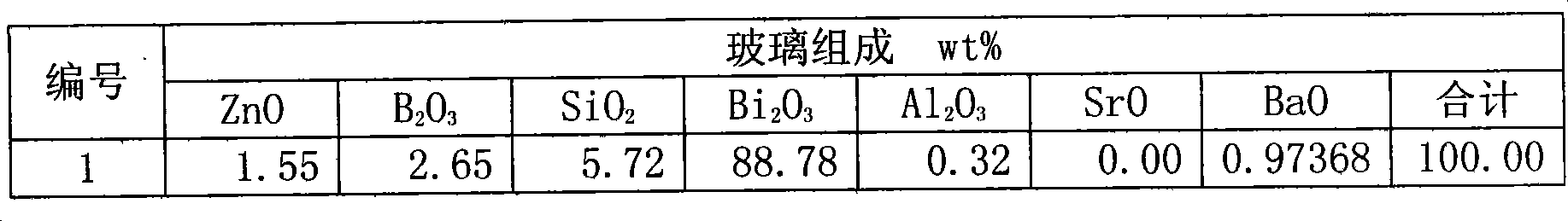

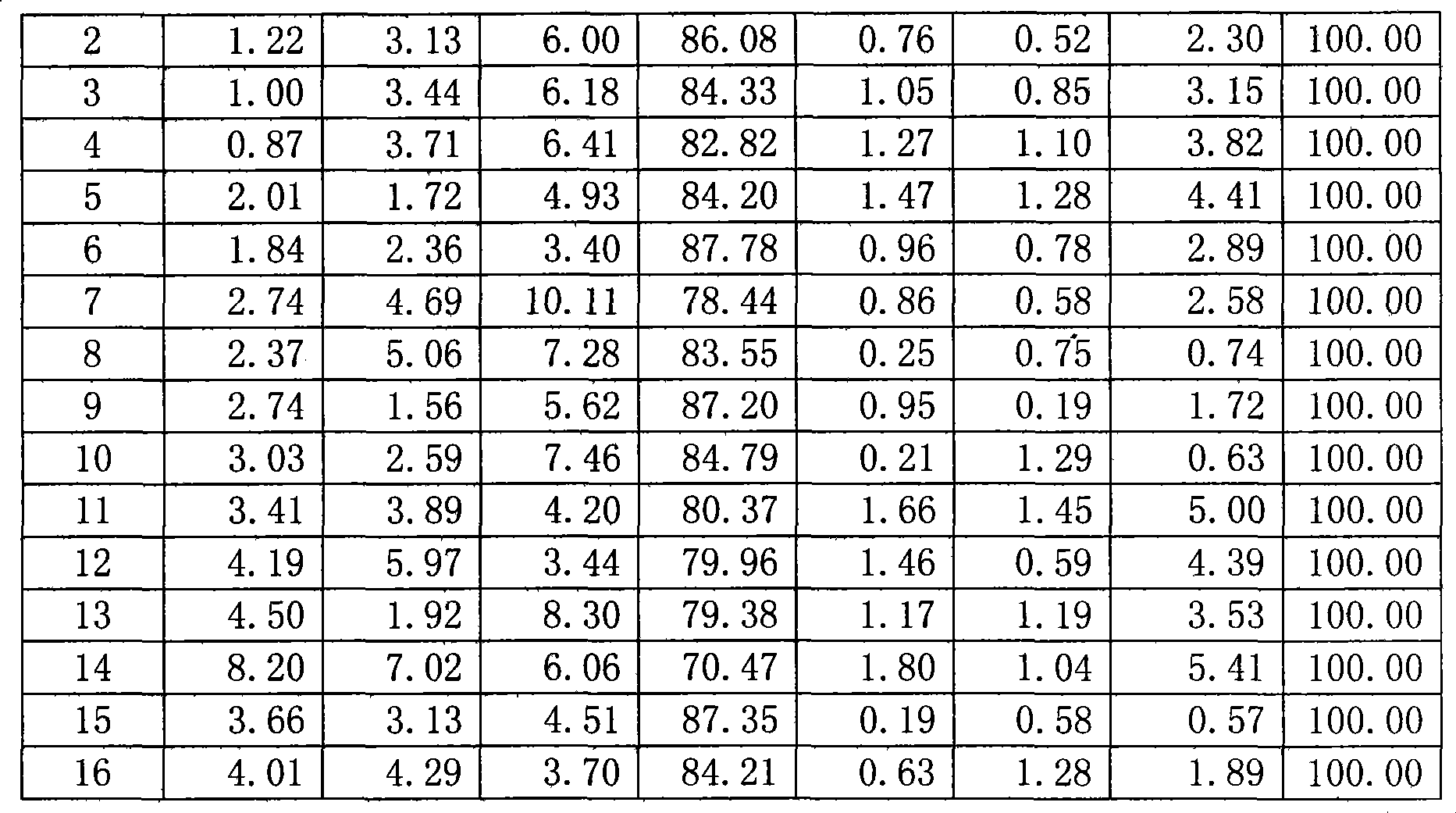

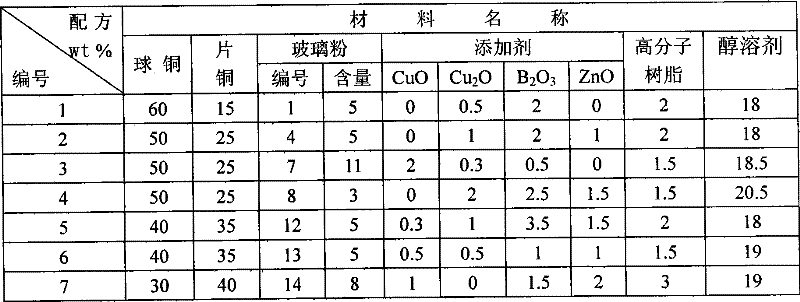

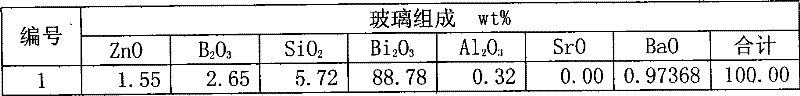

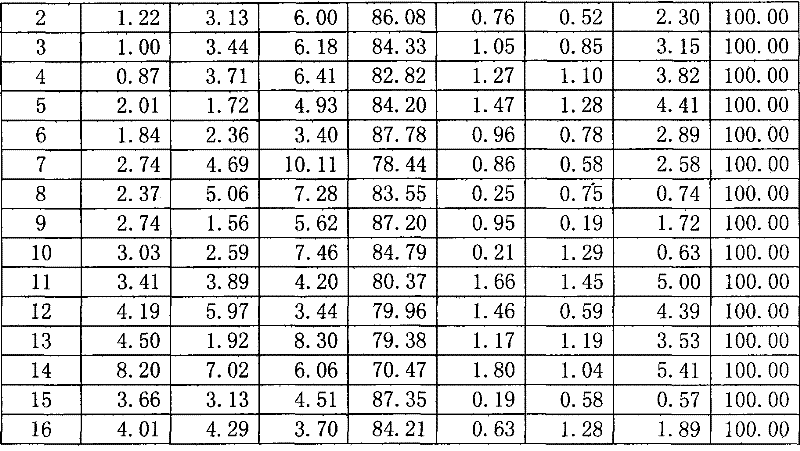

Base metal copper electrode paste and preparation of obtained capacitor

ActiveCN101364455APromote crystallizationImprove uniformityFixed capacitor electrodesConductive materialPolymer resinCopper electrode

The invention relates to base metal copper electrode slurry and a preparation method of a capacitor from the same. The base metal copper electrode slurry comprises the following components (wt%): 30-65 wt% of spherical copper, 10-30 wt% of sheet copper, 1.52-10 wt% of glass powder, 2-15 wt% of inorganic non-metallic additive, and 10.5-24 wt% of organic carrier, wherein the glass powder is a ZnO-B2O3-SiO2-Bi2O3 glass system; the inorganic non-metallic additive is one or more selected from CuO, Cu2O, ZnO and B2O3; and the organic carrier is polymer resin and a solvent. The base metal copper electrode slurry can be used in a ceramic disc capacitor and a semiconductor disc ceramic capacitor chip, the sintering temperature is 600-800 DEG C, and after sintering, the copper electrode slurry is converted to a copper electrode. The base metal copper electrode slurry has the characteristics of low cost, uniform material, uniform particle size distribution, high dispersibility, good forming process, and environmental friendliness.

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

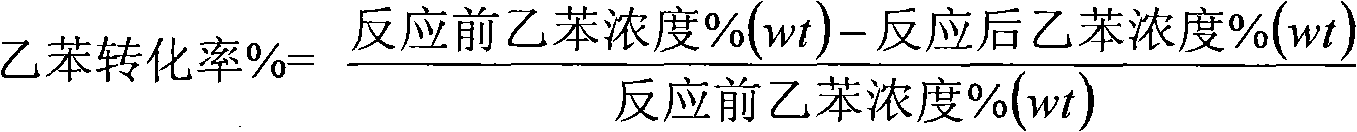

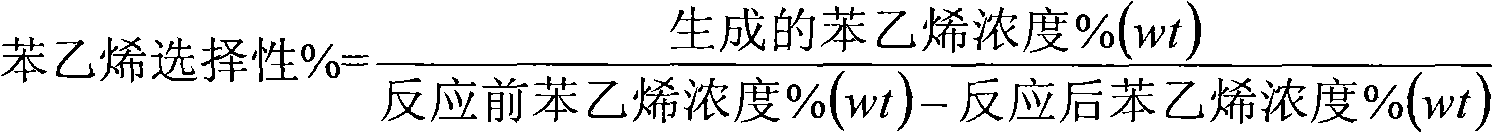

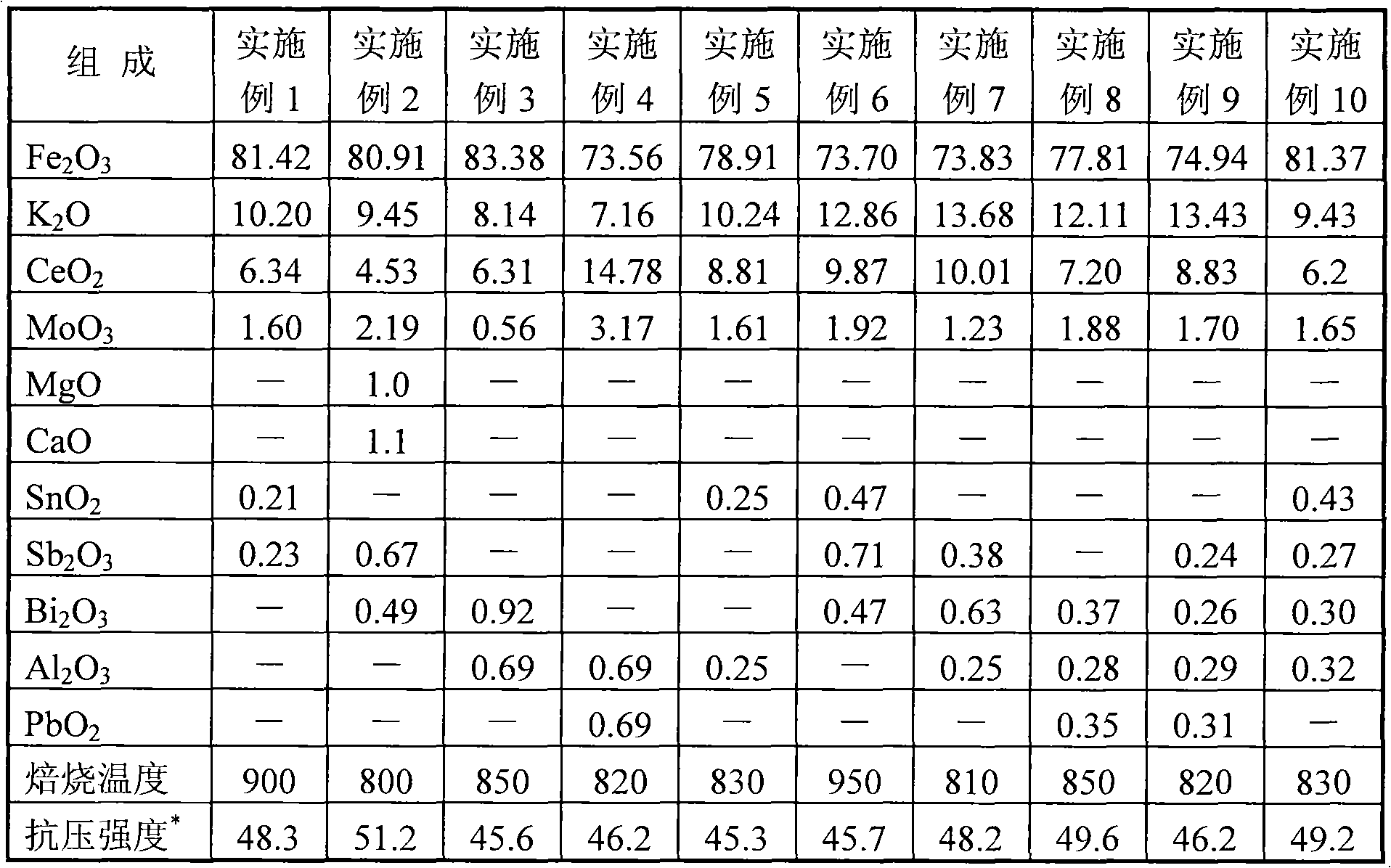

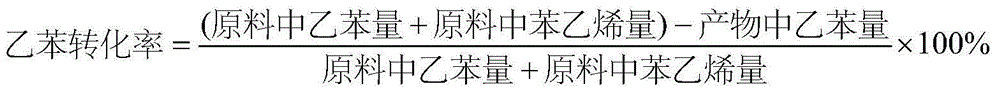

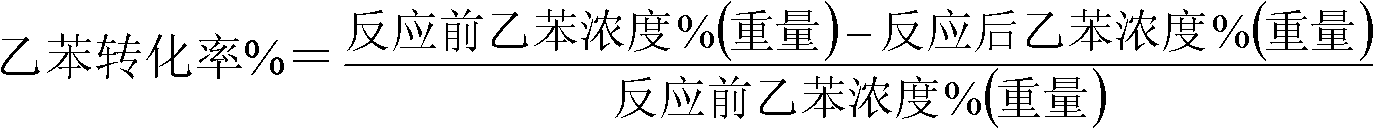

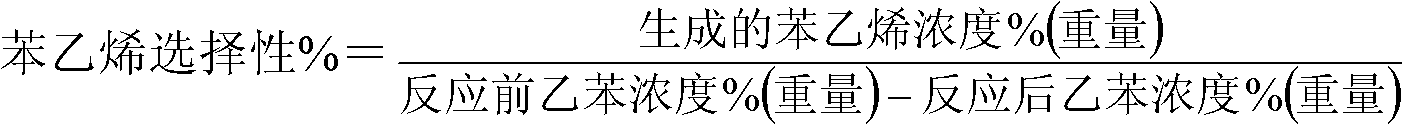

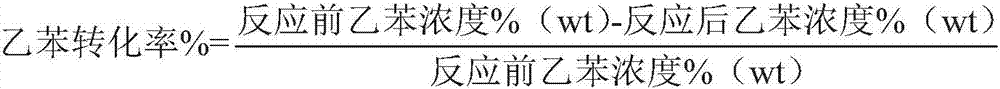

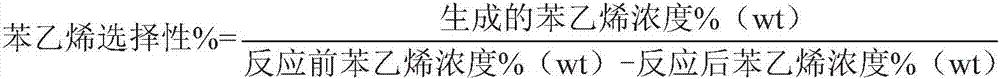

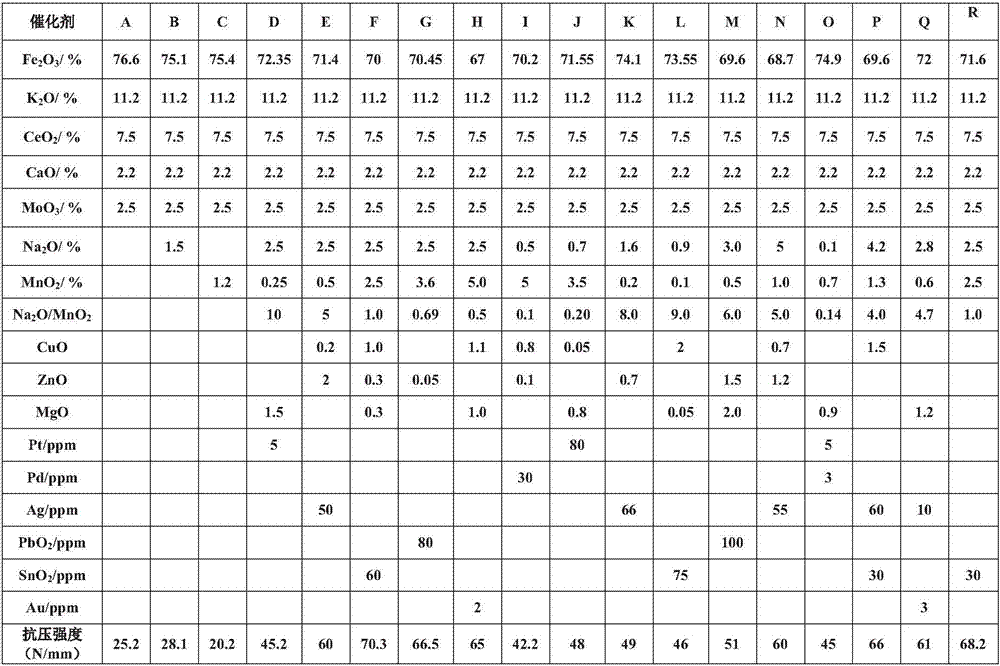

Method for preparing styrene through ethylbenzene dehydrogenation

ActiveCN102040466AImprove resistance to reductionImprove stabilityHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsCeriumStyrene

The invention relates to a method for preparing styrene through ethylbenzene dehydrogenation under the condition of a low water ratio, which mainly solves the problem that a low-potassium catalyst has poor stability under the condition of low water ratio in the prior art. In the invention, ethylbenzene is used as a raw material, the raw material and a catalyst are in contact to react to produce styrene under the conditions that the reaction air speed is 0.2-3.0 / h and the weight ratio of steam / ethylbenzene is 0.5-2.5, wherein the adopted catalyst is formed by adding at least two elements of IIA-IVA families into the iron- potassium-cerium-molybdenum system, and the roasting temperature of the catalyst is 800-950 DEG C. for the technical scheme for preparing styrene through ethylbenzene dehydrogenation better solves the problem, and can be used for the industrial production of ethylbenzene dehydrogenation under the condition of low water ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

High temperature stable X9R type multilayer ceramic capacitor dielectric material and preparation method thereof

ActiveCN103936414AOvercome the high temperature reduction effectReduce lossBarium titanateCeramic capacitor

The invention discloses a high temperature stable X9R type multilayer ceramic capacitor dielectric material and a preparation method of the high temperature stable X9R type multilayer ceramic capacitor dielectric material. The high temperature stable X9R type multilayer ceramic capacitor dielectric material disclosed by the invention is prepared by the steps of adding a calcium-boron-silicon compound to a barium titanate-sodium bismuth titanate-niobium pentoxide eutectic compound serving as a matrix, compounding one or more of Ce, Nd and La oxides, and compounding one or more of barium-manganese oxide, magnesium oxide and zinc oxide; and the invention provides the preparation method of the high temperature stable X9R type multilayer ceramic capacitor dielectric material. The X9R type multilayer ceramic capacitor dielectric material prepared by using the material and the method provided by the invention has high temperature resistance (above 200 DEG C), and good temperature stability, and enable components and parts such as multilayer ceramic capacitors, tuners and duplexers to be suitable for the application at a high temperature (above 200 DEG C), thus having extremely high industrialization prospect and industrial application value.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

High dielectric constant X8R type MLCC medium material and preparation method

ActiveCN102718477AImprove medium temperature stabilityHigh Curie temperatureFixed capacitor dielectricRare-earth elementOxygen vacancy

The invention relates to a high dielectric constant X8R type MLCC medium material and a preparation method, the high dielectric constant X8R type MLCC medium material takes 100 weight parts of barium titanate as a base material, and the medium material comprises the following components by weight: 1.6-2.5 parts of niobium cobalt compound, 0.722-1.805 parts of titanium bismuth sodium compound, 1.25-2.0 parts of zirconium calcium compound, 1-3 parts of glass powder, 0.369-1.2 parts of one or a plurality of oxides of Ce, Yb, Dy and Ho and 0.1-0.25 part of manganese carbonate. The key and core of the present invention are characterized in that a proper amount of manganese carbonate, rare earth elements and a zirconium calcium compound are added, the rare earth element can be taken as a donor or an acceptor in the barium titanate dielectric ceramic material for doping and modifying, the movement of the intrinsic oxygen vacancy and the oxygen vacancy brought by other B site donor doping can be inhibited, the insulation resistivity of a material system, the ageing resistance and the reduction resistance of a material system can be increased, and the method provided by the invention can be used for making silver-palladium electrodes and nickel electrodes MLCC.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

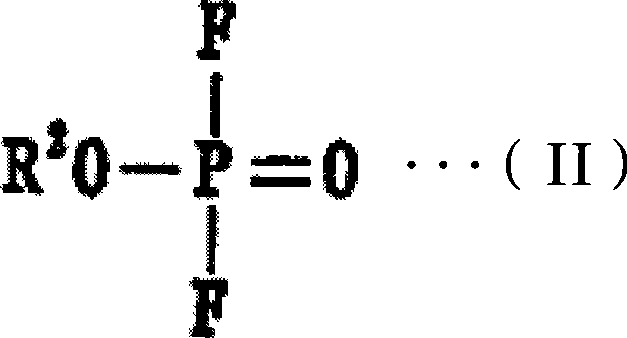

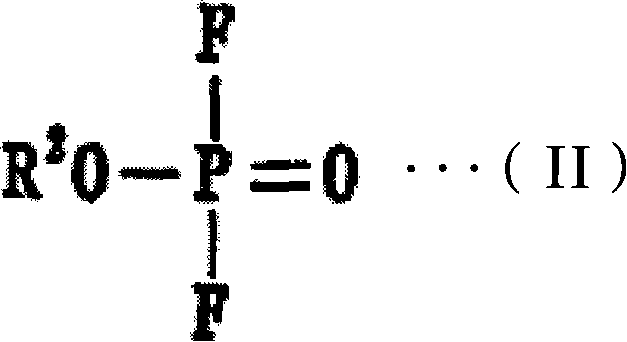

Non-aqueous electrolyte for battery and non-aqueous electrolyte battery comprising the same

InactiveCN101114716AImprove securityImprove flame retardant performanceOrganic electrolyte cellsSecondary cellsArylDifluorophosphate

The invention provides a nonaqueous electrolytic solution for batteries with high flame retardancy and high reduction resistance. A non-aqueous electrolytic solution for a battery, characterized in that it comprises: a non-aqueous solvent containing a cyclic phosphazene compound represented by the following general formula (I) and a difluorophosphate compound represented by the following general formula (II) , a dicarboxylic acid anhydride compound having a ring structure, and a supporting electrolyte, in the formula (I), R1 independently represents a halogen, an alkoxy group or an aryloxy group; n represents 3 to 4, and in the formula (II), R2 is an alkane radical, cycloalkyl, alkenyl, alkoxy-substituted alkyl or aryl.

Owner:BRIDGESTONE CORP

Heat insulation spray coating

The invention relates to a heat insulation spray coating, belonging to the field of fireproof materials. The heat insulation spray coating comprises the following components in parts by weight: 38-58 parts of waste lightweight clay bricks, 3-9 parts of raw perlite, 10-20 parts of cement, 20-30 parts of flint clay powder, 5-8 parts of Guangxi mud, 1-3 parts of talc powder and 0.5-2 parts of additional aluminum borate whiskers. The heat insulation spray coating disclosed by the invention can be used for rapid construction in use, is practical, does not need special maintenance, has good acid resistance and reduction resistance, is good in service performance, and is suitable for occasions requiring heat insulation or occasions with strong reducing properties.

Owner:浙江科明电子有限公司

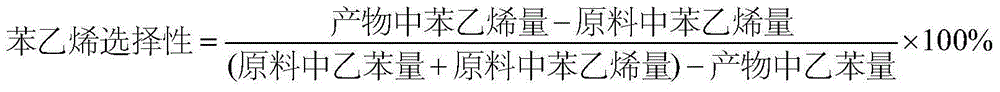

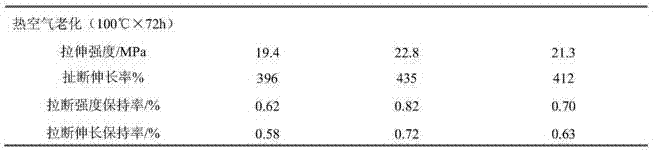

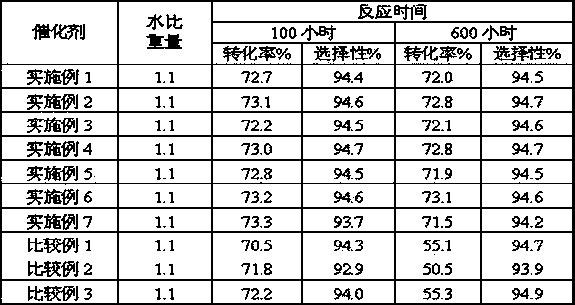

Catalyst used for low steam-to-oil ratio ethylbenzene dehydrogenation to prepare styrene, and preparation method thereof

ActiveCN105749934AHigh activityImprove resistance to reductionHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsAlkali metal oxideDehydrogenation

The invention relates to a catalyst used for low steam-to-oil ratio ethylbenzene dehydrogenation to prepare styrene. The catalyst comprises, by mass, 60-80 parts of iron oxide by Fe2O3, 5-15 parts of potassium oxide by K2O, 5-15 parts of cerium oxide by Ce2O3, 1-10 parts of molybdenum oxide by MoO3, 1-10 parts of magnesium or / and calcium oxide by MgO or / and CaO respectively, 1-5 parts of at least one of alkali metal oxides of Rb and Cs, respectively by Rb2O and Cs2O, wherein the alkali metal oxides are modified on the surface of the catalyst in a salt solution form; and light rare earth metal oxides of La, Pr and Nd without Ce, and oxides of Mn, Zn and Pb. The catalyst has a high activity and a good stability under a low steam-to-oil ratio.

Owner:PETROCHINA CO LTD

Catalyst for low-water ratio ethylbenzene dehydrogenation

ActiveCN103028419AImprove resistance to reductionSlow down the rate of lossHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsChemistryTungsten

The invention relates to a catalyst for low-water ratio ethylbenzene dehydrogenation, which mainly solves the problem that in the prior art, low-potassium catalyst has poor stability under the condition of low-water ratio. The invention adopts the technical scheme that ferrate is added into a ferrum-potassium-cerium-tungsten-magnesium catalytic system, so that the problem is well solved. The catalyst can be applied in industrial production of styrene prepared through ethylbenzene dehydrogenation under the condition of low-water ratio.

Owner:CHINA PETROLEUM & CHEM CORP +1

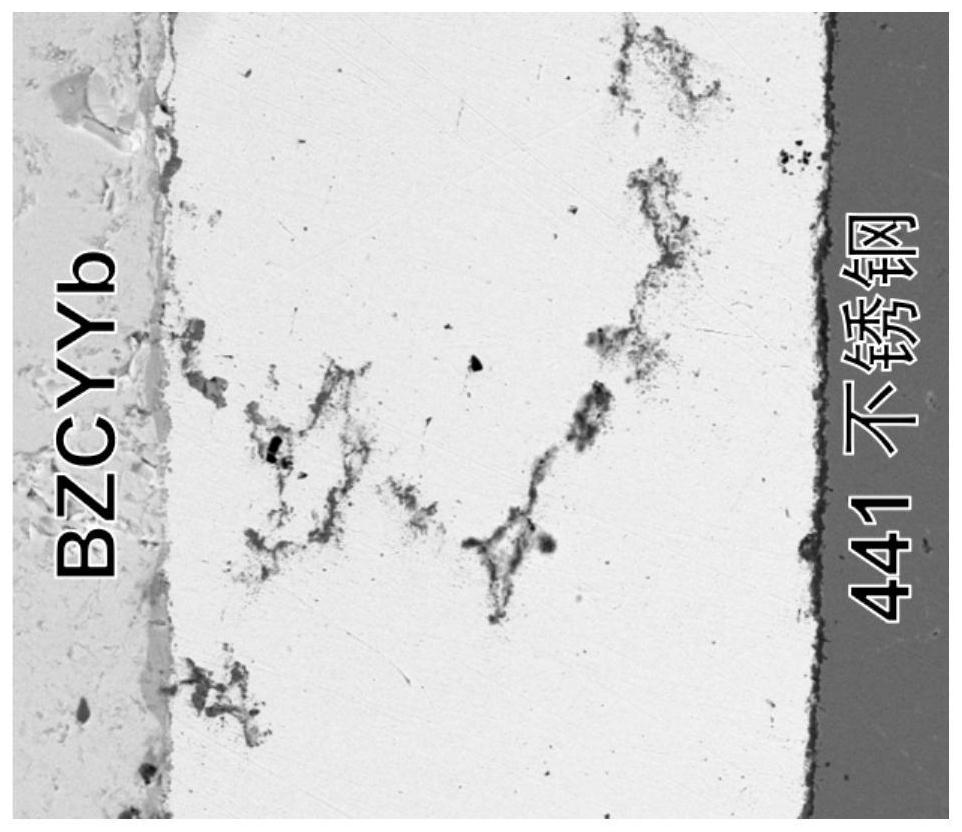

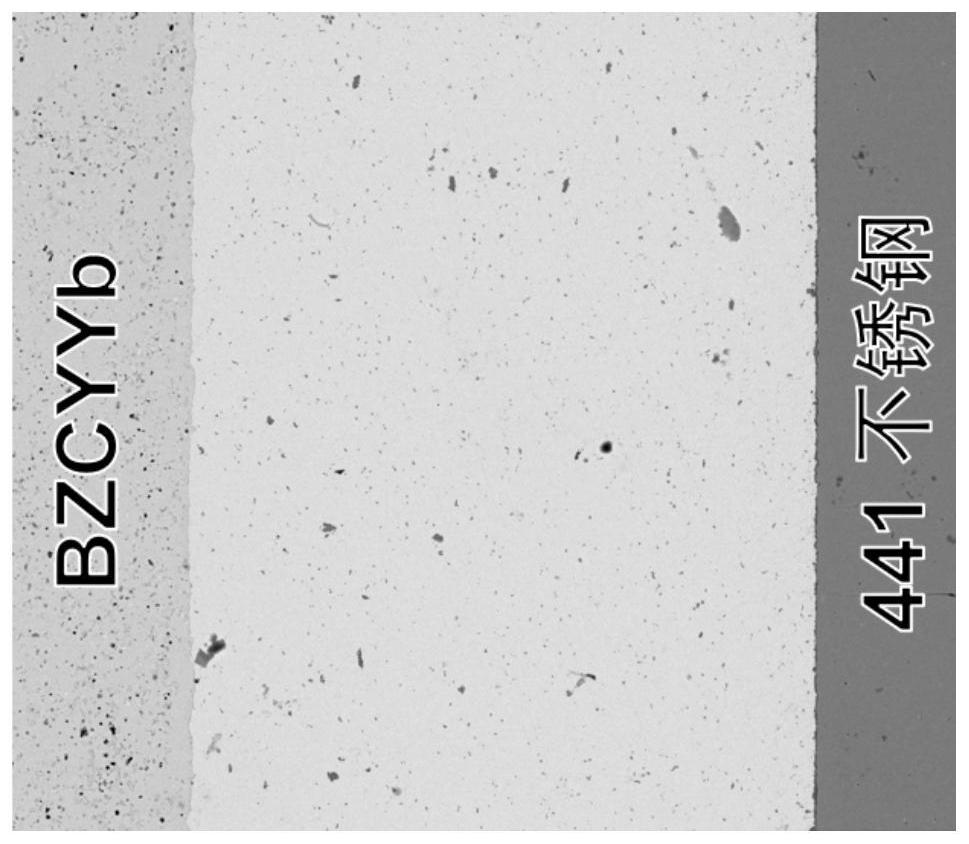

Composite oxide, sintering body, solid electrolyte and manufacturing method thereof

InactiveCN101901922AImprove ionic conductivityGood reduction resistanceFinal product manufactureMaterial analysis by electric/magnetic meansRare-earth elementComposite oxide

The invention discloses a composite oxide shown in the following chemical formula: Ce1-x(LnA1-yLnBy)xO2-x / 2, wherein LnA and LnB are different rare earth elements which are respectively selected from a group comprising the elements of Sm, Gd, Pr, Nd, Y, Sc, Yb, La, Dy and Ho, x is greater than 0 and less than or equal to 0.2, and y is greater than 0 and less than or equal to 0.5. The invention provides a manufacturing method of a solid electrolyte which has high ionic conductivity and reduction resistance in a lower temperature range. The invention further discloses a sintering body and a solid electrolyte which are formed by the composite oxide and a manufacturing method of the composite oxide. According to the invention, the solid electrolyte formed by the composite oxide has high ionic conductivity and reduction resistance at low temperature.

Owner:TSINGHUA UNIV +1

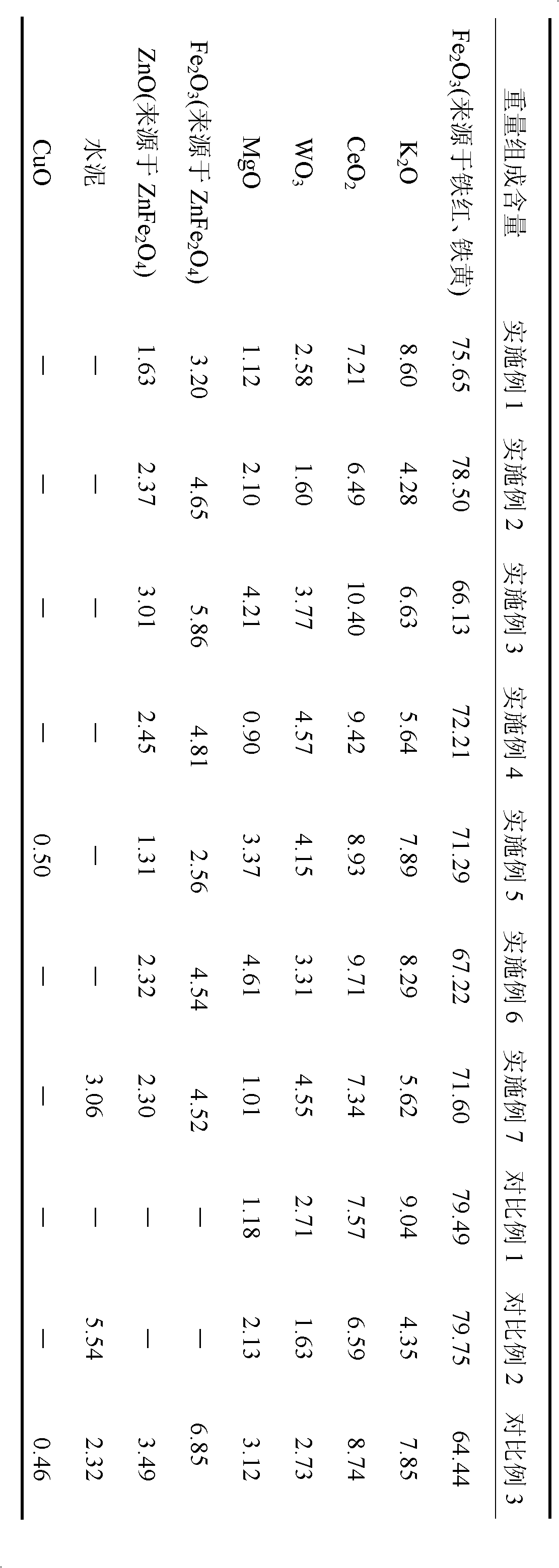

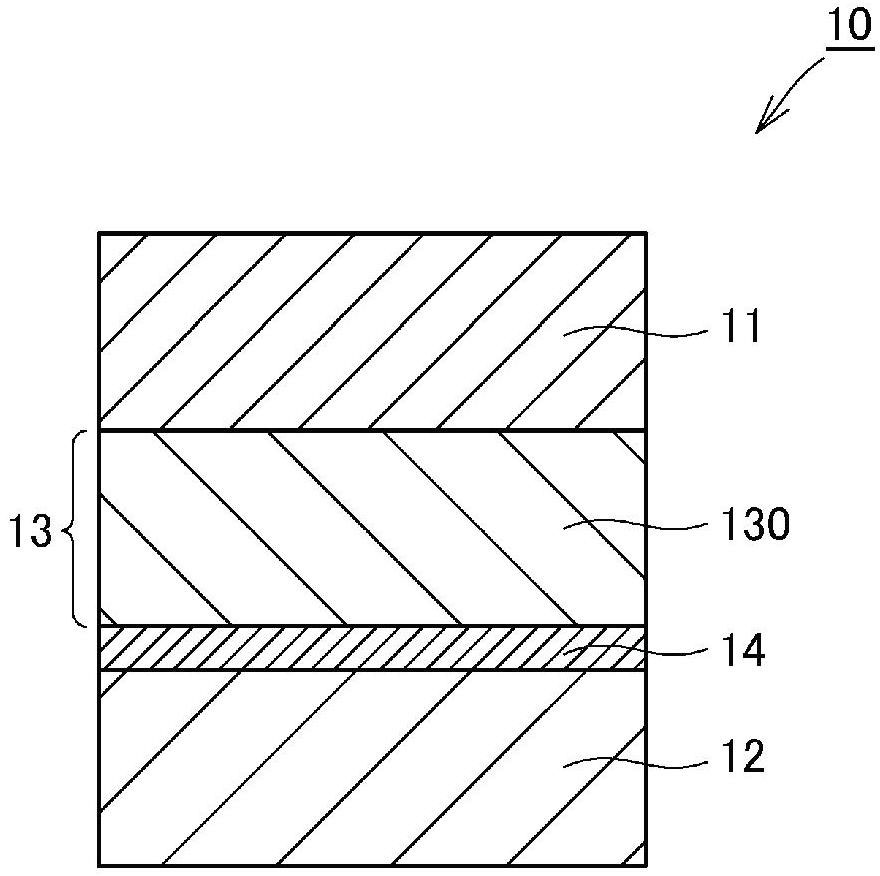

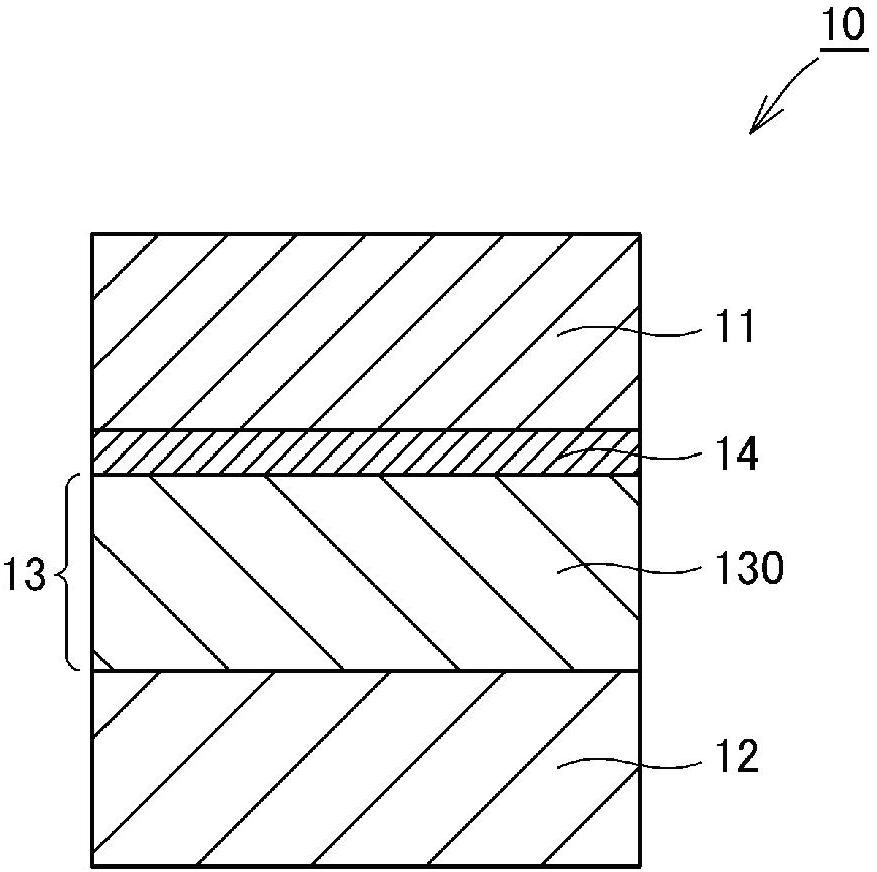

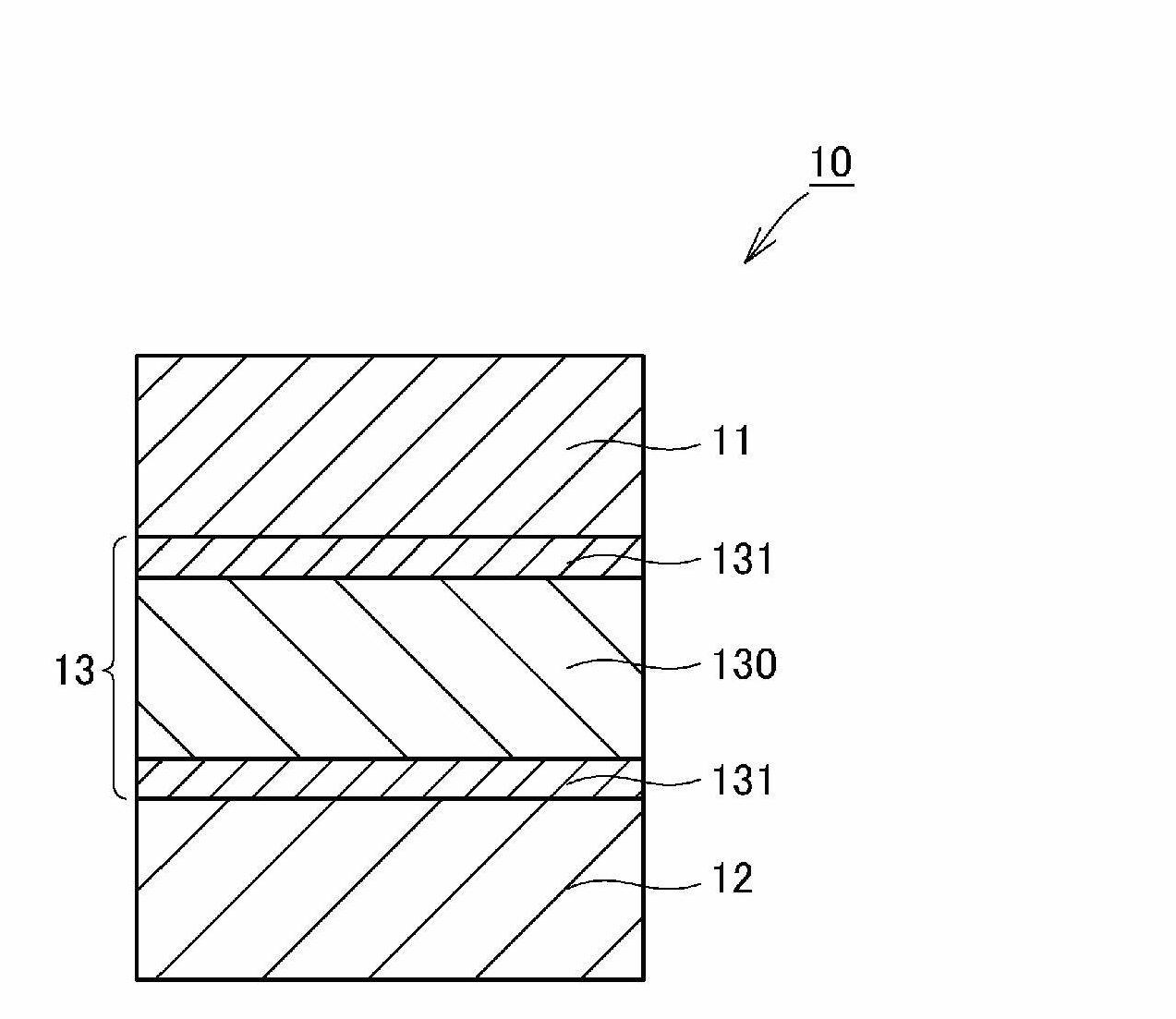

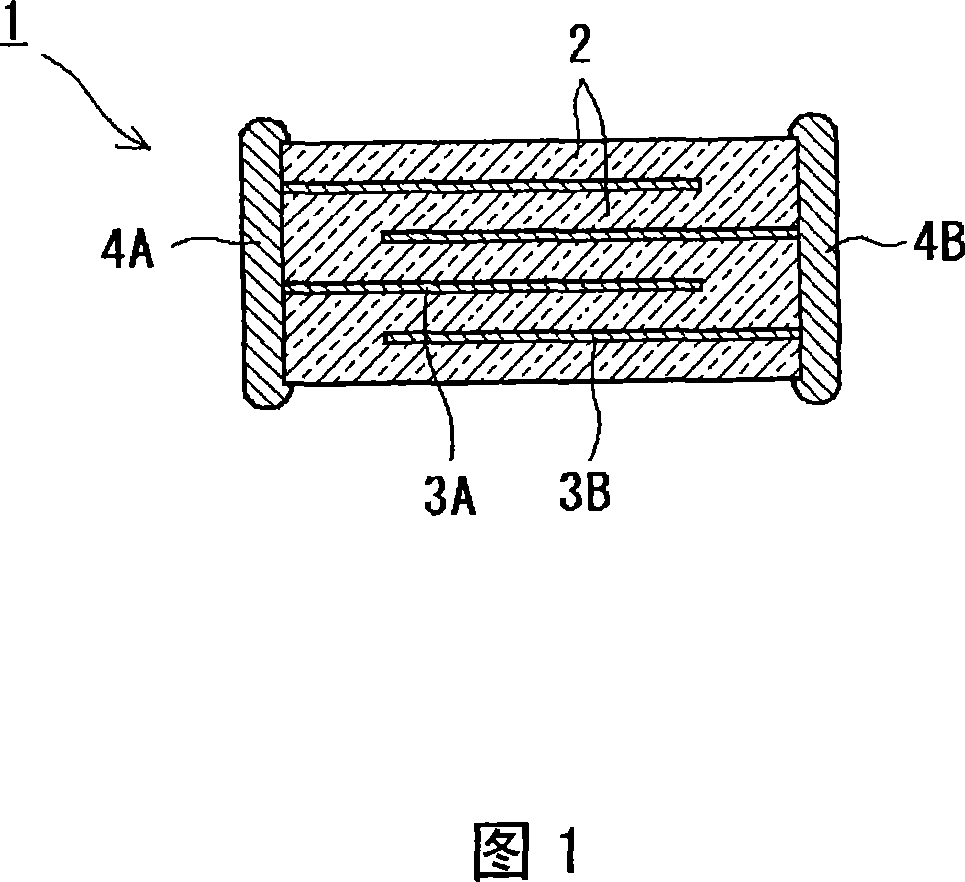

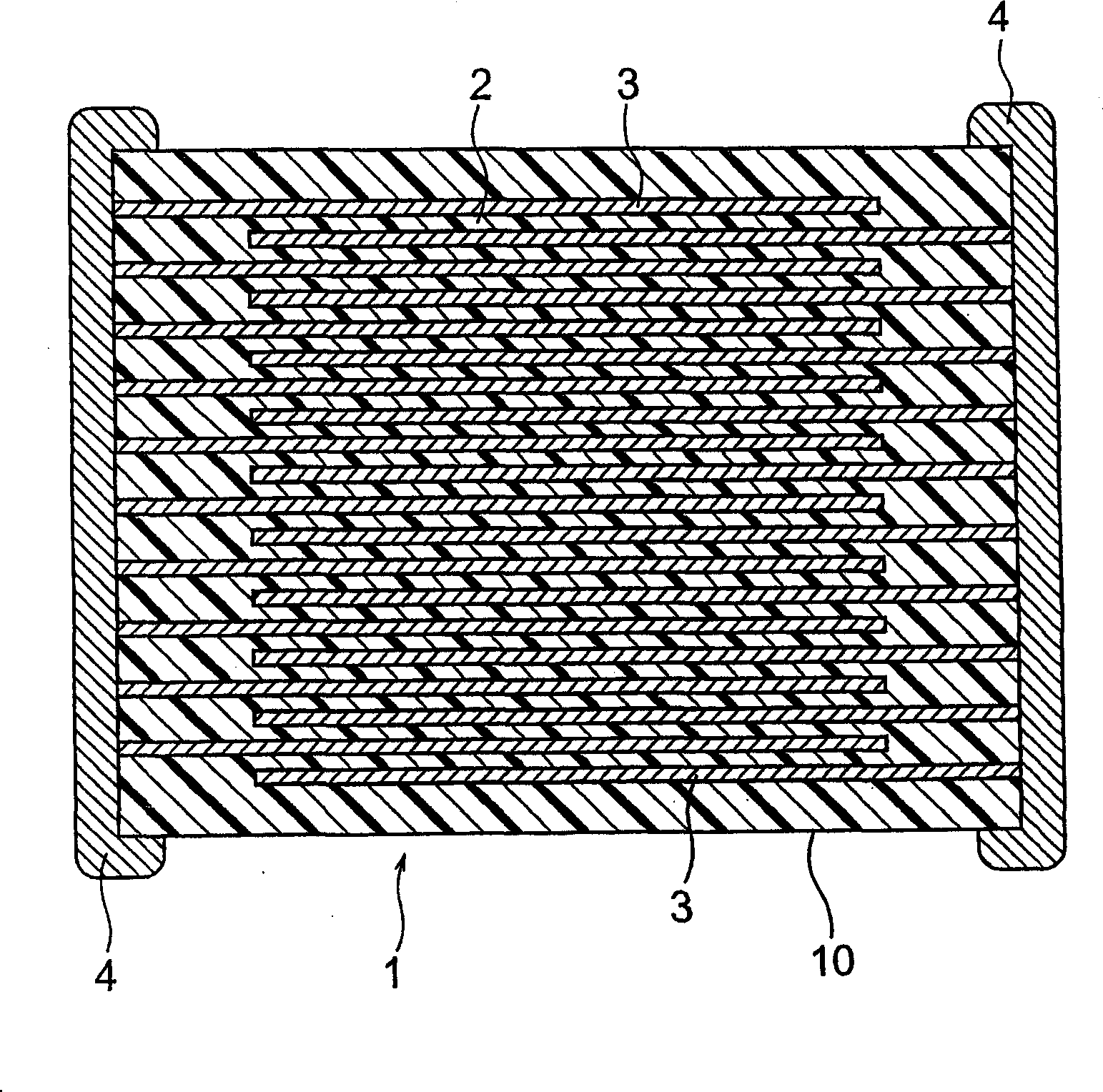

Solid-state battery

ActiveCN102612782AImprove resistance to reductionInhibition decreasedSolid electrolytesCell electrodesEngineeringSolid-state battery

Disclosed is a solid-state battery which has excellent stability by comprising a solid electrolyte that has improved reduction resistance. Specifically disclosed is a solid-state battery (10) which comprises a positive electrode layer (11), a negative electrode layer (12) and a solid electrolyte layer (13). The positive electrode layer (11) and the negative electrode layer (12) contain an electrode active material, and the solid electrolyte layer (13) contains a solid electrolyte. An LiZr2(PO4)3-containing layer (14) is provided between the solid electrolyte layer (13) and the positive electrode layer (11) and / or between the solid electrolyte layer (13) and the negative electrode layer (12).

Owner:MURATA MFG CO LTD

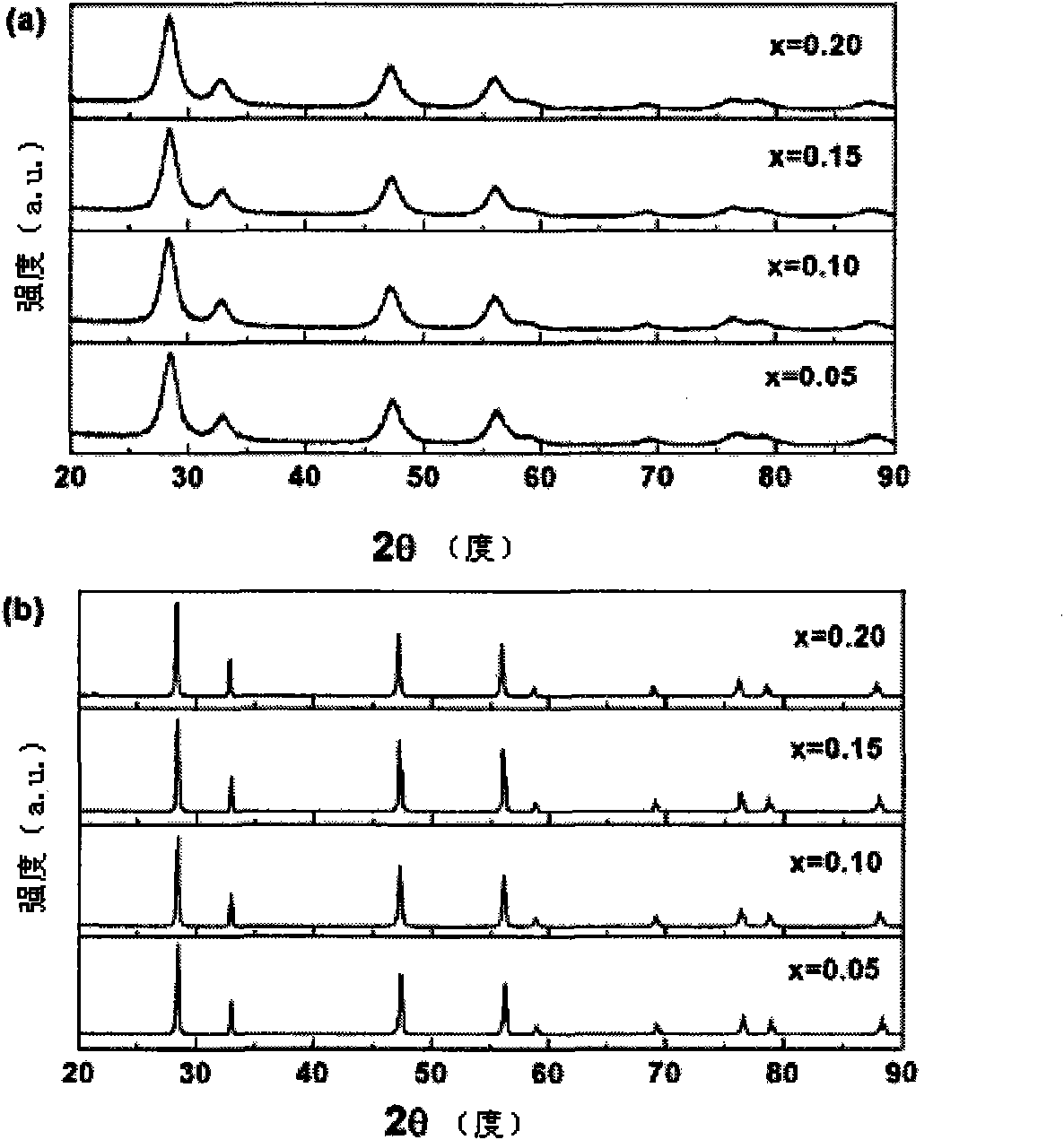

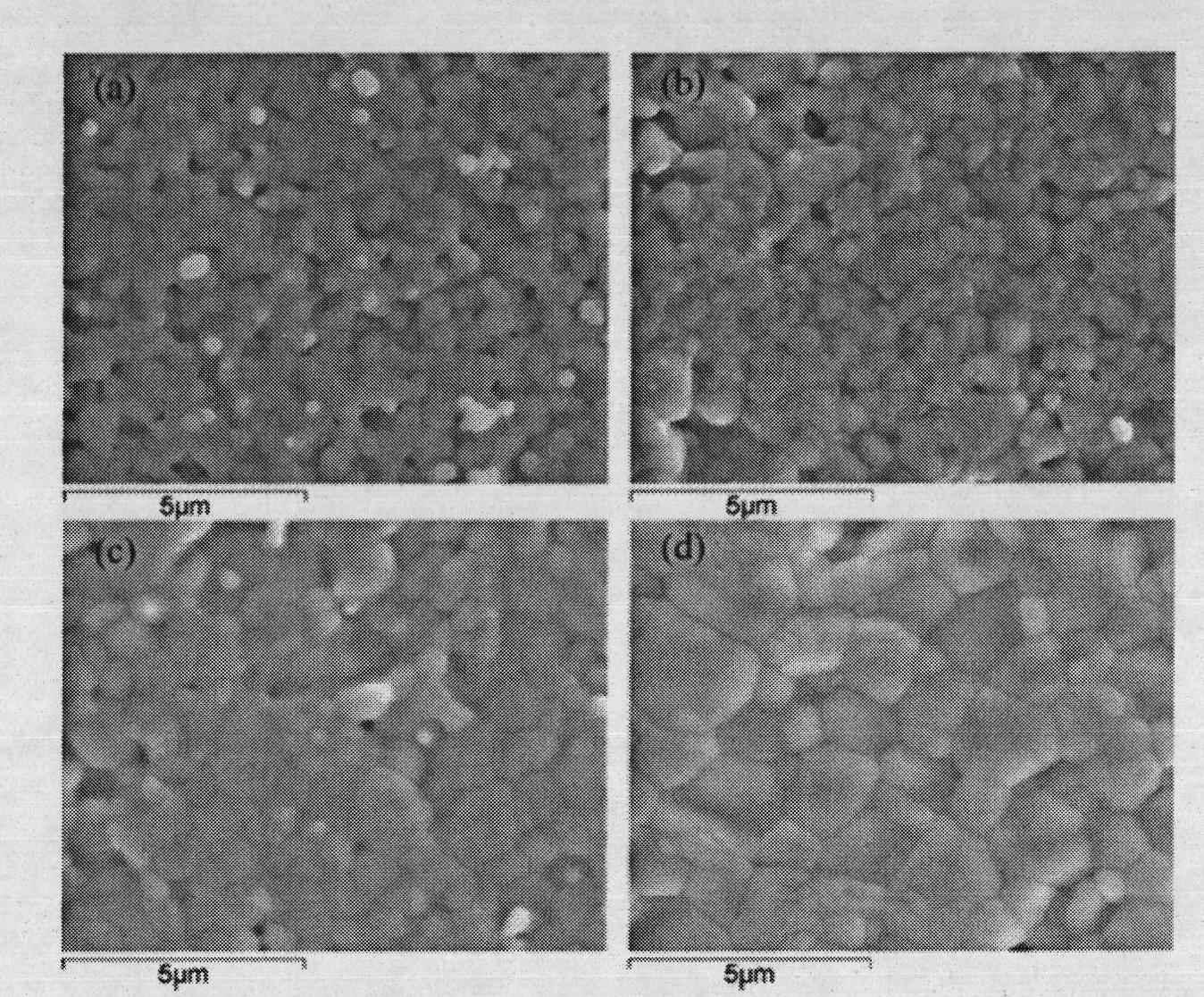

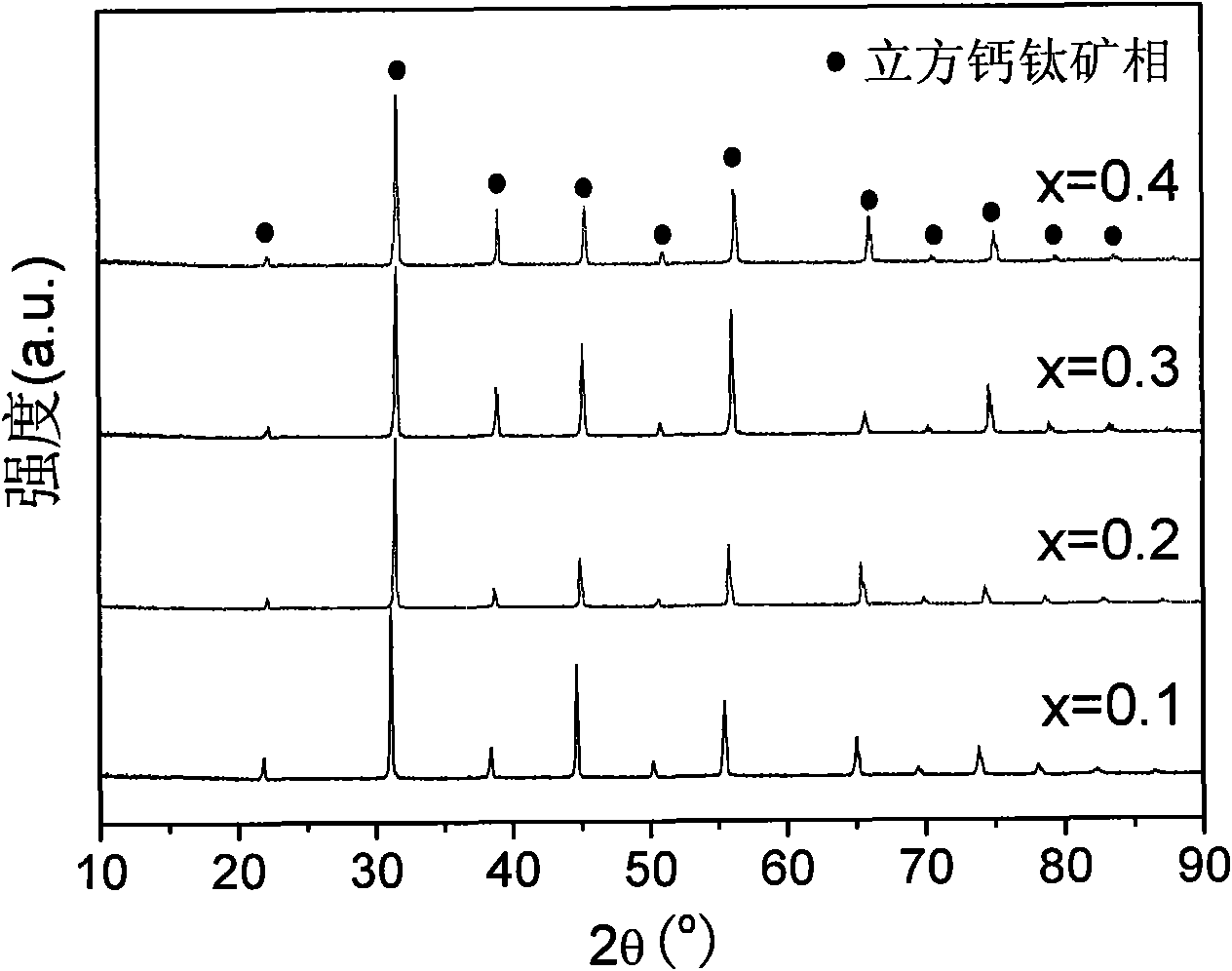

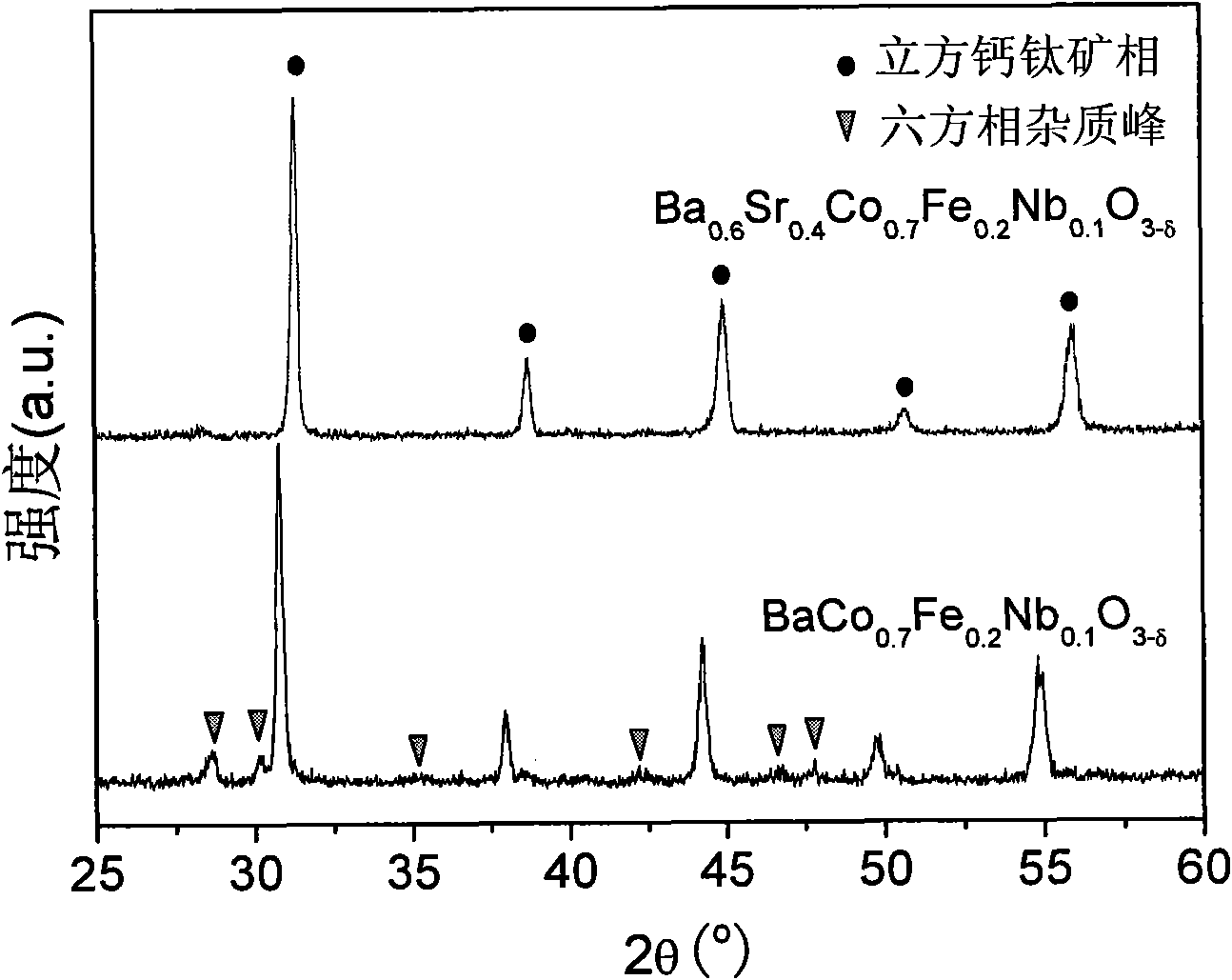

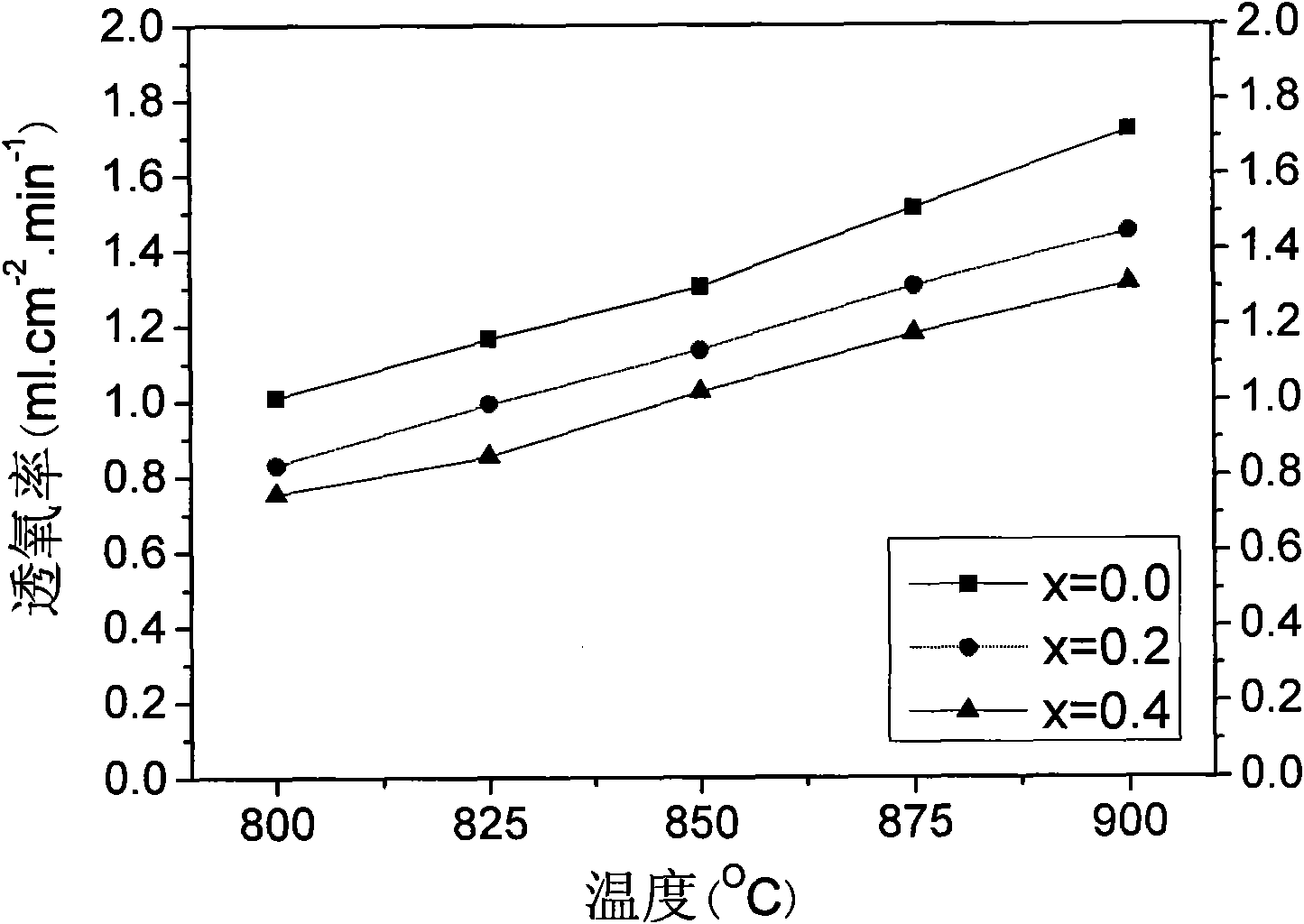

Method for improving structural stability of BaCo0.7Fe0.2Nb0.1O3-Delta oxygen permeation membrane material

InactiveCN101575210AImprove resistance to reductionGood solid solution effectSemi-permeable membranesHydrogenSr elementConcentration gradient

The invention relates to a method for improving the structural stability of a BaCo0.7Fe0.2Nb0.1O3-Delta oxygen permeation membrane material, which belongs to the technical field of oxygen permeation membranes. The method is characterized in that Sr element is doped into the BaCo0.7Fe0.2Nb0.1O3-Delta base material with a perovskite structure, and the obtained oxygen permeation membrane material has a chemical formula of Ba1-xSrxCo0.7Fe0.2Nb0.1O3-Delta, wherein x is equal to 0.05-0.4. The oxygen permeation membrane material provided by the method remarkably improves the phase structure stability of the BaCo0.7Fe0.2Nb0.1O3-Delta base material under the condition of high temperature and low oxygen partial pressure, and the improved oxygen permeation membrane material can be applied within wider oxygen partial pressure range and under larger oxygen concentration gradient.

Owner:UNIV OF SCI & TECH BEIJING

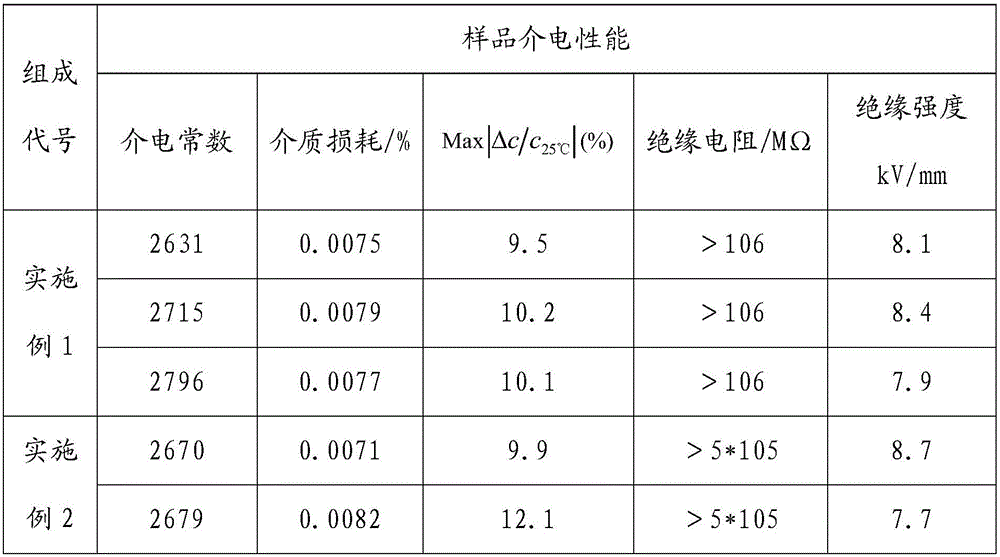

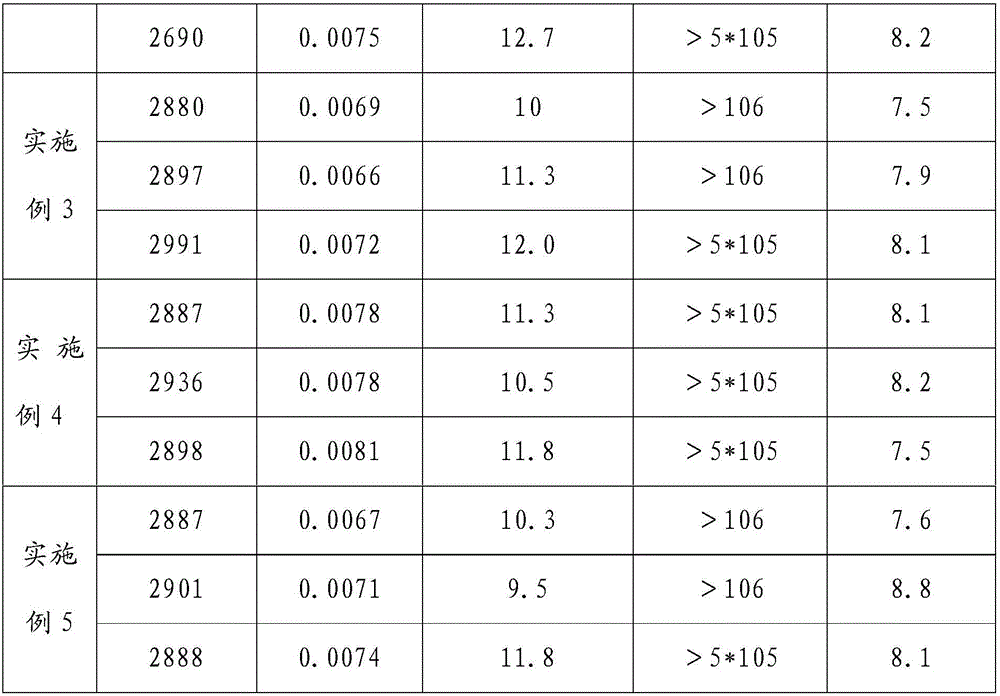

BME ceramic dielectric capacitor ceramic material and preparation method thereof

InactiveCN106045498AImprove resistance to reductionGood temperature characteristicsDielectric lossRare earth

A BME ceramic dielectric capacitor ceramic material is prepared from BaTiO3, CaZrO3, rare earth oxide, Er2O3, MnO2, BaCO3, Co2O3, ZnB2O4 and Li2SiO3, the materials are matched in a certain proportion and subjected to ball milling, drying, prilling, circular slice green body pressing, organic matter discharging, sintering and the like. The rare earth oxide is one or several of Yb2O3, Ho2O3, Dy2O3, Sm2O3 and Y2O3. An X7R type MLCC material with excellent performance can be sintered at the reducing atmosphere, the preparation technology is simple, the formula design is simple and adjustable, the sintering technology is easy to control, the material is suitable for large-scale production, the uniformity of the material is good, the material has a high dielectric constant, a low dielectric loss and good high-temperature insulation resistance and insulation strength, the production cost of MLCC can be effectively reduced, and the application range of the material is enlarged.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Dielectric ceramic composition and monolithic ceramic capacitor

ActiveCN101160269AImprove reliabilityHigh resistivityLayered productsFixed capacitor dielectricElectricityCeramic capacitor

The present invention provides a dielectric ceramic composition which can solve problems, involved in a conventional piezoelectric ceramic for an actuator using a tungsten bronze type composite oxide, i.e., a problem that the specific permittivity is so low (less than 2000) that the piezoelectric ceramic is unsuitable as a dielectric ceramic material for laminated ceramic capacitors, and a problem that, although Mn has the effect of improving the degree of sintering, since the specific permittivity is lowered with increasing the amount of Mn added, the conventional piezoelectric ceramic, when used as a dielectric ceramic material for laminated ceramic capacitors, poses a problem. The dielectric ceramic composition is composed mainly of a tungsten bronze type composite oxide represented by a compositional formula (K1-yNay)Sr2Nb5O15, wherein 0 = y < 0.2, and contains 0.1 to 40 parts by mole, based on 100 parts by mole of the main component, of Mn as an auxiliary component.

Owner:MURATA MFG CO LTD

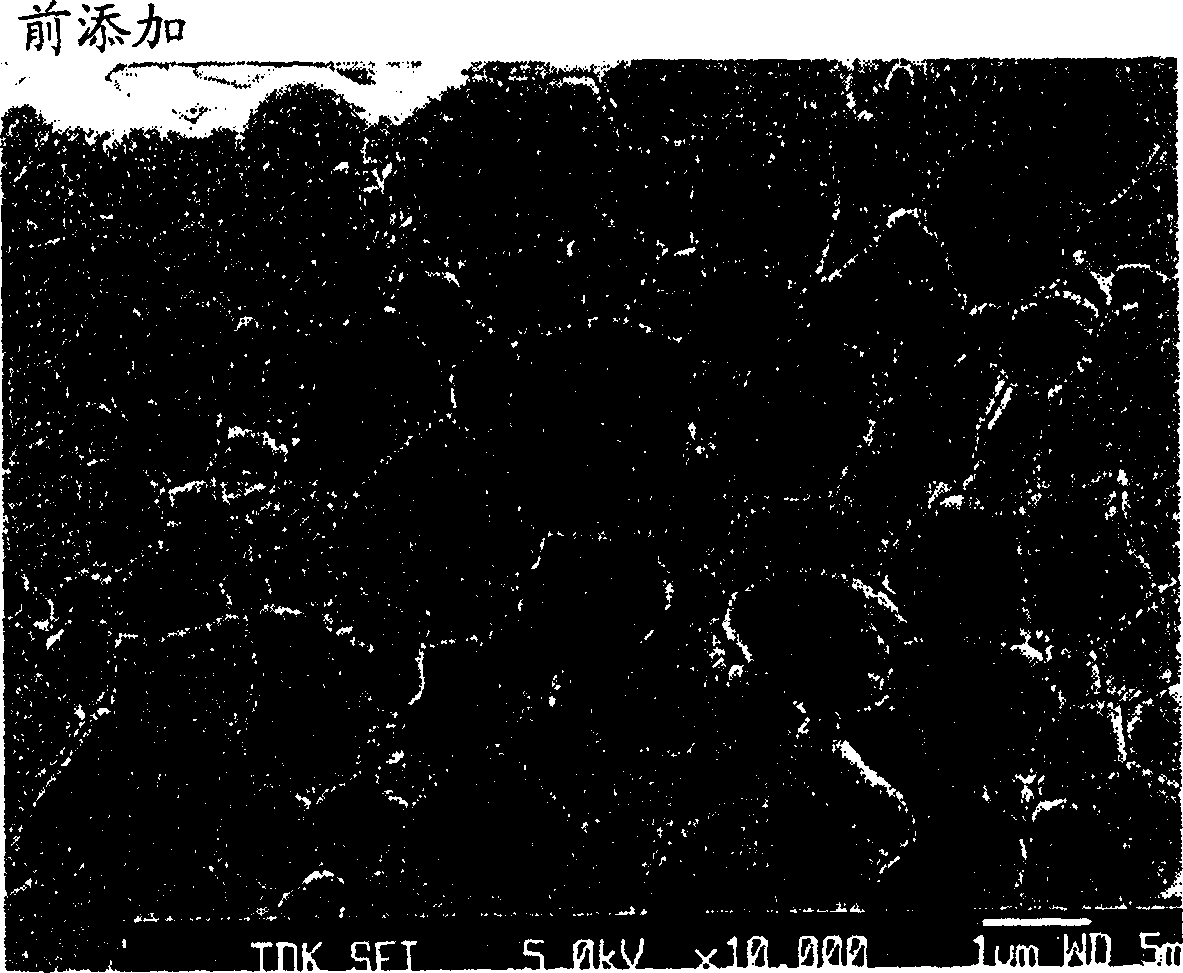

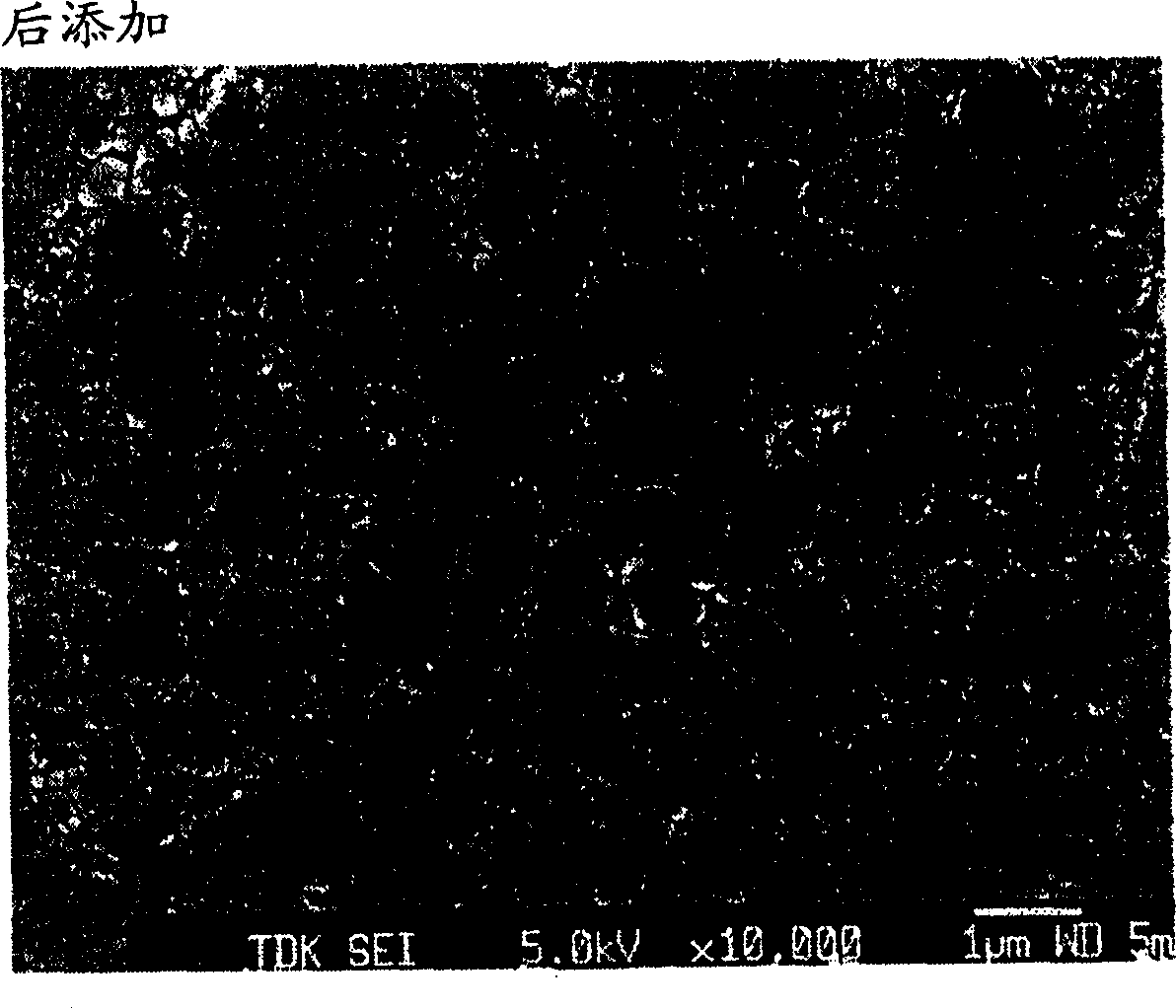

Dielectric ceramic composition and method of production and electronic device of the same

ActiveCN1778766AExtend your lifeImprove resistance to reductionLayered productsFixed capacitor dielectricElectrical resistance and conductanceDielectric ceramics

The present invention provides a method for producing a dielectric ceramic composition, wherein the dielectric ceramic composition contains the following components in a specific ratio: a main component containing a dielectric oxide having a specific composition, the main component can provide a Method for producing reduction-resistant dielectric ceramic composition with frequency dielectric characteristics and accelerated life of insulation resistance further improved, containing V oxide as the first subcomponent, Al oxide as the second subcomponent, and Mn oxide The 3rd subcomponent, and the 4th subcomponent containing a specific sintering aid; the method includes the following steps: removing at least one or two other subcomponents of the raw material of the 3rd subcomponent and the raw material of the 4th subcomponent A step of preparing a pre-reaction raw material by mixing at least a part of the component raw material with the starting raw material prepared to obtain the main component raw material; a step of reacting the prepared pre-reaction raw material to obtain a post-reaction raw material; and in the obtained post-reaction raw material , the process of mixing the auxiliary component raw materials removed when preparing the raw materials before the reaction to obtain the dielectric ceramic composition raw materials.

Owner:TDK CORPARATION

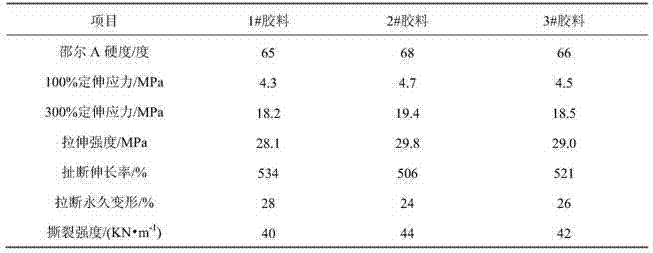

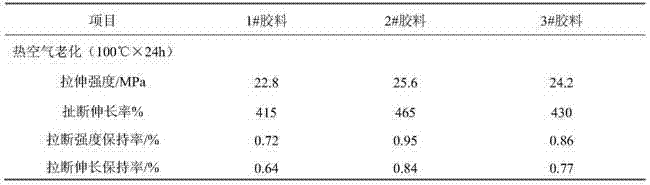

Novel tire shoulder separation-preventing agent and preparation method and application thereof

ActiveCN104262899AImprove thermal conductivityImprove resistance to reductionSpecial tyresSaline waterAging resistance

The invention relates to a novel tire shoulder separation-preventing agent. The tire shoulder separation-preventing agent comprises the following raw materials in percentage by mass: 15-50% of a heat stabilizer, 10-30% of reinforcing and hardening resin and 40-70% of a heat-conducting agent. The tire shoulder separation-preventing agent enhances the stability of a single-sulfur, bi-sulfur and multi-sulfur crosslink network in vulcanized rubber and has an excellent heat-conducting function, thereby enhancing reduction resistance of long-lasting high temperature aging resistance and saline water aging resistance of tire rubber and prolonging and improving the service life and the driving safety of a tire.

Owner:SHANDONG YANGGU HUATAI CHEM

Ethylbenzene dehydrogenation catalyst in low water ratio

ActiveCN103537296AReduce churn rateImprove resistance to reductionHydrocarbonsMetal/metal-oxides/metal-hydroxide catalystsPotassiumDehydrogenation

The invention relates to an ethylbenzene dehydrogenation catalyst in low water ratio, which mainly solves the problem that a low-potassium catalyst is poor in stability under a low water ratio condition in the prior art. Due to the adoption of the technical scheme of adding ferrate into a ferric-potassium-cerium-tungsten-magnesium catalytic system, the problem is well solved. The ethylbenzene dehydrogenation catalyst in low water ratio can be used for industrialized production of preparing styrene by ethylbenzene dehydrogenation under the low water ratio condition.

Owner:CHINA PETROLEUM & CHEM CORP +1

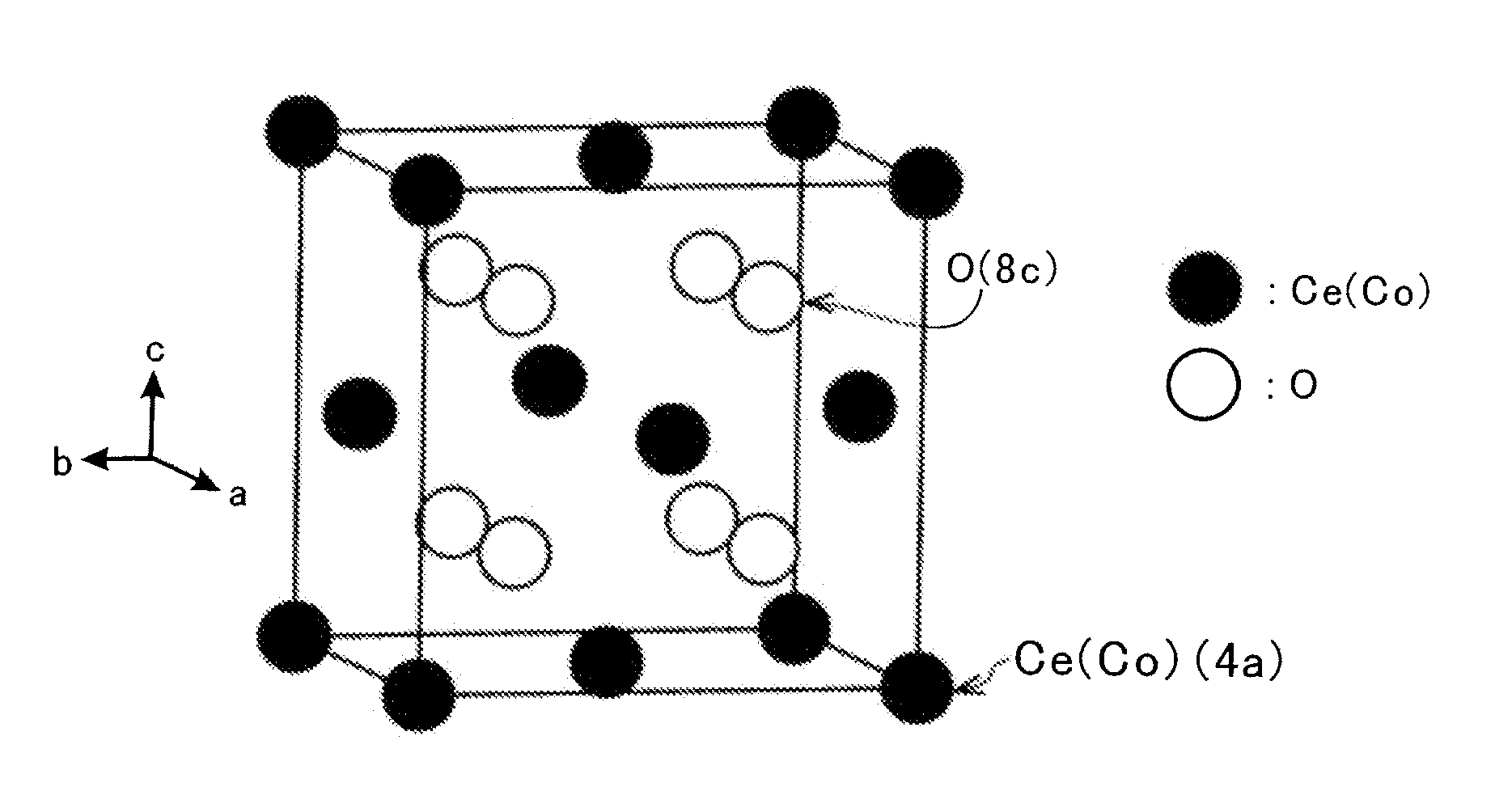

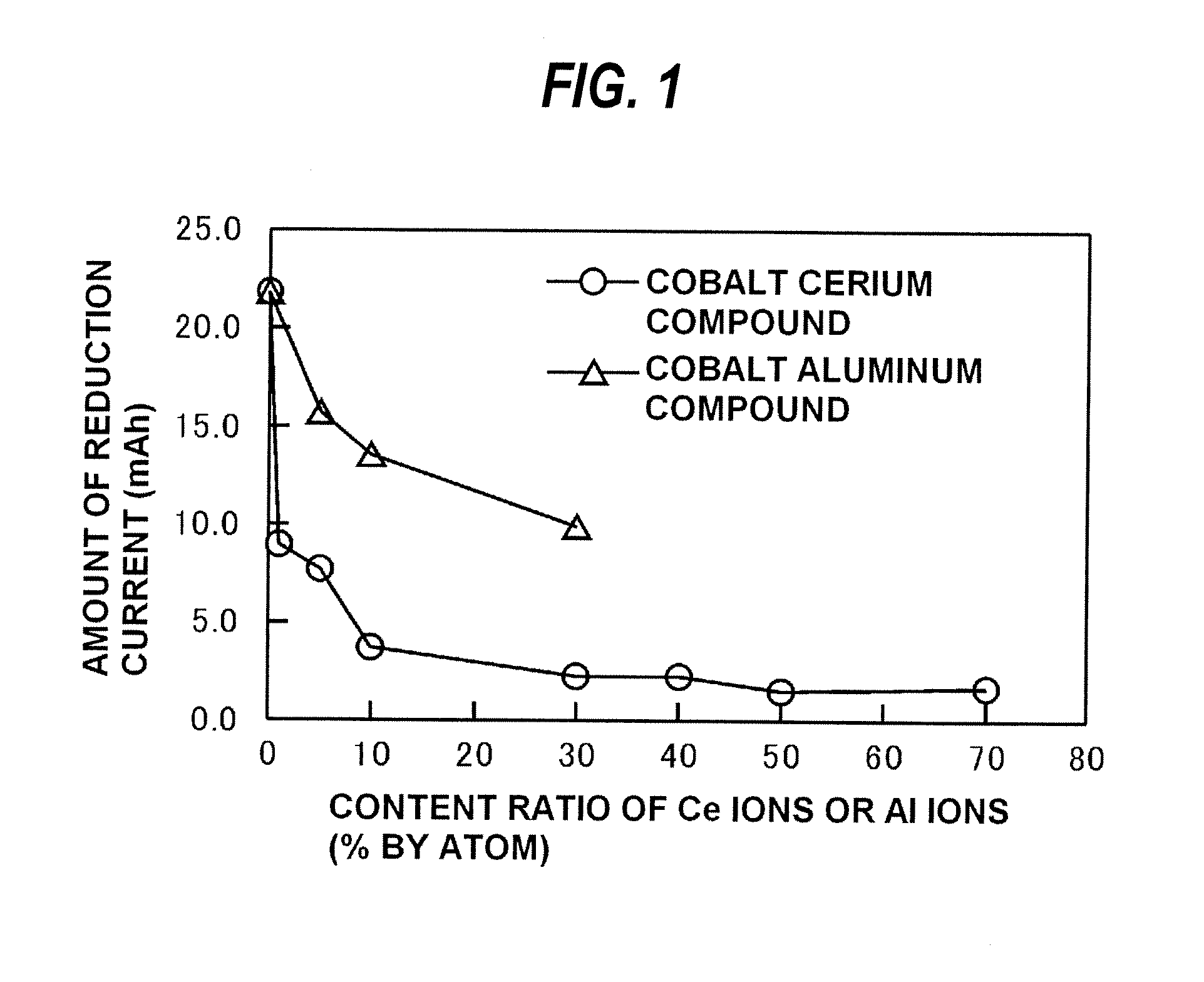

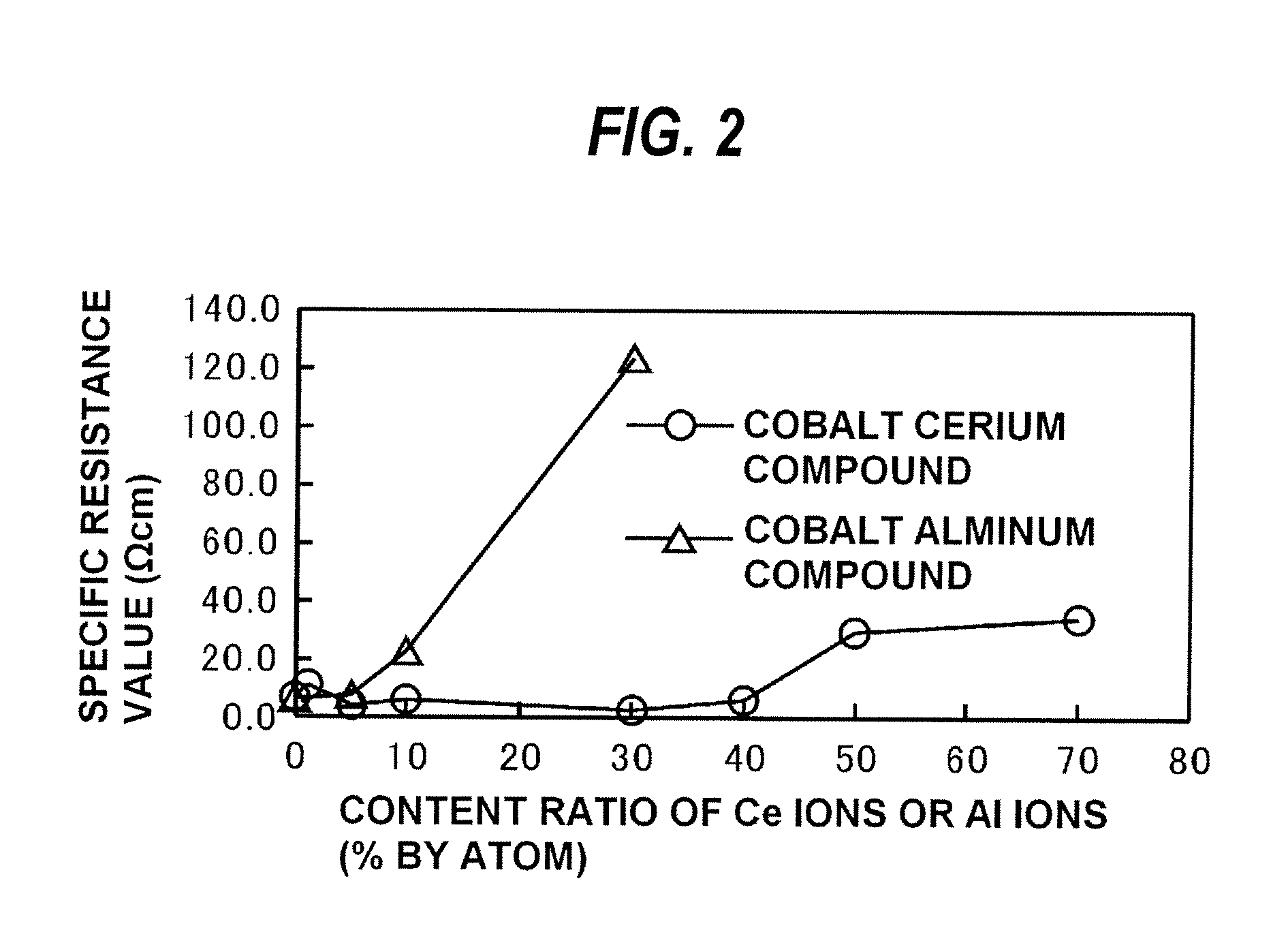

Cobalt cerium compound, alkaline secondary battery, and method for producing cobalt cerium compound

ActiveUS20120115034A1Improve resistance to reductionSolve the lack of functionAlkaline accumulatorsFinal product manufactureCompound aCerium

A compound having a high reduction resistance and being capable of sufficiently performing a function as an electronic conductive additive when added to a positive electrode active material as an electronic conductive additive is provided. In a method for producing a cobalt cerium compound including a step of depositing a hydroxide containing cobalt and cerium in an aqueous solution containing cobalt ions and cerium ions by changing the pH of the aqueous solution and thereafter performing a treatment of oxidizing the hydroxide, the ratio of the cerium ions contained in the aqueous solution containing the cobalt ions and the cerium ions is set to be more than 5% by atom and 70% by atom or less with respect to the sum of the cobalt ions and the cerium ions before the hydroxide is deposited.

Owner:GS YUASA INT LTD +1

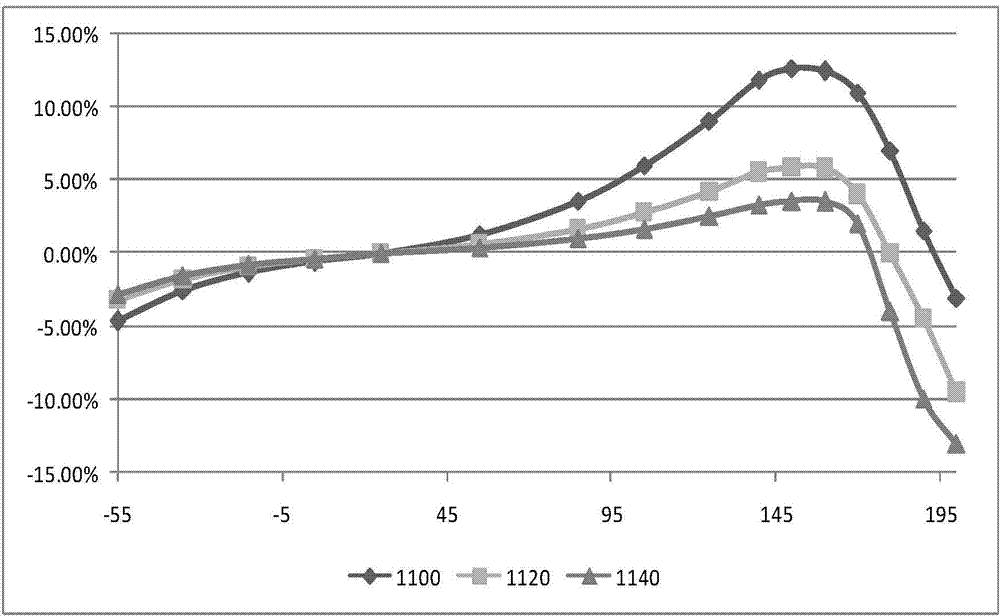

High-temperature ceramic capacitor dielectric material and preparation method thereof

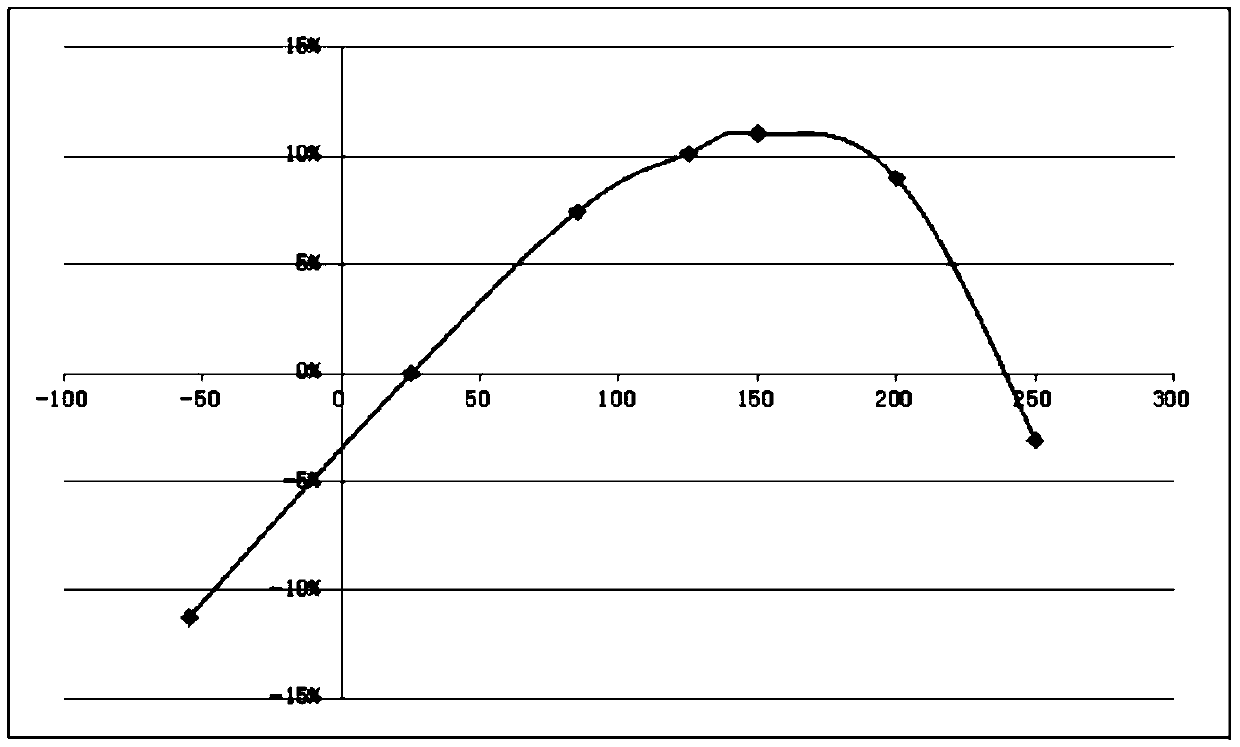

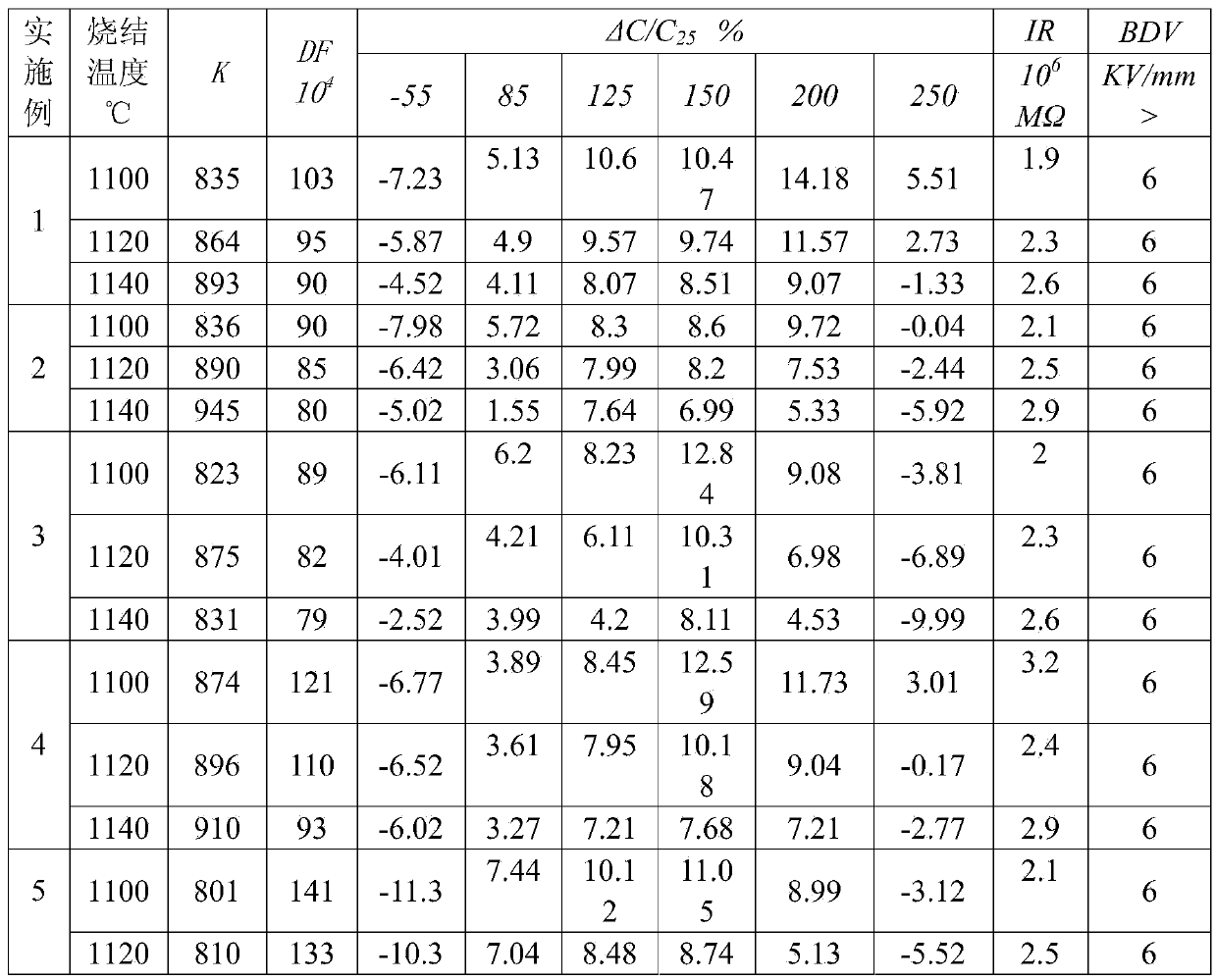

The invention discloses a high-temperature ceramic capacitor dielectric material and a preparation method thereof. A ceramic capacitor prepared from the material works at the temperature of -55 DEG C to 250 DEG C. The dielectric material is prepared from, by weight, 100 parts of [(1-x)BaTiO3-xBiyNazTiO3], 4-6 parts of NbO, 0.1-0.5 part of RE2O3, 0.05-0.15 part of MnO2 and 2-4 parts of CaSiB2O6, wherein x ranges from 0.08-0.20, y ranges from 0.4-0.6, z ranges from 0.4-0.6, the mole ratio of BaTiO3 to BiyNazTiO3 in [(1-x)BaTiO3-xBiyNazTiO3] is (1-x) to x, NbO is niobium-containing oxide including one or more of MgNb2O6, ZnNb2O6, Ca(Mg1 / 3,Nb2 / 3)O3 and Ba(Mg1 / 3,Nb2 / 3)O3, and RE is one or more of Y, Nd and Er. The high-temperature ceramic capacitor dielectric material has the advantages that the dielectric constant is larger than or equal to 800, dielectric loss is low, and temperature stability (-15%<=deltaC / C<=15%) is high.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Cerium-cobalt-coated nickel hydroxide composite material and preparation method and application thereof

ActiveCN104143638AImprove performanceImprove high temperature resistanceCell electrodesNickel accumulatorsNickel oxide hydroxideCerium

The invention discloses a cerium-cobalt-coated nickel hydroxide composite material which is of a core shell type structure. A core is spherical nickel hydroxide, an outer coating layer is mainly hydroxide containing cerium and cobalt, the molar ratio of nickel hydroxide to cerium is 1:0.007 to 0.056, and the molar ratio of nickel hydroxide to cobalt is 1:0.025 to 0.125. A preparation method of the cerium-cobalt-coated nickel hydroxide composite material includes the steps that cerous salt and cobalt salt are dissolved, a complexing agent and a salt mixture solution are mixed and then complexed, the obtained mixed solution and precipitant are added to a solution containing spherical nickel hydroxide, cerium-cobalt even co-precipitation reaction is conducted, the coating layer is formed on the surface, washing, drying and oxidizing are conducted, and then the cerium-cobalt-coated nickel hydroxide composite material is obtained. The cerium-cobalt-coated nickel hydroxide composite material can serve and be used as a positive electrode energy storage material for improving the high-temperature performance of a nickel-metal hydride battery, and conductivity, reducibility resistance and high-temperature resistance of spherical nickel hydroxide can be remarkably improved.

Owner:CHANGSHA RES INST OF MINING & METALLURGY +1

Base metal copper electrode paste and preparation of obtained capacitor

ActiveCN101364455BPromote crystallizationImprove uniformityFixed capacitor electrodesConductive materialEnvironmental resistanceElectricity

Owner:GUANGDONG FENGHUA ADVANCED TECH HLDG

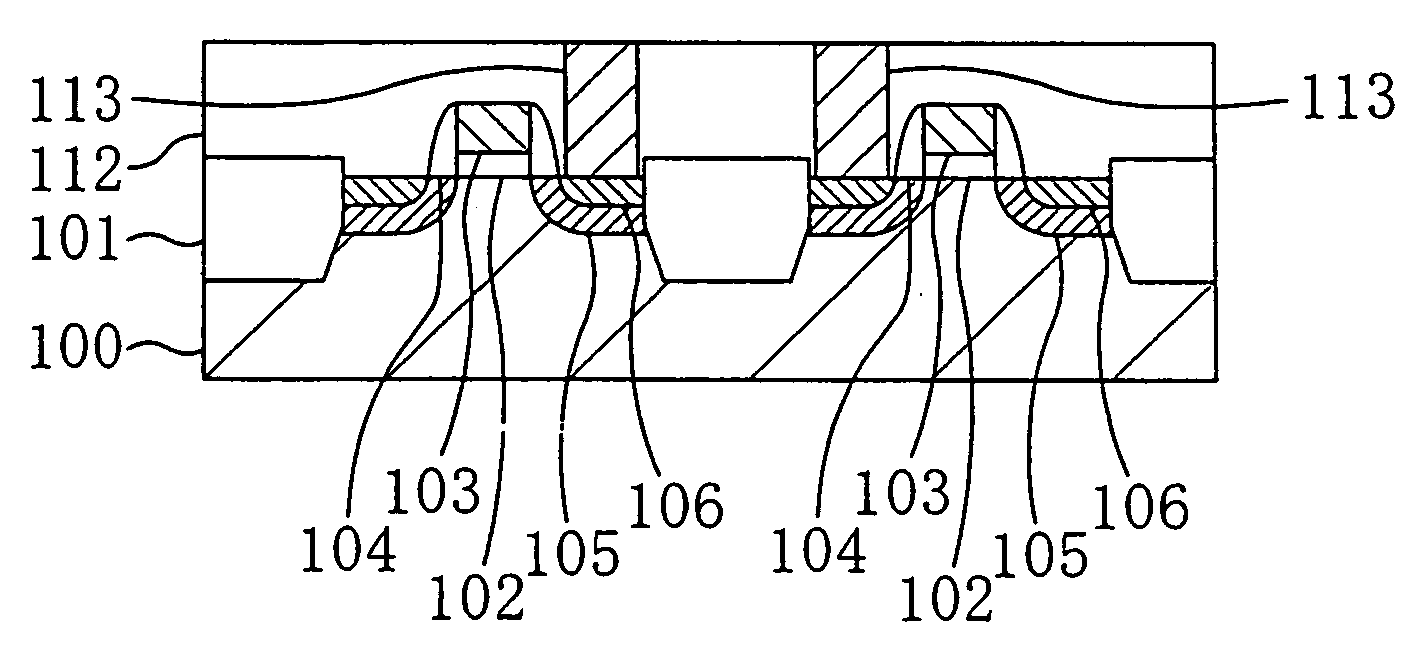

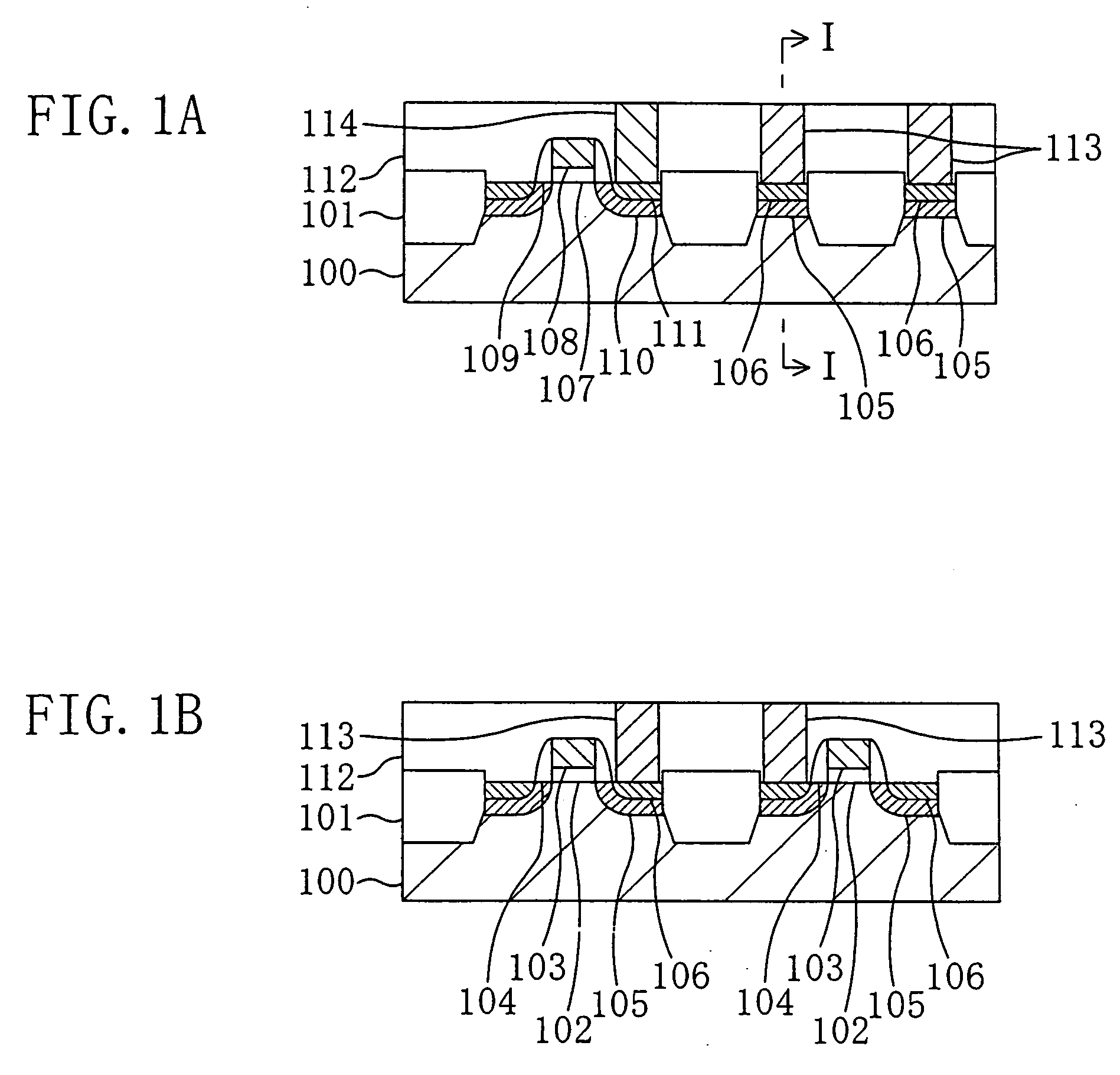

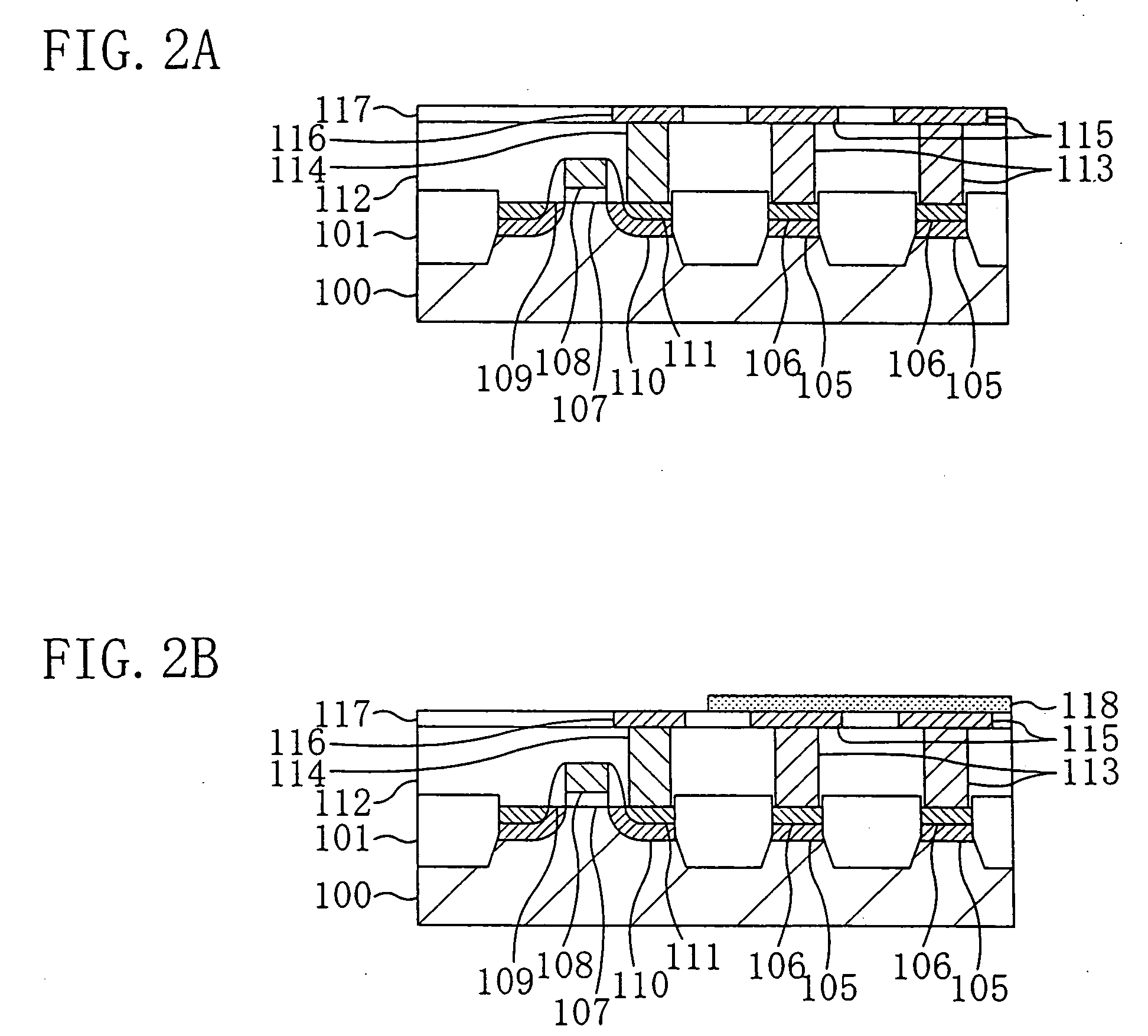

Ferroelectric memory and method for manufacturing the same

InactiveUS20050041505A1Improve resistance to reductionImprove reliabilitySolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceEngineering

A capacitor upper electrode and a wiring are electrically connected to each other by using a plug and a conductive layer formed below a capacitive element without using a plug that directly connects the capacitor upper electrode to the wiring provided thereon via an interlayer insulating film therebetween. Alternatively, the capacitor upper electrode is covered by a conductive hydrogen barrier film, and the capacitor upper electrode and the wiring are electrically connected to each other via both a plug connecting the wiring and the conductive hydrogen barrier film to each other and the conductive hydrogen barrier film.

Owner:TAIWAN SEMICON MFG CO LTD

High-strength low-water ratio ethylbenzene dehydrogenation catalyst not containing adhesive

PendingCN106994353AImprove bindingReduce churn rateHydrocarbon by dehydrogenationHeterogenous catalyst chemical elementsAdhesiveDehydrogenation

Owner:SUZHOU TORETO NEW MATERIAL LTD

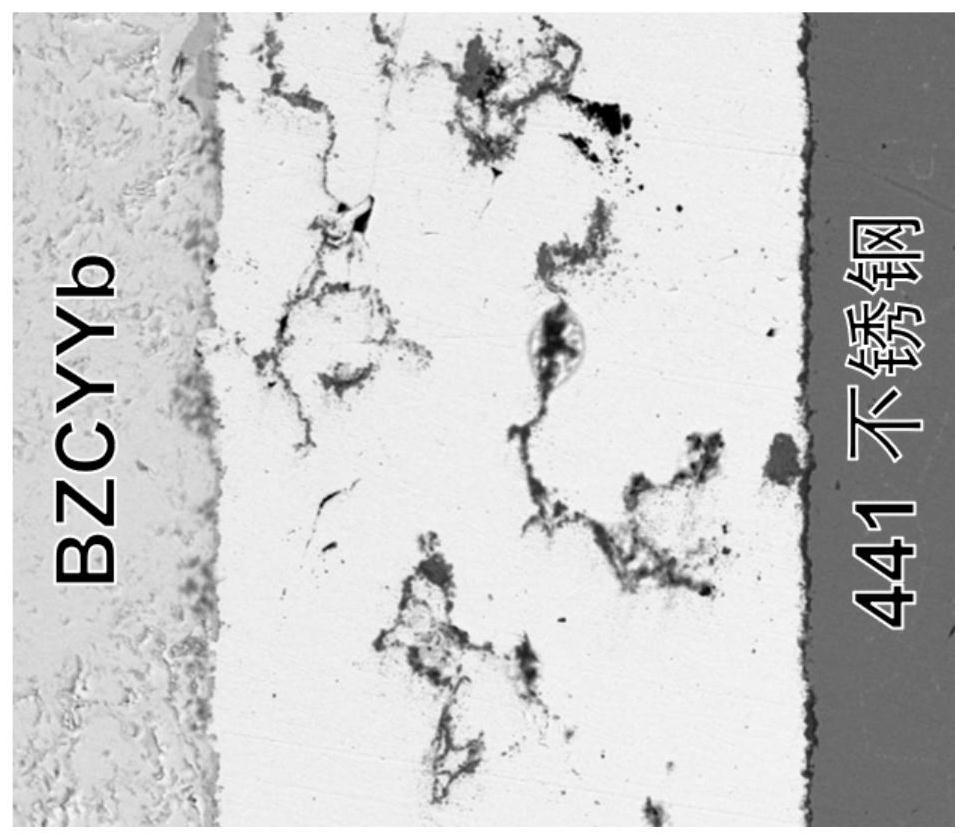

A kind of method for graphene sponge barrier layer to enhance anti-reduction performance of brazed joint

ActiveCN112756727BImprove resistance to reductionEasy to operateSoldering apparatusWelding/soldering/cutting articlesGraphiteGraphene

A method for enhancing the anti-reduction performance of a brazed joint by a graphene sponge barrier layer, the invention belongs to the field of metal and ceramic connection, and aims to solve the problem that the brazed joint of an existing metal support body / ceramic cell is reduced during high-temperature service. failure problem. Brazing method: 1. The graphene sponge is cut into thin slices; 2. Precious metal-oxide brazing filler metal is configured and pressed into sheets; 3. The metal to be welded and the ceramic to be welded are polished; 4. The parts to be welded are assembled; 2~8×10 ‑3 Pa, the brazing temperature is 960 ~ 1200 ℃ to carry out the brazing connection. In the present invention, a graphene sponge barrier layer is introduced in the brazing process. On the one hand, the introduction of graphene breaks the continuous grain boundary in the brazing joint and reduces the rate of intergranular diffusion of hydrogen; on the other hand, graphene absorbs hydrogen and binds and penetrates into The hydrogen in the joint, thereby inhibiting the reaction of hydrogen with oxides and oxygen in the joint, makes the anti-reduction performance of the joint significantly enhanced.

Owner:HARBIN INST OF TECH

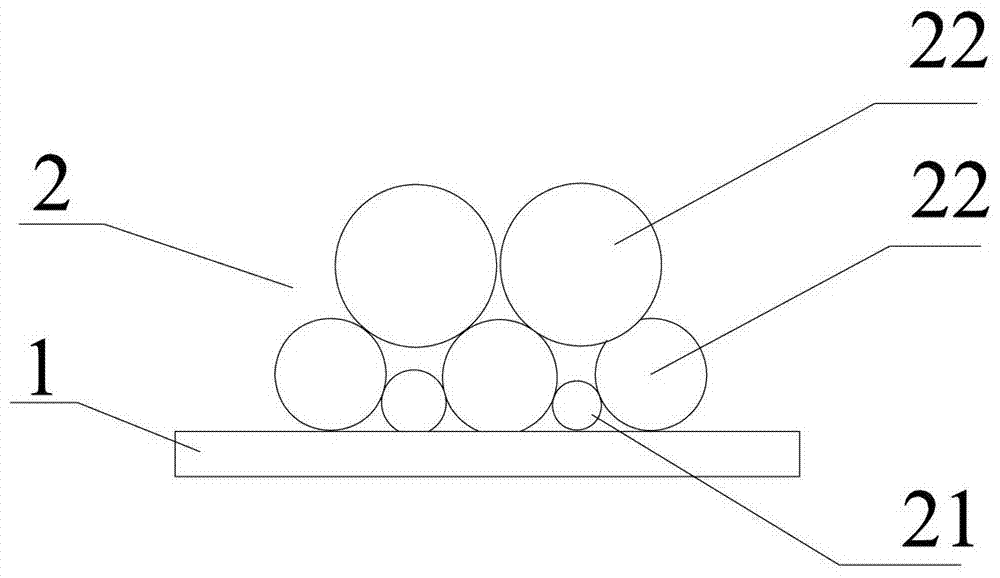

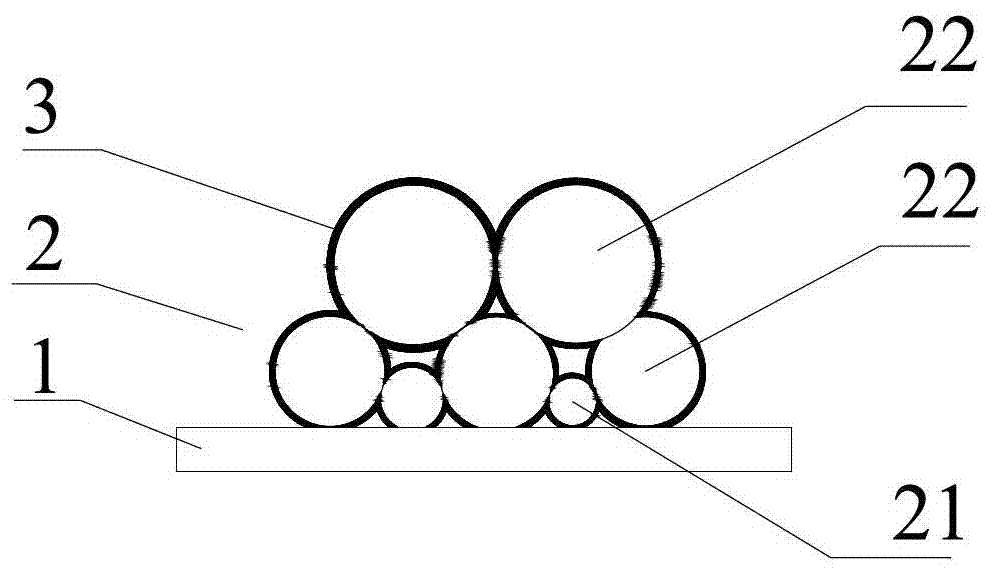

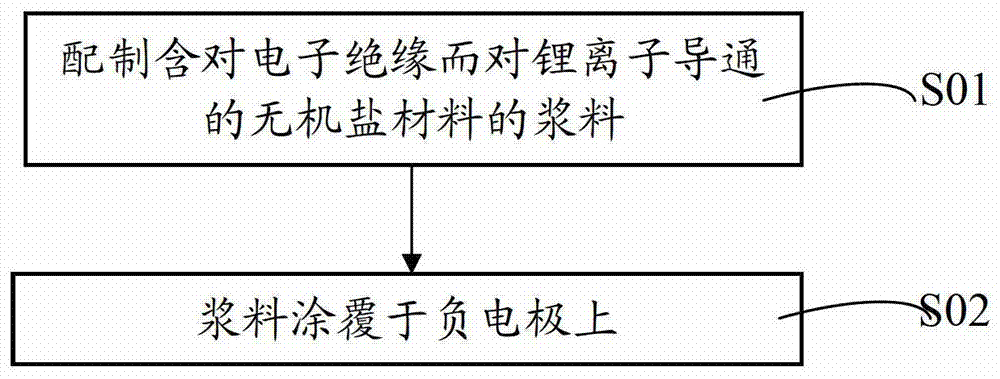

Lithium battery negative electrode and preparation method thereof, lithium battery and application

ActiveCN103855358BAvoid contactCurb consumptionSecondary cellsNon-aqueous electrolyte accumulator electrodesNickel–lithium batteryEngineering

The invention discloses a lithium battery negative electrode as well as a preparation method thereof, a lithium battery and application. The lithium battery negative electrode comprises a current collector, a negative active material layer which is connected onto the surface of the current collector, and protective layers which are respectively connected onto the surface of the negative active material layer and a porous wall of the negative active material layer. The contact between an electrolyte solvent and the surface of the negative electrode can be inhibited through the protective layers of the lithium battery negative electrode, so that the consumption of lithium ions can be reduced when an SEI (solid electrolyte interphase) membrane on the surface of the lithium battery negative electrode is formed and repaired, and the cycling performance of the lithium battery can be remarkably improved; the formation of the SEI membrane on the surface of the lithium battery negative electrode is inhibited, the heat production when the SEI membrane on the surface of the negative electrode is decomposed at high temperature and the exothermic reaction generated when the electrolyte is contacted with the negative electrode after the SEI membrane is decomposed can be avoided, and the safety of the lithium battery can be improved. The preparation method of the lithium battery negative electrode adopts a simple process and easily controlled conditions, is high in efficiency and applicable to industrialized production.

Owner:TONGDING INTERCONNECTION INFORMATION CO LTD

Anti-reduction BME ceramic dielectric capacitor and ceramic material for capacitor

ActiveCN112645708AReduced oxygen vacanciesImprove resistance to reductionFixed capacitor dielectricCalcium bicarbonateBarium titanate

The invention discloses an anti-reduction BME ceramic dielectric capacitor and a ceramic material for the capacitor. The ceramic material for the anti-reduction BME ceramic dielectric capacitor consists of the following raw materials: barium titanate, vanadyl oxalate, manganous nitrate, magnesium nitrate, strontium nitrate, rare earth nitrate A, rare earth nitrate B, chromic nitrate, barium nitrate, calcium bicarbonate, nano silicon dioxide and nano hafnium dioxide. By adding additives such as vanadyl oxalate, barium nitrate, calcium bicarbonate, nano silicon dioxide, nano hafnium dioxide and the like, the loss is reduced, the insulation resistance is improved, the dielectric withstand voltage is improved, and good electrical properties are obtained.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

Dielectric material with positive linear capacitance temperature change rate, and preparation method thereof

The invention discloses a dielectric material with a positive linear capacitance temperature change rate, and a preparation method thereof. According to the preparation method, [(1-x)BaTiO3-xBiyNazTiO3] is taken as a base material, and Nb2O5, RE2O3, MnCO3, and BiBO3 are added, wherein x=0.05-0.15, y=0.4=0.6, z=0.4-0.6, molar ratio of BaTiO3 to BiyNazTiO3 is (1-x):x, and RE is used for representing one or a plurality of elements selected from Sm, Er, or Ce. The dielectric material is suitable for preparing multilayer ceramic capacitors with a positive linear capacitance temperature change rate, and is low in dielectric loss; working temperature ranges from -55 to 150 DEG C, temperature stability is excellent (-15%<=delta C / C<=15%), and temperature changing accords with positive linear changing in the working temperature range. In the temperature range ranging from -55 to 150 DEG C, capacitance temperature compensating capacitors can be prepared from the dielectric material, compensating of negative effects caused by capacitor temperature increasing in functional circuits is realized, balancing of charge capacity in the whole temperature section is realized, and circuit stability and reliability are improved. The dielectric material possesses a promising industrialization prospect, and extremely high industrial application value.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

High-dielectric-constant X8R type MLCC medium material and preparing method thereof

ActiveCN103482975BImprove medium temperature stabilitySmall temperature change rateCapacitanceZinc compounds

The invention discloses a high-dielectric-constant X8R type MLCC medium material. 100 parts, by weight, of barium titanate are used as base materials which are added with, by weight, 0.5-1.5 parts of niobium zinc compound, 1.5-2.5 parts of MBi4Ti4O15, 0.3-0.75 part of zirconic oxide, 3-4 parts of flux glass powder, 1-2 parts of silicon zinc compound, 0-0.2 part of manganic carbonate and 0-0.2 part of one or more of oxides of Er, Yb, Dy, Ho and Nd. M is one or more of Sr, Ca and Ba. According to the high-dielectric-constant X8R type MLCC medium material, a proper amount of niobium zinc compounds are added to easily form a core-shell structure. The core-shell structure can facilitate stability of the medium temperature of a medium material and reduce the temperature coefficient of capacitance of the material.

Owner:FUJIAN TORCH ELECTRON TECH CO LTD

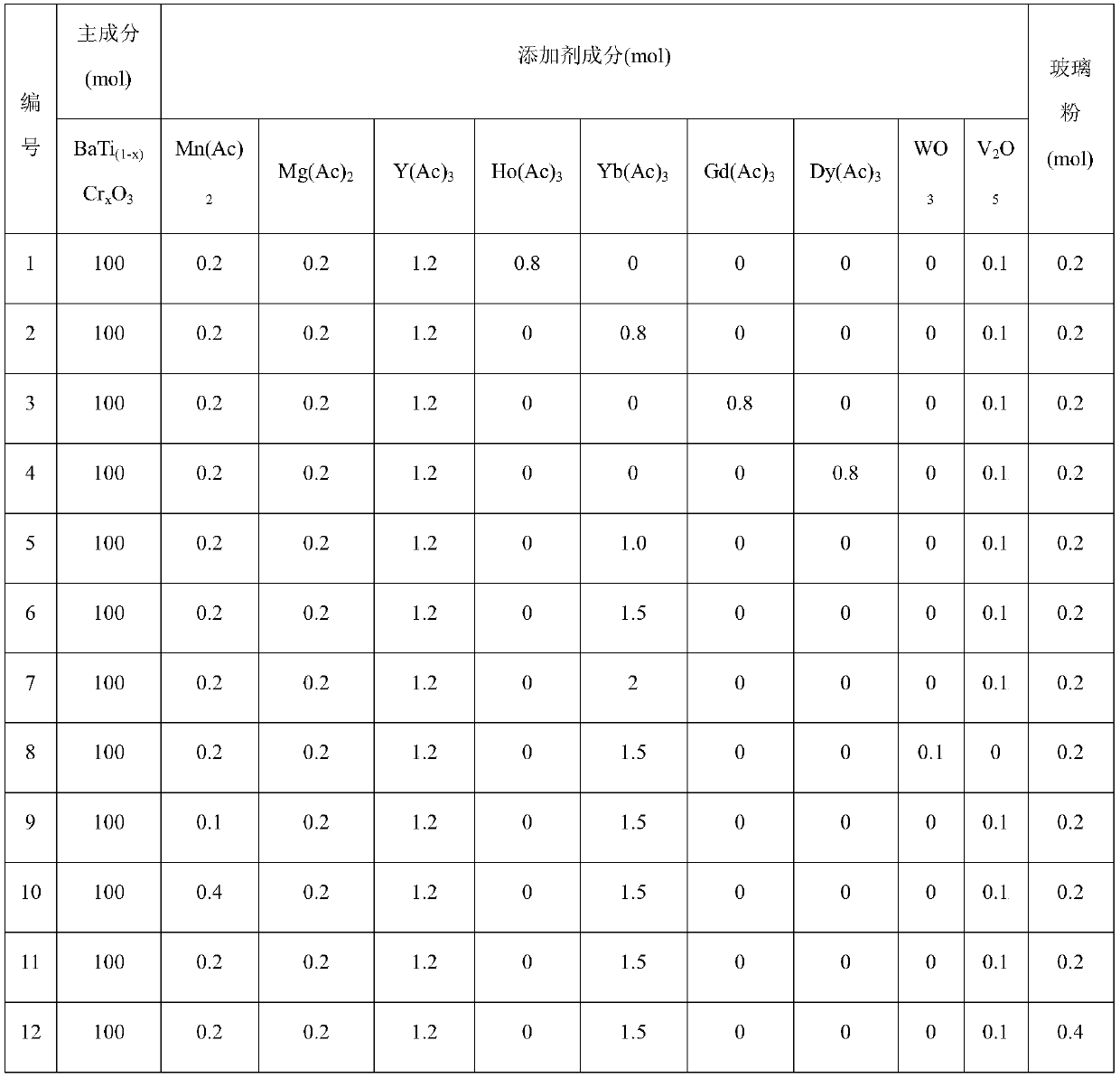

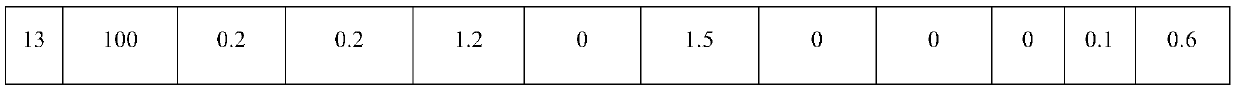

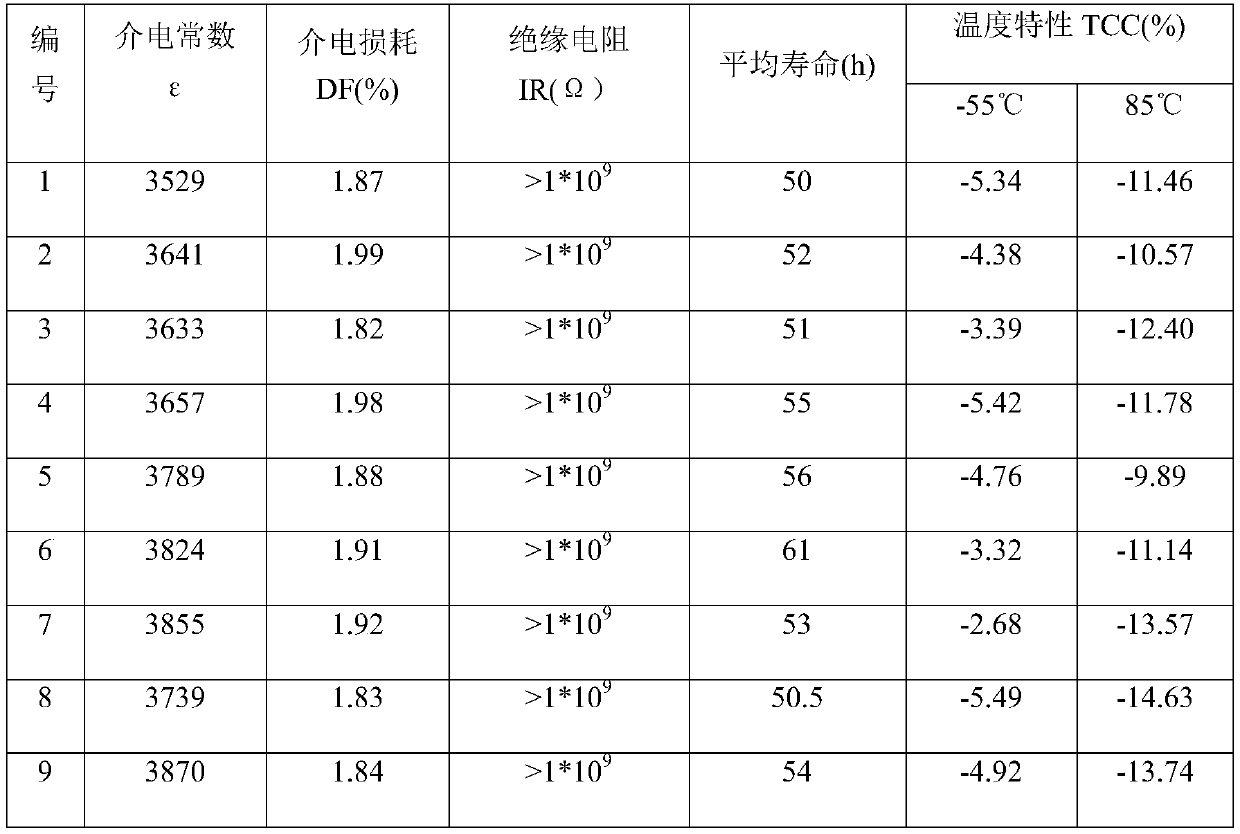

A kind of thin dielectric material for x5r type multilayer ceramic capacitor and its preparation method

ActiveCN106747420BImprove temperature stabilityImprove reliabilityFixed capacitor dielectricStacked capacitorsRare-earth elementBarium titanate

The invention provides a thin dielectric material for X5R multilayer ceramic capacitors. The thin dielectric material for X5R multilayer ceramic capacitors is composed of a main component and an auxiliary additive, wherein the main component is BaTi(1-x)CrxO3 (0.005<x<=0.05); on the basis of 100mol of the main component, the addition amount of the auxiliary additive is 0.32-5.6mol; and the auxiliary additive is composed of acetates, transition metal oxides and glass powder. The dielectric material provided by the invention has the advantages of favorable temperature stability and high reliability. By using the chromium barium titanate as the main component, the additive introduced into the formula mostly adopts water-soluble acetates, thereby being more beneficial to the mixing of the additive and main component on the atom level. The thin dielectric material solves the problem of poor product reliability since the oxides used as the main additive and the main component can not be mixed uniformly in the existing dielectric material. The glass powder added into the formula can effectively lower the sintering temperature of the product and enhance the sintering compactness of the product. The introduced rare earth element can enhance the reduction resistance of the dielectric material.

Owner:SHANDONG SINOCERA FUNCTIONAL MATERIAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com