BME ceramic dielectric capacitor ceramic material and preparation method thereof

A capacitor ceramic and ceramic dielectric technology is applied in the field of BME ceramic dielectric capacitor ceramic materials and their preparation, which can solve the problems of low volume resistivity at high temperature, low dielectric constant, low dielectric strength, etc. Good performance, the effect of improving the breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

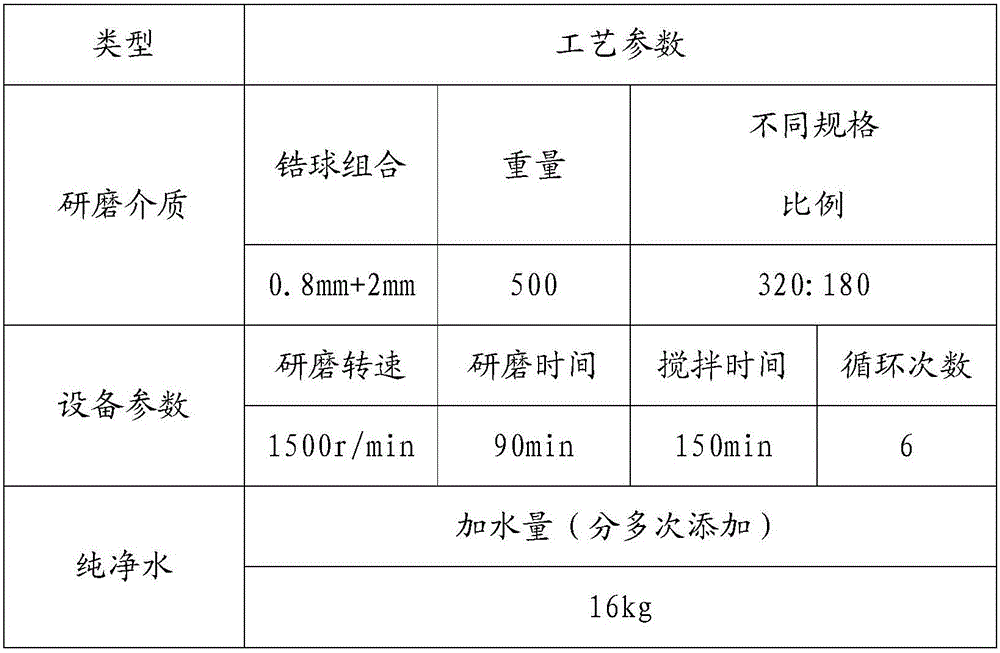

Examples

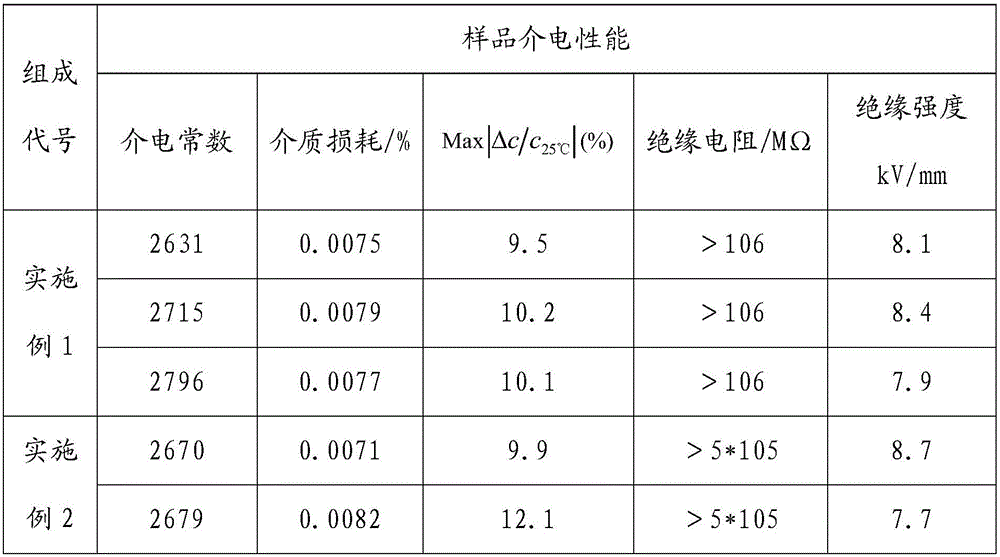

Embodiment 1

[0026] A kind of preparation method of BME ceramic dielectric capacitor ceramic material of the present invention comprises the following steps:

[0027] ① Separately prepare CaZrO 3 , ZnB 2 o 4 and Li 2 SiO 3 ;

[0028] Preparation of CaZrO 3 : Weigh analytically pure CaCO 3 10g, ZrO 2 12.32g, mixed, ball milled, sieved, and calcined at a temperature of 1150-1200°C, then ball milled and dried to obtain CaZrO 3 ;

[0029] Preparation of ZnB 2 o 4 : Weigh 8.14g ZnO and 12.37g H respectively 3 BO 3 , mixed, ball milled, sieved, and calcined at a temperature of 550-700°C, then ball milled and dried to obtain ZnB 2 o 4 ;

[0030] Preparation of Li 2 SiO 3 : Weigh 7.39g Li respectively 2 CO 3 and 6.0g SiO 2 , mixed, ball milled, sieved, and calcined at a temperature of 550-700°C, then ball milled and dried to obtain Li 2 SiO 3 .

[0031] ② Weigh 100g of BaTiO synthesized by hydrothermal method 3 , 0.5g of CaZrO 3 , 0.6g of rare earth oxide Yb 2 o 3 , 0.0...

Embodiment 2

[0035] A kind of preparation method of BME ceramic dielectric capacitor ceramic material of the present invention comprises the following steps:

[0036] ① Separately prepare CaZrO 3 , ZnB 2 o 4 and Li 2 SiO 3 ;

[0037] Preparation of CaZrO 3 : Weigh analytically pure CaCO 3 10g, ZrO 2 12.32g, mixed, ball milled, sieved, and calcined at a temperature of 1150-1200°C, then ball milled and dried to obtain CaZrO 3 ;

[0038] Preparation of ZnB 2 o 4 : Weigh 8.14g ZnO and 12.37g H respectively 3 BO 3 , mixed, ball milled, sieved, and calcined at a temperature of 550-700°C, then ball milled and dried to obtain ZnB 2 o 4 ;

[0039] Preparation of Li 2 SiO 3 : Weigh 7.39g Li respectively 2 CO 3 and 6.0g SiO 2 , mixed, ball milled, sieved, and calcined at a temperature of 550-700°C, then ball milled and dried to obtain Li 2 SiO 3 .

[0040] ② Weigh 100g of BaTiO synthesized by hydrothermal method 3 , 0.5g of CaZrO 3 , 1.0g of rare earth oxide Ho 2 o 3 , 0.0...

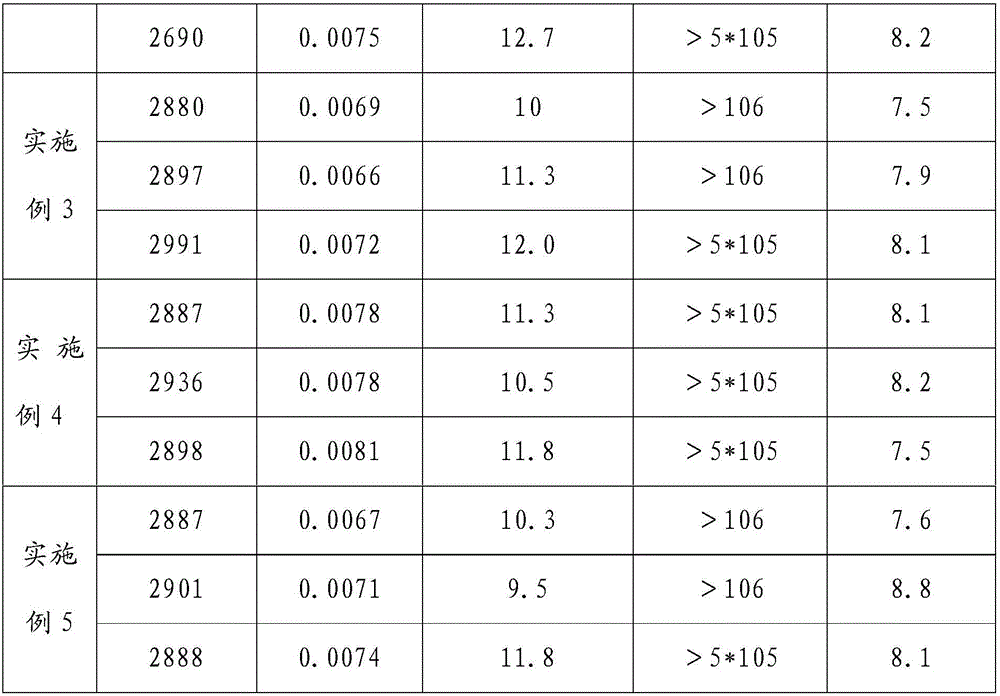

Embodiment 3

[0044] A kind of preparation method of BME ceramic dielectric capacitor ceramic material of the present invention comprises the following steps:

[0045] ① Separately prepare CaZrO 3 , ZnB 2 o 4 and Li 2 SiO 3 ;

[0046] Preparation of CaZrO 3 : Weigh analytically pure CaCO 3 10g, ZrO 2 12.32g, mixed, ball milled, sieved, and calcined at a temperature of 1150-1200°C, then ball milled and dried to obtain CaZrO 3 ;

[0047] Preparation of ZnB 2 o 4 : Weigh 8.14g ZnO and 12.37g H respectively 3 BO 3 , mixed, ball milled, sieved, and calcined at a temperature of 550-700°C, then ball milled and dried to obtain ZnB 2 o 4 ;

[0048] Preparation of Li 2 SiO 3 : Weigh 7.39g Li respectively 2 CO 3 and 6.0g SiO 2 , mixed, ball milled, sieved, and calcined at a temperature of 550-700°C, then ball milled and dried to obtain Li 2 SiO 3 .

[0049] ②Weigh 100g of BaTiO synthesized by hydrothermal method 3 , 2.0g of CaZrO 3 , 1.2g of rare earth oxide Sm 2 o 3 , 0.05...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com